重油是世界上重要的能源。加拿大阿尔伯塔省和萨斯喀彻温省北部蕴藏着大量的重油。稠油开采的关键是提高油藏条件下原油的流动性,最有效的开采方法是加热升温,如蒸汽驱、蒸汽吞吐(CSS)、蒸汽辅助重力驱油(SAGD)和火烧油层等,以实现稠油的热降粘。然而,由于有效厚度薄、深度大以及其他岩石、流体和地质条件,加热方法不适用于加拿大大多数稠油油藏,需要考虑其他冷采生产方法。近年来,溶剂注入法有了更多的发展。CO2因其高溶解度被认为是轻质油和重油开采最有前景的溶剂之一。在稀油开采中,CO2驱的生产压力保持在最小混相压力以上,以保持混相。稠油开采原油粘度较高,很难达到CO2混相,但注入CO2仍能在很大程度上提高稠油的采收率。 不同的CO2驱油方式会显著影响采收率。

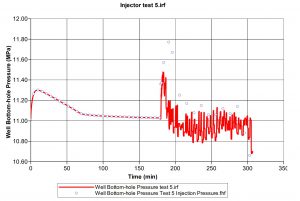

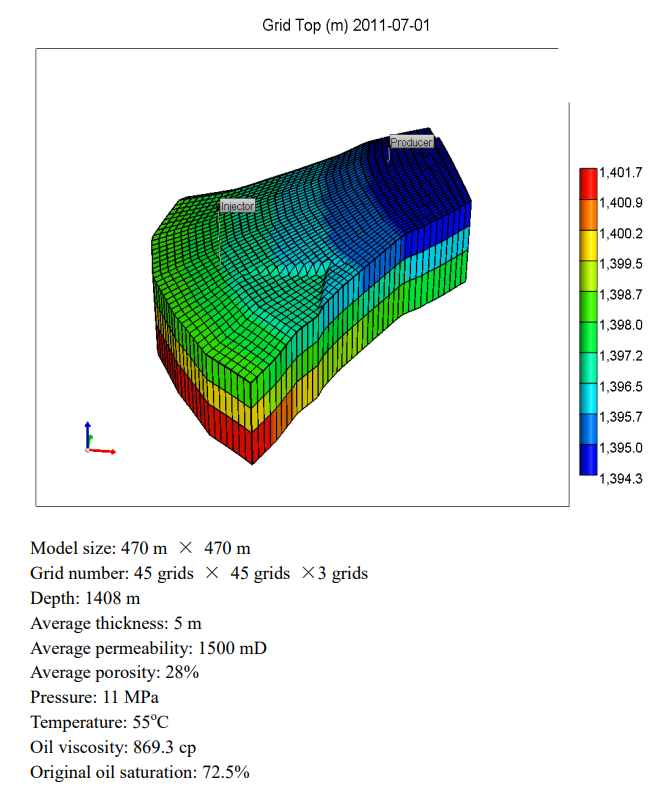

在本研究通过一维岩心驱实验,测试了不同的注入和压力控制方案,以获得最佳的注入和压力控制方案。利用华北某稠油油田的现场资料、油样和卤水进行了岩心驱油实验。实验结果表明,较低的CO2注入速率可使采收率从31.1%提高到36.7%。就不同生产策略的影响而言,生产出口(Production Port)的恒定生产压力可产生31.1%的采收率,生产出口的压力耗竭可产生7%以上的石油采收率;最佳的压力控制方案是,在CO2注入期间,生产压力保持恒定,然后在关闭注入井的情况下耗尽模型压力,产生初始OOIP的42.5%的采收率。 数值模拟结果与实验结果相吻合。采用相同的原油相对渗透率曲线将试验结果与所有试验进行拟合。不同的生产压力方案,得到了不同的气体相对渗透率曲线。与其他情况相比,在最佳压力控制方案的情况下,获得了更低的气体相对渗透率曲线和更高的临界气体饱和度。较低的气体相对渗透率曲线表明,泡沫油是在压力衰竭过程中形成的。根据现场数据和试验历史拟合的相对渗透率曲线,利用CMG软件建立了三维储层模型。采用了不同的策略,包括不同的注采方案和不同的注入流体,并选择了较好的结果进行分析。

Optimization of CO2 Flooding Strategy to Enhance Heavy Oil Recovery

ABSTRACT

Heavy oil is a significant energy resource around the world. In Canada, there are tremendous heavy oil reserves lying in the north of the provinces of Alberta and Saskatchewan. The key point for heavy oil recovery is to increase the mobility of heavy oil in the reservoir condition. The most effective methods of heavy oil recovery are thermal methods such as steam flooding, cyclic steam stimulation (CSS), steam-assisted gravity drainage (SAGD) and in-situ combustion for the great heavy oil viscosity reduction by heat. However, thermal methods are proving to be unsuitable for most of the heavy oil reservoirs in Canada because of the thin net-pay zones, large depths and other rock, fluid and geological conditions. Therefore, cold production methods are mostly considered.

In recent years there has been more development of solvent injection methods. CO2 is considered one of the most promising solvents used in both light and heavy oil for its high solubility. In light oil recovery, the production pressure in CO2 flooding is kept above the minimum miscible pressure in order to maintain the miscibility. Although in heavy oil recovery, CO2 miscibility can hardly be reached because of the high oil viscosity, but the oil recovery can still be stimulated to a great extent by CO2 injection.

Different CO2 flooding strategies can significantly affect the recovery factor. In this study, different injection and pressure control schemes were tested by 1-D core-flooding experiments to obtain an optimized one. Field data, oil samples and brine from a heavy oil field in north China were used for the core-flooding experiments. Experimental results indicated that a lower CO2 injection rate led to a higher recovery factor from 31.1% to 36.7%. In terms of the effects of different production strategies, a constant production pressure at the production port yielded a recovery factor of 31.1%, while a pressure depletion at the production port yielded 7% more oil recovery; and the best pressure control scheme was that in which the production pressure was kept constant during the CO2 injection period, then the model pressure was depleted with the injector shut-in, yielding a recovery factor of 42.5% of the initial OOIP.

Numerical simulations were conducted to history match the experimental results. The same oil relative permeability curve was used to match the experimental results to all tests. Different gas relative permeability curves were obtained when the production pressure schemes were different. A much lower gas relative permeability curve and higher critical gas saturation were achieved in the best pressure control scheme case compared to other cases. The lower gas relative permeability curve indicated that foamy oil was formed in the pressure depletion processes. A 3-D reservoir model was built by Computer Modeling Group (CMG) software based on field data and relative permeability curves from history match of the tests. Different strategies, including different injection and production schemes and different injection materials were used, and the better results were chosen for analysis.