Immiscible Viscous Fingering at the Field Scale: Numerical Simulation of the Captain Polymer Flood

赫瑞瓦特大学 Ithaca Energy (UK) Limited

非混相指进指的是在油藏中,高黏度原油被低黏度非混相流体(通常是水)所置换而产生的现象。在石油开采过程中,通常注入水来改善原油采收率和提供压力支持。由于原油和水的黏度比值(µo/µw)可能导致非混相黏稠指进的形成,从而导致油被绕过,因此会导致原油采收率较低。聚合物驱,通过添加高分子量聚合物来增加注入水的黏度,旨在通过降低µo/µw比值来减少黏稠指进的影响。

在过去十年中,人们在改善聚合物驱的机理理解以及开发可靠模拟其过程的数值模拟方法方面做出了可观的努力。其中两个关键发展是:(i)对聚合物驱作用下黏稠原油排水的黏稠横流机制的理解;(ii)由Sorbie等人(2020年)提出的模拟方法,可以在传统油藏模拟器中简单地匹配非混相指进和黏稠横流。

本文将Beteta等人(2022年)的工作扩展到目前正在进行聚合物驱的田块案例的概念模型——北海的Captain油田。这种模拟方法基本上是通过一些简单的缩放假设进行简单的“升尺度”。本文考虑了聚合物黏度和注入量大小对于具有和没有“水下降”的系统的一系列二维和三维模型的影响,以阐明聚合物在这些系统中的作用。水下降受油和水的密度差异、油藏的垂直通讯以及流体速度的控制,当发生水下降时,注入水会直接沿着油藏底部通向生产井。

模拟结果表明,聚合物驱对于各种油藏都非常适用,仅需适度的注入黏度和堆积物尺寸即可获得可观的原油增产量。实际上,在各种二维和三维案例的模拟中,预测的原油增收率(IR)在29%至89%之间变化,具体取决于非降水和下降水情况下的注聚物设计。当存在较强的水下降时,聚合物驱的性能对于注聚物设计更为敏感,因为除了黏稠横流机制外,聚合物还介入了另一个角色——通过黏稠聚合物驱使“阁楼”油区被扫净的作用,该作用能够克服由重力驱动的水下降,我们也将这种机制识别为略有不同形式的黏稠横流。在水下降系统中,务必在扫净阁楼油区之前避免破坏聚合物堆积物。然而,与非降水系统一样,适度的注入黏度和堆积物尺寸仍然对采收率有着非常显著的影响。本文使用的概念模型与实际田块结果具有很好的定性相似性。我们的模拟结果表明,在黏稠原油采收方面很少有聚合物驱不会带来益处的情况。

