Characterization of the Porosity and Permeability of Gasified Coal in UCG Process: An Experimental and Simulation Study

在全球能源转型的背景下,地下煤气化(UCG)是实现深部煤炭资源绿色清洁开发和利用的重要手段。由于一系列复杂的化学反应,煤炭的孔隙度和渗透率发生了显著变化。准确表征气化煤的孔隙度和渗透率对UCG项目的现场筛选、生产控制和数值模拟具有重要意义。

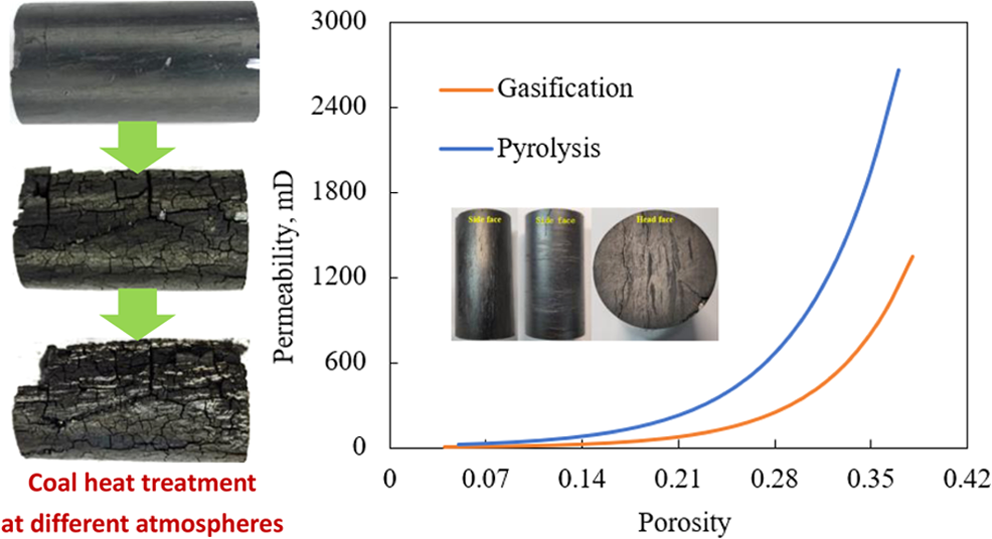

本研究通过实验和数值模拟相结合的方法,研究了煤炭样品的孔隙度和渗透率,并建立了孔隙度-渗透率关系的预测模型,其可行性通过与以往实验结果的比较得到了验证。在实验阶段,采用氮气气氛模拟热解条件,空气气氛模拟气化环境。通过扫描电子显微镜(SEM)对热处理后的煤炭样品的孔隙度和渗透率变化进行表征。

