Preliminary Study by Reservoir Simulation of Field Trial Polymer Injection in SBR Field Using Silica-Modified HPAM

聚丙烯酰胺(PAM)是最无机的聚合物类型,通常用于提高采收率的注入。此外,水解聚丙烯酰胺(HPAM)是聚合物驱中常用的聚合物,但它对矿化度和温度敏感。因此,用二氧化硅改性PAM和HPAM的实验旨在提高聚合物在高温和高矿化度下的性能。实验包括聚合物合成、聚合物改性、产品流变学测量和储层模拟研究。进行了一些实验以评估产品的可行性。在聚合物注入模拟中,聚合物的物性被称为产品的物性。

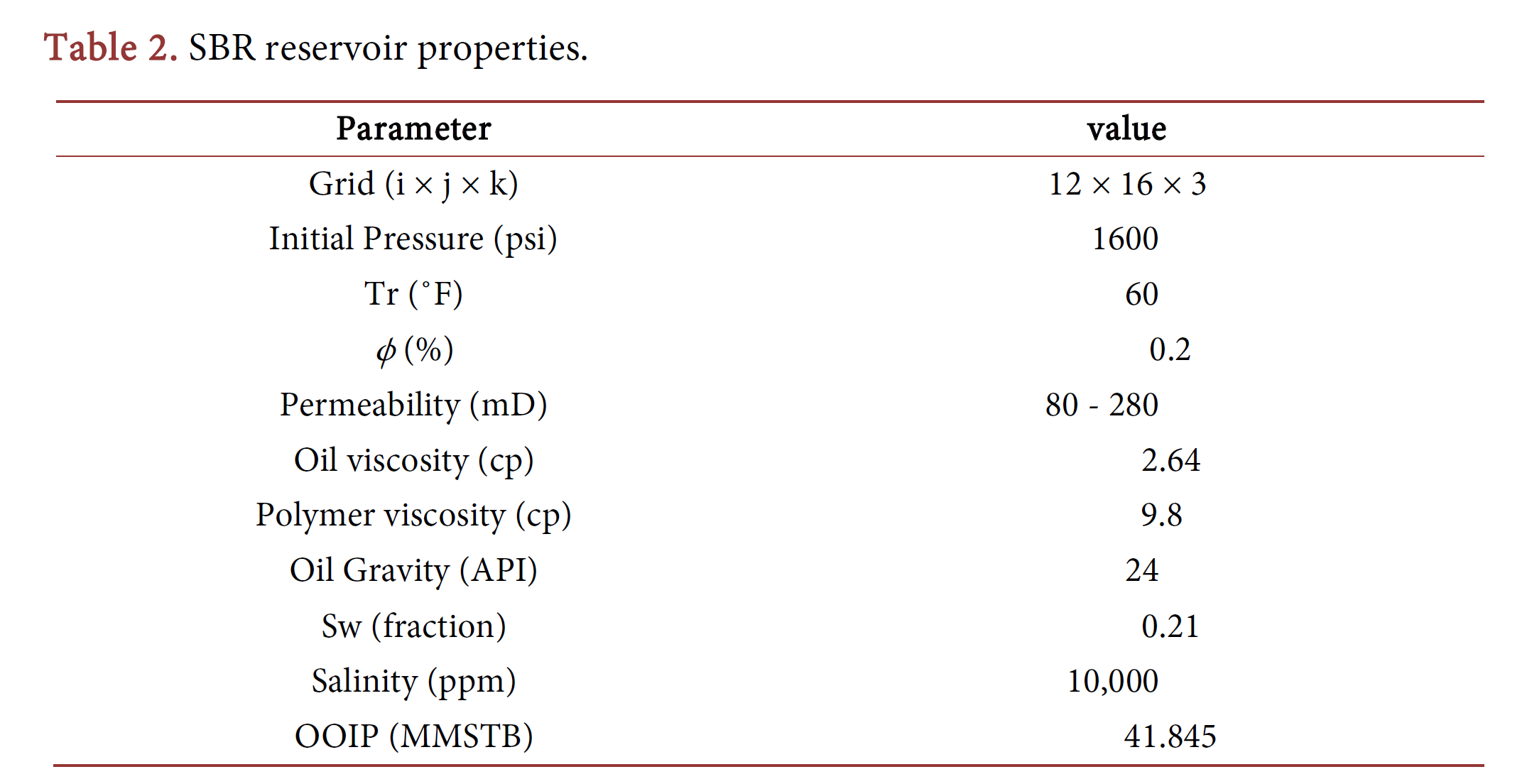

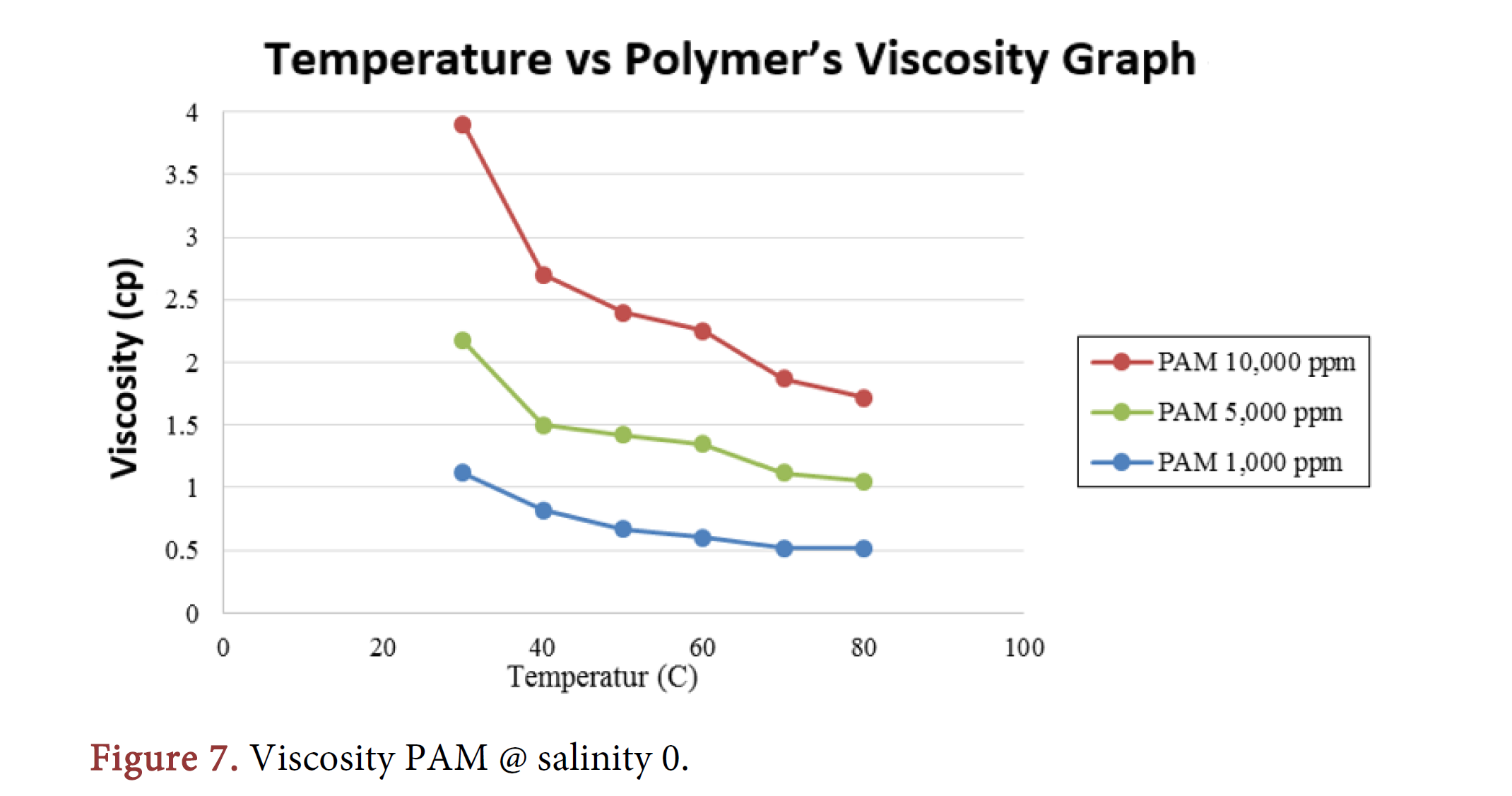

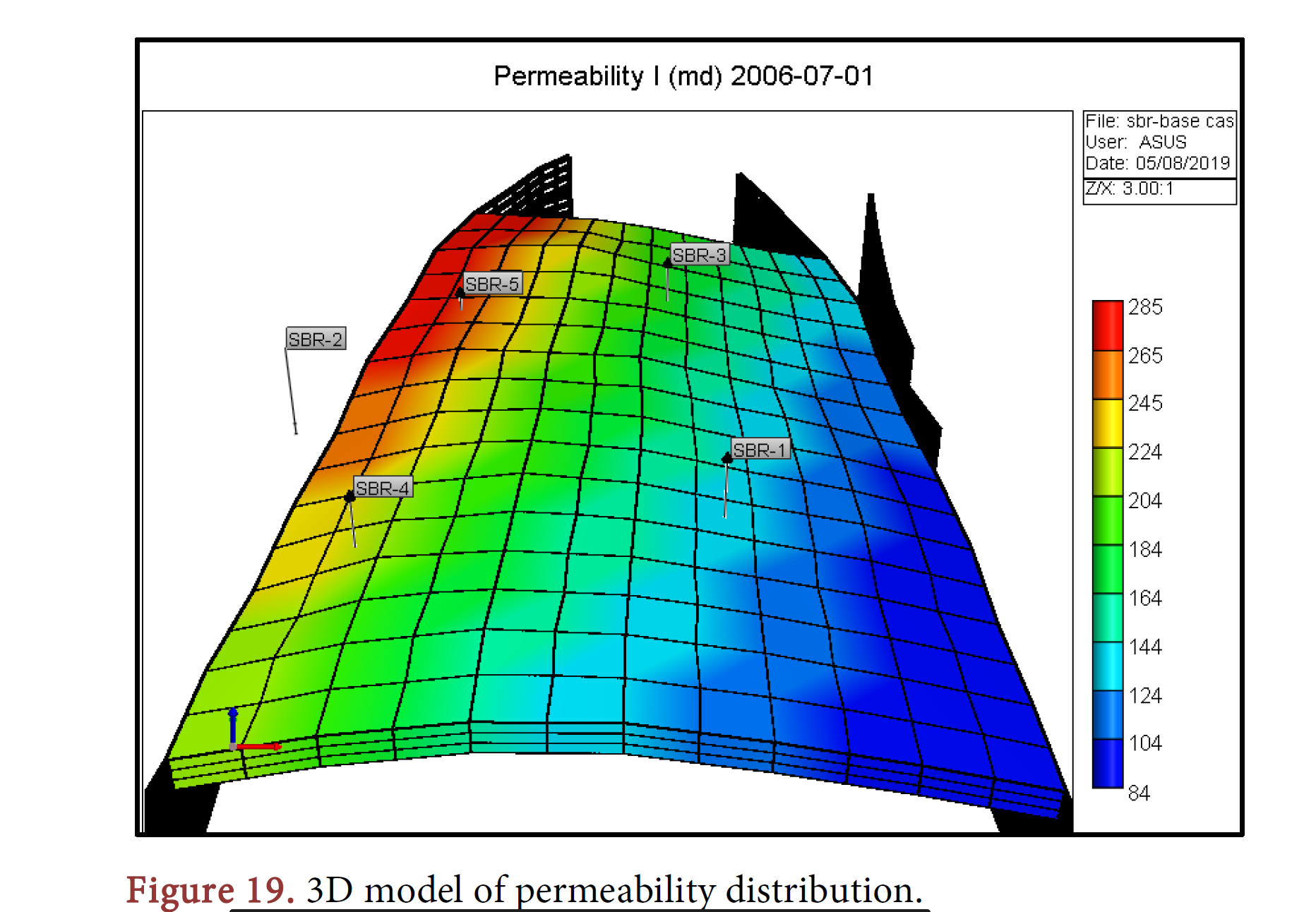

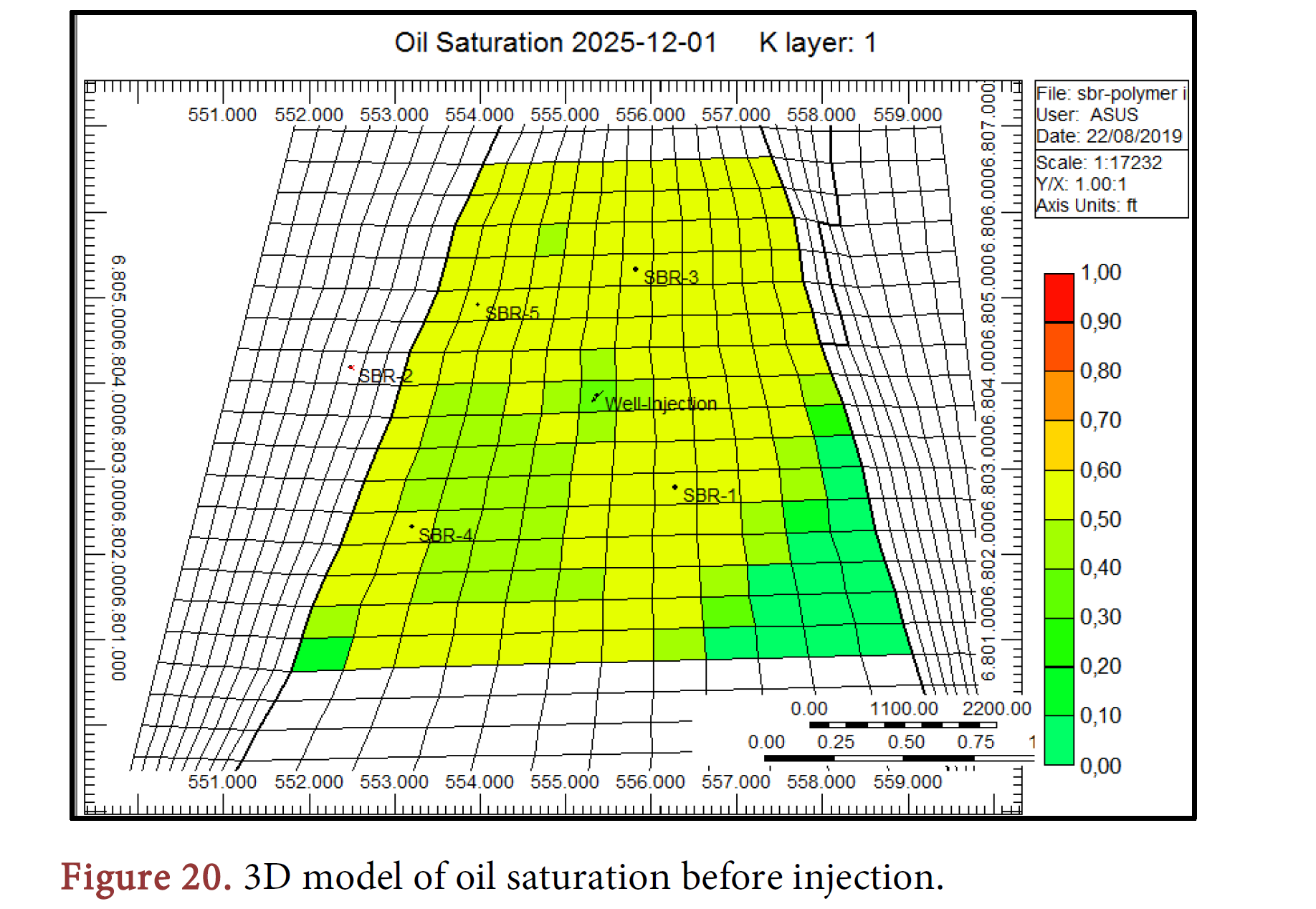

选择最佳配方在SBR油田进行实施。在SBR油田试验之前,进行了数值模拟研究。模拟预测了增油量,确定最佳注入速率和最佳注入井位置。SBR油田温度、矿化度度和油相粘度分别约为60˚C、10000 ppm和2.64 cp。从粘度测量中得出结论,HPAM-Si是较好的驱替剂,因为它在其他产品中具有最高的粘度,约为9.8厘泊。

