三相多组分热模拟器STARS基于组分的汽液分配比,K值来执行相平衡计算,而非使用状态方程(EOS)。壳牌公司已经将CMG-STARS应用于其油页岩原位改质项目的模拟,但尚未公开用于模拟的输入参数的详细信息。因此,通过对美国绿河组各种油页岩矿床的广泛文献调研,获得了数值模拟所需的各种热物理参数,如热导率、比热容、孔隙度、渗透率,建立并验证了模拟模型,以复制壳牌示范项目南部(MDPS)中的原位转化过程(ICP)。直接加热模式和间距的敏感性分析再现了以前的工作。然后,使用经验证的模型来评估足以在其他直接和间接加热方法中加热油页岩的尺寸和裂缝间距,并在碳氢化合物生产和能源效率方面将加压热流体循环与加热元件进行比较,同时保持每种方法的所有模型输入相似。

这项研究还为考虑储层深度以及间接加热时循环流体的压力和温度的直接和间接加热方法提供了油页岩井设计建议。

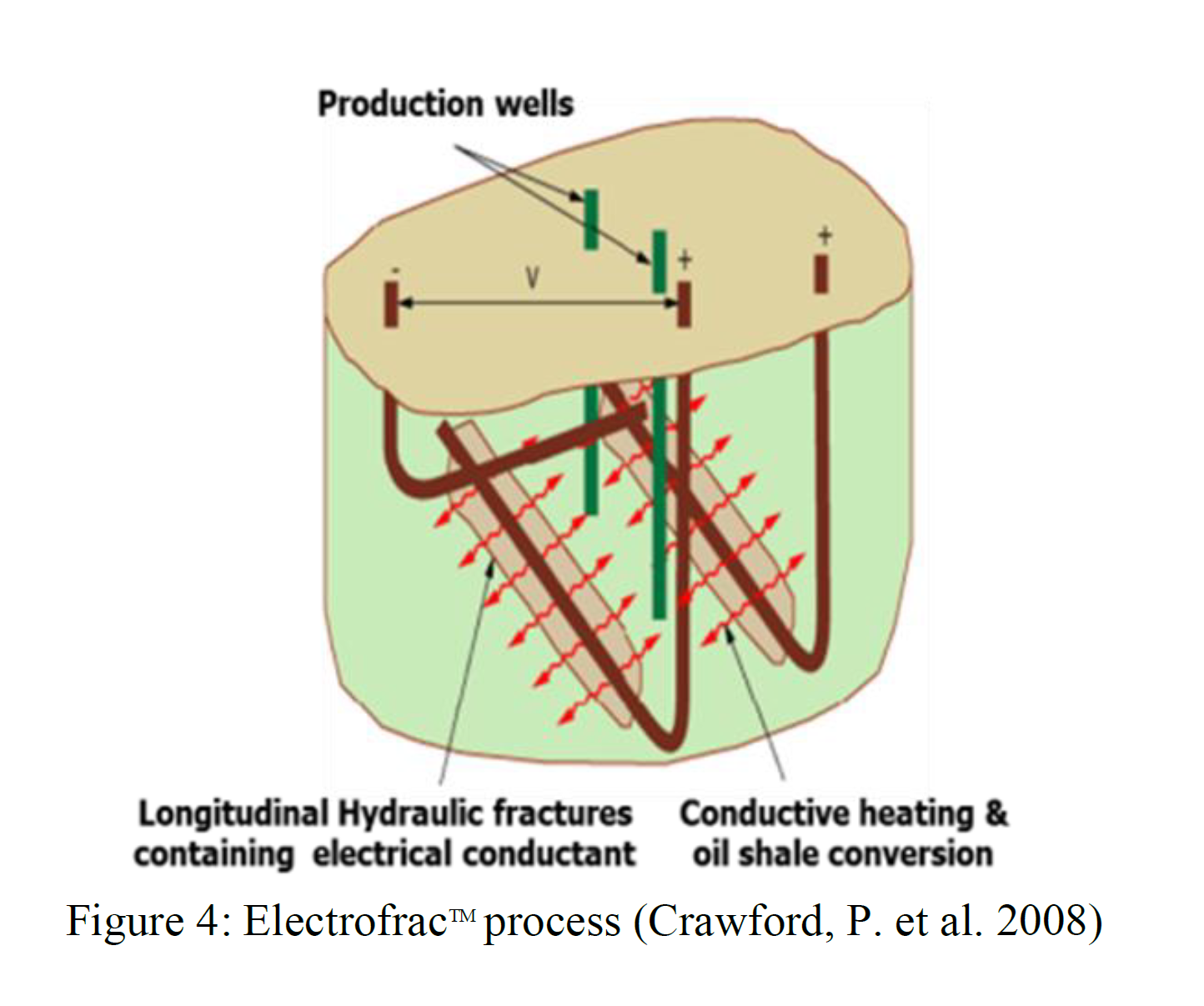

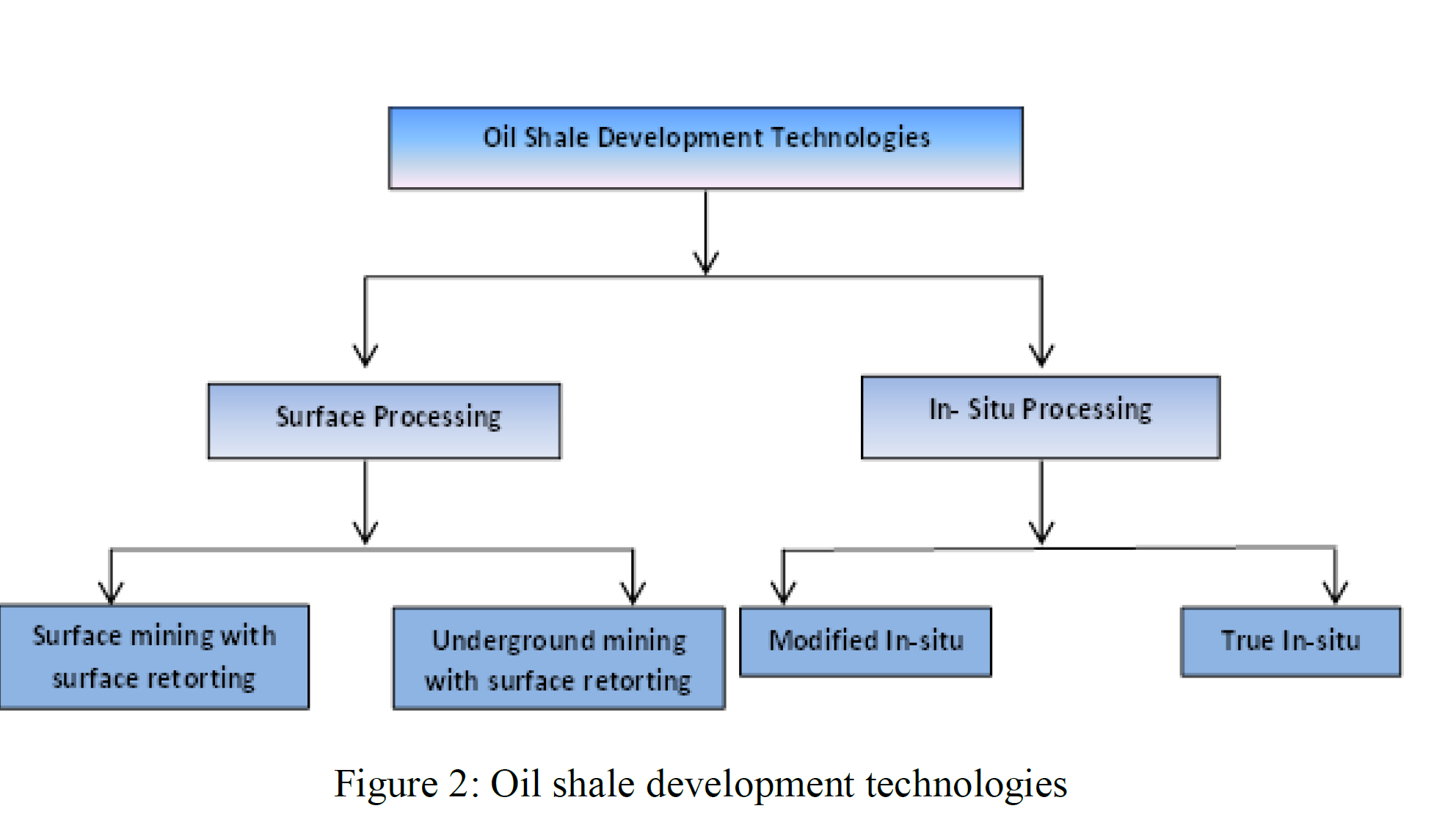

油页岩是层状、无孔、不透水的含烃岩石,含有称为干酪根的有机物,当在约600-800摄氏度的热解温度下加热时,热化学分解以释放碳氢化合物。它们处于资源三角的基础,因为经济地生产它们需要尖端技术和更高的燃料价格。油页岩生产技术包括表面和原位干馏。