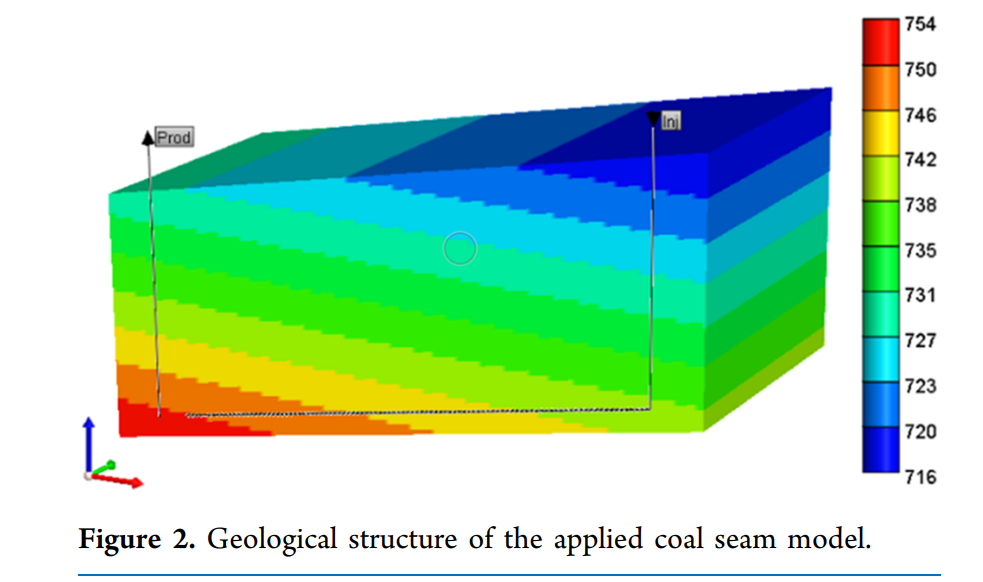

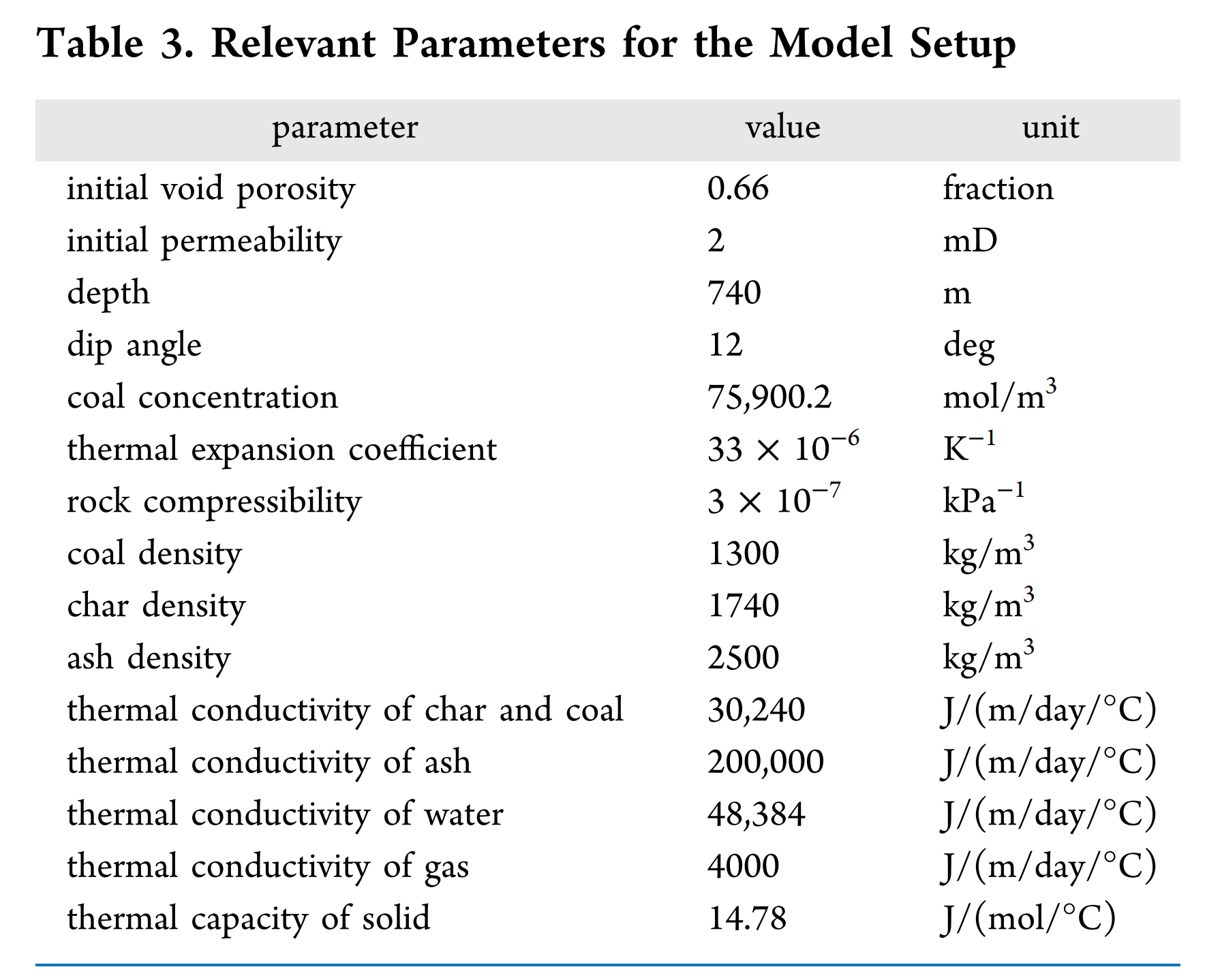

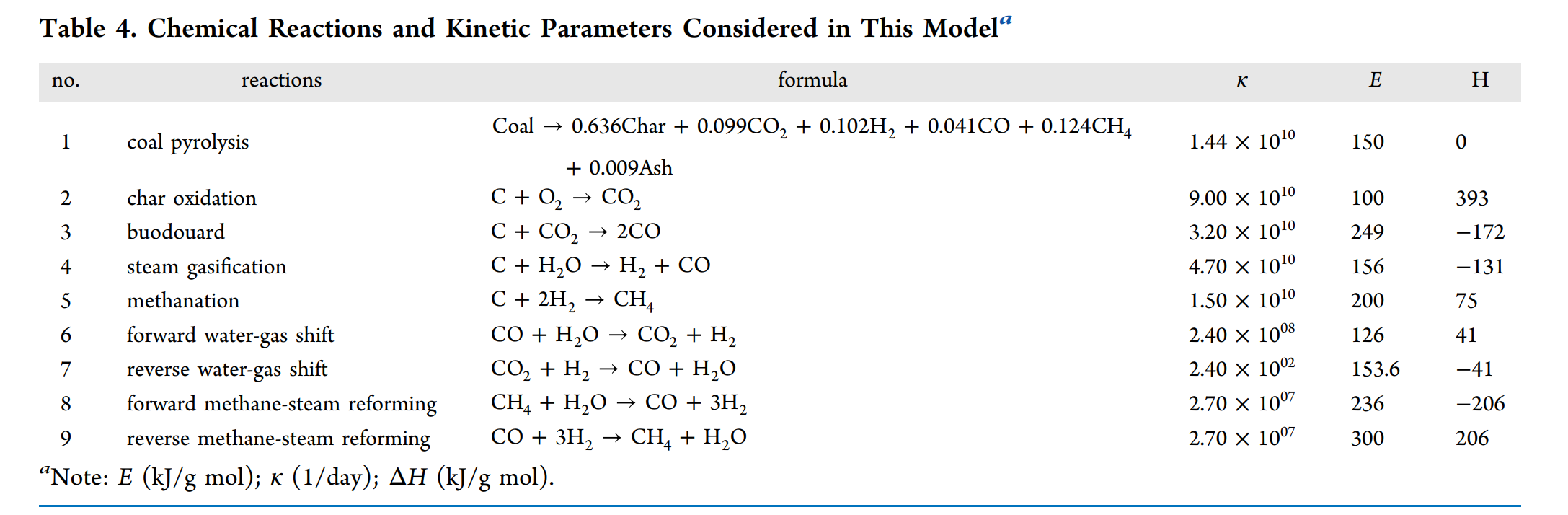

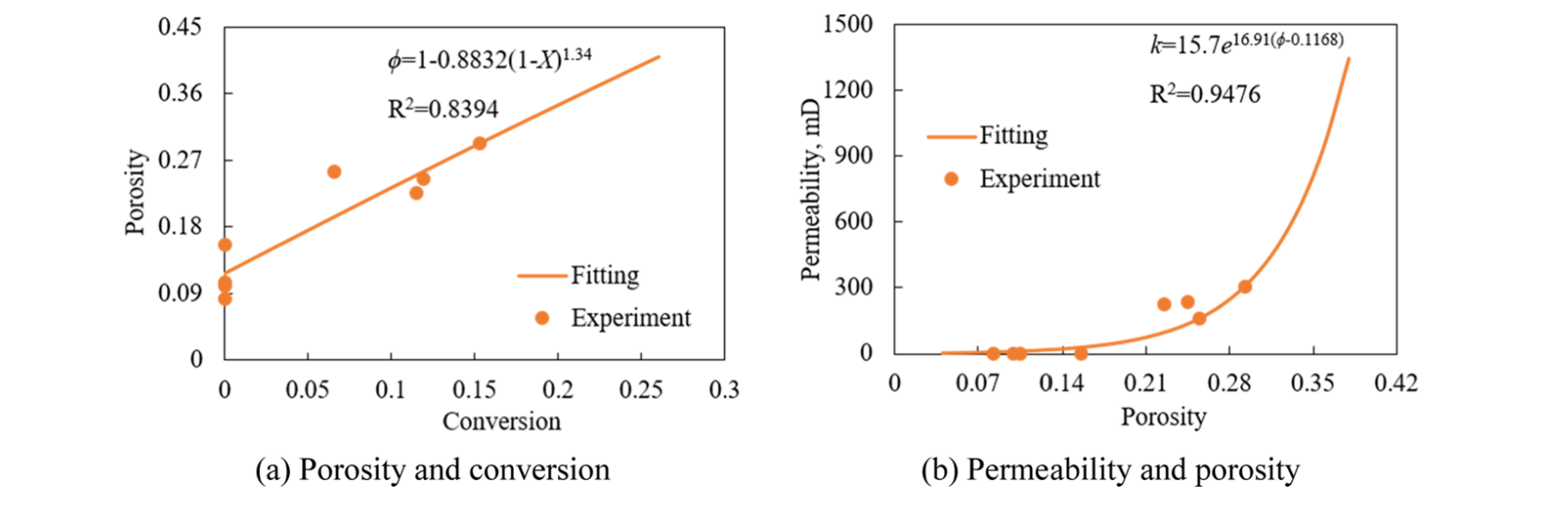

在数值模拟部分,通过分析UCG的物理和化学过程,利用CMG-STARS模拟软件建立了矿场尺度的UCG三维数值模拟模型,并分析了煤炭气化过程中孔隙度和渗透率的变化。结果表明,经过热处理实验后,煤炭样品的平均等效孔径增加到0.748微米,增长了493.65%,孔径普遍扩大。此外,平均形状因子从3.20下降到2.584,表明孔隙特征的圆度增强。通过3D UCG数值模拟,煤炭孔隙度和渗透率的演变被划分为三个不同的阶段:25-320°C、320-750°C和750-1000°C。这一分类反映了煤炭气化过程中孔隙结构的演变模型。在预测模型中,煤炭在热解和气化过程中的渗透率被表示为孔隙度的指数函数。随着孔隙度的增加,渗透率的增长率先是缓慢上升,然后逐渐加速。此外,在气化过程中,煤炭渗透率随孔隙度的增加不如热解过程中显著。本文的研究结果对UCG应用的现场筛选、工艺设计和优化具有重要意义。

CMG软件应用情况

在本研究中,CMG-STARS模拟软件被用于建立地下煤气化(UCG)过程的三维数值模拟模型。该模型用于分析煤炭气化过程中孔隙度和渗透率的变化。研究假设了多相流遵循达西定律,并考虑了煤炭的热解、气化和燃烧反应。模型通过模拟典型的可控可伸缩注入点(CRIP)UCG过程,研究了氧气和蒸汽作为气化剂时的生产压力变化。通过数值模拟,研究分析了煤炭孔隙度和渗透率的动态变化,并将其与实验数据进行了对比,验证了模型的可行性。

Abstract

Under the environment of energy transformation in the world, underground coal gasification (UCG) is an important means to realize the green and clean development and utilization of deep coal resources. Due to a series of complex chemical reactions, the porosity and permeability of coal have changed significantly. Accurately characterizing the porosity and permeability of gasified coal is