Numerical Simulation by STARS (CMG) using Surfactants for Enhanced Oil Recovery in a Reservoir

在厄瓜多尔,重质原油占全国已探明储量的20%。然而,由于其低采收率、高粘度和低流动性等特性,开采一直具有挑战性。因此,开发和实施改进的或三次采油方法和技术变得必要,以环保的方式最大化资源开采。本文研究了使用化学方法,通过注入溶剂来改变水溶液的粘度,从而降低原油与水之间的界面张力。通过选择符合该方法应用要求的油藏,进行了一系列的模拟实验,结果显示连续表面活性剂驱替的采收率为84.5%,SP(表面活性剂-聚合物)驱替为89.4%,而ASP(碱-表面活性剂-聚合物)驱替的采收率最高,达到90.13%。这归因于表面活性剂降低界面张力和聚合物降低流动比的协同作用,从而显著提高了整体扫油效率。

CMG软件应用情况

研究中使用了CMG的STARS模拟器来模拟实验数据。STARS模拟器是一款用于热和先进采油过程的模拟软件,适用于模拟化学驱油方法,如表面活性剂驱替。通过创建水驱和表面活性剂驱替的模拟模型,研究者能够成功拟合实验数据,并比较不同驱替方法的效果。具体步骤包括:

- 输入/输出控制:设置模拟器类型、工作单位、孔隙度和模拟开始日期等。

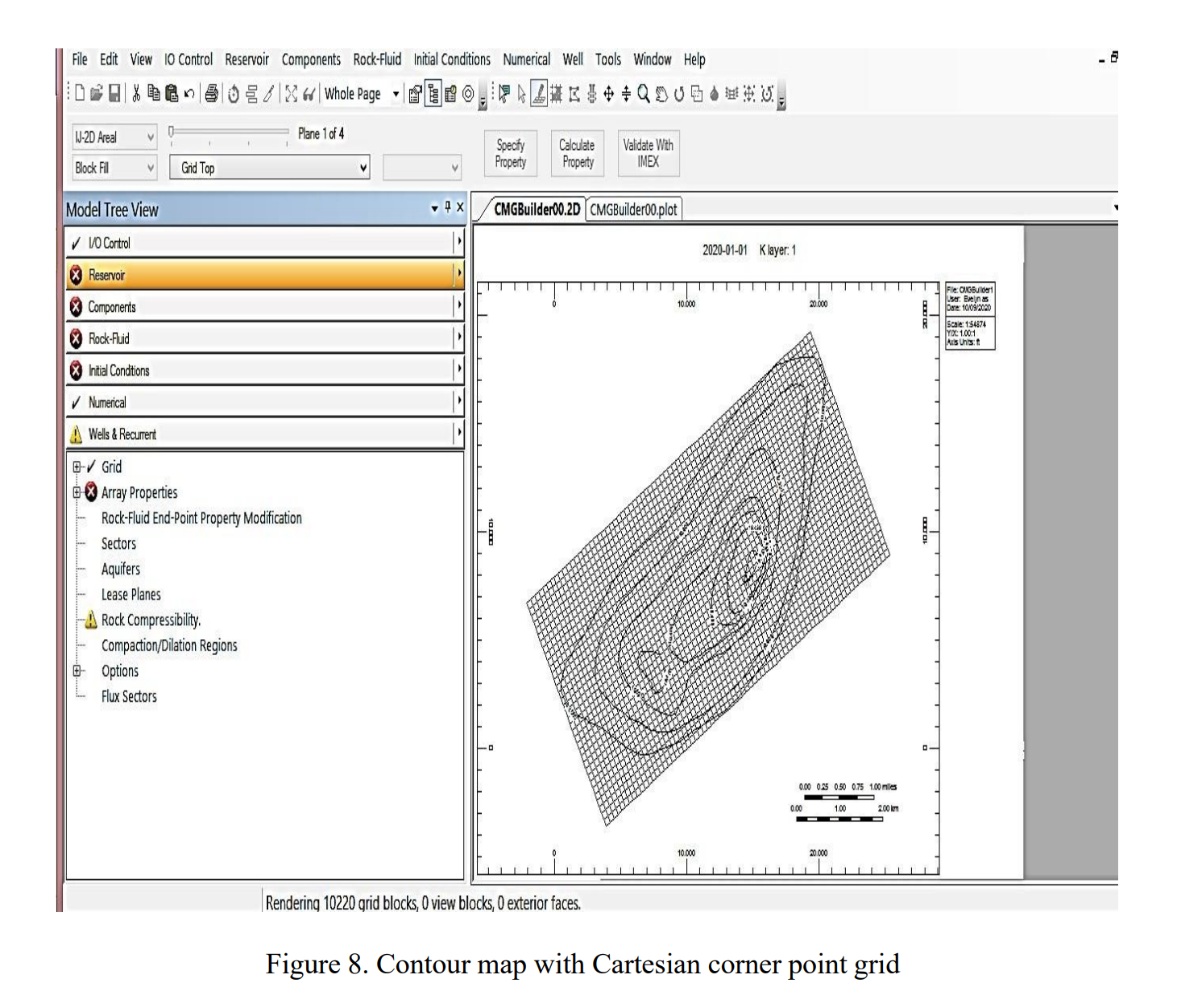

- 油藏描述:详细描述网格的几何特征、岩层属性、结构图(顶部和厚度)、孔隙度和渗透率等。

- 流体属性:输入流体的PVT信息,包括油藏温度、压力、API重力、溶解气比和水盐度等。

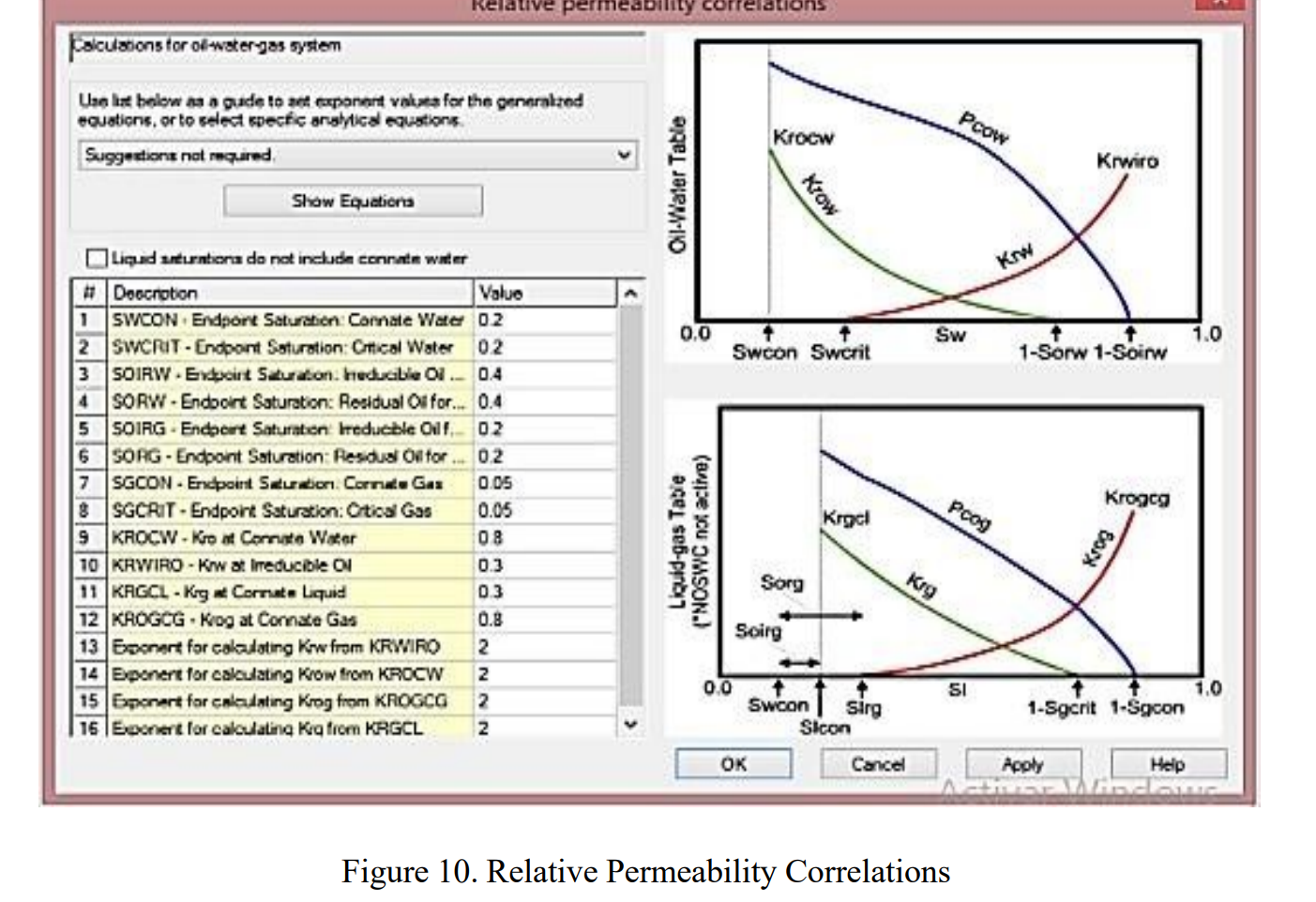

- 岩-流体相互作用:详细描述与驱替和模拟类型(两相或三相)相关的流程类型,以及润湿性,并添加相对渗透率曲线。

- 初始条件:指定油藏压力和参考深度数据,以及油-水界面。

- 数值方法:设置最大时间步长、压力和饱和度等默认值。

- 井和重复数据:定义井,使用五点井网进行模拟。

- 日期和时间:配置模拟的日期和时间。

- 创建表面活性剂组分:选择‘Process Wizard’选项,选择CMG STARS中的流体包,定义模拟模型,并添加表面活性剂、聚合物和碱的组分。

