使用CMG的软件创建一个3D耦合组分模拟模型,以模拟页岩气一体化开发的钻井、完井、增产(DCS)和生产过程。该模型利用Marcellus页岩的地质特征参数,生成了实际污水和天然气产量下降剖面以及页岩气组分随时间变化参数,将这些数据输入到通用代数模拟系统。结果表明,很难从单一且数学上简单的井场设计方案得出最大的页岩气产量和最优项目净现值。储层非均质性和现实的DCS策略对页岩气项目的技术经济性有着巨大的影响。本文揭示了一种保守但可信的方法,可以优化井场设计、污水回采和一体化工过程,同时最大限度地降低页岩气重复压裂成本。

The Application of Compositional Modelling to the Integration of Realistic Re-Stimulation Strategies and Unconventional Shale Gas Supply Chain Optimization

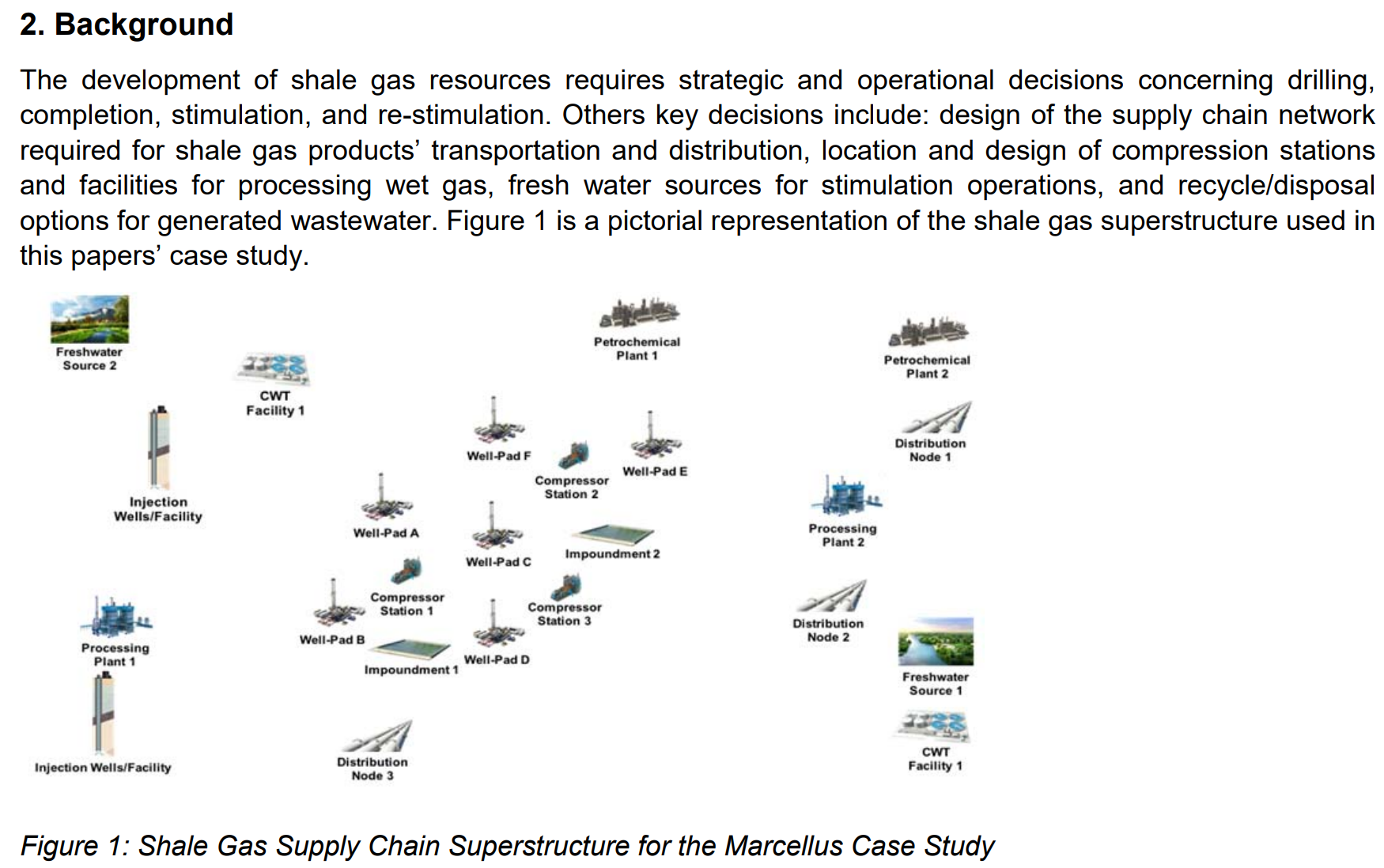

Shale gas supply chain network optimization received increased focus following the global economic recession that occurred between 2014 and 2016. Increasing the efficiency of upstream and downstream operations while maximizing shale gas project profitability became the best strategy for offsetting low oil and gas prices. This work suggests a multidisciplinary approach for the design and optimization of a given shale gas supply chain network. This integrated approach incorporates realistic drilling, completion and stimulation strategies through the compositional modelling of a geologically heterogeneous shale gas reservoir. Previous work in this area considered mixed integer linear programming (MILP) optimization models with minimal consideration for pragmatic shale gas reservoir development. This resulted in grossly over-estimated shale gas project NPV’s and impractical payback times.

