多年来,断块油气藏开发一直是行业面临的重大挑战。这一现象在预测井产能和总采收率方面带来了一些复杂性和不确定性。过去为了提高采收率,钻了多口垂直井。最新发展的多分枝井和完井技术成为生产多个断块的可行替代方案,尤其是海上断块储层。断块可能具有一组独特的特征,如平均压力、厚度、渗透率和孔隙度分布。使用先进的井系统预测复杂储层构造的混合产量数据和总采收率时,这种性质的变化引入了复杂的动力学。

MULTILATERAL WELL MODELING FROM COMPARTMENTALIZED RESERVOIRS

Abstract

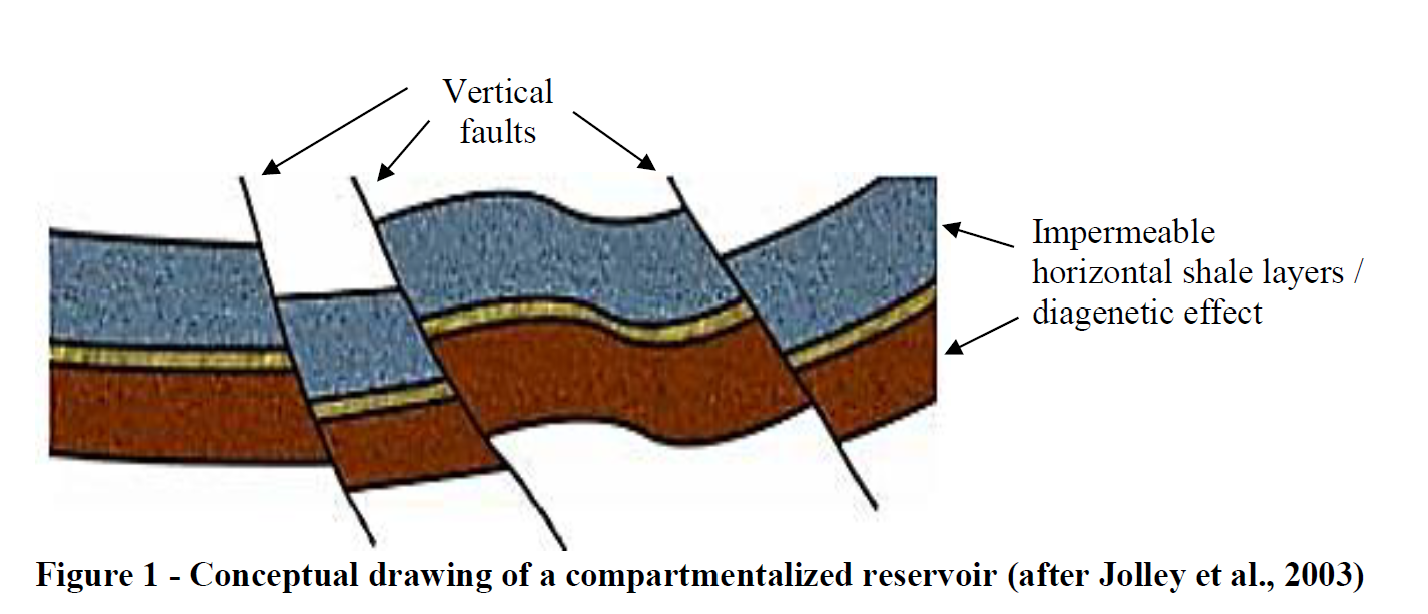

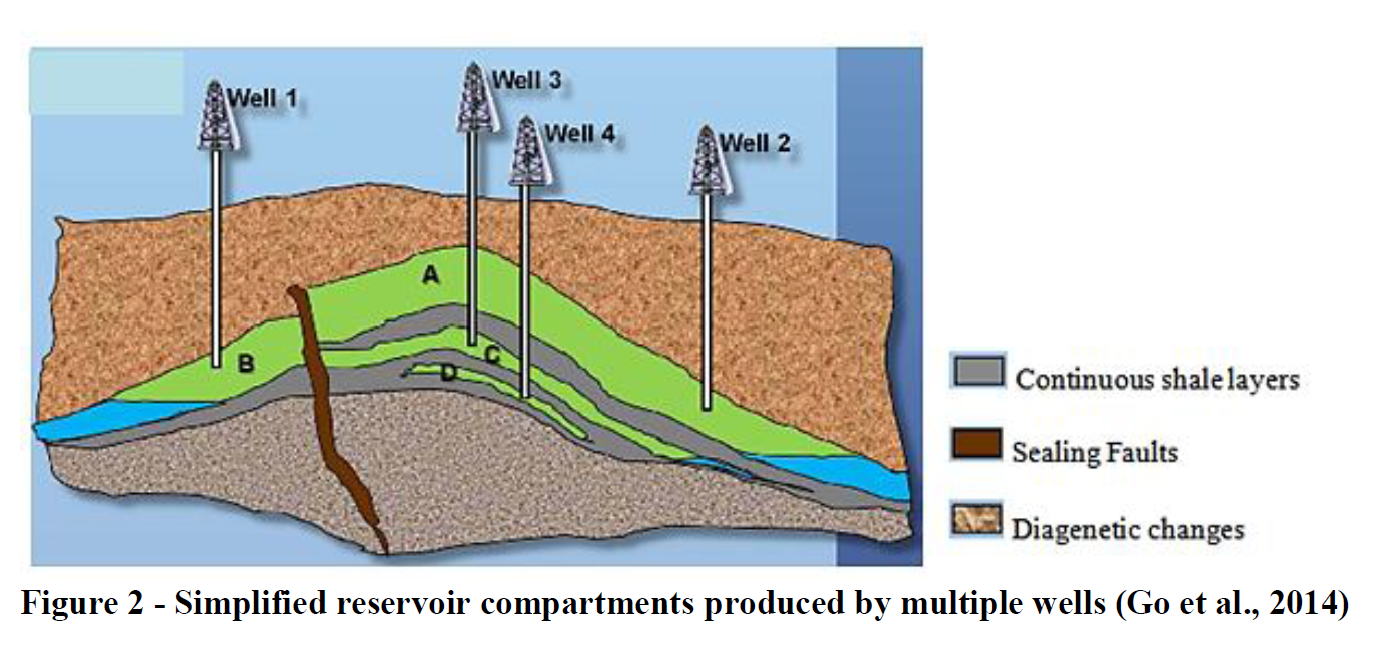

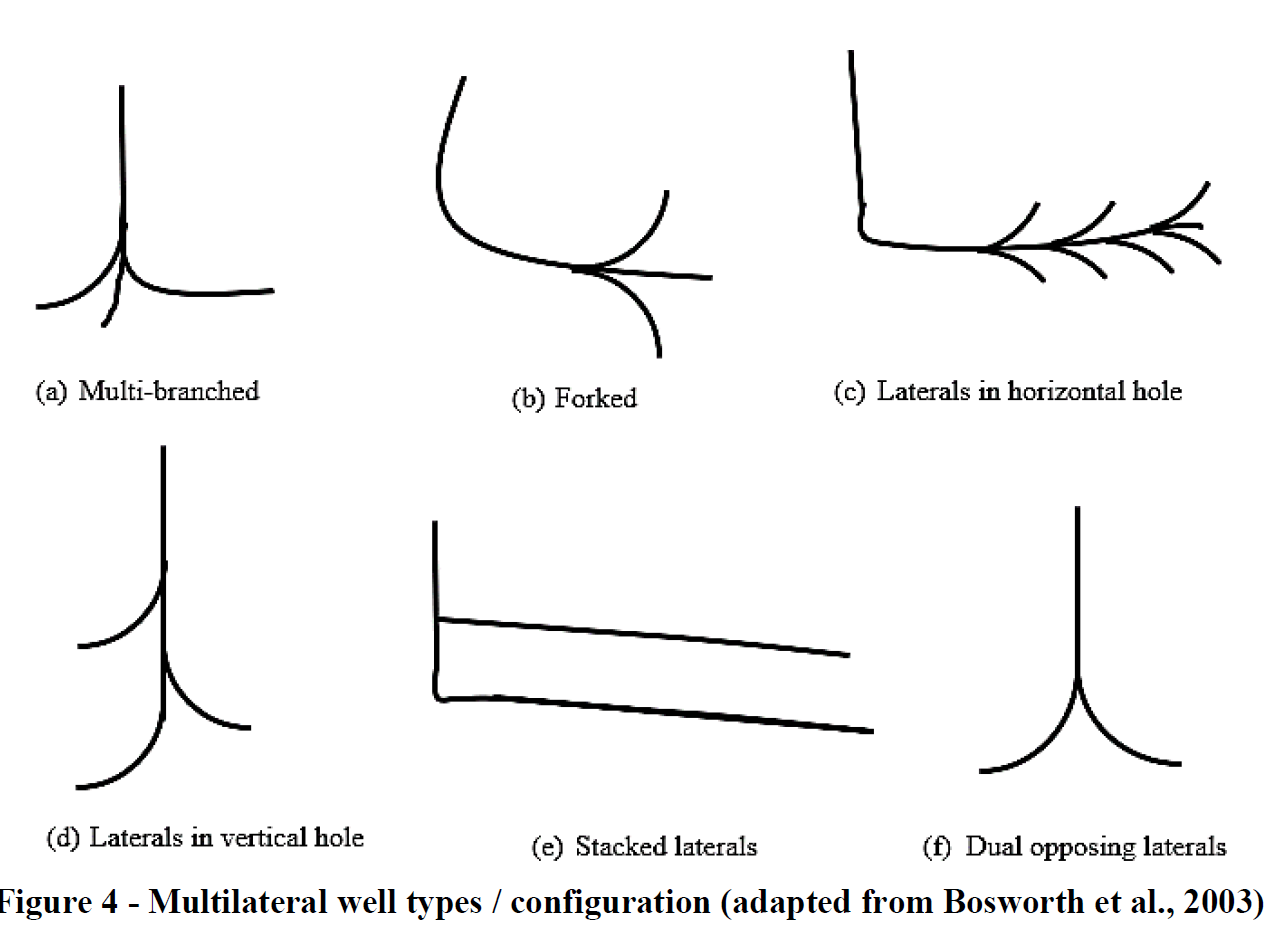

The existence of compartmentalization in oil and gas fields have been a major industry challenge for decades. This phenomenon introduces some complexity and uncertainty in the prediction of well productivities and the overall hydrocarbon recovery factor. In the past, multiple vertical wells were drilled to increase recovery. The recent advancement of the multilateral and completions technology made multilateral wells a viable alternative to produce multiple reservoir compartments, most especially offshore. Reservoir compartments may possess a set of unique characteristics, such as average pressures, thicknesses, permeabilities, and porosity distribution. This variation in properties introduced complex dynamics in forecasting the commingled production figures and overall recovery factor from complex reservoir structures using advanced well systems.

