A Comprehensive Study of Fluid Flow and Its Interactions within Porous Media in Steam-Assisted Gravity Drainage (SAGD) – Experimental and Simulation Studies

本文全面研究了蒸汽辅助重力泄油(SAGD)过程中多孔介质内的流体流动及其相互作用。研究重点探讨了三个之前被忽视的参数对油藏压力和饱和度分布的影响:蒸汽腔形状、流体的热膨胀以及油墙的形成。研究结果表明,忽略这些参数会导致对油藏压力和饱和度分布的不准确描述。例如,研究发现从蒸汽腔边缘到流动区域的压力梯度通常是正的(dxdp>0),这与之前关于水平压力梯度单调递减(dxdp<0)的假设相反。此外,研究还发现油墙限制了从蒸汽腔边缘到冷油区的水平冷凝水流,这与之前关于冷凝水流路径的假设不符。本文还通过实验研究了SAGD过程中水包油(W/O)乳化现象的形成机制,探讨了非润湿相和润湿相粘度、多孔介质润湿性、乳化剂所在相以及流量比对乳化现象的影响。

CMG软件应用情况

本文使用CMG STARS软件对SAGD过程进行模拟研究。CMG STARS是一款商业油藏模拟器,能够模拟热采过程,并考虑能量平衡。模拟研究中,作者构建了一个二维均质油藏模型,基于典型的阿尔伯达油砂特征。模型中详细考虑了油藏的几何形状、油藏和流体性质以及操作参数。模拟结果用于分析压力和流体分布,以及流体在蒸汽腔边缘前方的流动方向。通过模拟,作者研究了蒸汽腔形状、流体热膨胀和油墙对油藏压力和饱和度分布的影响,并探讨了这些因素对SAGD性能的影响。

结论

- 压力和饱和度分布:

- 蒸汽腔形状对压力分布有显著影响,正斜率的蒸汽腔边缘会导致从流动区域向蒸汽腔边缘的水平流体流动。

- 初始水的流动性有助于蒸汽腔压力在油藏上层的传播,并导致下层压力升高,使冷区的水向蒸汽腔边缘流动。

- 流体的热膨胀在初始水不移动的油藏中形成扩展屏障,阻止冷凝水从流动区域向冷区的水平侵入。

- 在初始水移动的油藏中,流动区域形成油墙,限制或阻止冷凝水从流动区域向过渡区和冷区的流动。

- 乳化现象:

- 实验结果表明,当非润湿相粘度大于1 cP时,多孔介质内会形成乳化现象。乳化的发生与非润湿相的毛细管数有关,当毛管数大于或等于阈值3.6×10⁻⁵时,乳化现象才会发生。

- 乳化现象的发生与润湿相的粘度无关,也不依赖于乳化剂所在的相。在SAGD过程中,由于非润湿相(加热的沥青)的毛管数较低(约10⁻⁶),预计在流动区域内不会生成W/O乳化现象。

