On the ability to store and recover hydrogen in post-SAGD reservoirs

在典型的蒸汽辅助重力泄油(SAGD)作业中,商业作业完成后,储层内超过60%的油被开采出来。这意味着在商业作业完成后,会留下一个充满蒸汽的储层,其中还有少量残留的水和油,被称为枯竭带。根据SAGD枯竭带的尺寸大约为1,000米长、100米宽、20至30米高,可以看出它具有很大的体积,可以用于储存物质。在地下储存的选项中,有人提议利用盐穴和枯竭油气藏。还有一种新颖的选项是在SAGD枯竭带中储存氢气,该选项尚未进行研究。

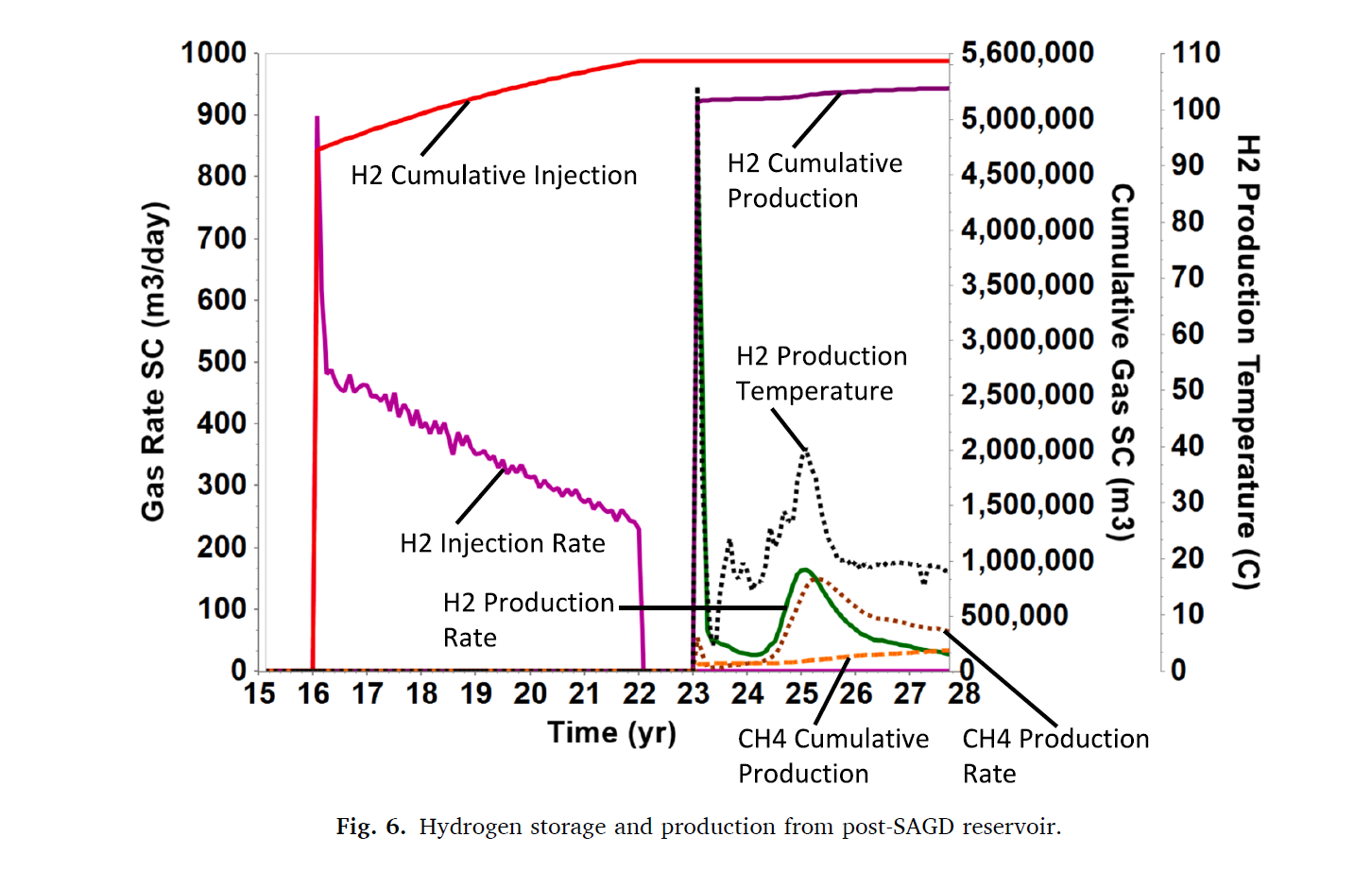

本研究描述了对SAGD枯竭带进行注入和产氢的评估。结果表明,在SAGD枯竭带中可以储存数百吨的氢气。随着时间的推移,储存的氢气纯度从开始时的98%逐渐降低到5年后的96%。这种纯度的变化是由于原始溶解气体即原油中的甲烷的存在。随着多次循环储存,储氢能力的增加使得所产生的氢气纯度得到改善,达到进行了4次循环后的最高回收率为99.2%。