of great significance to the field screening, production control, and numerical simulation of the UCG project. In this study, the porosity and permeability of coal samples are studied by means of experiment and numerical simulation, respectively. Subsequently, a predictive model for porosity–permeability relationships is established with its feasibility verified by comparison to previous experimental results. In the experimental phase, a nitrogen atmosphere simulates pyrolysis conditions, while an air atmosphere replicates gasification environments. Scanning electron microscopy (SEM) is employed to characterize the porosity and permeability changes in heat-treated coal samples. For the numerical simulation component, through the analysis of UCG physical and chemical processes, the UCG three-dimensional numerical simulation model at the field scale is established by using CMG-STARS simulation software, and the changes in porosity and permeability during coal gasification are analyzed. The result shows that following heat treatment experiments, the average equivalent pore diameter of the coal sample increases to 0.748 μm, an increase of 493.65%, with general expansion observed across pore diameters. Additionally, the average shape factor decreases from 3.20 to 2.584, suggesting enhanced roundness in the porosity characteristics. Post-heat treatment observations reveal an increase in pore quantity alongside expanded diameters, thus indicating significant alterations in pore structure. Through 3D UCG numerical simulation, the evolution of coal porosity and permeability is categorized into three distinct stages: 25–320, 320–750, and 750–1000 °C. This categorization reflects the evolutionary model of the pore structure during coal gasification. In the predictive model, the permeability of coal during pyrolysis and gasification is represented as an exponential function of the porosity. As the porosity increases, the growth rate of permeability initially rises slowly before gradually accelerating. Furthermore, it is observed that in the gasification process, the increase in coal permeability with respect to porosity is less pronounced than that observed during pyrolysis. The findings presented in this paper hold significant implications for field screening, process design, and optimization of UCG applications.

作者单位

中国石油勘探开发研究院