结论

表面活性剂驱替是一种在一次和二次采油不足时应用的提高采收率(EOR)方法。研究表明,这种方法可以显著提高水驱后的累积油产量。ASP驱替方法由于其协同作用,能够进一步降低界面张力和提高扫油效率,从而实现更高的采收率。研究结果表明,连续表面活性剂驱替的采收率为84.5%,SP驱替为89.4%,而ASP驱替的采收率最高,达到90.13%。此外,使用ASP方法后,含水率从100%降低到12.76%,进一步证明了其有效性。

Abstract

In Ecuador, heavy crude oil represents 20% of the proven reserves at the national level. However, producing them has been challenging because of their low recovery factor due to their characteristics, high oil viscosities, and low mobility, among others. This makes developing and implementing improved or tertiary recovery methods and technologies necessary; therefore, the aim is to produce the maximum available resources in an environmentally friendly way. New advances in hydrocarbon extraction technologies in recent years have been tested and one of them, on which this research focuses, is using chemical methods in which solvents are injected to modify viscosity in aqueous solutions. Thus, displacing the oil generates very low interfacial tensions between the crude oil and water by adsorption in the liquid-liquid phase. Therefore, the selection of a reservoir that meets the required characteristics for the respective application of this method was carried out. Furthermore, increasing the sweep efficiency will optimize the mobility of the oil bank toward the producing wells, thus improving the recovery factor. Consequently, upon running the simulation, the results show that continuous surfactant flooding resulted in 84.5% recovery, SP flooding 89.4%, and ASP flooding with the highest recovery factor of 90.13%. This is due to the synergistic contribution of the IFT reduction using surfactant and the mobility ratio per polymer reduction, thus improving the overall sweep efficiency by a better margin. At the same time, alkali is responsible for decreasing the amount of the active surfactant used as it is a lower-cost agent [1].

作者单位

厄瓜多尔圣埃伦纳半岛国立大学(Universidad Estatal Península de Santa Elena)。