Productivity Simulation of Multilayer Commingled Production in Deep Coalbed Methane Reservoirs: A Coupled Stress-Desorption-Flow Model

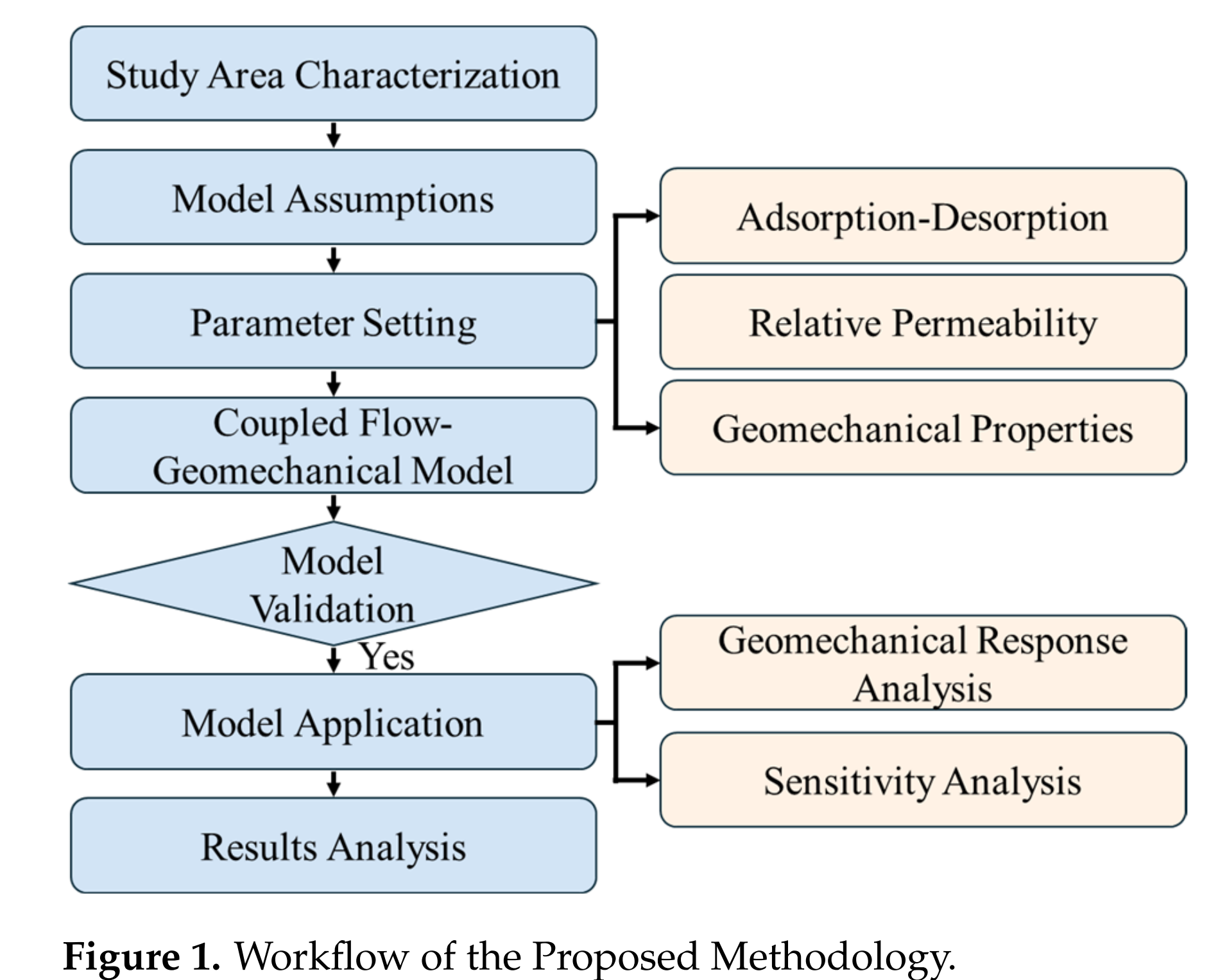

本文针对深层煤层气(CBM)开发面临的高应力、高压力、高温等极端地质条件,构建了一个多煤层合采的应力-解吸-流动耦合数值模型。模型基于CMG平台,综合考虑气-水两相渗流、Langmuir吸附/解吸、动态地应力演化等机制,模拟了新疆呼吉尔台区块(埋深2140–2170m)深层煤层气的产能动态。模型通过与实际生产数据对比验证,平均日产气量误差仅为1.2%。该模型为深层煤层气压裂设计、合采层段优选和动态配产提供了理论依据。

