Performance of steam injection process in layered heavy oil reservoirs: An experimental and numerical investigation

层状稠油油藏由于层间非均质性强,传统笼统蒸汽注入方式存在蒸汽窜流、层间动用不均等问题。本文以中国典型层状稠油油藏为背景,结合二维高温高压物理模拟实验与CMG-STARS数值模拟,系统对比了笼统蒸汽注入(基础方案)与分层蒸汽注入(优化方案)在蒸汽腔扩展、加热均匀性、产油效果等方面的差异。本研究为层状稠油油藏蒸汽注入优化提供了实验与数值依据,有助于提高采收率与蒸汽利用效率,降低碳排放。

CMG软件应用情况

- 使用模块:CMG-STARS(热采数值模拟)

- 模拟方式:

- 建立实验室尺度三维模型(34×8×27网格);

- 参数来源于物理实验(温度、压力、采收率等);

- 通过历史拟合调整相对渗透率曲线与井指数;

- 实现实验与模拟误差<6%,验证模型可靠性;

- 用于分析蒸汽驱阶段划分、温度场与饱和度演化;

- 开展敏感性与层间差异分析,指导现场参数优化。

主要结论

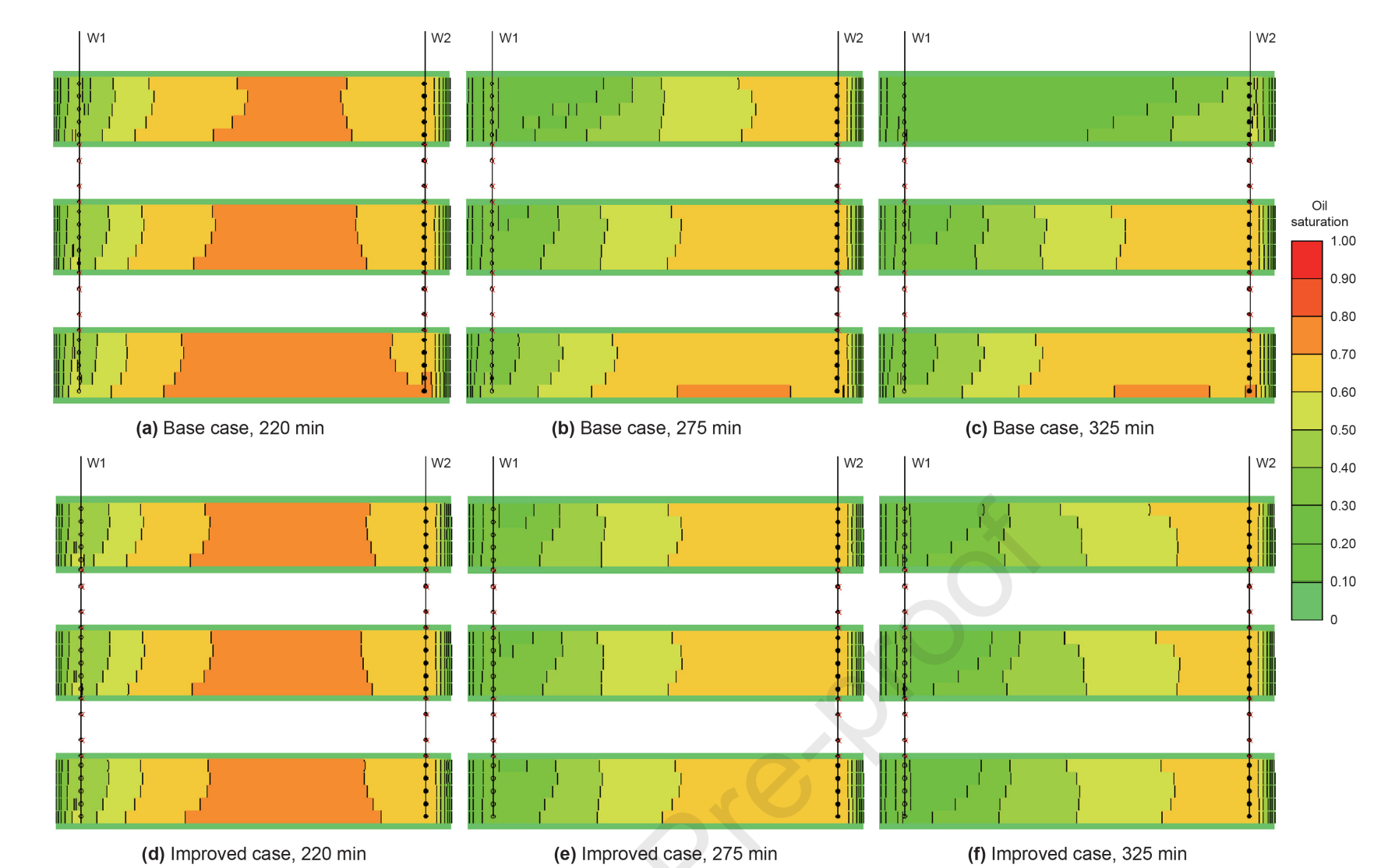

- 分层蒸汽注入优于笼统注入:

