Impact of Shale Compaction on Productivity of Marcellus Shale Horizontal Well with Multiple Hydraulic Fractures

本研究旨在探讨页岩压实作用对马塞勒斯页岩多段压裂水平井产能的影响。由于马塞勒斯页岩具有较低的杨氏模量和中等泊松比,其对应力变化非常敏感,生产过程中易发生页岩压实,进而影响水力裂缝和天然裂缝的导流能力,降低气井产能。文章基于美国西弗吉尼亚大学在马塞勒斯页岩能源与环境实验室(MSEEL)获取的岩心、测井、压裂和生产数据,建立了耦合地质力学与流体流动的数值模型,模拟页岩压实对基质孔隙度、渗透率、天然裂缝导流能力以及人工裂缝导流能力的影响。

CMG软件应用情况

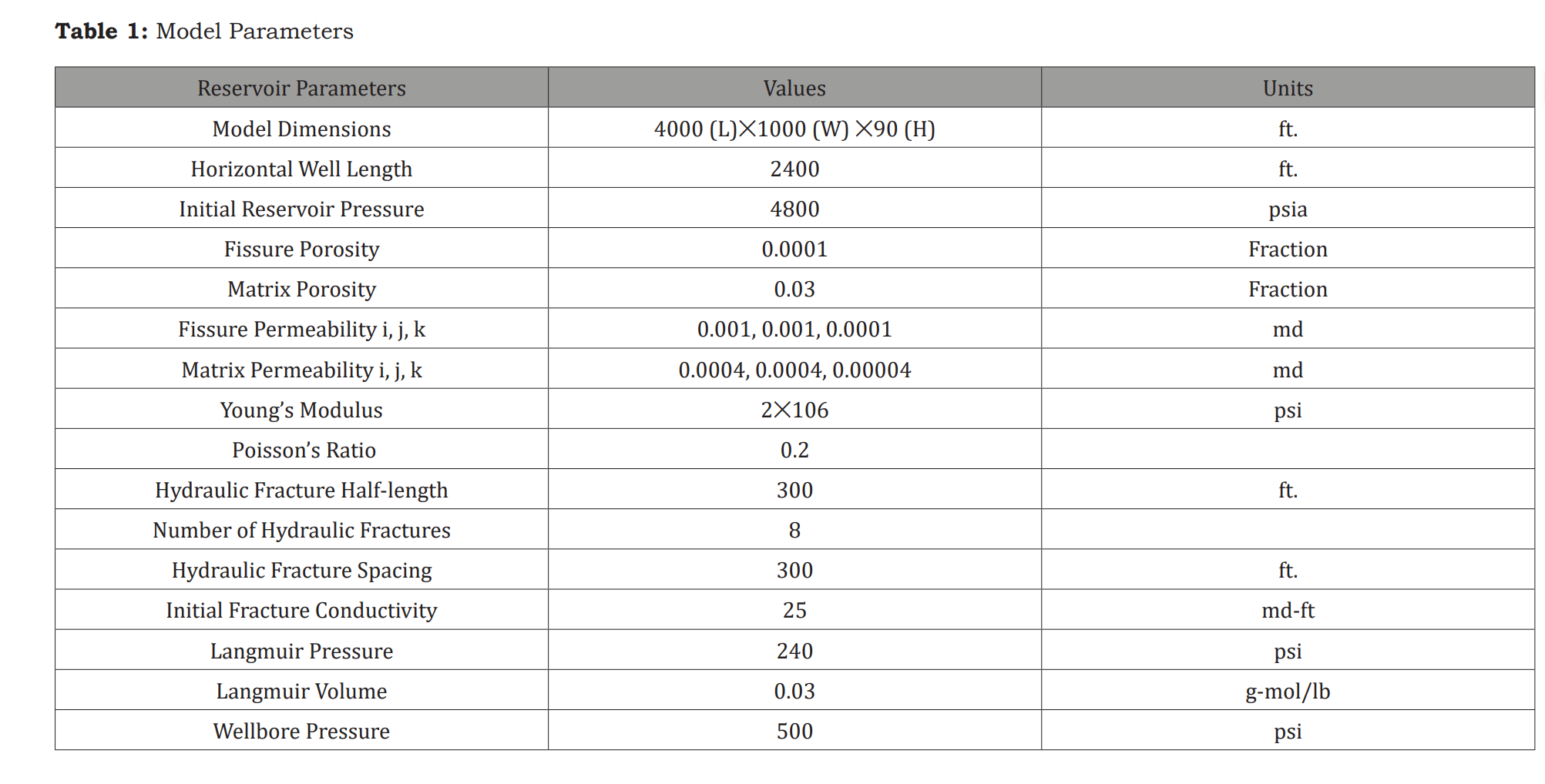

本研究采用CMG-GEM(2021版)数值模拟软件建立马塞勒斯页岩水平井的多段压裂模型。模型中引入了双重渗透率系统和局部网格加密(LGR)技术,以准确模拟裂缝周围的瞬态气体流动。为了考虑页岩压实对储层物性和裂缝导流能力的影响,研究团队将CMG模型与地质力学模块进行双向耦合(two-way coupling),实现了以下功能:

- 模拟有效应力变化对基质孔隙度、渗透率、天然裂缝渗透率和人工裂缝导流能力的动态影响;

- 利用实验数据建立渗透率与裂缝导流能力的应力敏感性乘子(multipliers);

- 对比有无耦合地质力学的模拟结果,验证模型的准确性;

- 分析不同裂缝参数、页岩力学性质及操作条件对产能的影响。

结论

- 马塞勒斯页岩由于其力学性质(低杨氏模量、中等泊松比)对有效应力变化敏感,易发生压实;

- 页岩压实会导致基质孔隙度、渗透率、天然裂缝渗透率和人工裂缝导流能力降低;

- 耦合地质力学与流体流动的模拟能更准确预测气井产能;

- 页岩压实对产能的负面影响在生产初期最为显著,随时间推移逐渐减弱;