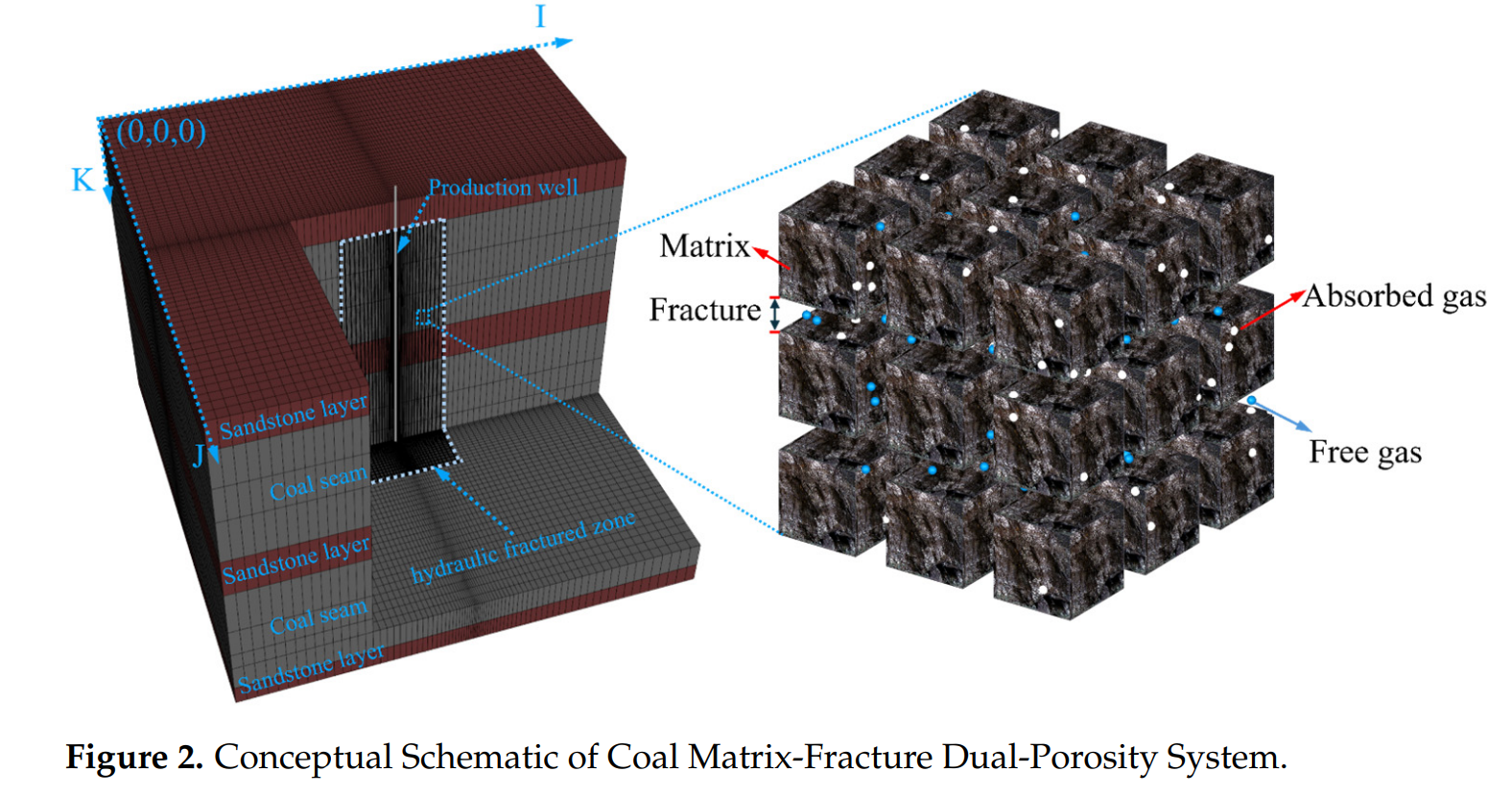

CMG软件应用情况

本研究采用 CMG(Computer Modeling Group)数值模拟平台 进行建模与模拟,主要应用包括:

