Experimental Evaluation of Recoverable Oil Dynamic and CO2 Storage Efficiency in Pore Scale by the NMR CO2 Huff-and-Puff Injection Process in Tight Oil Reservoirs

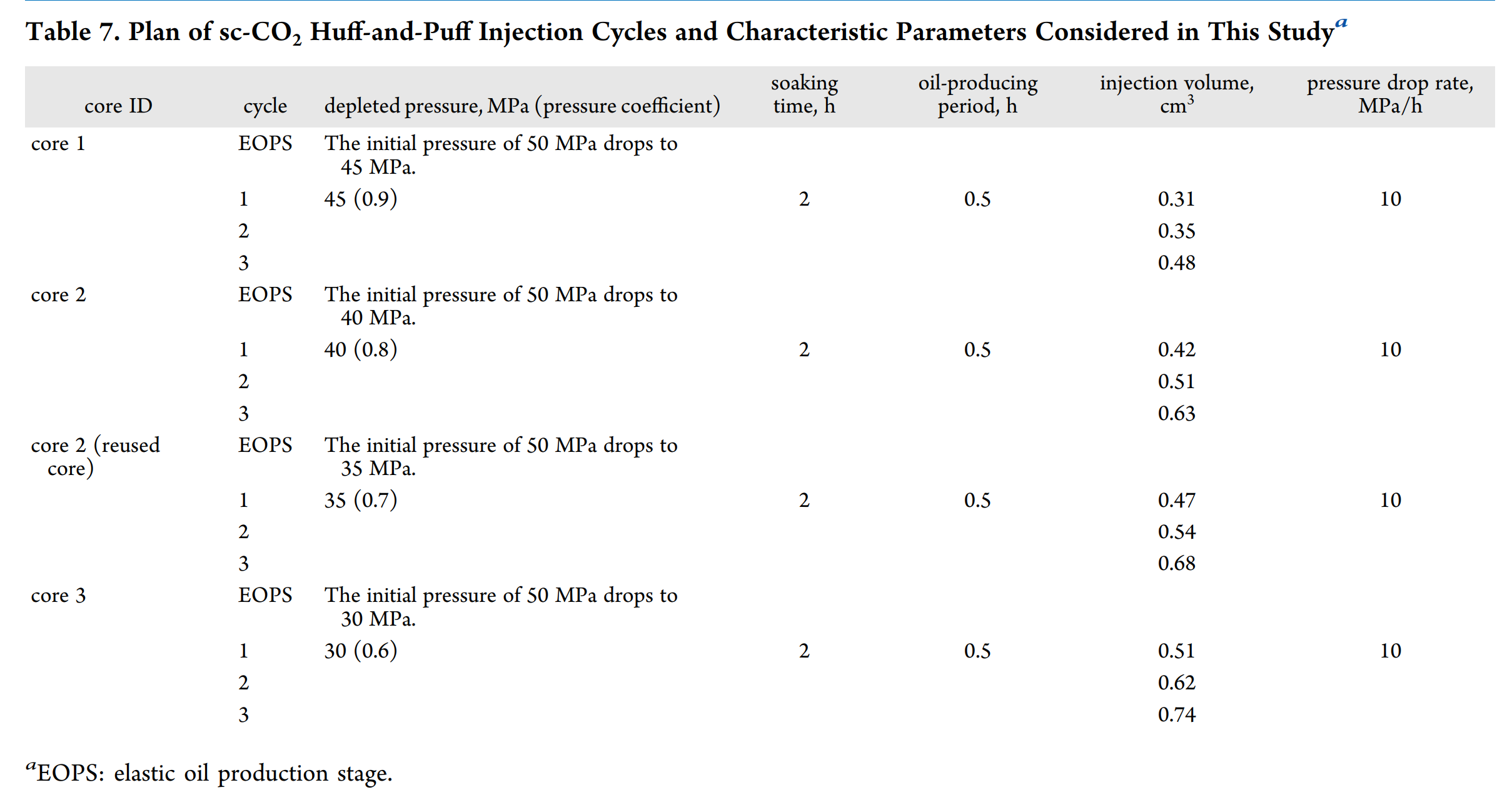

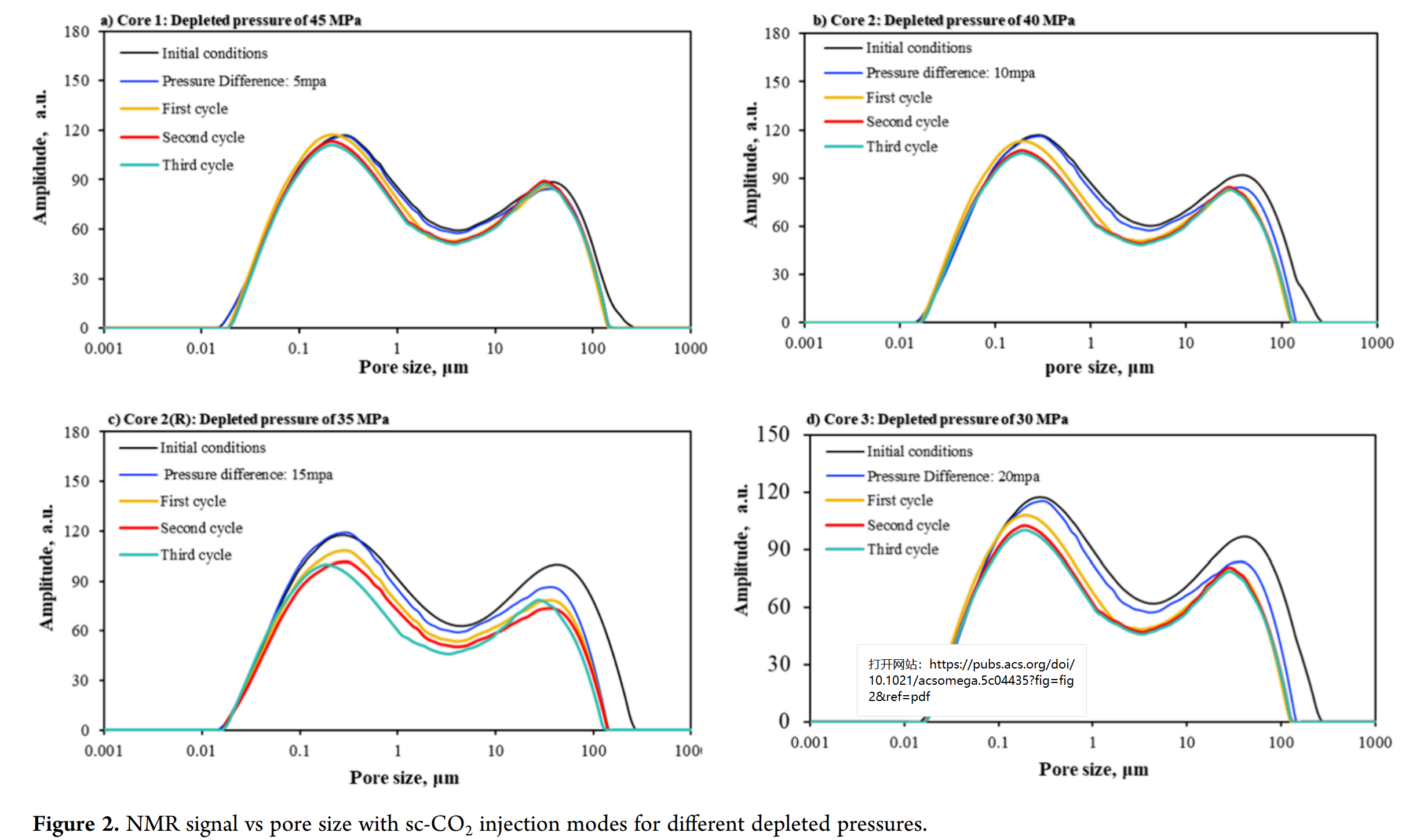

本研究以中国冀东油田高5断块V油组致密油藏为对象,采用高温高压在线核磁共振(NMR)岩心驱替实验技术,系统评价了CO₂吞吐过程中注入时机(压力系数)对孔隙尺度采油动态与CO₂封存效率的影响。实验在55 MPa、127°C的油藏条件下进行,通过设定不同的衰竭压力(45、40、35、30 MPa),模拟了多轮CO₂吞吐过程。本研究首次在孔隙尺度揭示了CO₂吞吐过程中注入时机对采油与封存的协同影响机制,为致密油藏CO₂-EOR与CCUS优化设计提供了实验依据。

CMG软件应用情况

- 使用模块:CMG-GEM(组分模拟器)

- 应用场景:

- 模拟CO₂吞吐过程中浸泡时间与注入轮次对采收率的影响;

- 模拟对象为低渗储层(渗透率1–26.2 mD),初始采收率仅5.82%;