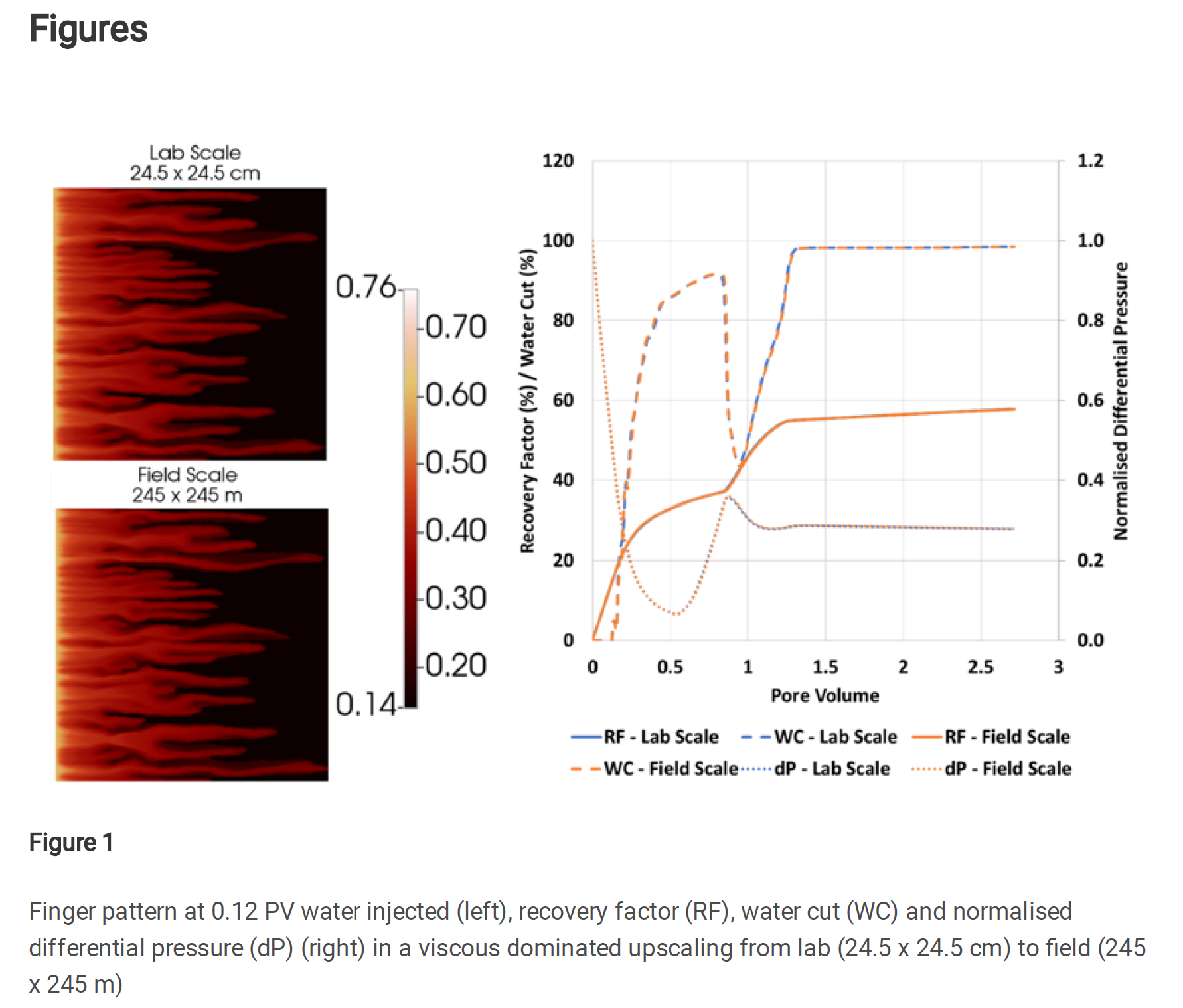

Immiscible fingering in reservoirs results from the displacement of a resident high viscosity oil by a significantly less viscous immiscible fluid, usually water. During oil recovery processes, where water is often injected for sweep improvement and pressure support, the viscosity ratio between oil and water (µo/µw) can lead to poor oil recovery due to formation of immiscible viscous fingers resulting in oil bypassing. Polymer flooding, where the injection water is viscosified by the addition of high molecular weight polymers, is designed to reduce the impact of viscous fingering by reducing the µo/µw ratio. A considerable effort has been made in the past decade to improve the mechanistic understanding of polymer flooding as well as in developing the numerical simulation methodologies required to model it reliably. Two key developments have been (i) the understanding of the viscous crossflow mechanism by which polymer flooding operates in the displacement of viscous oil; and (ii) the simulation methodology put forward by Sorbie et al. (2020), whereby immiscible fingering and viscous crossflow can be simply matched in conventional reservoir simulators.