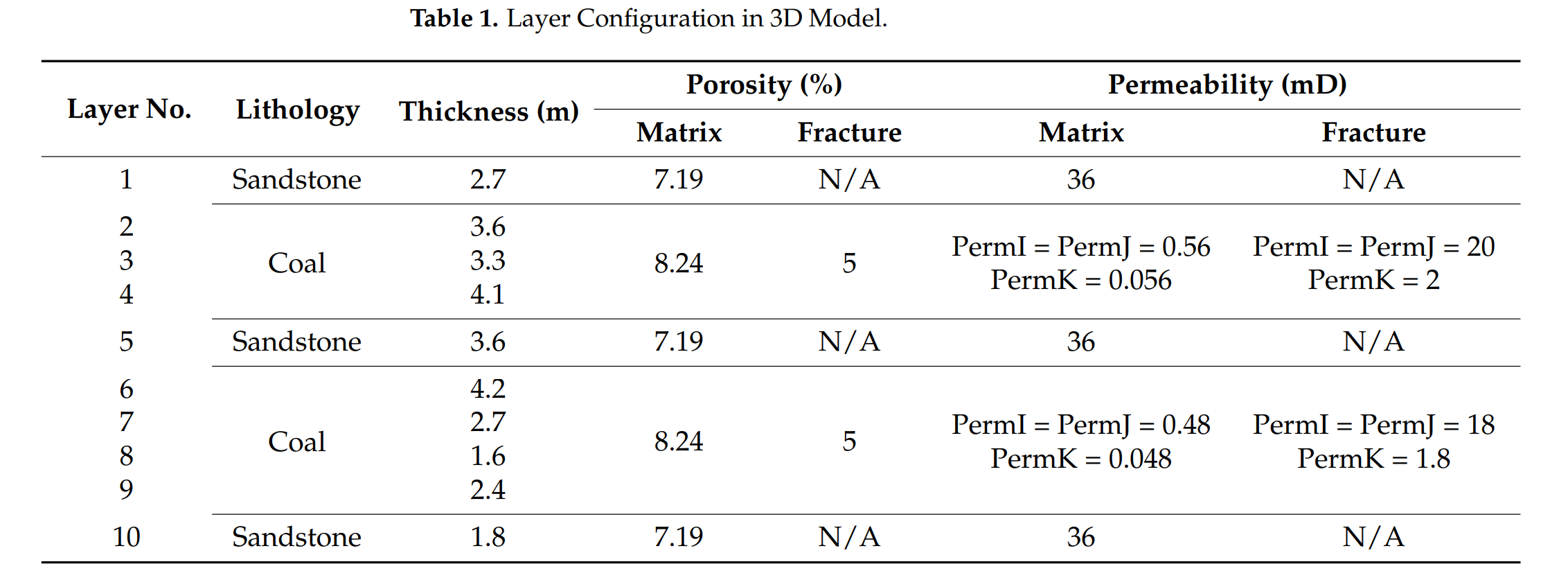

- 构建三维地质模型(80×80×10网格,含7层煤+3层砂岩);

- 模拟气-水两相流动、吸附/解吸、应力敏感渗透率演化;

- 引入双孔单渗(DPSP)模型表征煤岩基质-裂隙系统;

- 使用Kozeny-Carman方程描述孔隙度-渗透率关系;

- 模拟不同压裂参数(SRV、裂缝导流能力)对产能的影响;