- 加热腔扩展更均匀,平均加热体积提高18%;

- 最终采收率提高约6%,油气比更优;

- 有效抑制蒸汽窜流,提升层间动用程度。

- 蒸汽驱可划分为三个阶段:

- 热连通阶段(0–0.23 PV):产油启动,层间差异小;

- 热驱替阶段(0.23–1.38 PV):主力产油阶段;

- 热突破阶段(1.38–2.10 PV):蒸汽窜流,采收率增长减缓。

- 操作参数优化建议:

- 周期注汽量:6000–7000 m³;

- 注汽速率:≤250 m³/d;

- 蒸汽干度:约0.4;

- 层间渗透率差异达3倍时,推荐采用分层注入。

- 层间非均质性是关键限制因素:

- 渗透率、厚度差异越大,层间加热差异越明显;

- 分层注入可有效缓解层间干扰,提升整体开发效果。

作者单位

中国石油大学(北京)

Abstract

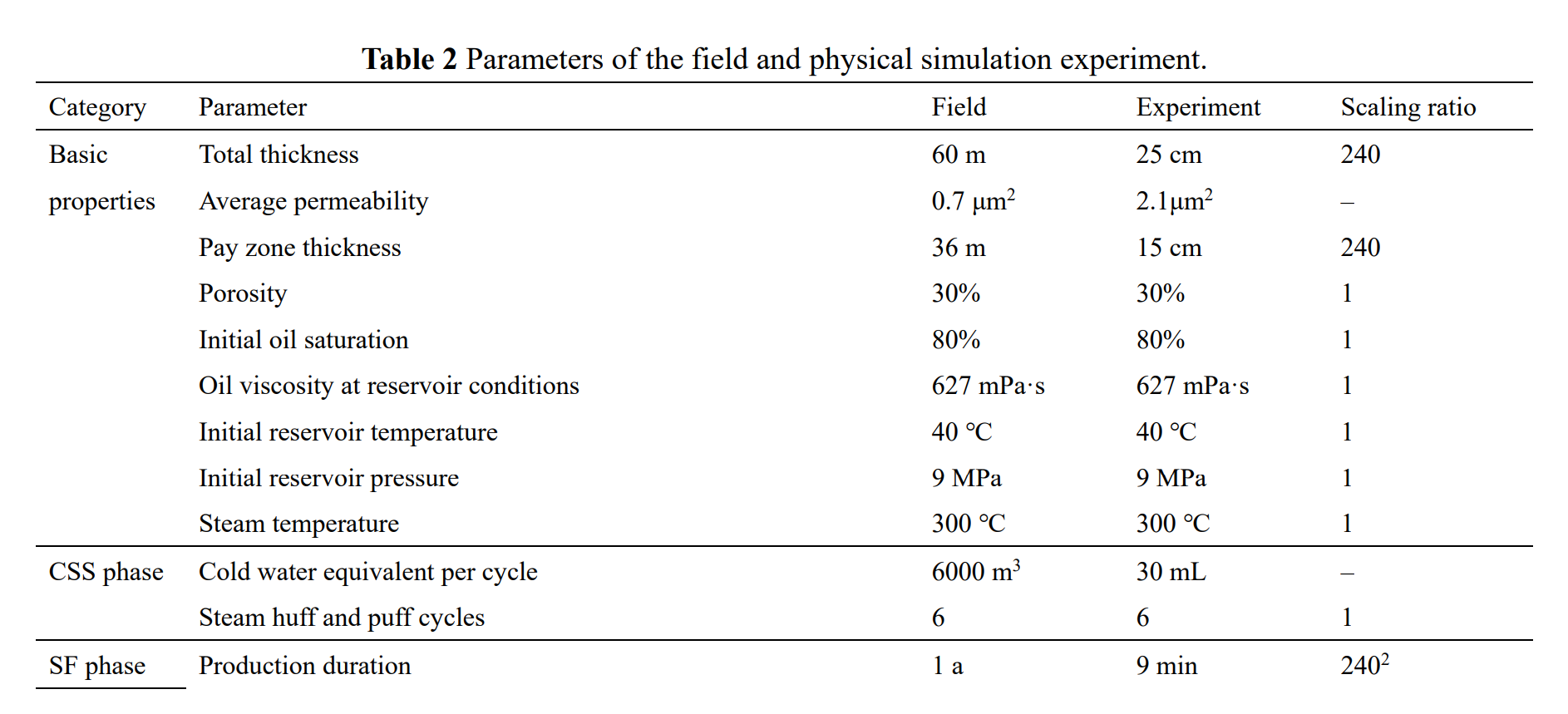

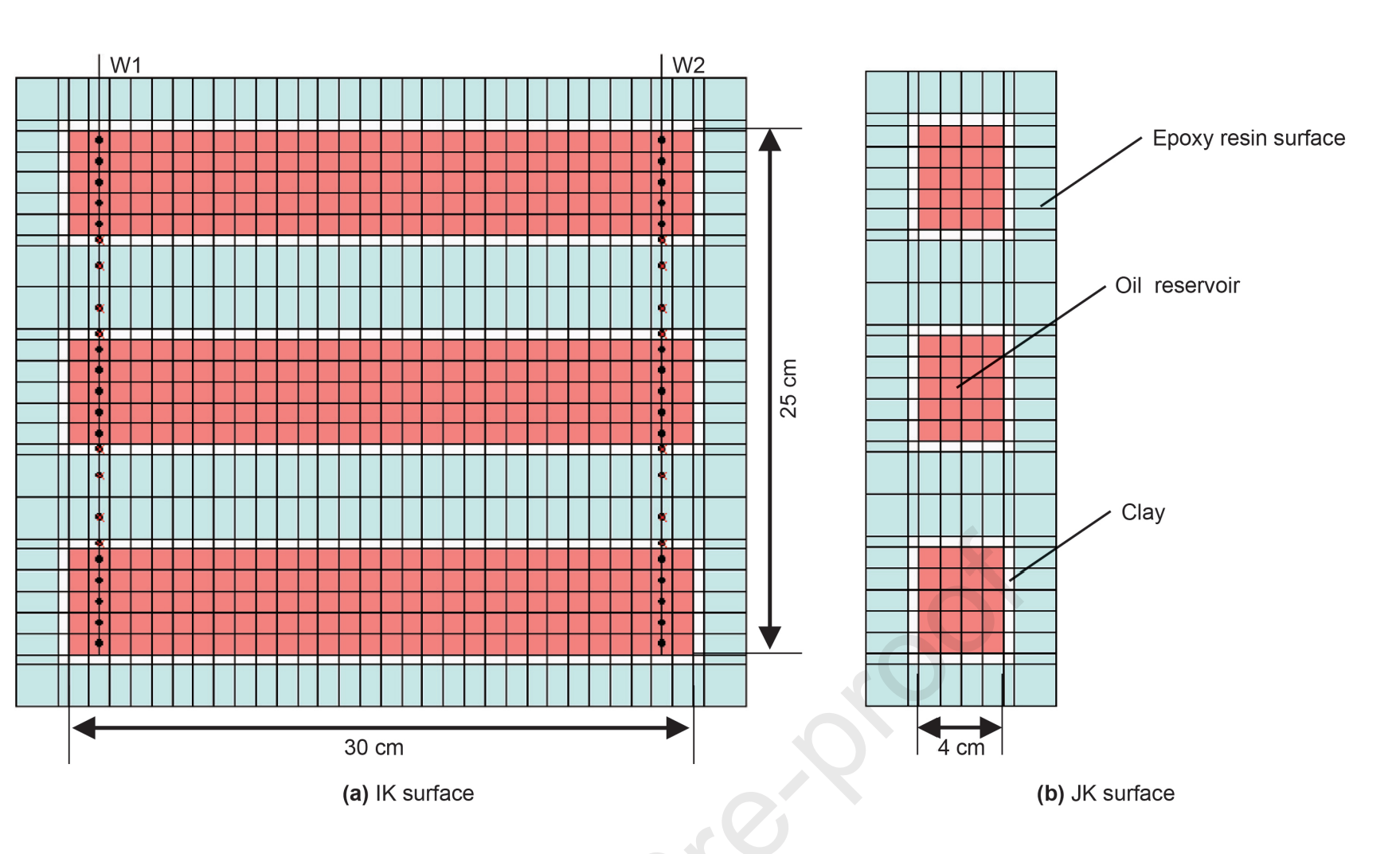

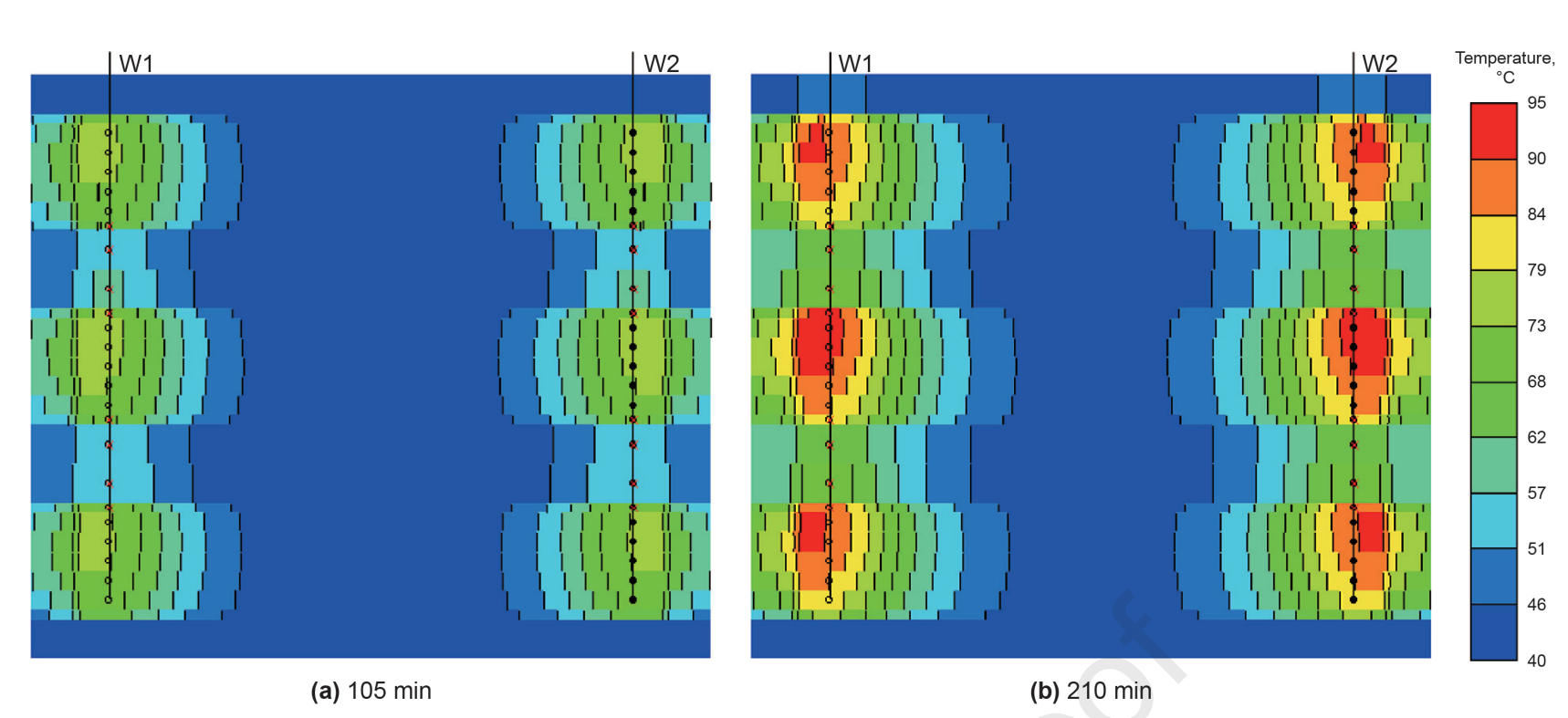

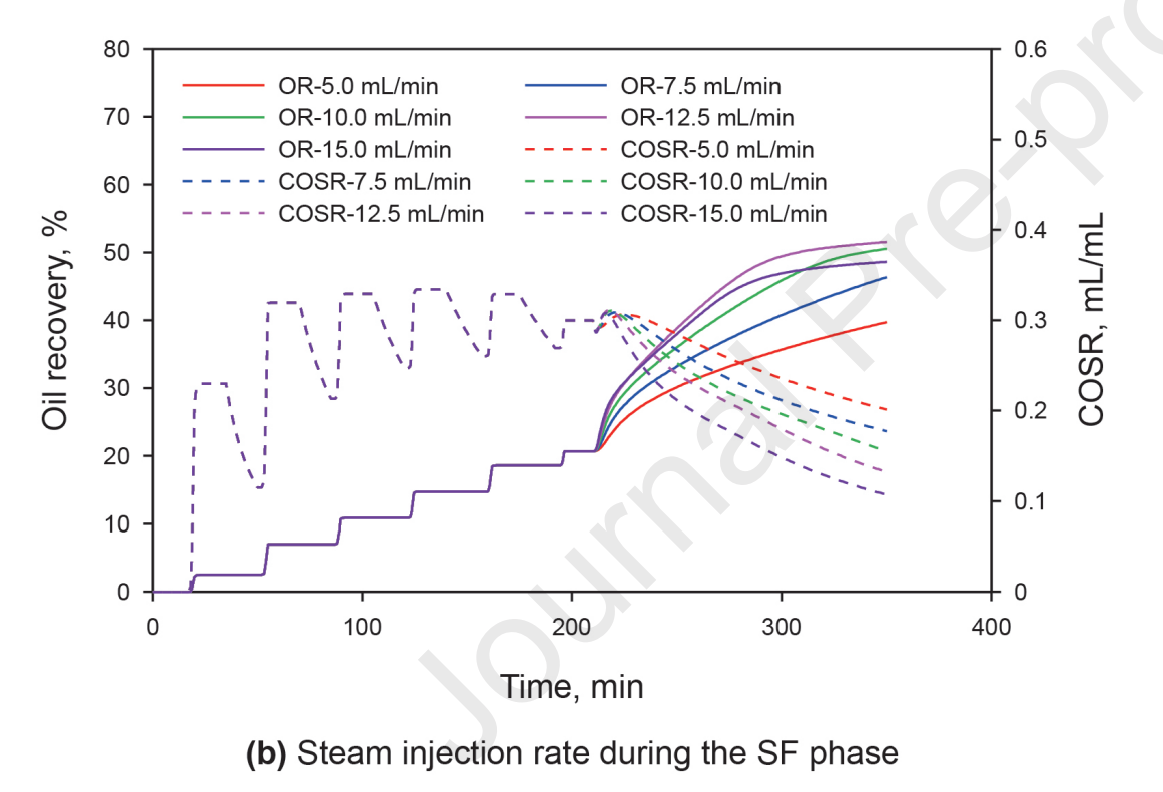

Layered heavy oil reservoirs are widely distributed hydrocarbon resources and play a crucial role in fulfilling the global increasing demand for energy. Due to the existence of interlayer heterogeneity, however, the traditional commingled steam injection process has been confronted