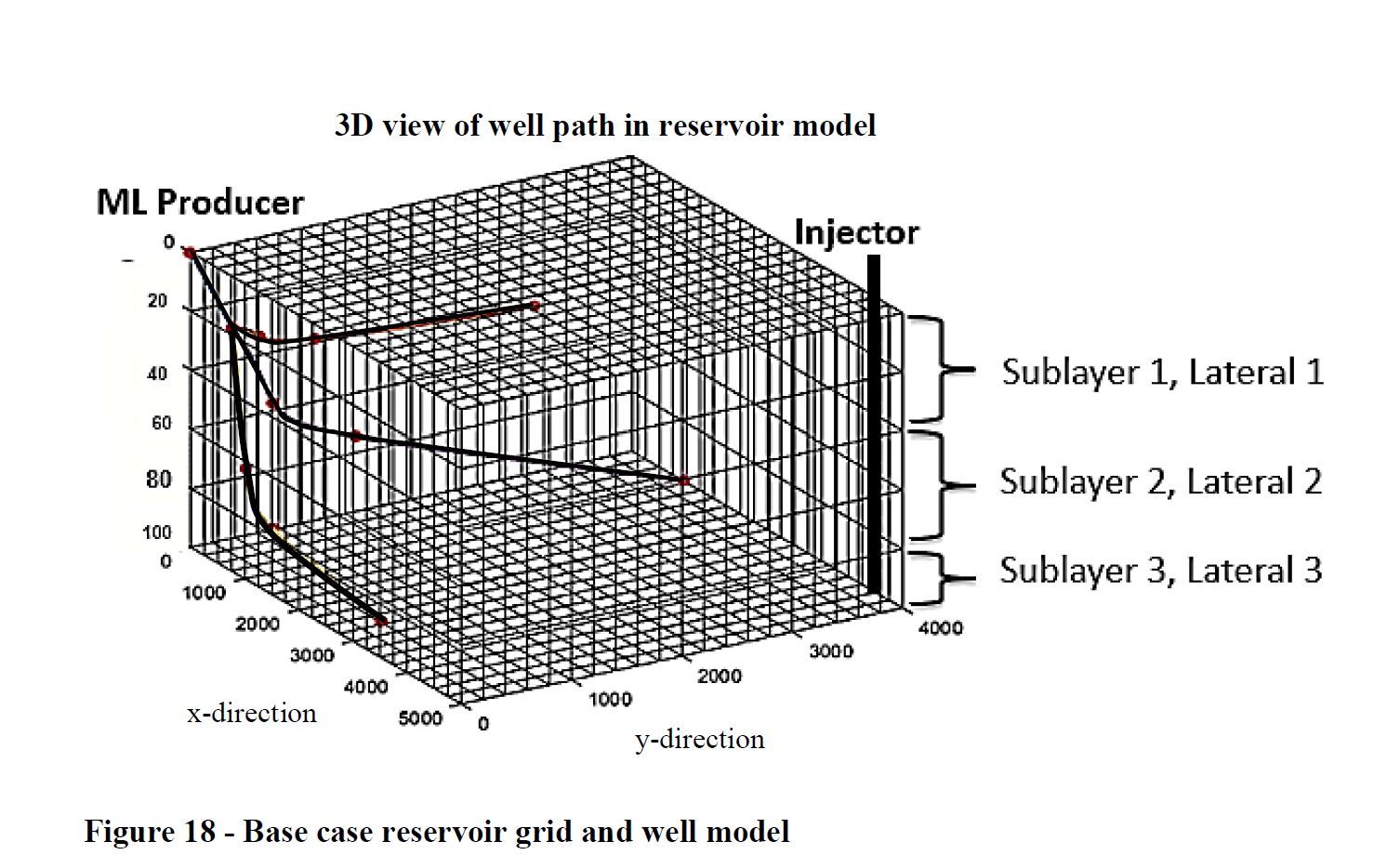

Existing analytical and semi-analytical productivity models due to the simplifying assumptions in their development are only suitable for first approximations and early estimates in field applications. In this work, a comparison is made between the more widely known finite difference numerical method and the finite volume numerical discretization method in field productivity predictions. The Matlab Reservoir Simulation Toolbox (MRST) which is a collection of open source codes, based on the finite volume discretization methodology is used to develop the reservoir compartment and multilateral well model used in this study. We investigate the pressure drop behavior over time through the lateral for a conventional well completion and compare with the pressure drop behavior for a smart well completion with downhole flow control devices for flow control and optimization.

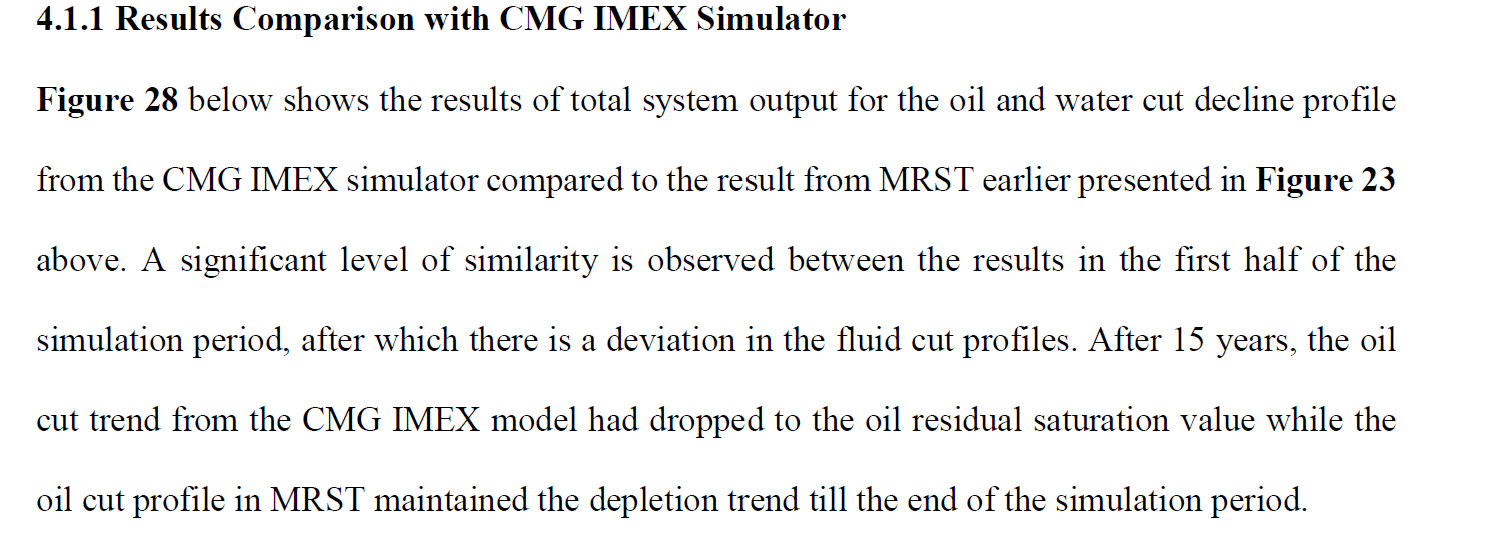

Several cases of compartmentalized reservoirs with faults of varying orientation and sealing capacity is then investigated. The production profile results obtained from the base reservoir case from MRST is compared to those from the IMEX simulator tool in CMG (Computer Modeling Group), a commercial reservoir simulator, based on the finite difference numerical discretization method. The results we obtain show a more accurate production profile prediction based on the finite volume method over the finite difference method, as expected. The ability of the simulation toolbox as well as the importance of using an improved and more efficient numerical discretization scheme in solving an increasingly complex array of reservoir structures and advanced well geometries, with multiphase fluid flow is demonstrated. Finally, an adjoint gradient – based method of optimization implemented in the toolbox is used to investigate the optimization potential of using the smart well completions versus a conventional well completion with the net present value as the objective function. Results obtained show that an investment in smart completions for the multilateral well ultimately yields a higher net cash flow and net present value over a conventional well of equivalent length designed without smart completions.