Numerical Simulation Study of Low-Tension-Gas (LTG) Flooding for Enhanced Oil Recovery in Tight Formations

本文重点研究了低张力气体(LTG)过程的数值模拟,该过程涉及注入表面活性剂和气体来生成和传播泡沫以控制流度,并通过降低油水界面张力来降低剩余油。该EOR工艺是表面活性剂聚合物工艺的替代方案,适用于具有挑战性的条件,包括致密地层、高温和高盐油藏,其由于物理和/或经济限制,聚合物实施不可行。在本研究中,用于数值模拟的实验数据涉及地层矿化度较高的致密碳酸盐岩。

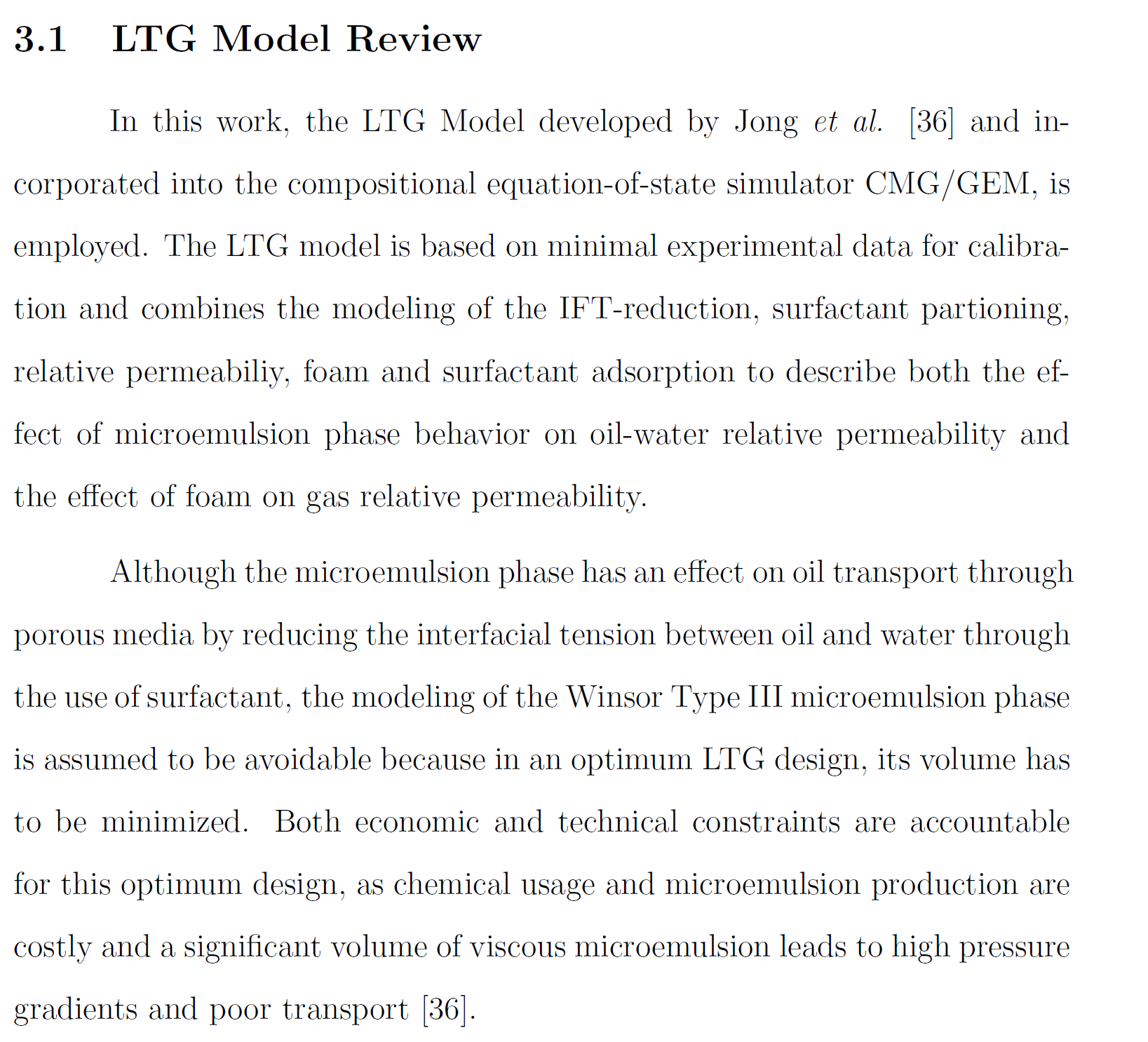

在数值模拟研究中,使用了德克萨斯大学奥斯汀分校开发的LTG模型,并将其纳入了组成状态方程CMG/GEM模拟器中。该模型包括IFT降低、表面活性剂分配、相对渗透率、泡沫和吸附的模拟。

