Influence Mechanism of Well Location and Near-Well Secondary Hydrates on Gas Production of Class 1S Hydrate Reservoirs

本文针对在中国南海琼东南盆地发现的新型天然气水合物储层——1S类水合物储层,开展地质建模与数值模拟研究。该类储层具有游离气与水合物在同一层位共存的特征,具备良好的商业开发潜力。文章构建了典型地质模型,设置5种不同井位方案,采用降压开采方式,系统分析井位布局对产气动态的影响,重点探讨井周二次形成水合物生成对产能的抑制作用。研究结果表明:

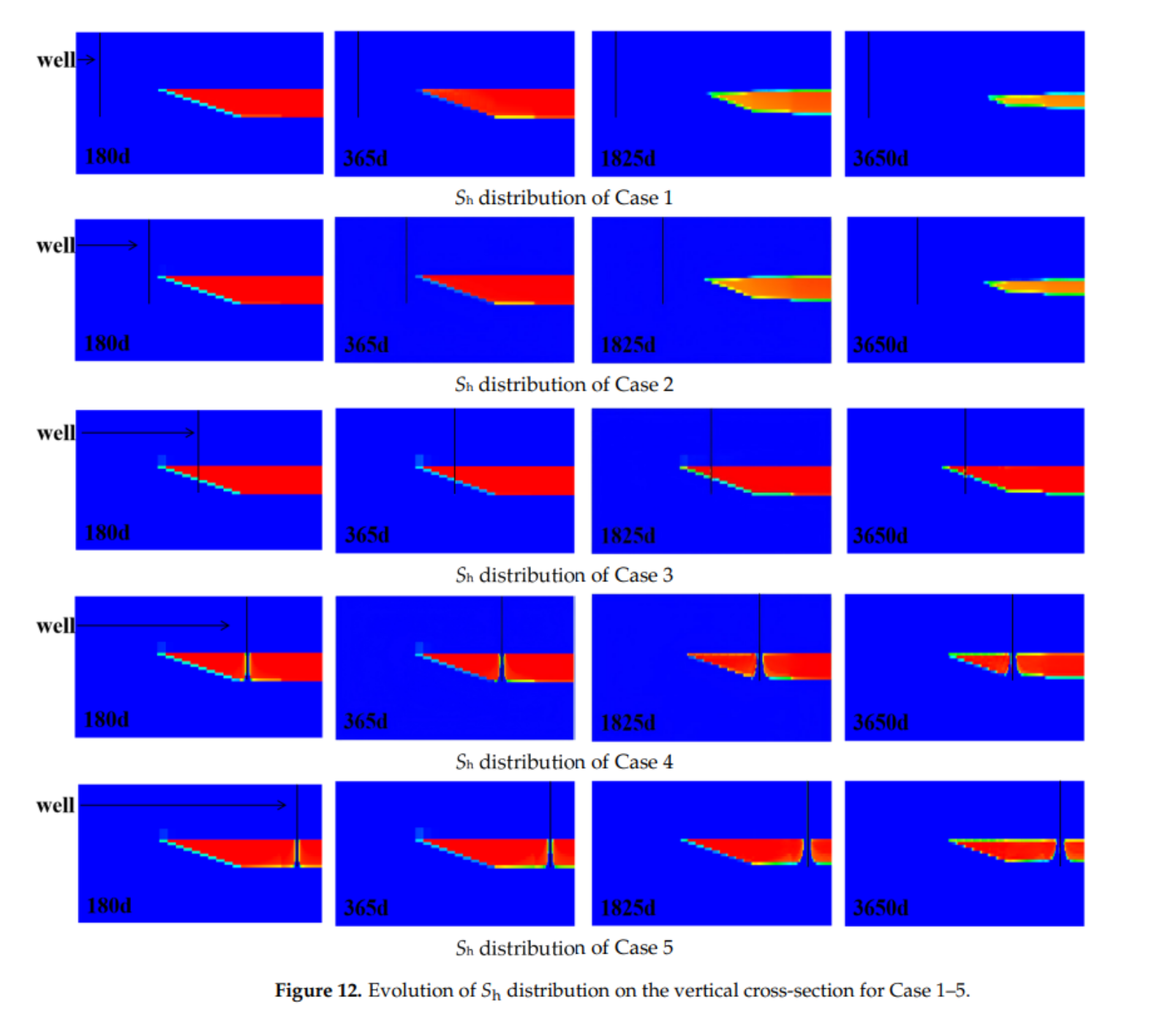

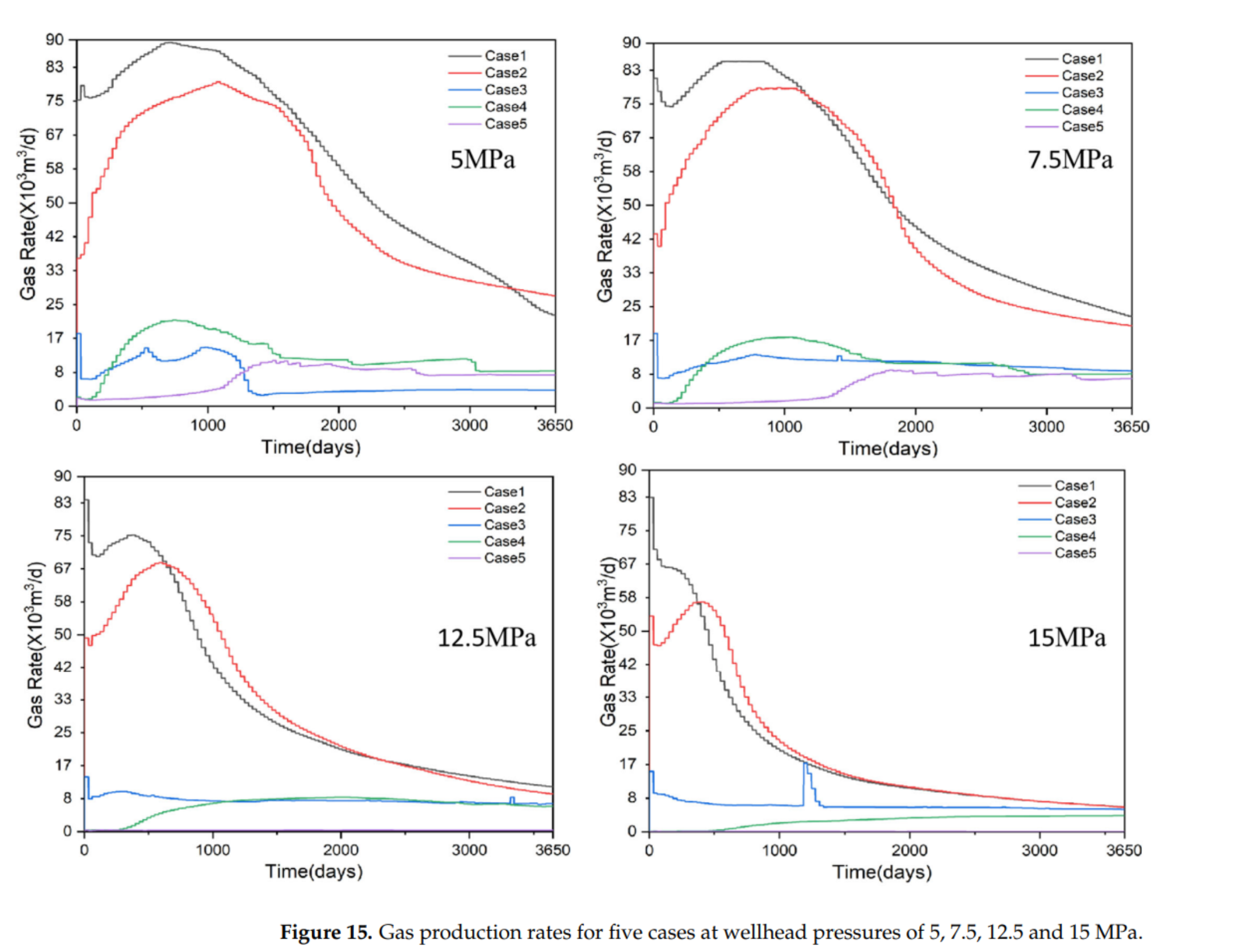

- 井位布设在气体富集区可获得最高的累积产气量;

- 井周二次形成水合物生成会显著降低产气率,需采取如井筒加热等措施加以控制;

- 不同井位与生产压差组合下,产气行为差异显著,应优化井位与压差设计以提升开发效果。

CMG软件应用情况

- 软件平台:CMG-STARS

- 模拟内容:

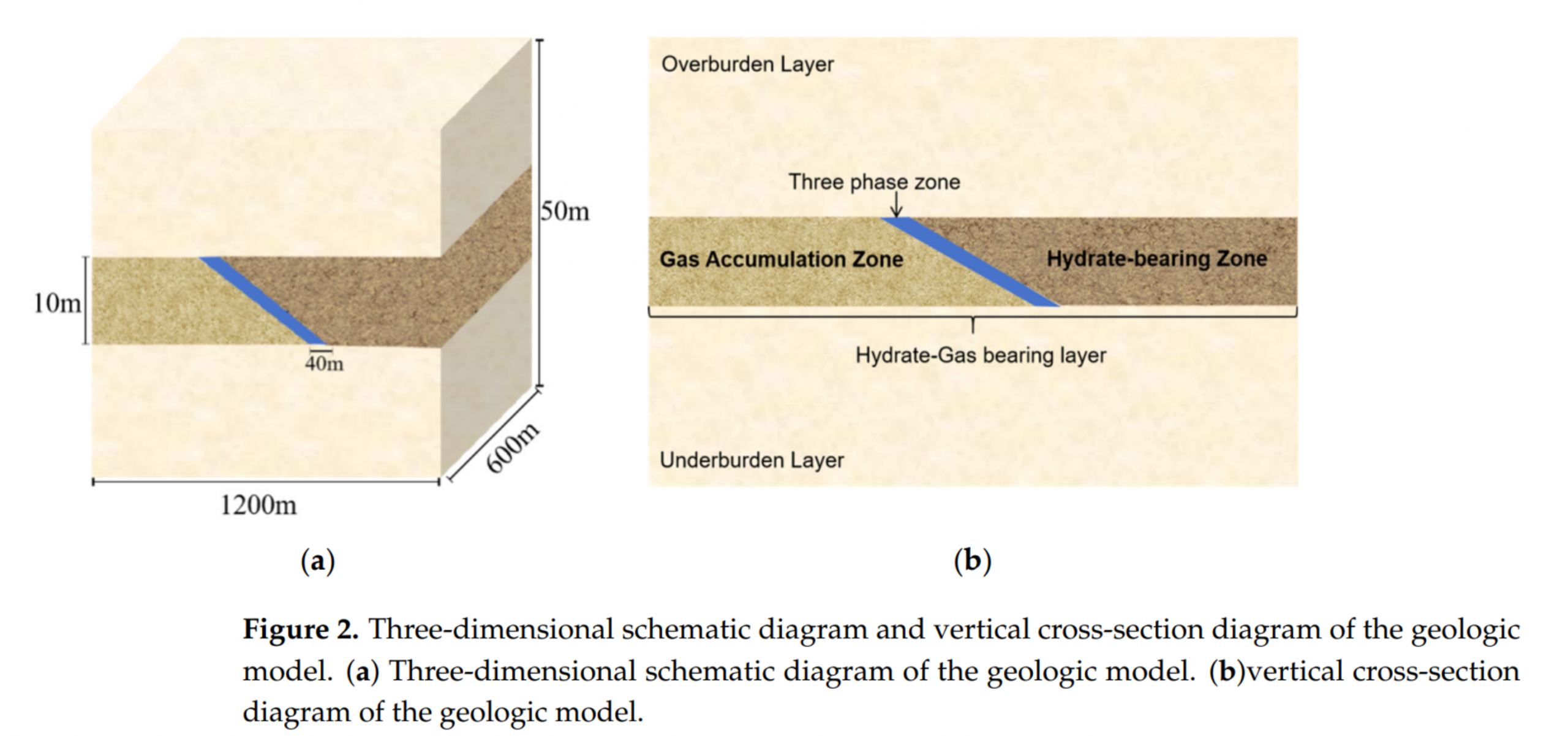

- 建立三维非均质水合物储层模型,包含气体富集区、三相区(气+水+水合物)和水合物富集区;

- 模拟不同井位(5种方案)下的降压开采过程,分析产气速率、累积产气量、水合物分解动态;

- 模拟井周二次水合物生成过程及其对渗透率、产气能力的影响;

- 对比不同井筒压力(5~15 MPa)下的产气表现与井周水合物饱和度变化;

- 模拟验证:通过与实验数据对比,累积产气量误差控制在6%以内,验证了模型的可靠性。

结论

- 1S类水合物储层形成机制:深层气源供给+气烟囱输导+盖层封闭+水合物稳定域协同作用。

- 井位优选:优先将生产井布设在气体富集区(如Case 1),可获得最高产气量;后期可考虑增加井数以提高采收率。

- 二次形成水合物影响显著:井周二次水合物生成会堵塞渗流通道,显著抑制产气,尤其在三相区与水合物富集区,建议采用井筒加热等措施抑制其生成。

- 井底压力影响:较低井底压力(如5~10 MPa)有利于提高产气量,但也更易诱发井周二次水合物;需权衡压差与井周稳定性。

- 模型可靠性:CMG-STARS模拟结果与实验数据吻合良好,误差小于6%,验证了模型在产气预测与水合物分解模拟中的适用性。

作者单位:

广州海洋地质调查局

Abstract

In recent years, a new type of natural gas hydrate reservoir (designated as Class 1S reservoir) has been discovered in the Qiongdongnan Basin. Within this hydrate reservoir, free gas and hydrate coexist within the same stratum. The Class 1S reservoir is comprised of three distinct zones: the gas accumulation zone, the three-phase zone, and the hydrate-bearing zone. It exhibits significant commercial development potential. This paper analyzes the formation mechanism and geological context of Class 1S hydrates. A geological model was established and numerical simulation methods were employed to evaluate its production capacity, elucidating the evolutionary patterns of hydrate saturation distribution at different well locations. The simulation results indicate that production wells should be prioritised in gas accumulation zones in order to achieve the highest cumulative gas production. Additional production wells may be considered in later stages to enhance recovery rates. Secondary hydrate formation significantly impacts production in Hydrate-bearing zone and three-phase zone. Measures such as wellbore heating can be employed to minimize secondary hydrate formation around the wellbore.