A New Steam Assisted Gravity Drainage Process Utilizing Vertical Wells

本研究开发了一种新型的蒸汽辅助重力排水(VWSAGD)工艺,该工艺利用垂直井来提高重油的采收率。在VWSAGD过程中,垂直井包含两个生产管柱,由三个封隔器(一个双封隔器和两个单封隔器)分隔:短注入管(SIS)连接在环形空间的底部,并在射孔的顶部四分之一处完成,而长生产管(LPS)连接在生产管底部,并在射孔的底部四分之一处完成。新工艺(VWSAGD)需要一个初始启动期(注热阶段),在这个阶段,两个注入管和生产管中同时注蒸汽,持续一段时间(约14-30天),然后两个管柱关闭,停止注入一段时间(焖井期),大约7-10天。注热和焖井期之后,长生产管用于生产,短注入管用于持续的蒸汽注入,直到模拟时间结束。使用商业模拟器(CMG-STAR Simulator)研究了新VWSAGD工艺的性能。对网格尺寸、焖井时间、蒸汽干度、生产井底压力、蒸汽注入速度、储层厚度、储层面积和水平/垂直渗透率各向异性进行了敏感性分析。研究结果表明,新的VWSAGD工艺更适合于具有高水平/垂直渗透率比和厚储层油区的储层条件。

CMG软件应用情况:

在本研究中,使用了Computer Modeling Group(CMG)的STARS热模拟器,包括模拟VWSAGD过程和进行敏感性分析。通过改变网格尺寸、焖井时间、蒸汽干度、蒸汽注入速度、井底压力、储层高度、储层面积、渗透率各向异性等参数,研究了这些因素对VWSAGD过程性能的影响。

作者单位:

加拿大里贾纳大学(University of Regina)工程学院

Abstract

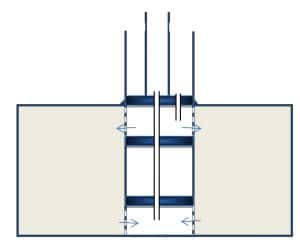

A novel process utilizing vertical wells to enhance heavy oil recovery during steam assisted gravity drainage has been developed. In the vertical well steam assisted gravity drainage (VWSAGD) process shown in Figure 1, the vertical well includes two production strings which are separated by three packers (one dual and two single packers): the short injection string (SIS) is attached to the bottom of the annulus and completed in the top quarter of the perforated formation, while the long production string (LPS) is attached to the bottom of the production tubing and completed in the bottom quarter of the perforated formation. The new process (VWSAGD) requires an initial start-up period (warm-up stage) where the steam is injected into both of the injection strings and production string for a specified period of time of about 14-30 days; then both strings are closed to injection for a specified time period of approximately 7 - 10 days (soaking period). After the initial warm-up and the soaking period, the long production string is opened for production, and the short injection string is opened to continuous steam injection for the rest of the specified simulation time. A commercial simulator (CMG-STARS Simulator) was used to study the performance of the new VWSAGD process. A sensitivity analysis was performed for the grid density, soaking time, steam quality, bottom hole producing pressure, steam injection rate, reservoir thickness, reservoir area, and horizontal to vertical permeability anisotropy. The results f this study have shown that the new VWSAGD process is more preferable for reservoir conditions such as high horizontal to vertical permeability ratio and thick reservoir oil zones.