作者单位

加拿大卡尔加里大学化学与石油工程系

Abstract

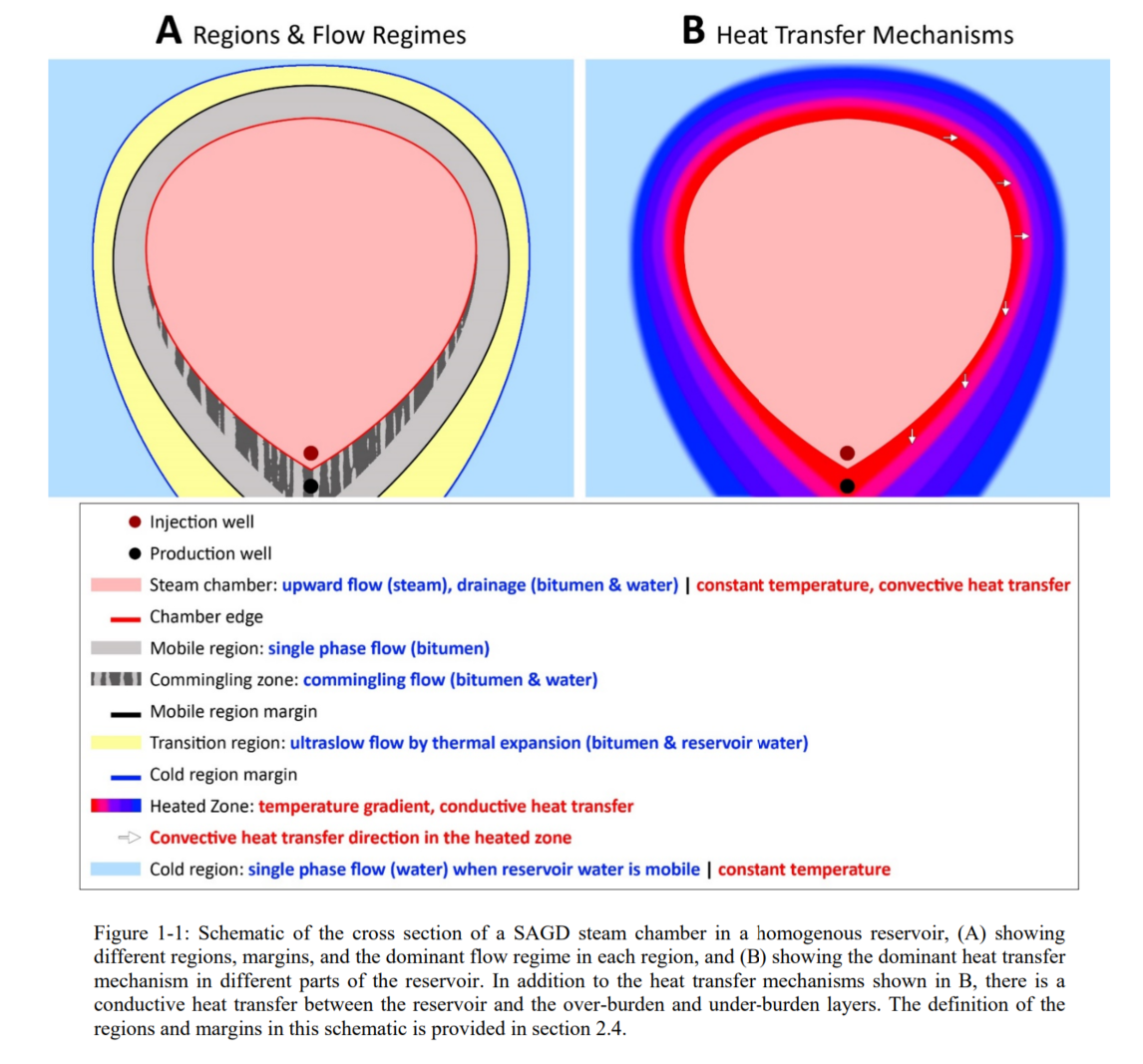

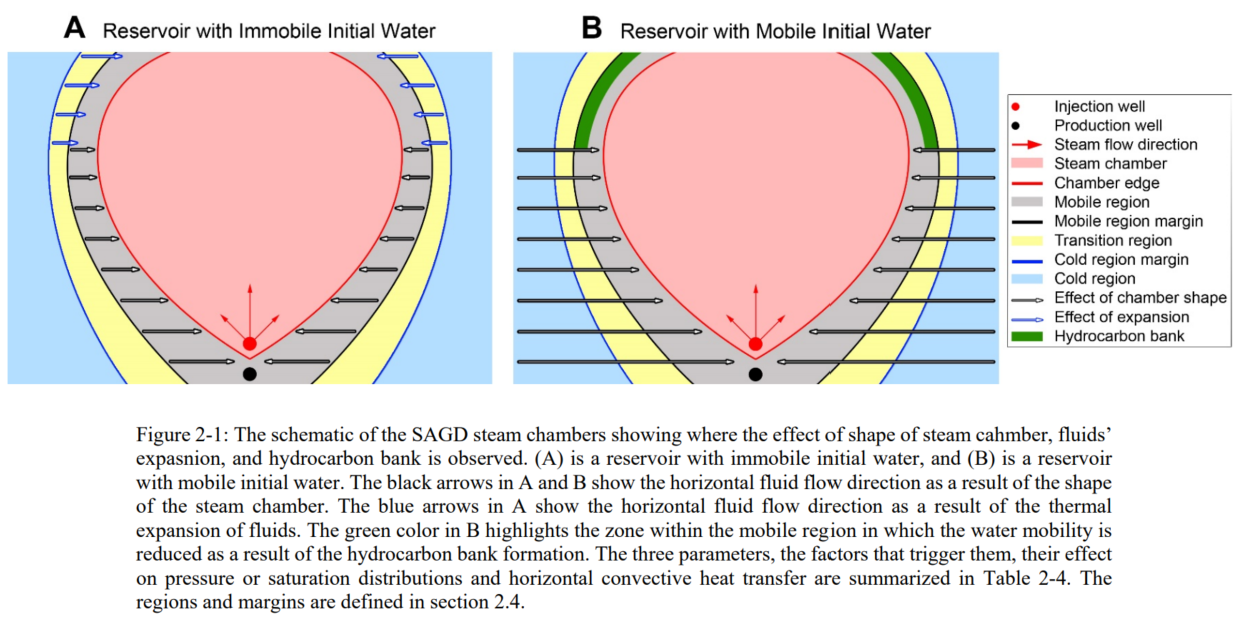

Since the invention of steam assisted gravity drainage (SAGD), numerous efforts have been made to explore and enhance the process. This work studies three previously overlooked parameters and the noteworthy effect they have on reservoir pressure and saturation distributions: the shape of the steam chamber, the thermal expansion of the fluids, and the creation of a hydrocarbon bank. The results show that neglecting to consider these yields an inaccurate description of pressure and saturation distributions. Most notably, the pressure gradient is generally positive from the chamber edge into the mobile region, contrary to an alleged monotonic pressure gradient horizontally from the chamber edge toward the cold part of the reservoir. Secondly, a hydrocarbon bank barrier limits the horizontal condensate flow from the chamber edge to the cold region, contrary to previous assertions of a horizontal flow path from the chamber edge into the cold region due to the initial water mobility in the reservoir. Consequently, neither the initial water mobility nor the difference between the injection pressure and the reservoir pressure result in a notable horizontal convective heat transfer from the chamber edge to the cold reservoir.

A variety of SAGD studies have reported the production of water-in-oil emulsions. A key question is whether the emulsions are generated in situ. Exploring potential causes for in situ emulsification in SAGD has been limited to steam condensation. No rigorous investigation has been done on the possibility of in situ emulsification during commingling flow of the bitumen and condensed steam toward the production well. To this end, a detailed experimental study was performed, focusing on the role of four parameters: the viscosities of wetting and non-wetting phases, the wettability of porous media, the phase containing emulsifier, and the flow rate ratio. The in situ emulsification – for both non-wet in wet and wet in non-wet type of emulsions – only occurs if the capillary number of the non-wetting fluid is equal or larger than 3.6×10-5 . The capillary number analyses suggest that water-in-oil emulsions are unlikely to be generated in the mobile region in SAGD.