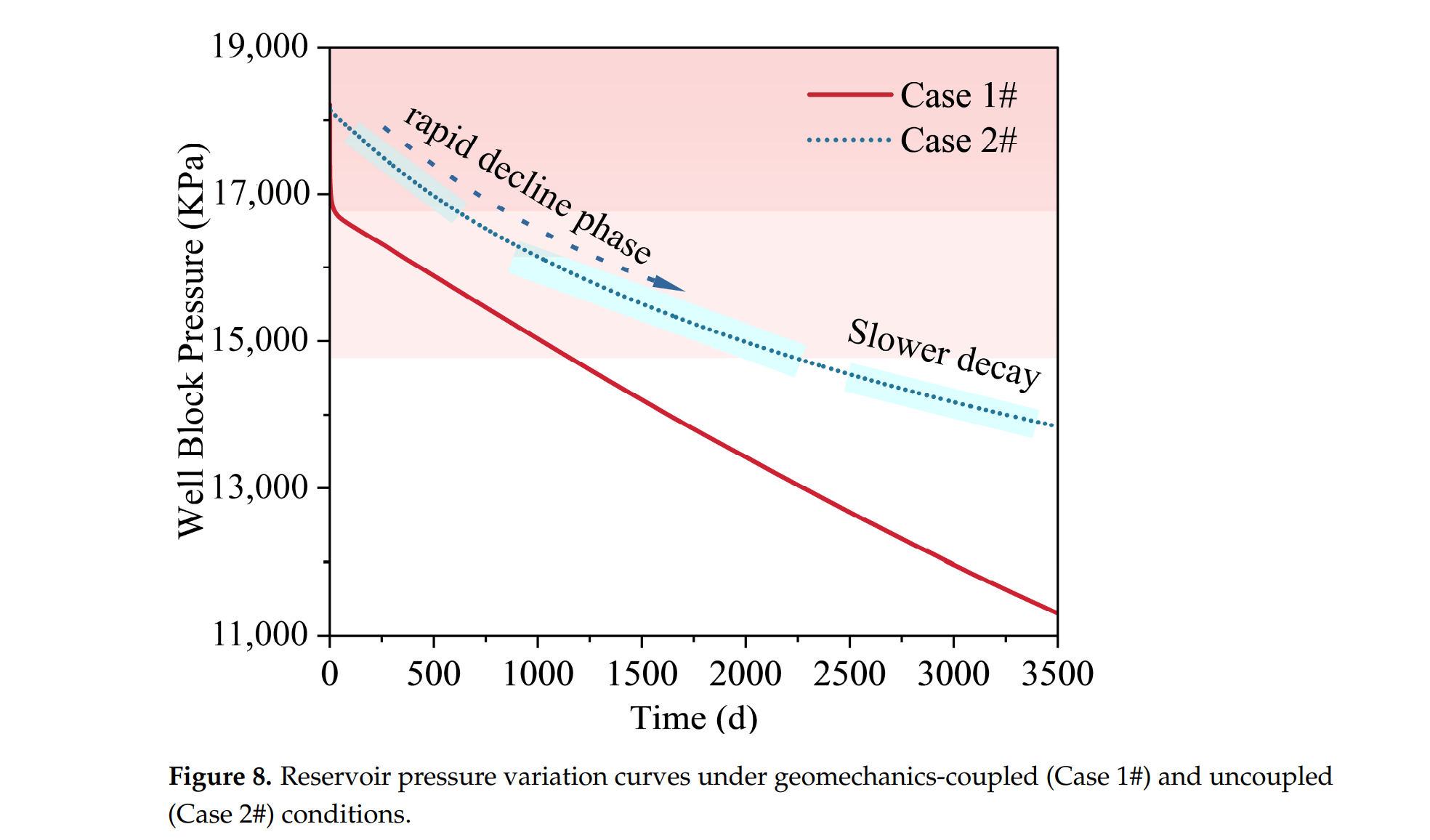

- 对比耦合与非耦合地质力学模型的产能差异。

结论

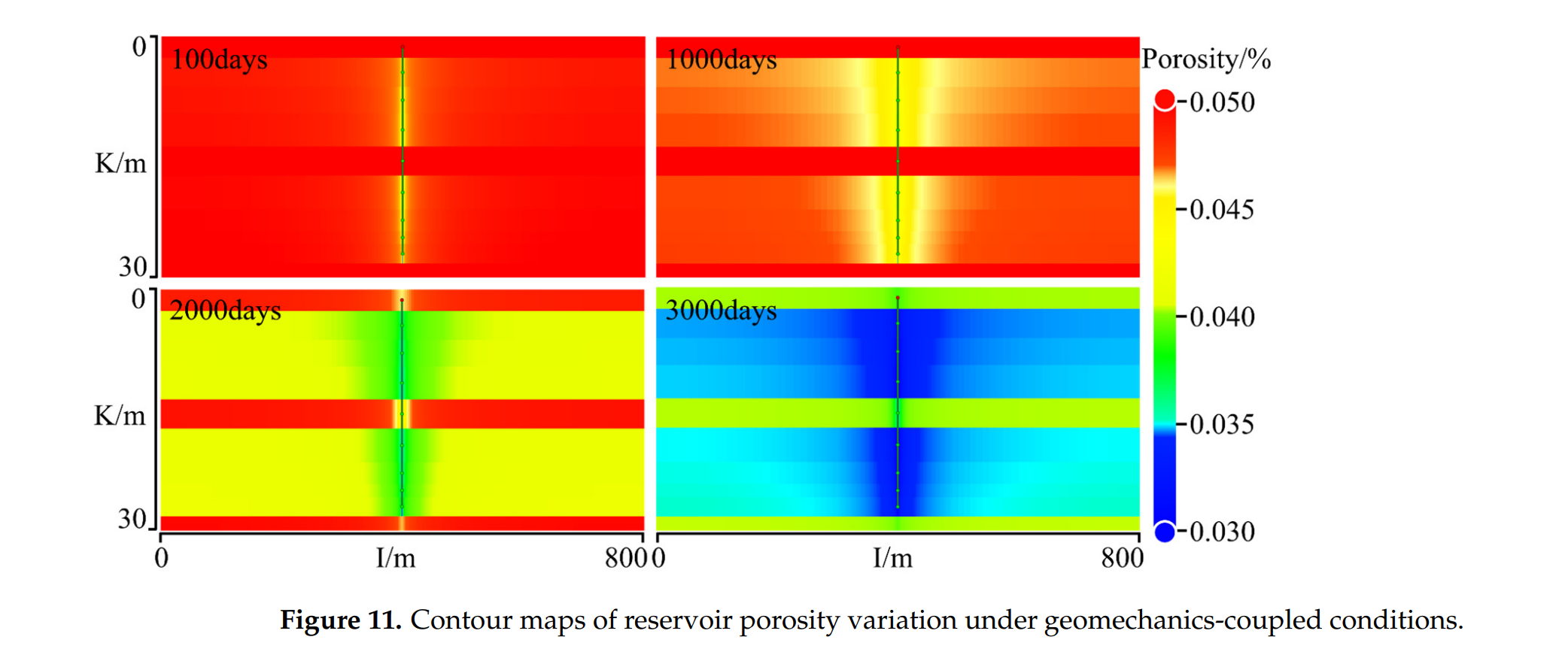

- 地质力学耦合是深层煤层气稳产的关键机制,有效应力压实与基质收缩共同作用,使裂隙孔隙度仅下降约2%,形成“快速上升—1~2年稳产—缓慢递减”的典型产出曲线;