Abstract

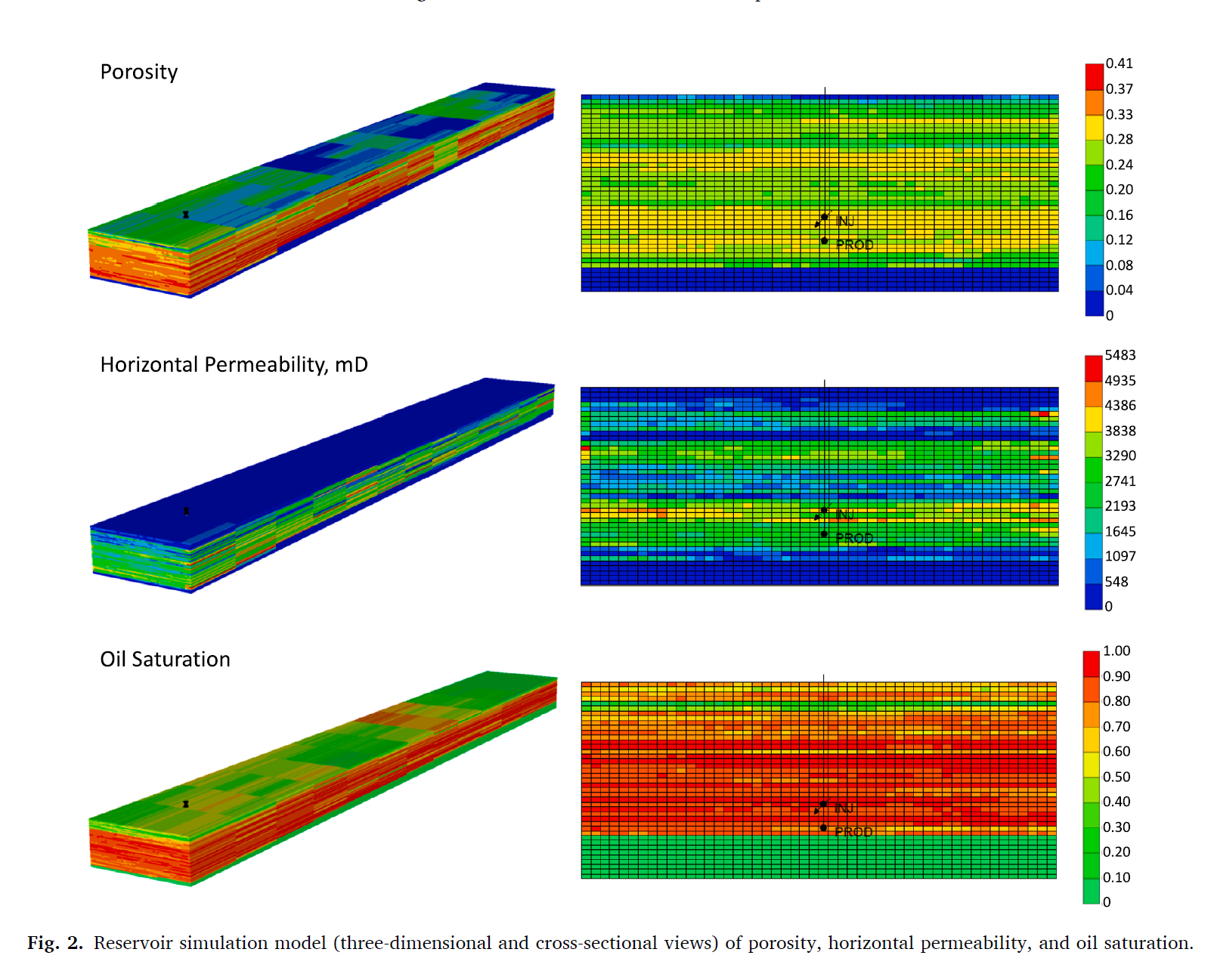

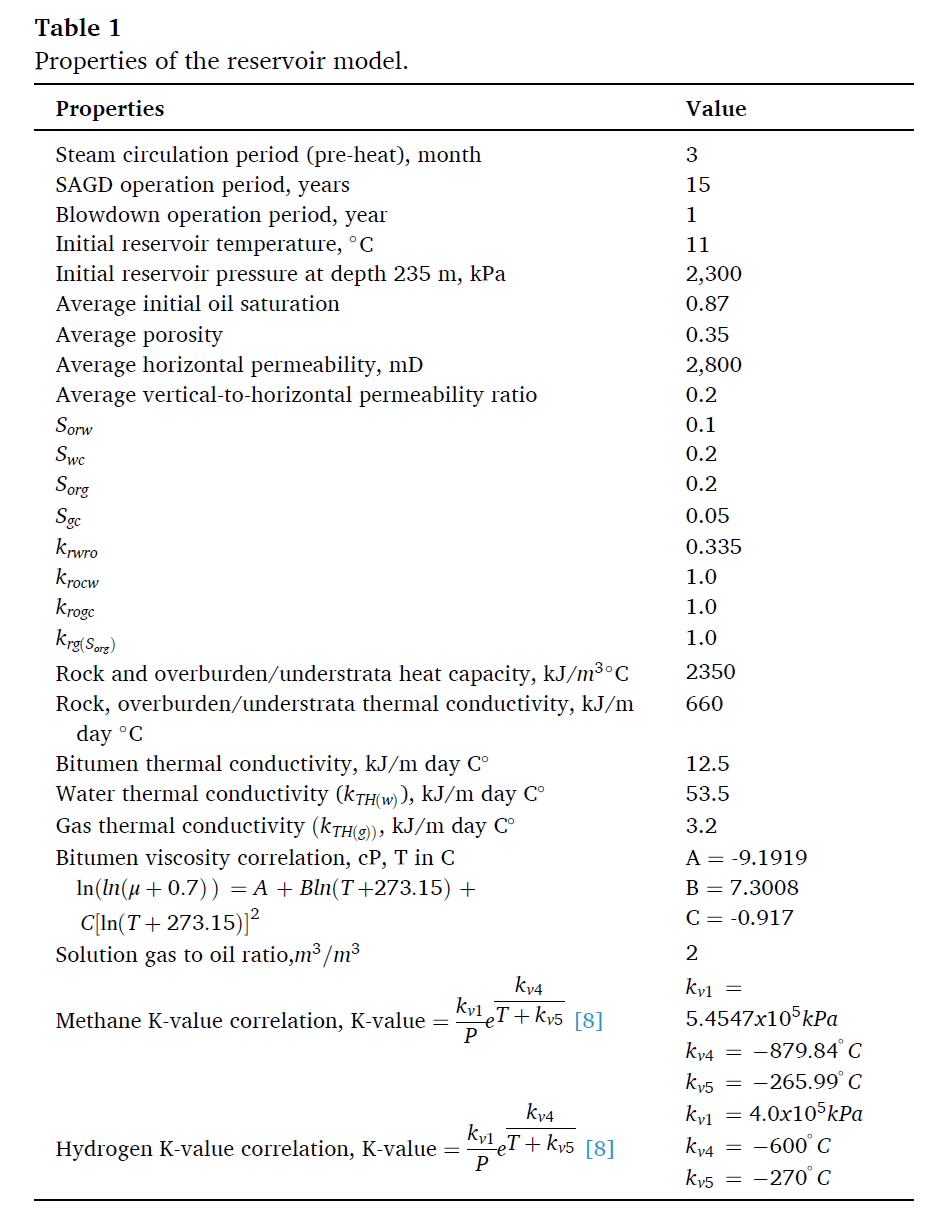

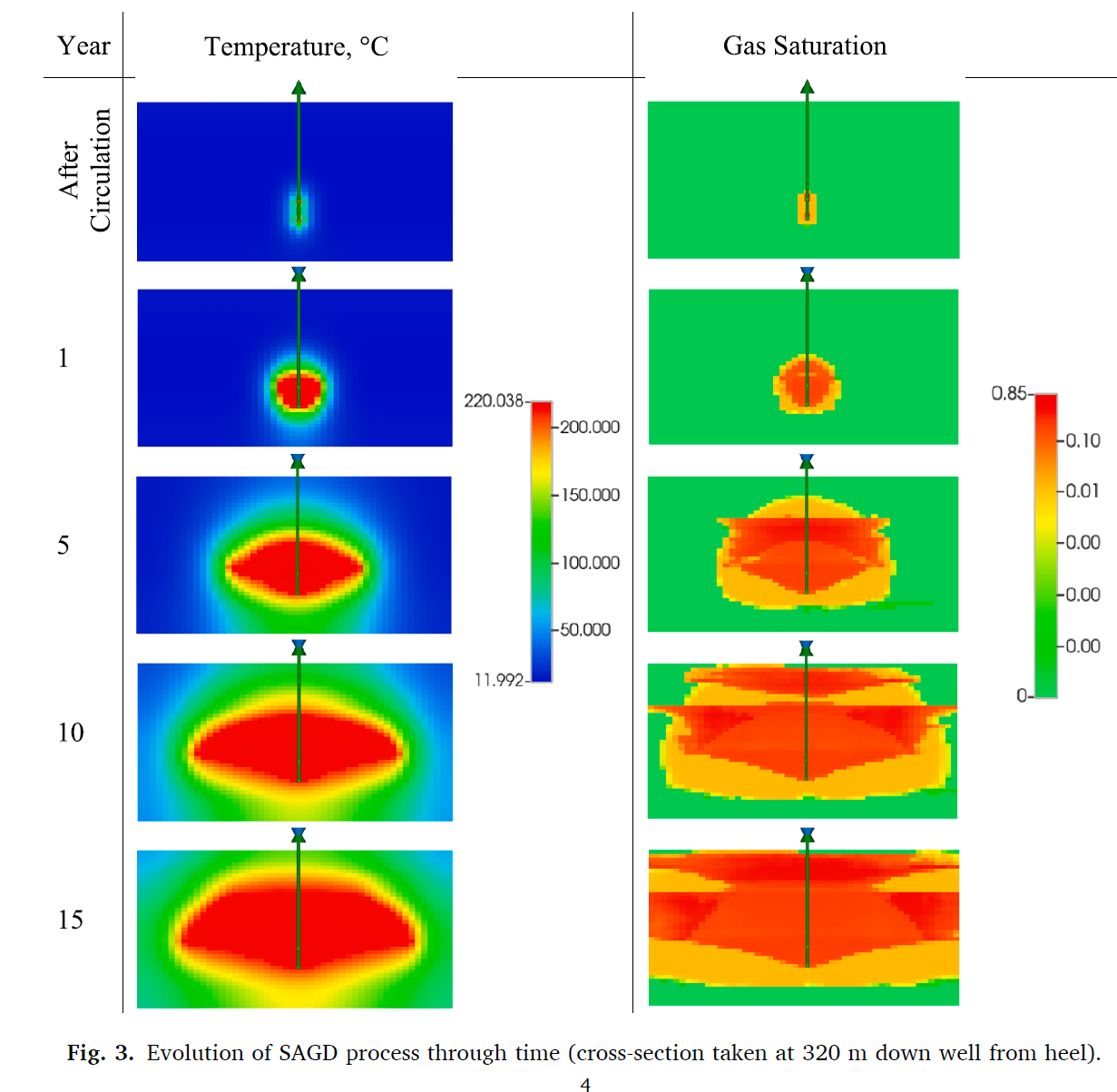

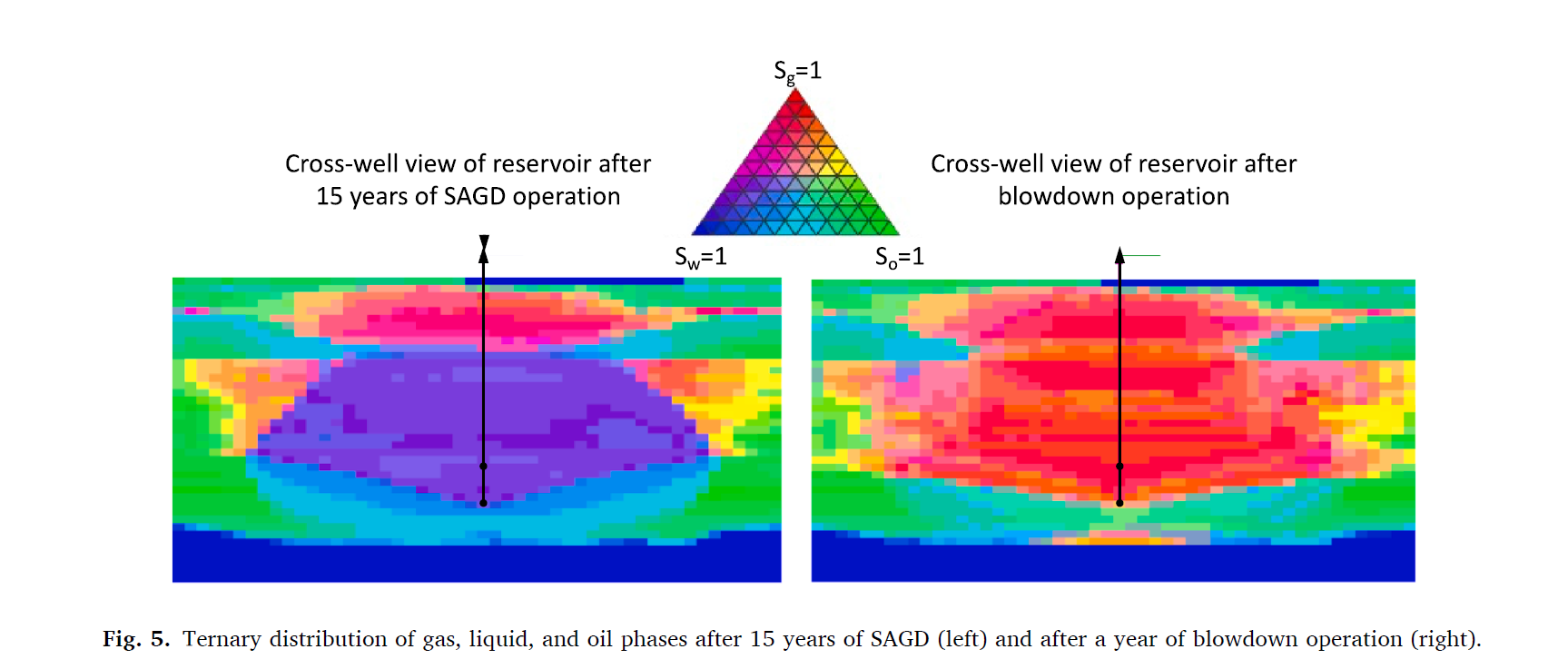

In typical steam-assisted gravity drainage (SAGD) operations, after commercial operations are complete, over 60% of the oil within the reservoir is produced. This means that after commercial operations, there is a steam-filled gas porous rock zone with small amounts residual water and oil referred to as the depletion zone. Given the dimensions of a SAGD depletion zone is of order of 1,000 long, 100 m wide, and between 20 and 30 m tall, this represents a large pore volume that could be used for