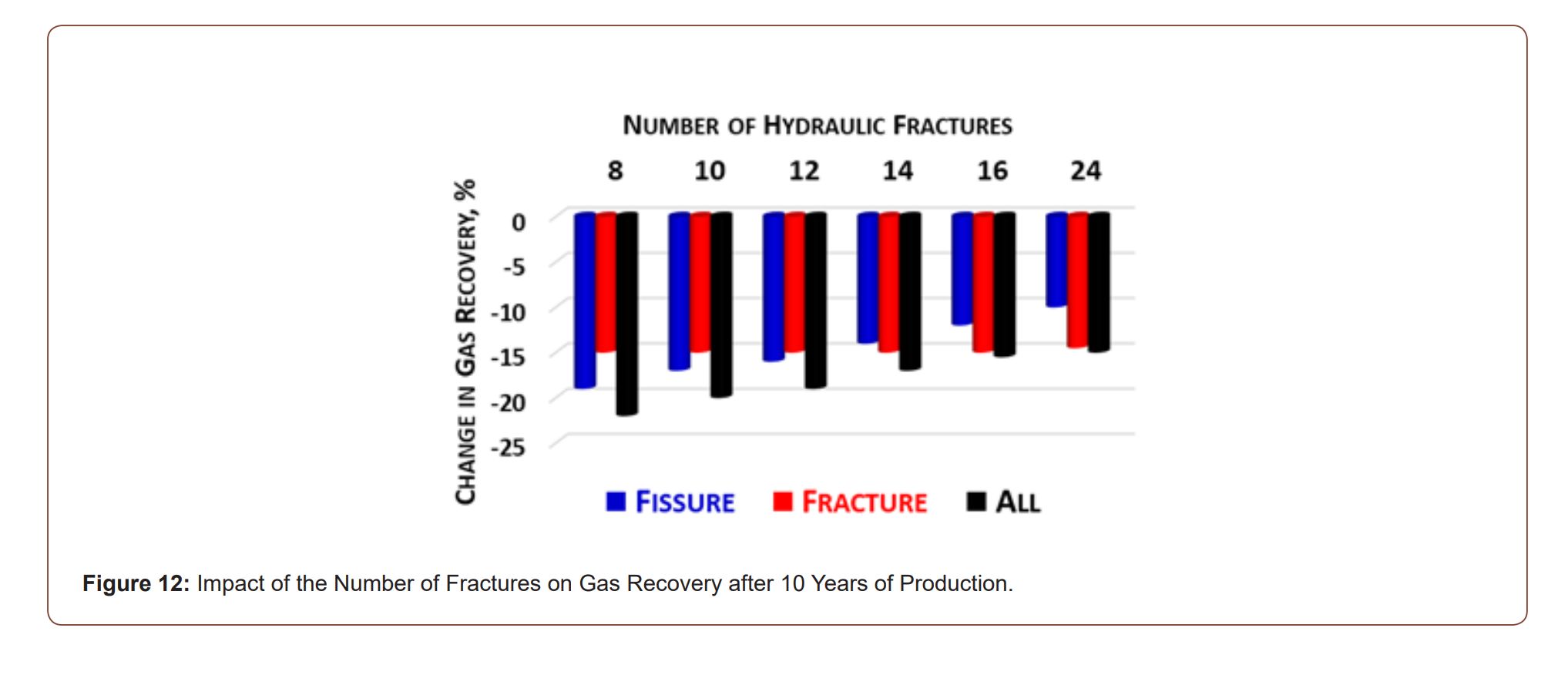

- 人工裂缝导流能力的下降是影响产能的最主要因素;

- 提高杨氏模量和泊松比可缓解压实影响;

- 增加裂缝长度和减小裂缝间距会加剧压实影响;

- 提高初始裂缝导流能力有助于减轻压实带来的负面效应;

- 降低井底流压(增大压差)会加剧压实影响,但可提高初期产量,需权衡经济性。

作者单位

- 美国西弗吉尼亚大学

Abstract

Marcellus shale, because of its mechanical properties, is sensitive to stress which leads to shale compaction as gas is produced from the shale. Shale compaction impacts hydraulic fractures and fissures both of which play significant roles in well performance. This is particularly significant for a Marcellus shale horizontal well with multi-stage hydraulic fractures. It is therefore necessary to couple the geomechanics and fluid flow simulations to accurately predict the gas recovery from a horizontal Marcellus shale well. The intensity of effective stress increase depends on the initial productivity of the well, which is influenced by the shale initial properties, hydraulic fracture properties, stage spacing, as well as the operating conditions. The objective of this study was to investigate the impact of the shale properties (Initial fissure permeability, Young’s modulus and Poisson’s ratio), the hydraulic fracture properties (length, initial conductivity, spacing), as well as operating conditions on the productivity of a horizontal Marcellus shale well with multi-stage fractures. In this study, both individual and combined effects of fissures and hydraulic fracture closures on gas recovery are investigated. The advanced technical information available from the Marcellus shale horizontal wells located at the Marcellus Shale Energy and Environment Laboratory (MSEEL) site provided an opportunity to investigate the impact of the shale compaction on gas recovery. The core, well log, well test, completion, stimulation, and production data from the wells at MSEEL site were utilized to estimate the shale mechanical and