本研究的重点是现场油页岩生产方法。将油页岩加热到热解温度的过程可以通过直接或间接加热来实现。直接加热几何结构包括在垂直井中使用井下电加热器的壳牌原位转化工艺(ICP)和使用由水平井产生的纵向垂直裂缝并用燃烧焦炭等导电材料支撑的埃克森美孚电压裂(EF)方法。间接加热方法建议注入和循环蒸汽或不凝气体,如二氧化碳。其中包括Chevron CRUSH从垂直井创建水平裂缝的概念,或德克萨斯农工大学(TAMU)使用水平井穿透的多个垂直横向裂缝的概念(MTFH)。本研究的目的是使用商用自适应隐式热模拟器,即计算机模拟软件集团(CMG)的STARS,比较不同加热方案和井结构的各种原位干馏技术的能效。

Comparison of Heating Methods for In-Situ Oil Shale Extraction.

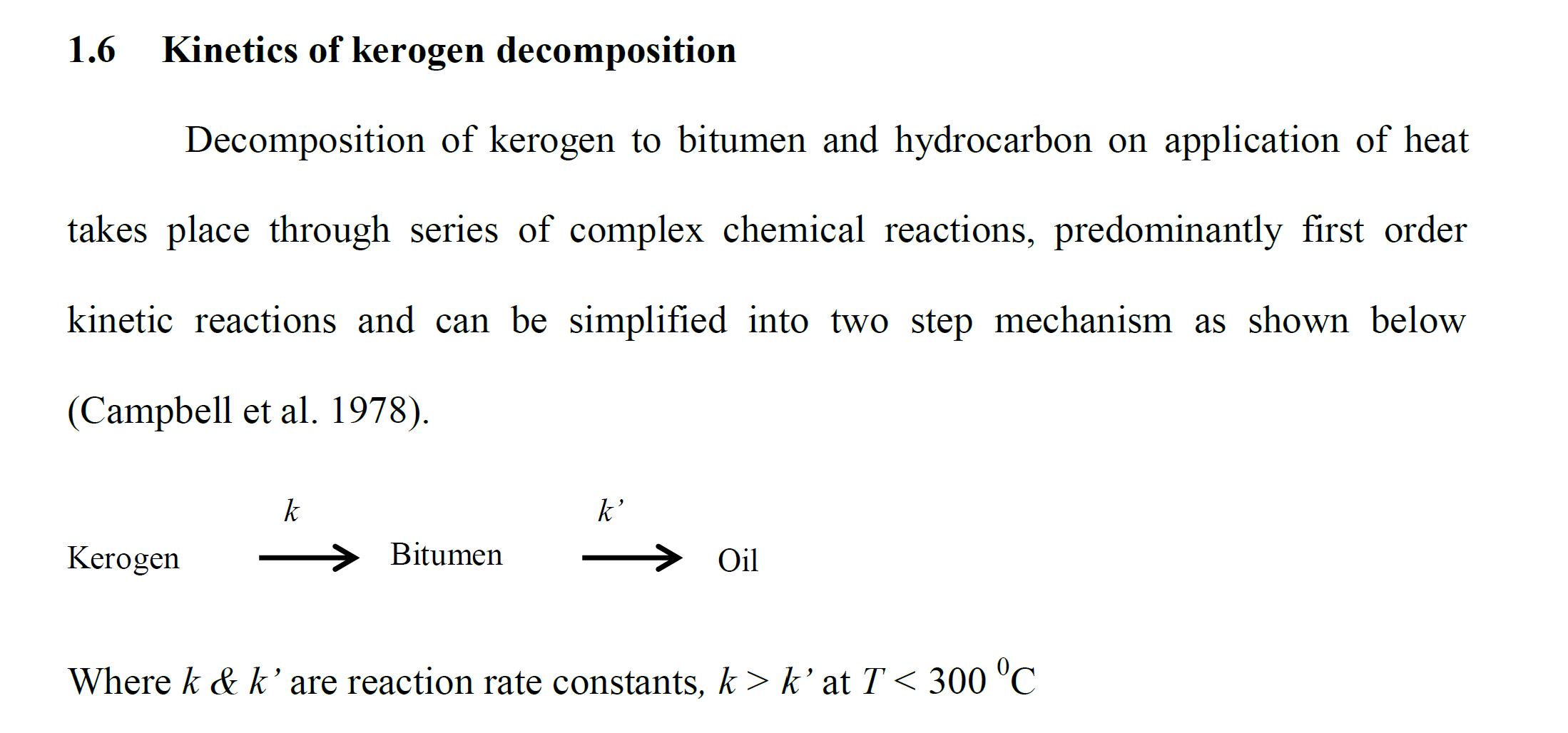

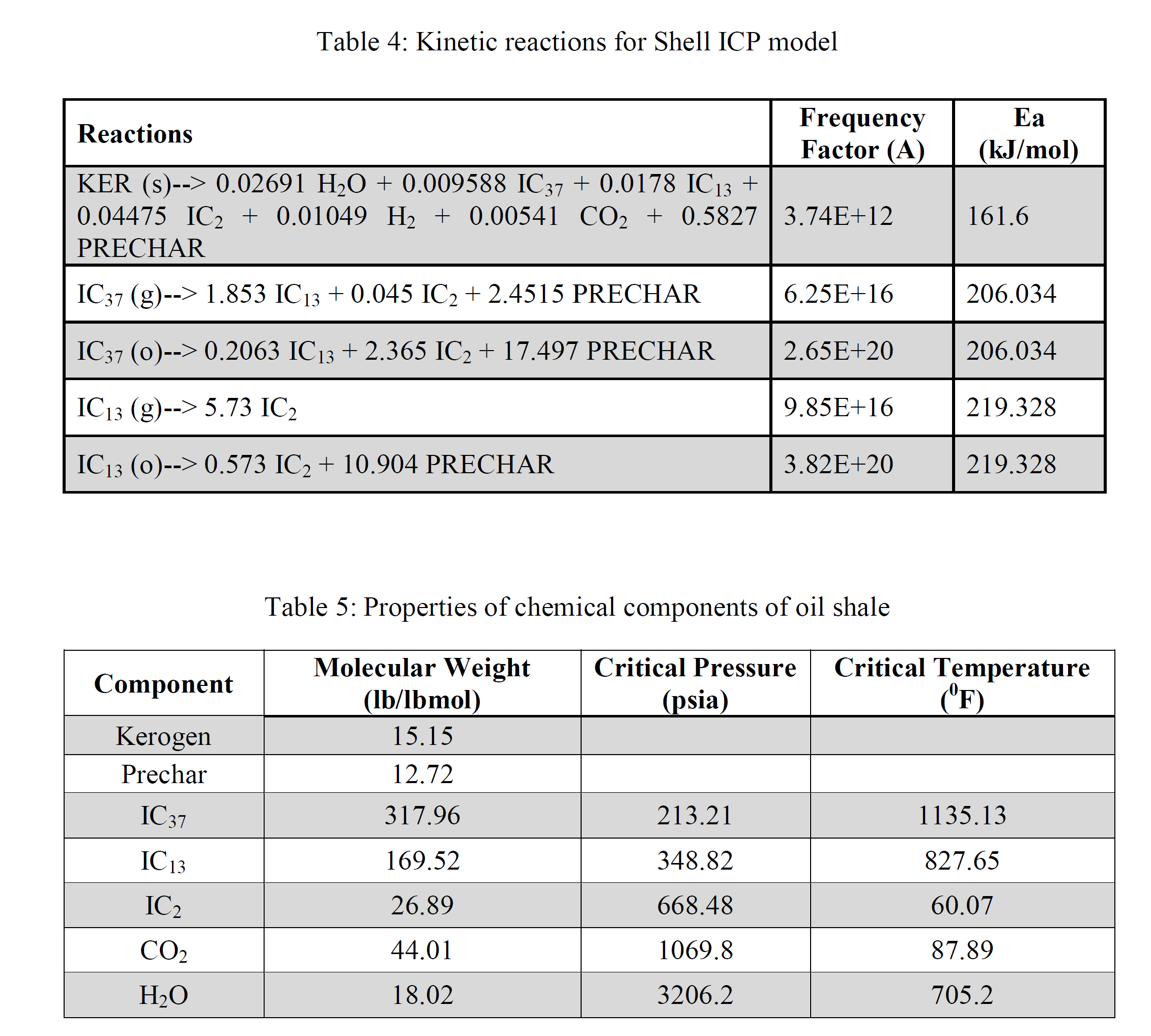

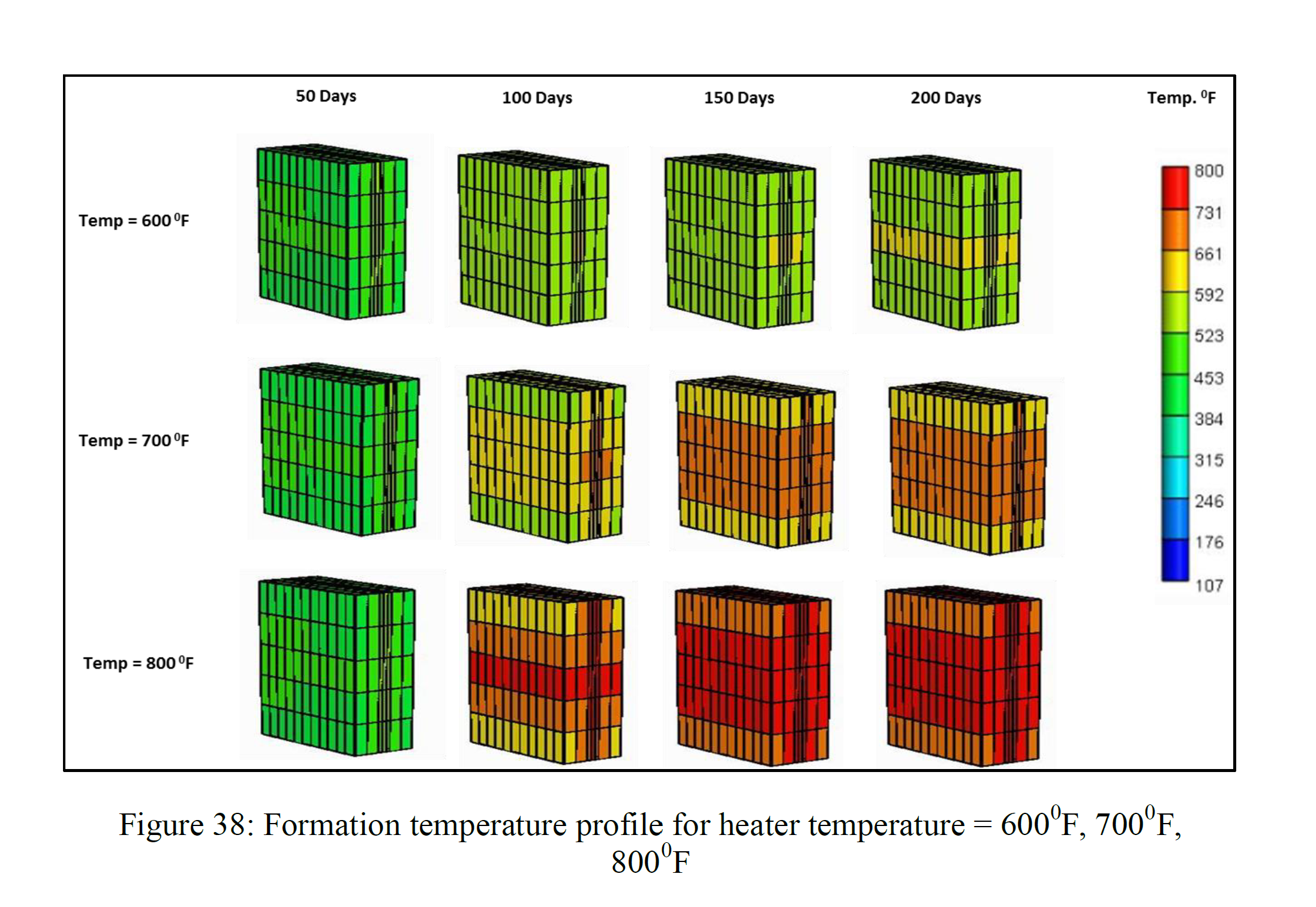

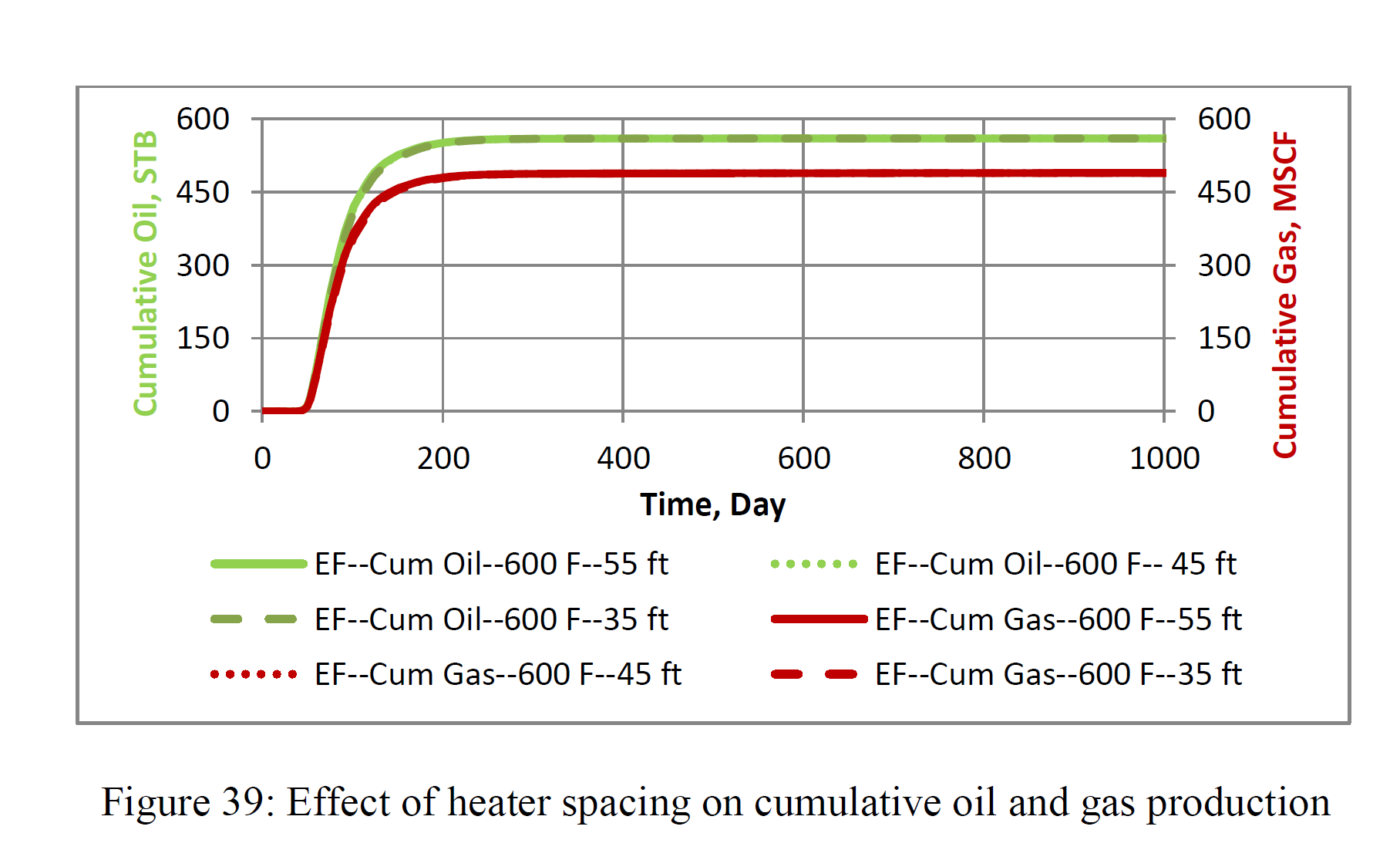