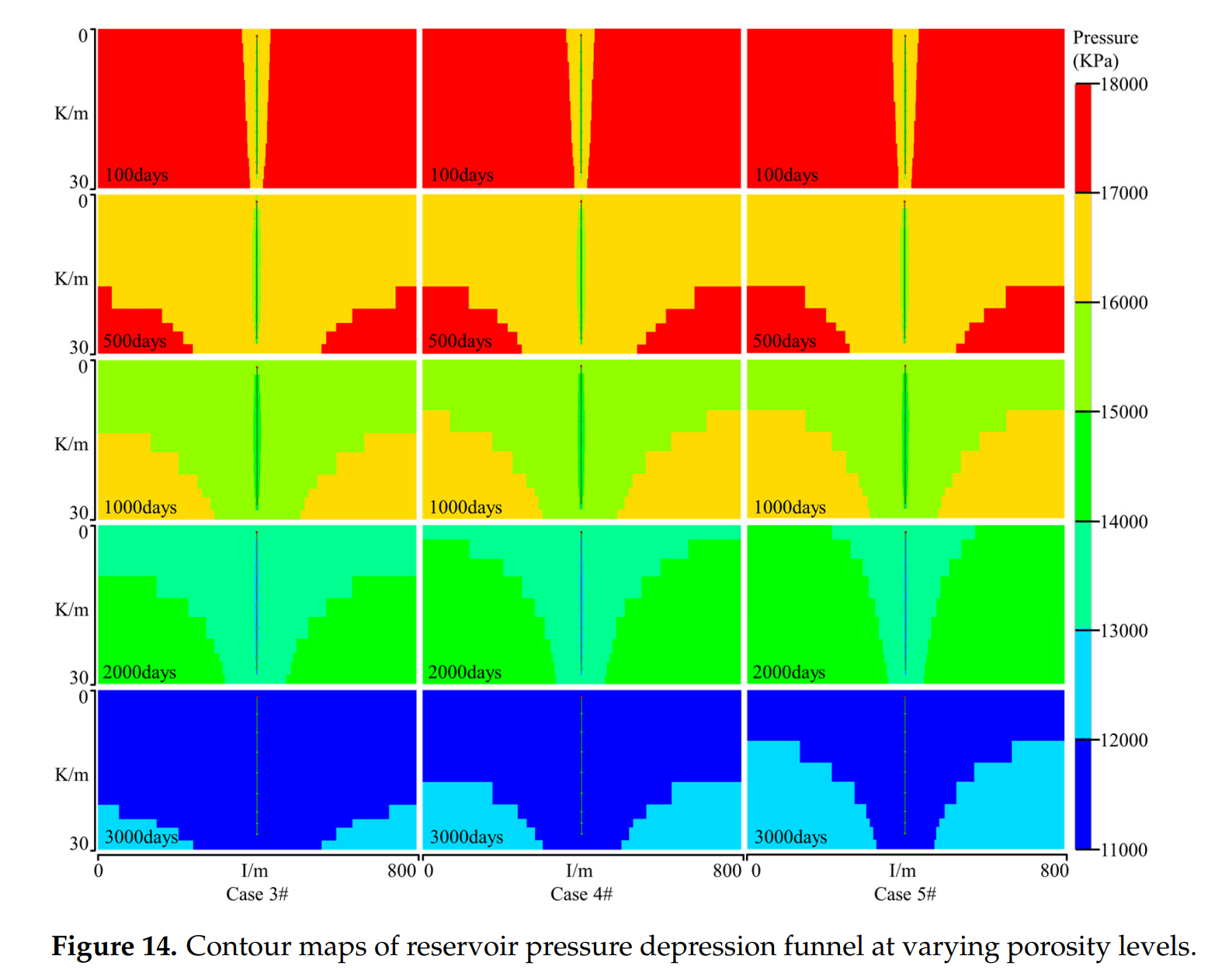

- 孔隙度(10~30%)与产能正相关,每增加10个百分点,峰值产量提高2.1%,累计产量增加2.8%;

- 天然裂隙渗透率过高(>20mD)虽提升初期产量,但会加速压力衰减与裂隙闭合,导致长期产量下降;

- 压裂改造体积(SRV)主要影响近井地带短期产能,裂缝渗透率每增加500mD,峰值产量提高约17%,但也会加剧后期递减;

- 模型经现场数据验证,平均日产气量误差仅1.2%,具有良好的工程适用性。

作者单位

- 中国石油大学(北京)克拉玛依校区

Abstract

Deep coalbed methane (CBM) development faces significant challenges due to extreme geological conditions (high stress, elevated pressure, high temperature) that differ fundamentally from shallow reservoirs. Traditional productivity models developed for shallow CBM often fail to accurately predict deep reservoir performance. The complex “stress-desorption-flow” multi-field coupling mechanism, intensified under deep conditions, critically controls production dynamics but remains poorly understood. This study develops a multi-layer, commingled, coupled geomechanical-flow model for the Hujiertai deep CBM block (2140~2170 m) in Xinjiang, China. The model, integrating gas-water two-phase flow, Langmuir adsorption, and transient geostress evolution, was validated against field production data, achieving a low relative error of 1.2% in the simulated average daily gas rate. Results indicate that: (1) Geomechanical coupling is critical. The dynamic competition between effective stress compaction and matrix shrinkage limits fracture porosity reduction to ~2%, enabling a characteristic “rapid incline, 1–2-year plateau, gradual decline” production profile and significantly enhancing cumulative gas production. (2) Porosity (10~30%) is positively correlated with productivity: a 10-percentage-point increase raises the peak gas rate by 2.1% and cumulative production by 2.8%. Conversely, high initial cleat permeability boosts early rates but accelerates geomechanical damage (cleat closure), lowering long-term productivity. (3) Stimulation parameters show a trade-off. SRV only dictates short-term, near-wellbore production. Higher fracture permeability (peak rate +17% per 500 mD) boosts early output but accelerates depletion and stress-induced closure. The multi-field coupling mechanisms revealed and the robust model developed provide a theoretical basis for optimizing fracturing design and production strategies for analogous deep CBM plays.