petrophysical properties as well as the hydraulic fracture characteristics. The results of the data analysis were then utilized to develop a reservoir model for a horizontal well completed in Marcellus shale with multi-stage hydraulic fractures. A geomechanically with geomechanic module was coupled with reservoir model to determine the effective stress and the shale compaction and its impact on the shale permeability and porosity. The impact of the shale compaction on the permeability (for both matrix and fissure) and the conductivity of the hydraulic fractures were determined from the published measurements on Marcellus shale core plug analysis as well as the propped fracture conductivity in Marcellus shale and were incorporated in the reservoir model. The inclusion of the compaction in the reservoir model provided a more realistic simulated production profile. The gas recovery was found to be adversely impacted by the compaction. The compaction impact on gas recovery was found to be more severe during the early production due to higher production rates but diminishes as production time increases. The reduction in the conductivity of the hydraulic fractures due to the compaction was found to have the most adverse effect on the gas recovery during the early production period. This confirms the major role that fracture conductivity plays in early production. Finally, the model was employed to investigate the impact of the formation mechanical properties, hydraulic fracture properties, and the operating conditions on the recovery of the gas. The higher values of the Young’s modulus and Poisson’s ratio can mitigate the compaction impact and lead to improved recovery. Conversely, the higher values of the fracture half-length as well as the closer fracture spacing will amplify the adverse impact of the compaction on the early gas recovery.