在某些情况下,数值模拟模型可能涉及大量不确定参数,这些参数往往超过可用的实验数据。因此,可能存在多个参数组合,在模型和实验之间提供良好的一致性。因此,开展了一项数值模拟研究,以便通过一系列模拟和战略性选定实验数据的数据拟合,开发确定LTG模型参数的方法,以减少问题的非唯一性,同时保持过程的物理特性。

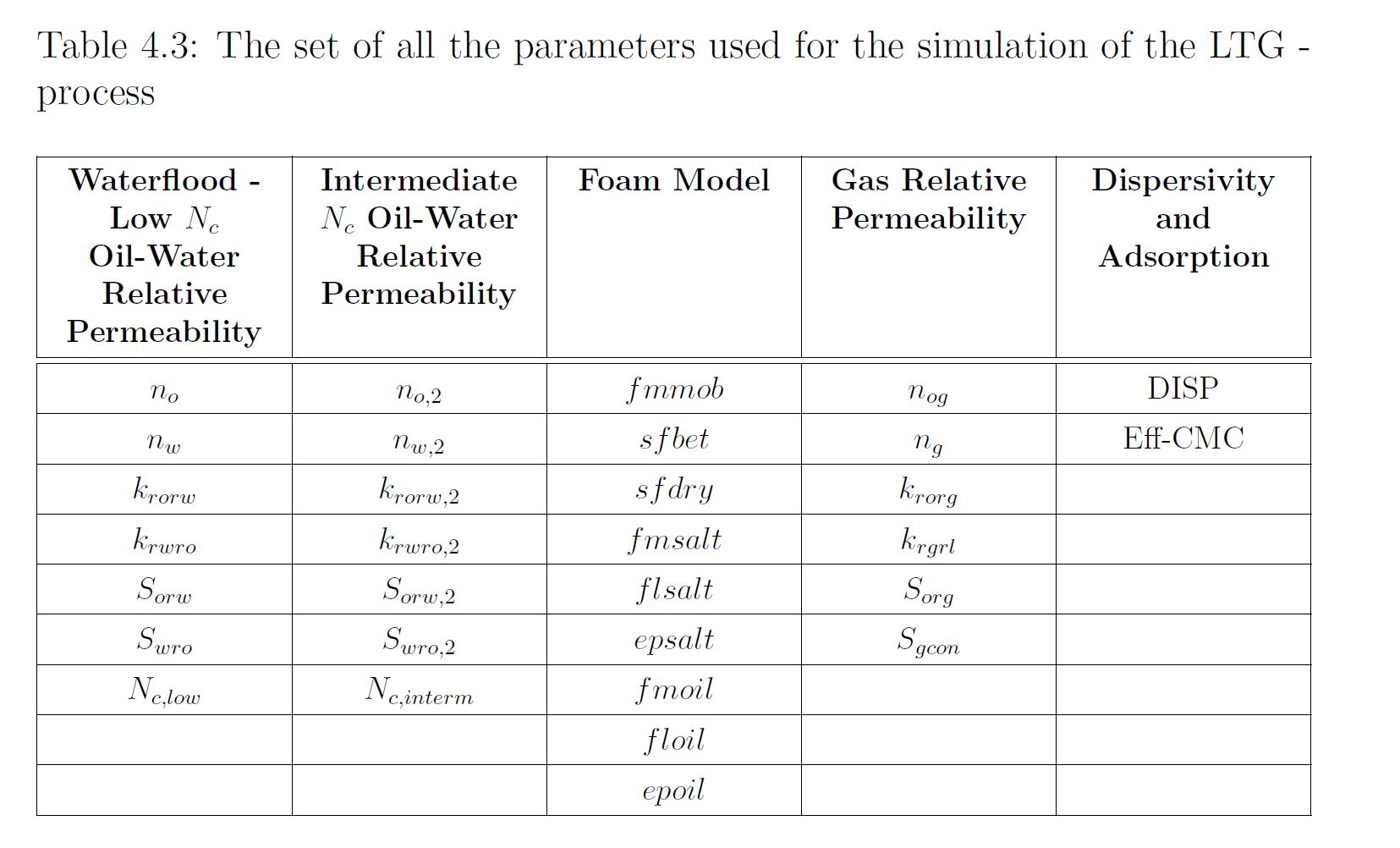

低毛管数水-油相对渗透率参数是通过水驱实验数据的拟合确定的,这是LTG驱油的初步步骤。此外,通过泡沫质量测试的拟合,估算了参考泡沫流度降低系数、干涸函数和气体相对渗透率曲线。然后,对剩余的不确定参数进行敏感性分析,以研究这些参数对原油采收率和压降的影响。然后对LTG驱替实验数据进行数据拟合,以确定其余参数空间的估计值,包括表面活性剂吸附、分散性、中间毛细管数和相关油水相对渗透率曲线、油气曲率以及其余泡沫参数。

总之,本文为LTG模拟提供了估算相对渗透率、泡沫强度、吸附和分散参数的方法。这些发现将被证明有助于理解三次采油过程中的LTG驱油行为。

低张力气体(LTG)工艺是SP方法的替代方法,其中保留表面活性剂注入,以降低界面张力IFT并动用不流动的油,但泡沫代替聚合物,用于液体流度控制。泡沫是由表面活性剂和氮气或碳氢化合物气体产生和传播的。因此,使用表面活性剂有两个目的;用于乳化和发泡,以控制流动性,提高驱替和波及效率。

Abstract

This thesis focuses on the numerical simulation of Low-Tension-Gas (LTG) process, that involves the injection of surfactant and gas to generate and propagate foam for mobility control, and to mobilize the residual oil to waterflood by reducing the interfacial tension between oil and water. This EOR process, is an alternative to surfactant-polymer process and is applicable to challenging conditions including tight formations, high temperature and high salinity reservoirs where polymer implementation is not feasible due to physical and/or economic constraints. In this study, the experimental data used for numerical simulation involve tight carbonate rock with high formation salinity.

For the numerical simulation study, a LTG model developed by the University of Texas at Austin and incorporated into the compositional equation- of-state CMG/GEM simulator is utilized. The model includes the modeling of IFT reduction, surfactant partitioning, relative permeability, foam, and ad- sorption.