Oil shales are lamellar, non-porous, impermeable hydrocarbon bearing rocks that contain organic matter called kerogen which, when heated at pyrolysis temperature of approximately 600-800 ?, thermo-chemically decomposes to liberate hydrocarbons. They are at the base of the resource triangle because cutting edge technology and higher fuel prices are required to economically produce them. Technologies for oil shale production include surface and in-situ retorting. This study focuses on in-situ oil shale production methodologies. The process of heating oil shale to the pyrolysis temperature can be achieved by direct or indirect heating. Direct heating geometries include the Shell in-situ conversion process (ICP) using down hole electric heaters in vertical holes and the ExxonMobil Electrofrac (EF) approach using longitudinal vertical fractures created from horizontal wells and propped with electrically conductive material such as calcined coke. Indirect heating approaches propose injection and circulation of steam or a non-condensable gas like CO_(2). These include the Chevron CRUSH concept of creating horizontal fractures from vertical wells or the Texas A&M University (TAMU) concept using multiple vertical transverse fractures penetrated by horizontal wells (MTFH). The objective of this study is to compare energy efficiency of various in-situ retorting technologies for different heating schemes and well configurations using the commercial adaptive-implicit thermal simulator, STARS of Computer Modelling Group Ltd. (CMG).

STARS is a three phase multi-component thermal simulator and is based on vapor-liquid distribution ratio of a component, K values to perform phase equilibrium calculation instead of using the Equation of state (EOS). Shell has applied CMG -STARS to model its in-situ upgrading project, but is yet to publish details on the input parameters used for modeling. As such, the various thermo-physical parameters like thermal conductivity, specific heat capacity, porosity, permeability needed for the numerical simulation are obtained by extensive literature survey of various oil shale deposits in Green river formation of USA. Using CMG -STARS, we have built and validated simulation model to replicate Shell’s in-situ Conversion Process (ICP) in the Mahogany Demonstration Project South (MDPS). A sensitivity analysis of direct heating pattern and spacing reproduces previous work. Then the validated model is used to evaluate the size and fracture spacing sufficient to heat the oil shale in other direct and indirect heating approaches and to compare pressurized hot fluid circulation to heating elements on terms of hydrocarbon production and energy efficiency while keeping all the model inputs similar for each method. This research also enables oil shale well design recommendations for direct and indirect heating methodologies considering the depth of the reservoir and, for indirect heating, the pressure and temperature for the circulation fluid.