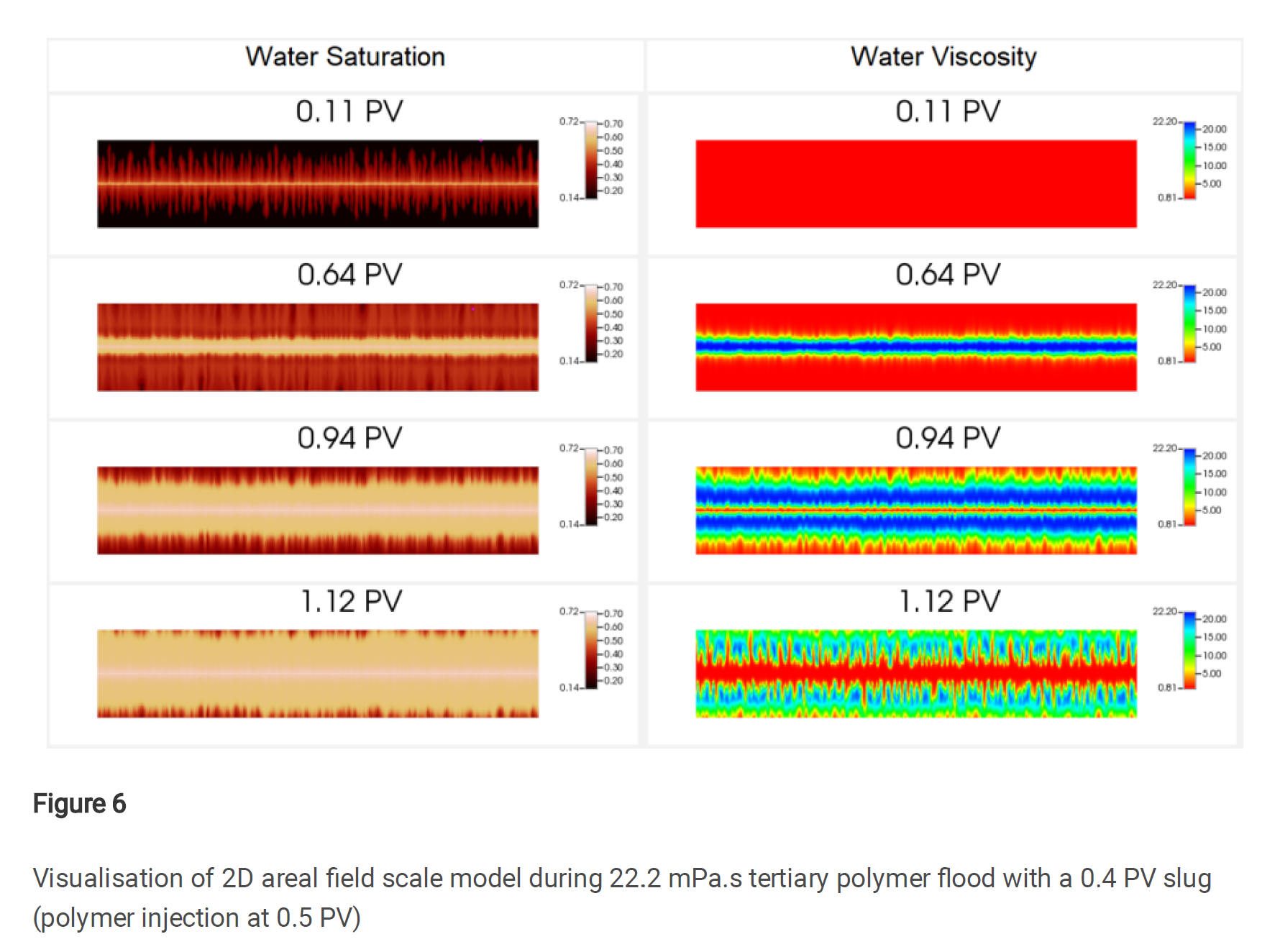

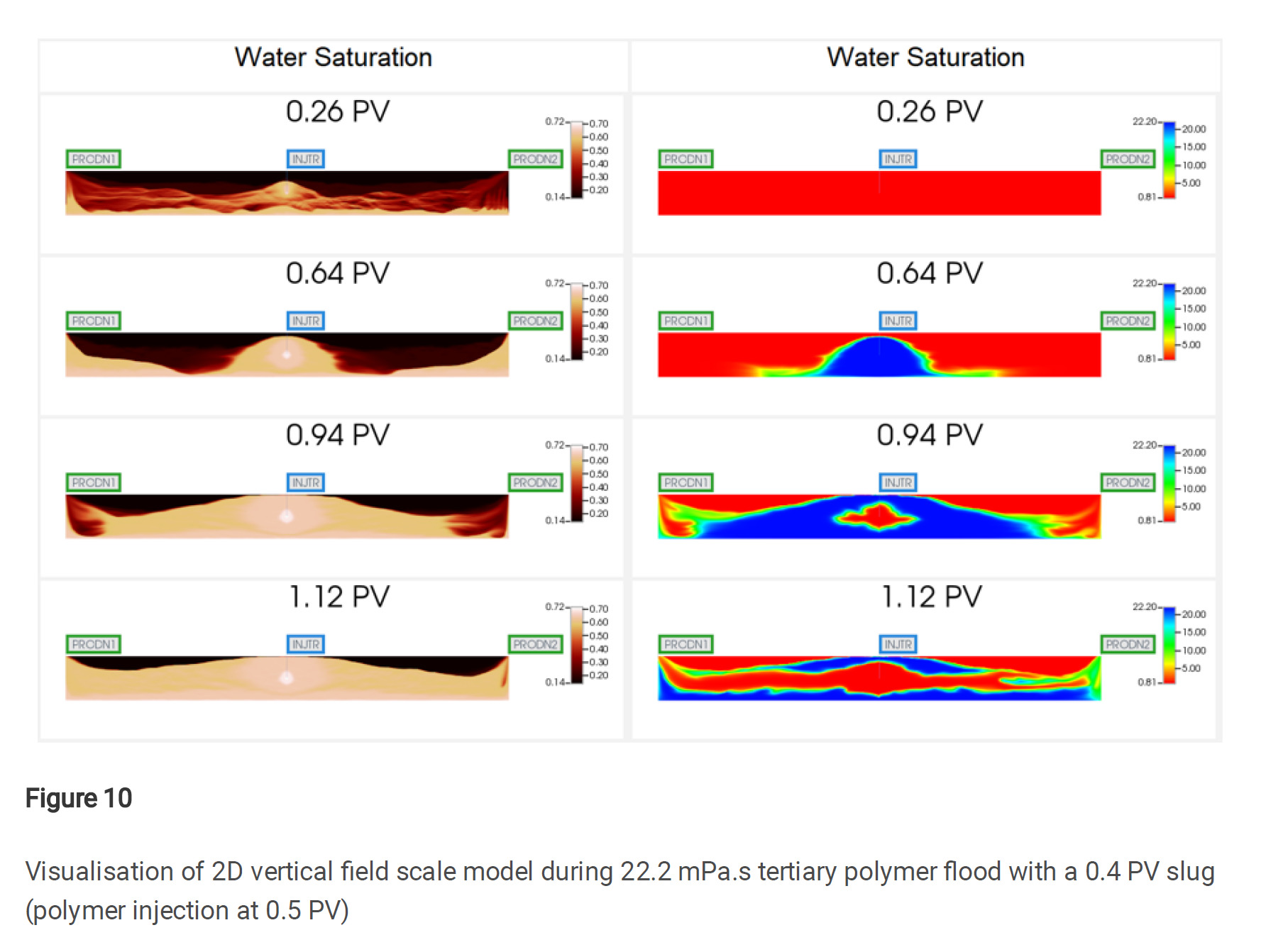

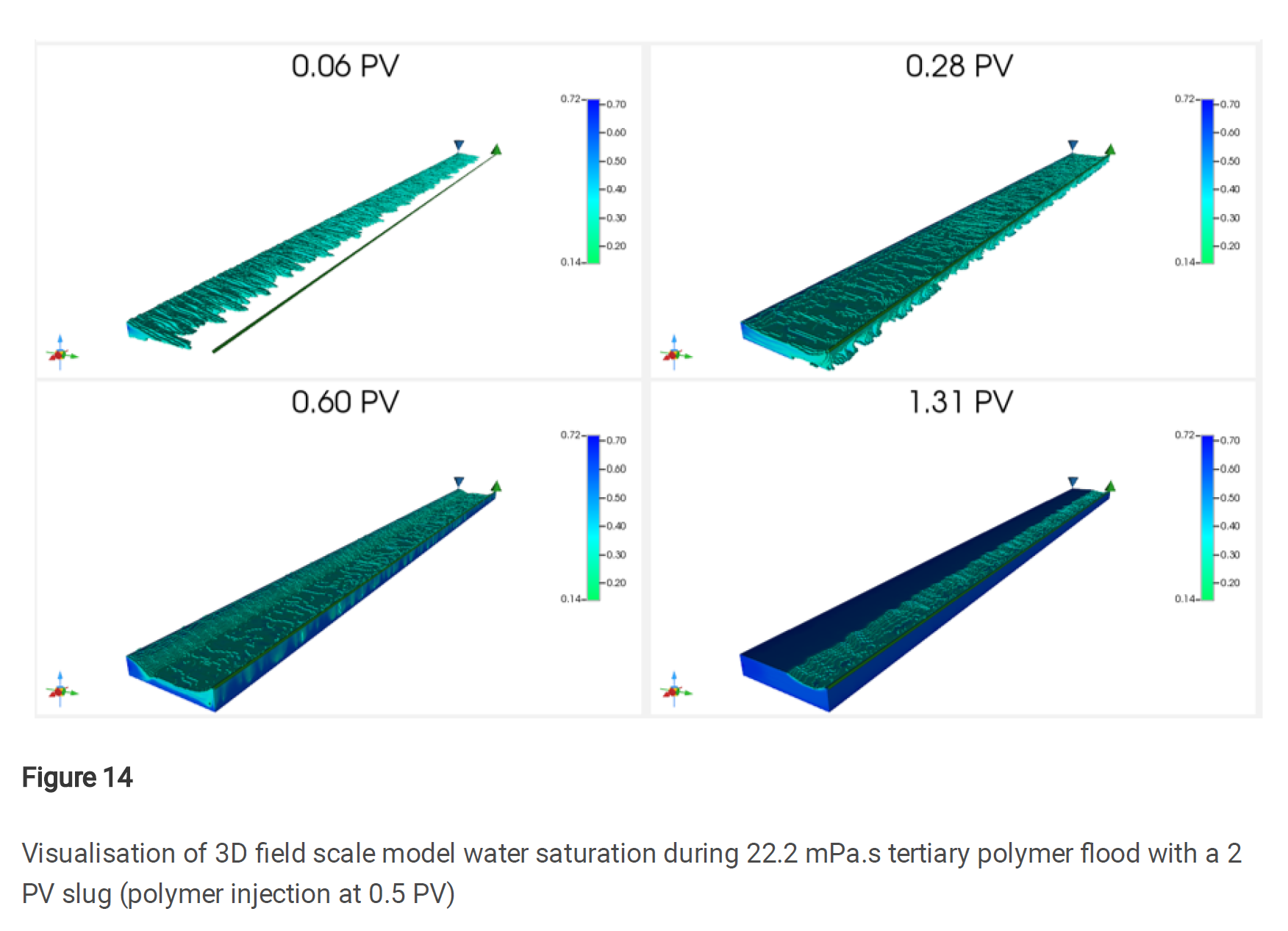

This publication extends the work of Beteta et al. (2022) to conceptual models of a field case currently undergoing polymer flooding – the Captain field in the North Sea. The simulation methodology is essentially “upscaled” in a straightforward manner using some simple scaling assumptions. The effects of polymer viscosity and slug size are considered in a range of both 2D and 3D models designed to elucidate the role of polymer in systems both with and without “water slumping”. Slumping is governed by the density contrast between oil and water, the vertical communication of the reservoir and the fluid velocity and, when it occurs, the injection water channels along the bottom of the reservoir directly to the production well(s).

It is shown that polymer flooding is very applicable to a wide range of reservoirs, with only modest injection viscosities and bank sizes return significant volumes of incremental oil. Indeed, oil incremental recoveries (IR) of between 29–89% are predicted in the simulations of the various 2D and 3D cases, depending on the slug design for both non-slumping and slumping cases. When strong water slumping is present the performance of the polymer flood is significantly more sensitive to slug design, as alongside the viscous crossflow mechanism of recovery, a further role of the polymer is introduced – sweep of the ‘attic’ oil by the viscous polymer flood, which is able to overcome the gravity driven slumping and we also identify this mechanism as a slightly different form of viscous crossflow. In slumping systems, it is critical to avoid disrupting the polymer bank before sweeping of the attic oil has been performed. However, as with the non-slumping system, modest injection viscosities and bank sizes still have a very significant impact on recovery. The conceptual models used here have been found to be qualitatively very similar to real field results. Our simulations indicate that there are few cases of viscous oil recovery where polymer flooding would not be of benefit.