- 模拟结果表明:2轮注入+21天浸泡为最优参数组合,可提高采收率约17%;

- 模拟结果与实验数据趋势一致,验证了实验设计的合理性。

主要结论

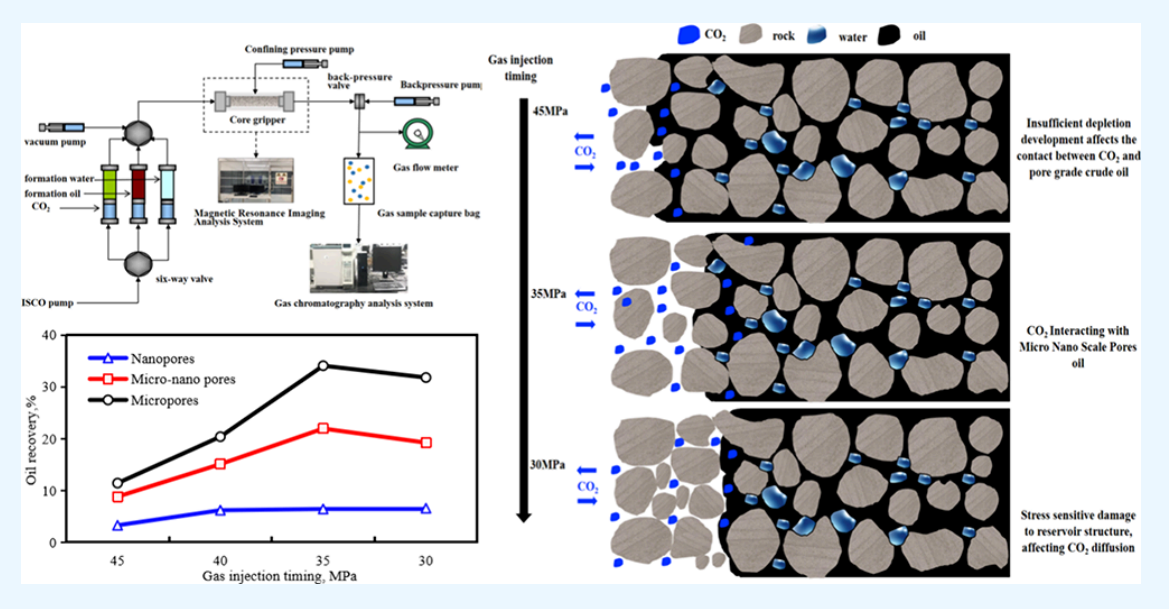

- 注入时机显著影响采收率:

- 最佳注入时机为35 MPa(压力系数0.7),采收率达26.42%;

- 注入过晚(30 MPa)将因应力敏感造成微孔结构伤害,采收率下降8.02%。

- 孔隙尺度产油机制明确:

- 微孔(>1 μm)为主要产油空间,贡献约48.57%采收率;