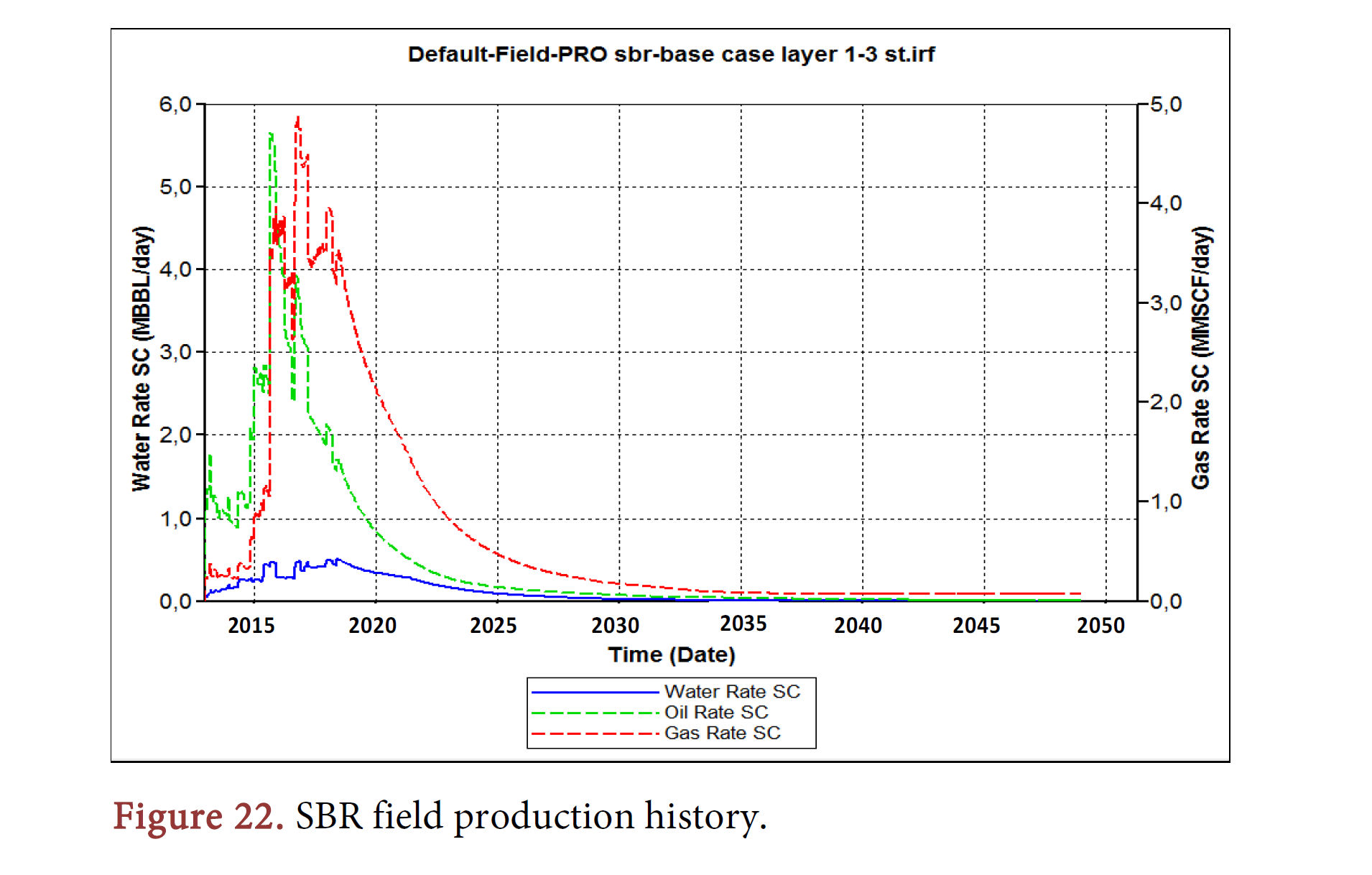

本研究使用的模拟器是CMG的IMEX黑油模拟器。模拟了三种方案,分别是基础方案、注水和注聚合物方案。基础方案的采收率约为15.26%,而以约2000桶/天的速度注水的采收率约为21.33%。最佳方案是注聚合物方案,最佳聚合物注入速度约为2000桶/日,最高采收率约30.73%。

Abstract

Polyacrylamide (PAM) is the most inorganic polymer type which is usually used in injection for enhanced oil recovery. Furthermore, hydrolyzed polyacrylamide (HPAM) is a common polymer used in polymer injection, but it has the sensitivity towards salinity and temperature. Thus, the experiment modified PAM and HPAM with silica aims to improve the performance of polymer toward temperature and salinity. This experiment included polymer synthesis, polymer modification, rheological measurement of the product and reservoir modeling study. Some experiments were performed to assess the feasibility of the product. In the polymer injection simulation, the properties of a polymer are referred to as product properties.

The best outcome is selected to be implemented in SBR field. Prior to do trial in the real SBR field, the study by simulation is needed. The simulation predicts the incremental oil recovery and helps to determine an optimum injection rate and the best injection well location. The SBR field temperature, the salinity and the oil viscosity were about 60˚C, 10,000 ppm and 2.64 cp, respectively. From the viscosity measurement, it was concluded that HPAM-Si was qualified to become a displacing agent because it had the highest viscosity among other product which was about 9.8 cp.

The simulator used in this study was black oil IMEX-CMG simulator. The three scenarios applied were the base case, water injection and polymer injection. The base case gained recovery about 15.26%, whereas the water injection with a rate of about 2000 bbl/day gained oil recovery about 21.33%. The best scenario is polymer injection, where the optimum polymer injection rate is about 2000 bbl/day and the highest recovery is approximately 30.73%.