with the challenges of uneven production and poor performance in the field. In this study, to investigate the improvement effects of a separate steam injection process for the layered heavy oil reservoirs, combining the methods of experiments and numerical simulation, the expansion behavior of the heated chamber and production performance of these two steam injection modes (base case and improved case) are compared and analyzed. First, based on the 2D scaling criteria of steam stimulation experiments and actual properties of a typical layered heavy oil reservoir in China, the experimental parameters are obtained. During experiments, to better simulate the field operation condition, a 2D HTHP (high temperature and high pressure) thermal recovery experimental apparatus equipped with a pressure chamber is proposed. From the experimental observations, the advantages of the separate steam injection mode are illustrated from the expansion behavior of the heated chamber and the production performance characteristics. Thereafter, through a history matching of the experimental results, the laboratory-scale numerical simulation model is developed. Then, from the same-scale numerical simulation model, the steam flooding stage of the base case for the layered heavy oil reservoirs is divided into three phases, and the primary features and critical indices of different phases are obtained. Finally, the effects of reservoir properties and operation parameters on production performance and interlayer divergence are discussed. Experimental results show that the separate steam injection mode achieves uniform heated chamber expansion across layers, and the average proportion of heated chamber is 18% higher than that of the commingled steam injection process. Meanwhile, the improved case increases the final oil recovery factor by around 6%. The simulation results of the developed laboratory-scale numerical simulation model are in good agreement with the experimental observations. For the layered reservoirs with an interlayer permeability contrast of the oil layer reaching 3, it is recommended to adopt the separate steam injection mode. In addition, the optimum cyclic steam injection volume for the reservoir is 6000–7000 m3, and the steam injection rate should be no more than 250 m3/d. This paper contributes to a systematic understanding of steam stimulation performance with different steam injection modes for layered heavy oil reservoirs.