- 延迟注入主要影响微-纳孔(0.1–1 μm)产油,降低整体采收率。

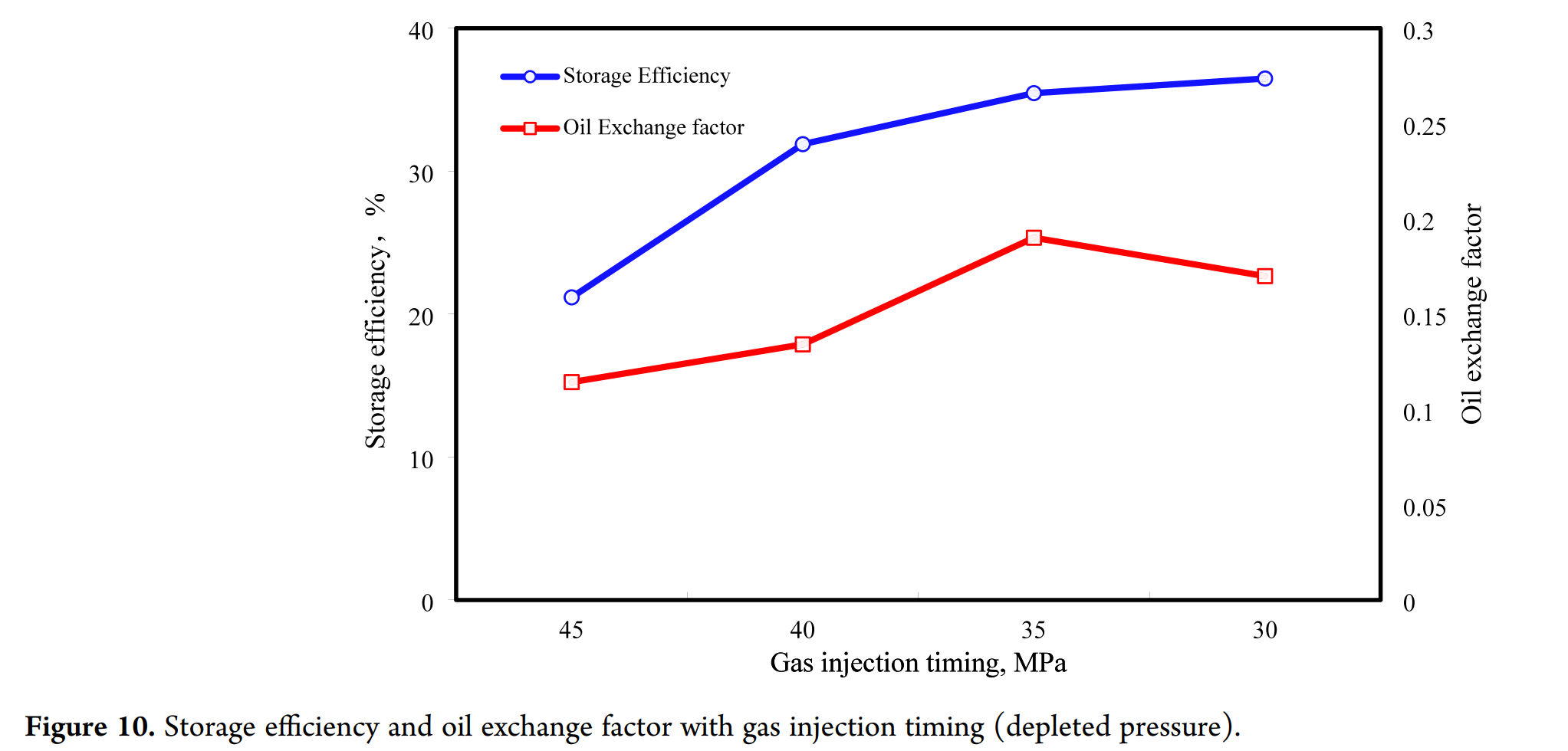

- CO₂封存效率与容量分析:

- 封存效率随注入压力降低而升高;

- 封存容量在40 MPa时最大,为最佳封存窗口;

- 综合考虑采收率与封存效率,35 MPa为最佳注入时机。

- 多轮吞吐存在“回捕”现象:

- 第三轮采收率下降,主要因“吐”阶段原油重新滞留;

- NMR图像显示:随着轮次增加,CO₂波及范围扩大,但产油效率下降。

作者单位

中国石油冀东油田分公司

Abstract

This study investigates the impact of various factors on the carbon dioxide (CO2) huff-and-puff-enhanced oil recovery process in tight oil reservoirs, particularly the V oil group in the Gao 5 fault block. Utilizing the online NMR core flooding technology, experiments were conducted under reservoir conditions (55 MPa pressure and 127 °C temperature) to analyze the effects of injection timing, pressure, and soaking time on displacement efficiency, oil production dynamics at the pore scale, and CO2 storage efficiency. Breaking new ground in understanding the interplay between operational parameters and reservoir response, the research reveals that a precisely calibrated pressure coefficient of 0.7 maximizes recovery across multiple cycles, while deviations from 0.8 trigger an unexpected 8.02% decline in recovery, uncovering a previously unrecognized threshold in pressure optimization. The work fundamentally advances knowledge of pore-scale fluid behavior by demonstrating how excessive pressure differentials induce irreversible pore structure damage, with striking evidence that micropores (>1 μm) serve as dual-function hotspots─contributing over 48.57% of total oil production while unexpectedly emerging as dominant CO2 sequestration sites. Challenging conventional wisdom, the study identifies a critical time-dependent mechanism where delayed injection timing selectively impairs oil mobilization from micro- to nanoscale pores (0.1–1 μm), creating novel opportunities for the synchronized optimization of both recovery efficiency and carbon storage. These transformative insights redefine the engineering paradigm for tight reservoir development by establishing quantitative relationships between injection protocols, pore-scale fluid redistribution, and the coupled performance of hydrocarbon production and CO2 storage.