In some case, a numerical simulation model may involve a large number of uncertain parameters, which often exceeds the experimental data available. Hence, there may exist more than one combination of the parameters that provide a good agreement between the model and the experiments. Therefore, a numerical simulation study is undertaken in order to develop a methodology for determining the LTG model parameters through a series of simulations and data-fitting of strategically selected experimental data to reduce the non-uniqueness of the problem while preserving the physics of the process.

Low capillary number water-oil relative permeability parameters are determined through matching of waterflood experimental data, which is a pre liminary procedure of LTG flooding. In addition, the reference foam mobility reduction factor, the dry-out function, and the gas relative permeability curve are estimated through matching of foam quality tests. Thereafter, a sensitivity analysis of the remaining uncertain parameters is performed to investigate the significance of the parameters on the oil recovery and pressure drop. Data-fitting of the LTG flood experimental data is then performed to determine estimations for the rest of the parameter space, including surfactant adsorption, dispersity, intermediate capillary number and associated oil-water relative permeability curves, oil-gas curvature, and the rest of the foam parameters.

In conclusion, this thesis provides a methodology for estimating relative permeability, foam strength, adsorption and dispersity parameters for LTG simulation. These findings will be proven useful for understanding LTG flooding behavior in EOR processes.

The Low Tension Gas (LTG) process, is an alternative to SP method, where surfactant injection is preserved for IFT reduction and mobilization of the otherwise immobile oil, but instead of polymer, foam is used for liquid mobility control. Foam is generated and propagated by surfactant and typically nitrogen or hydrocarbon gas. Therefore, the use of surfactant has two purposes; for emulsification and foaming for mobility control and improved displacement and sweep efficiency.