storage. For underground options, there have been suggestions of using salt caverns and produced gas or oil reservoirs. One novel option that has not yet been examined is hydrogen storage in post-SAGD depletion chambers. The research described here an evaluation of post-SAGD chambers for injection and production of hydrogen. The results show that hundreds of tonnes of hydrogen can be stored within post-SAGD chambers and the purity of the hydrogen that is produced varies from 98% at start to 96% after 5 years of production during co-production of methane originated from the original solution gas that is the oil. The purity of produced hydrogen improved with increased hydrogen storage capacity after multiple cycle storage reaching its highest recovery factor of 99.2 % after 4 cycles.

Conclusions

For the first time, the potential for hydrogen storage in post-SAGD reservoirs has been evaluated. The results reveal that the depletion chamber can store hydrogen and that the recovery factor of the stored hydrogen is about 95% and that multiple cycles of storage and production improves the amount of stored hydrogen and its purity when produced. The implications of the results open a new option for large-scale storage of hydrogen in the Ft, McMurray area where a large amount of hydrogen is consumed for bitumen upgrading. Stored hydrogen in post-SAGD reservoirs could support ongoing upgrading operations, add to natural gas (up to about 15%) as fuel for steam or power generation, used as fuel in steam generators for SAGD (thus removing the largest greenhouse gas emission source in the process), and power generation via fuel cells. This could be done in a cyclic manner with hydrogen storage occurring during time periods where natural gas costs are lower (if from steam-methane reforming) or electrolysis during the warmer months. For example, large amounts of hydrogen could be generated and stored in summer when natural gas consumption for heating is lower. It can then replace natural gas usage during winter when natural gas