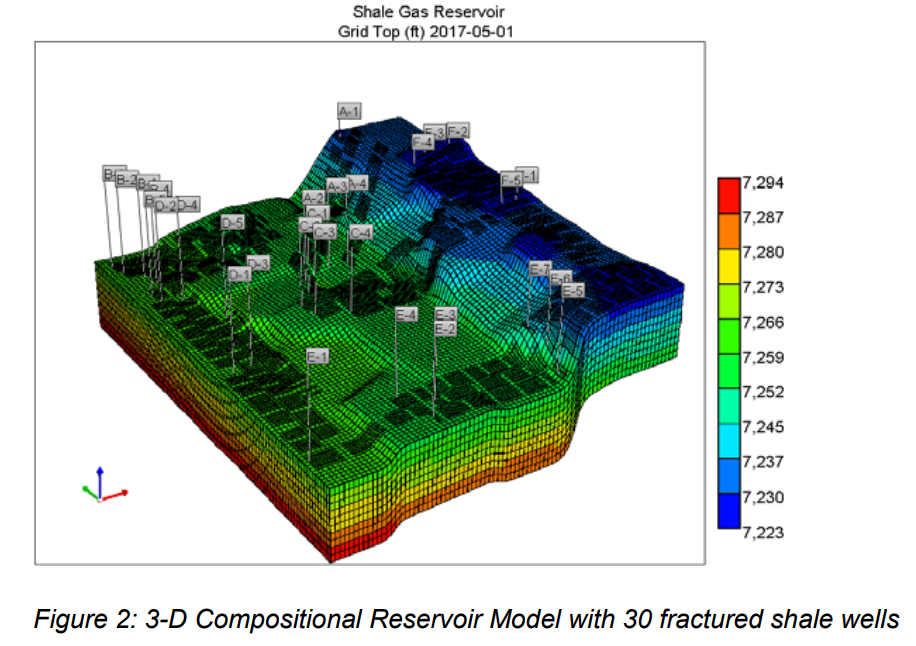

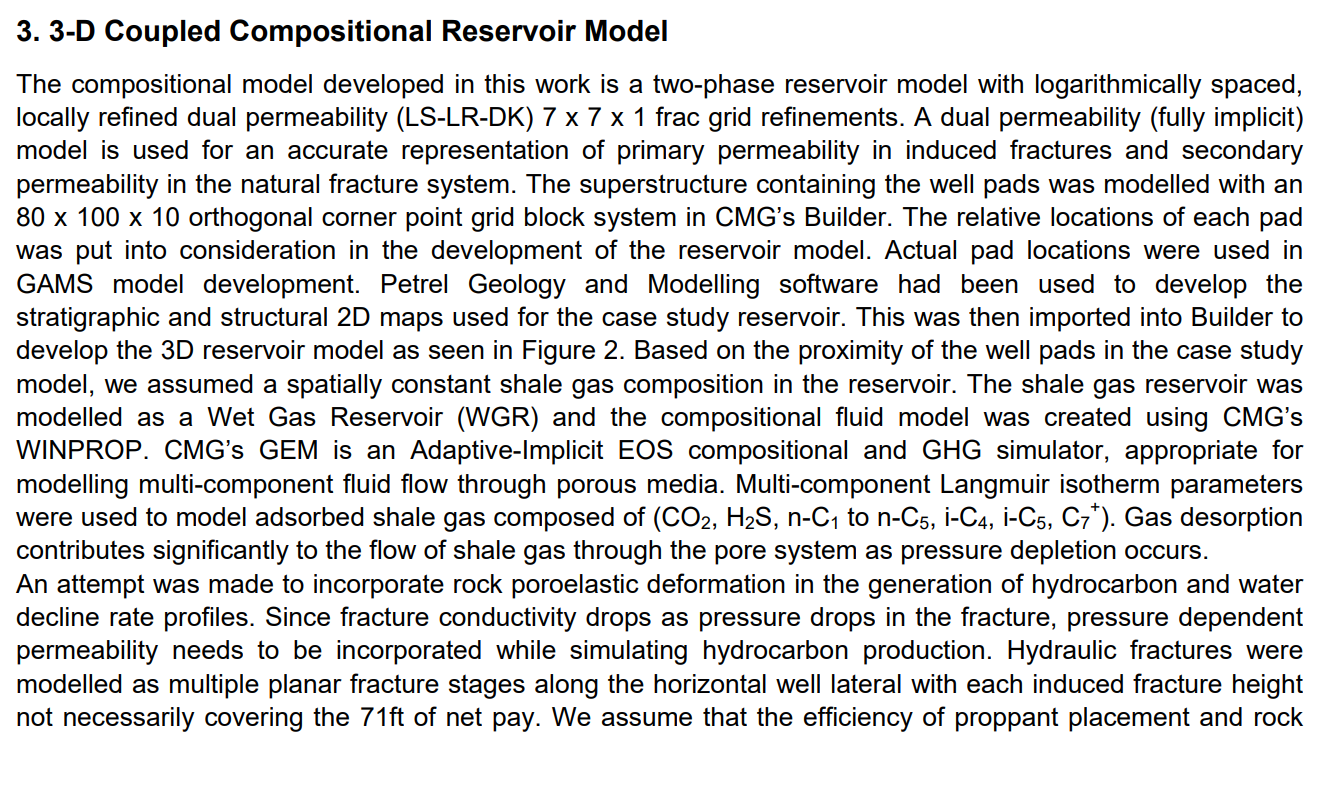

A 3D coupled compositional reservoir model is constructed using CMG’s software suites, to simulate drilling, completion, stimulation (DCS) and well pad production processes for a supply chain network. Utilizing geological parameters, characteristic of the Marcellus shale, this model generates realistic wastewater and gas rate decline profiles as well as the temporal variation of shale gas components, which are inputs for Quasi-MINLP optimization in General Algebraic Modelling System (GAMS). The results show that the optimization of shale gas production and project NPV are rarely obtained from singular and mathematically convenient well pad design configurations. Reservoir heterogeneity and realistic DCS strategies have a huge influence on the techno-economics of shale gas projects. This paper reveals a conservative and yet credible approach to optimizing well pad designs, waste water recycle structures and supply chain networks, while minimizing shale gas re-stimulation costs.