is likely to increase in price due to the demands for heating. Overall, the results suggest that there is a potential opportunity to store and produce large amounts of high purity hydrogen within post-SAGD reservoirs and that this UHS option should be examined further.

结论:

此次评估首次揭示了典型后SAGD储层中氢气储存的潜力。实验结果表明,衰竭腔可以高效储存氢气,并且其储氢的回收率可达95%。通过多次储存与生产循环,储存的氢气量和纯度可以进一步提高。这些发现为在迈克默里地区开展大规模储存氢气提供了新的选择。该地区有大量氢气被用于沥青改质。后SAGD储层中的氢气储存能够支持持续的改质操作,并且可以添加到天然气中,最多约占15%,用于制造蒸汽或发电。氢气还可以作为干燥蒸汽发生器的燃料,从而消除该过程的最大温室气体排放源,并且可以通过燃料电池进行发电。氢气储存可以通过循环方式进行,其中储氢发生在天然气成本较低的时期(如从蒸汽-甲烷重整中获得)或在较暖的月份进行电解。例如,在夏季生产和储存大量氢气,而在冬季运用氢气替代天然气用于供暖,从而避免天然气价格上涨的影响。总体而言,本研究结果表明后SAGD储层具有储存和生产大量高纯度氢气的潜力,并且应进一步研究这种超高容量储氢选择。