Wellbore injectivity response to step-rate CO2 injection: Coupled thermo-poro-elastic analysis in a vertically heterogeneous formation

Abstract

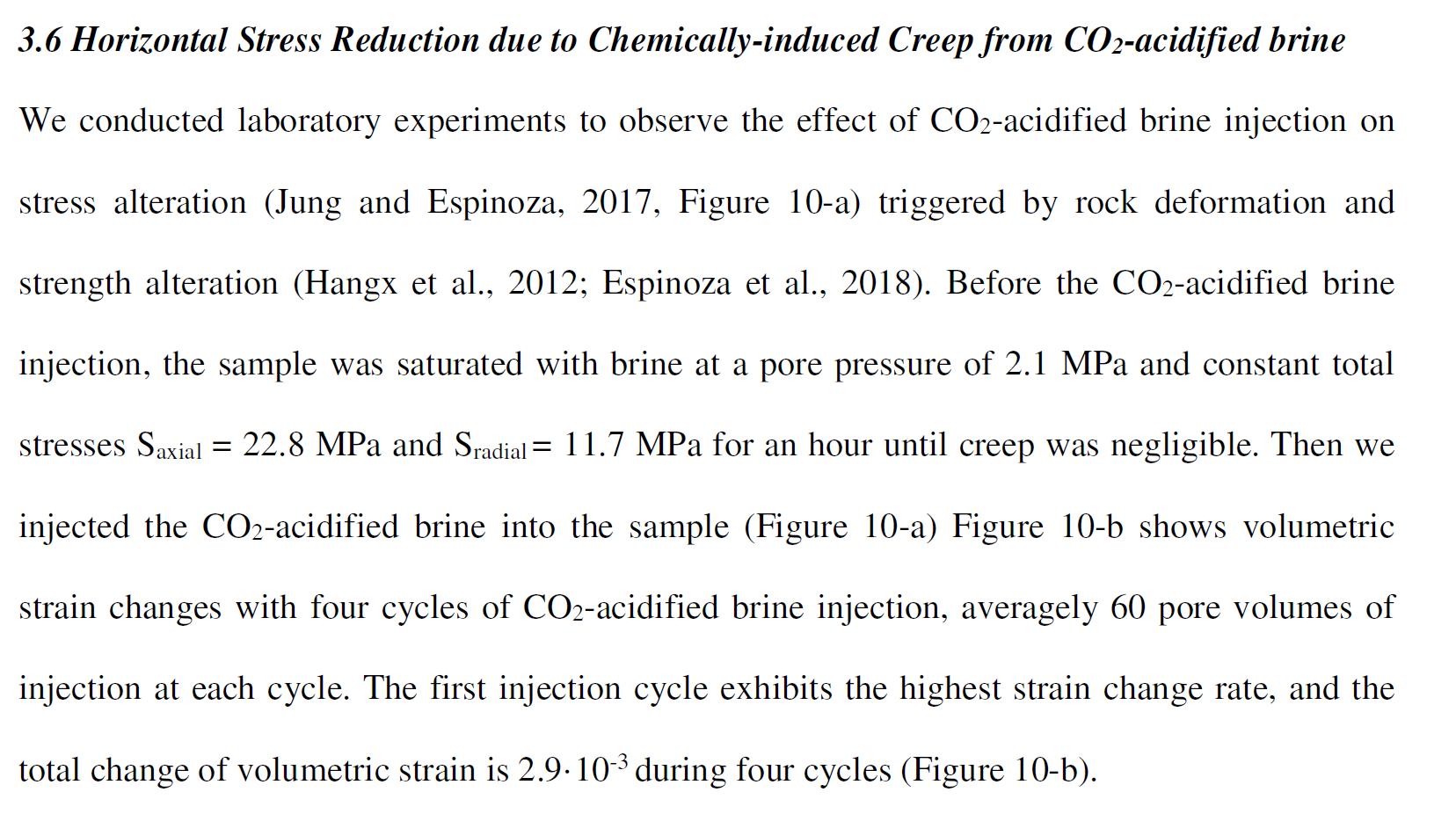

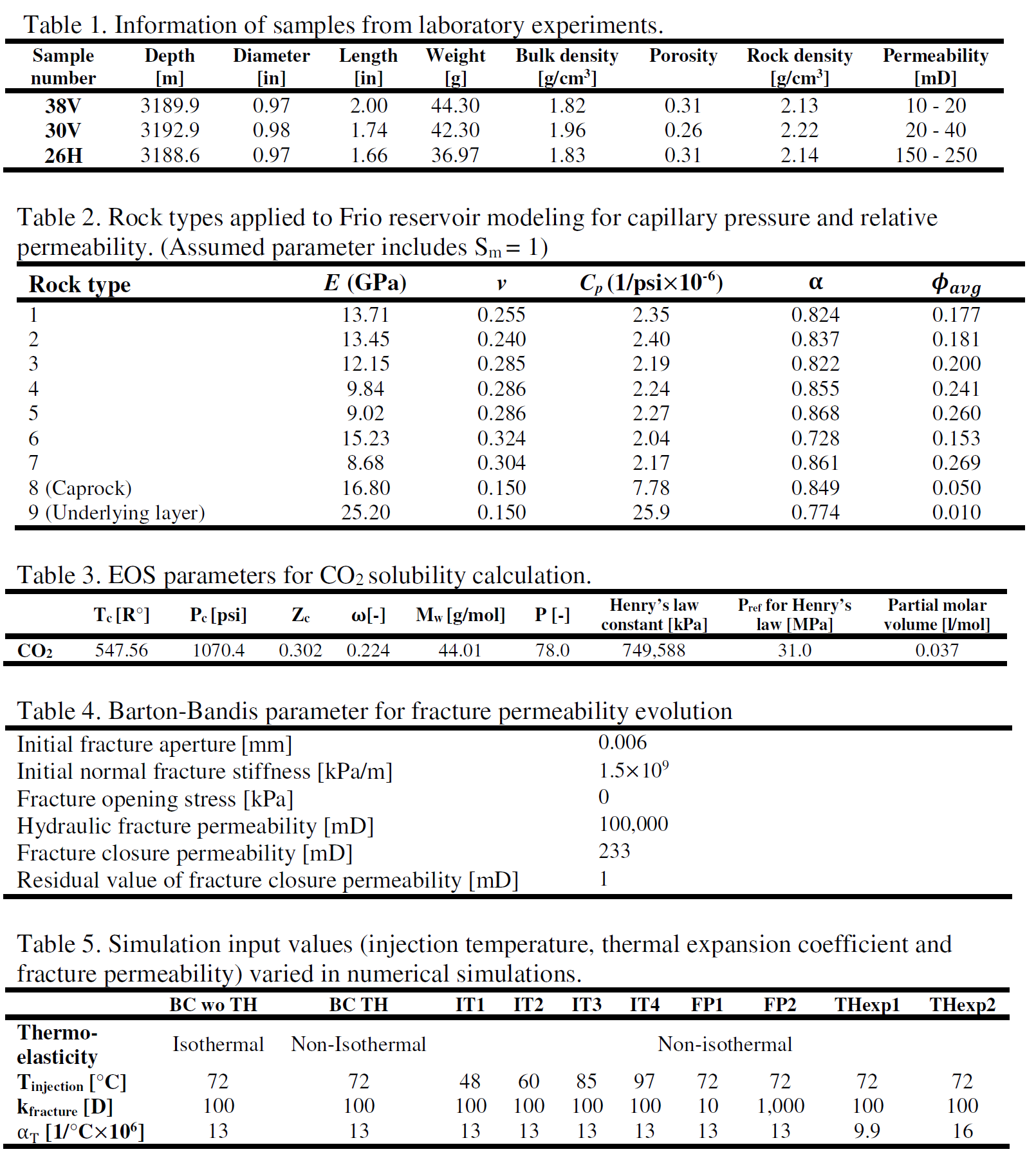

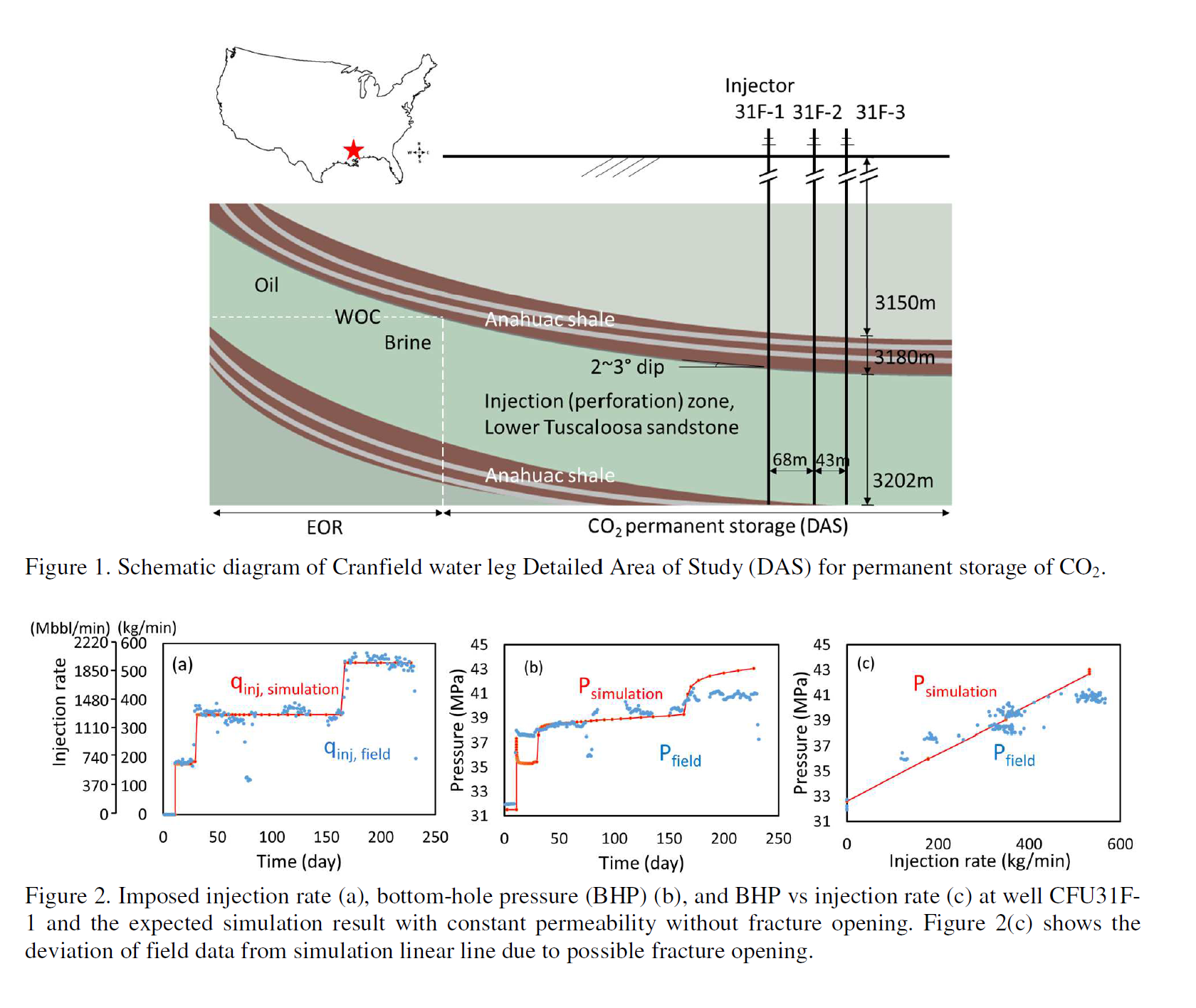

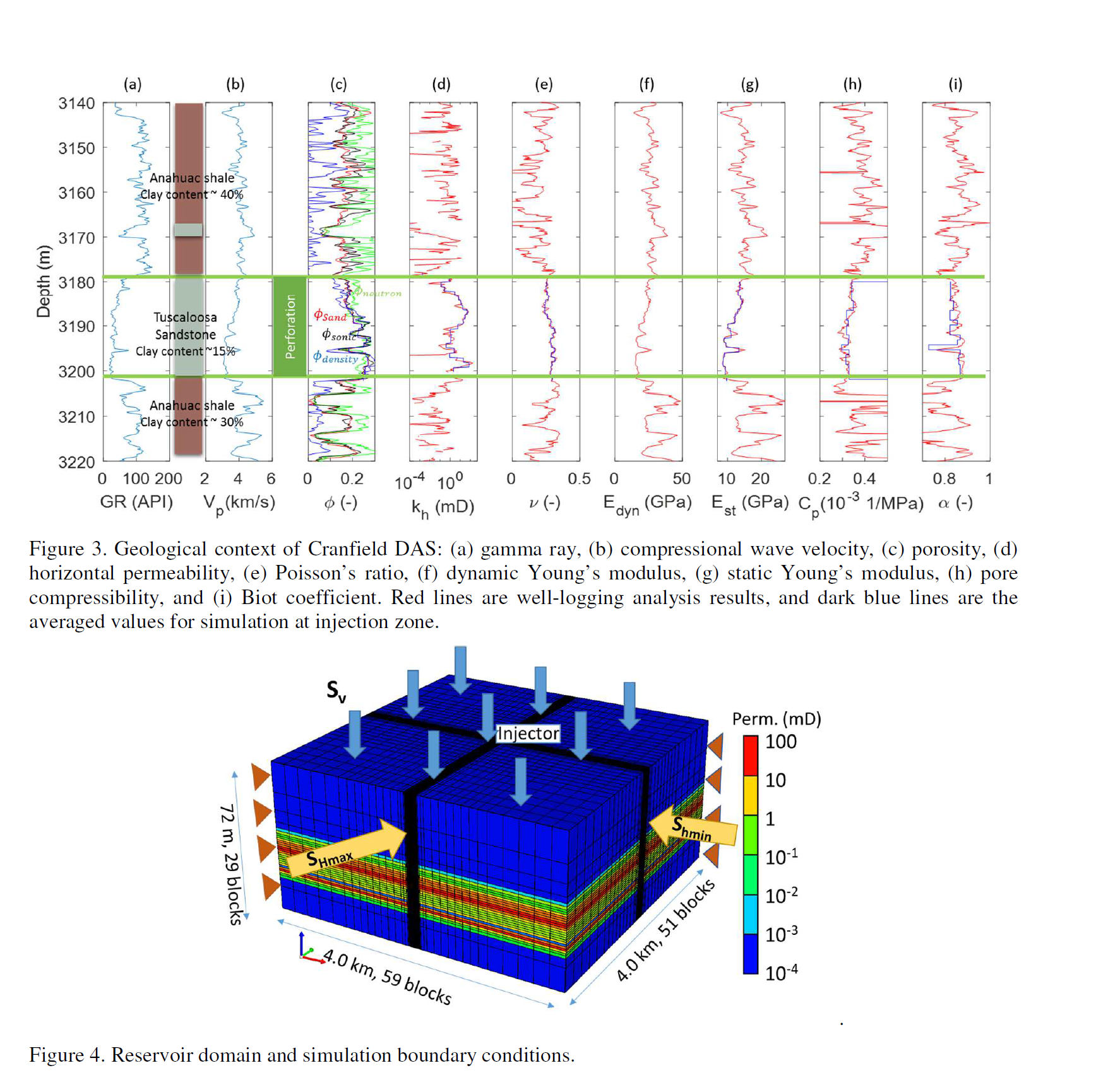

Safe and permanent carbon geological storages require an elaborate analysis of geomechanical stability. Subsurface injection of CO2 changes the local temperature and pore pressure and, further, alters the stress due to thermo-poro-elastic responses. A permanent CO2 storage testing was conducted in the water leg of Cranfield reservoir in Mississippi, USA, where hosted CO2 enhanced-oil recovery activities. During CO2 injection, the injection rate was ramped up twice but the bottom-hole pressure did not increase with the imposed injection rates as expected. This unexpected field observation suggests the possibility of an open-mode fracture development at the injector. However, the injector response and potential fracture development have not been rigorously interpreted with detailed near-wellbore temperature and pore pressure change upon the CO2 injection. In this study, we performed history matching of CO2 injection using coupled thermo-poro-elastic reservoir simulation to examine the possibility of fracturing. We built a reservoir model including vertical heterogeneity in both petrophysical and geomechanical properties estimated from well-logging analysis and laboratory experiments. The simulation results show that CO2 injection changes stresses and support the hypothesis of development of an open-mode fracture at the injector during the Cranfield test. The near-injector region exhibits a large temperature reduction up to 55 °C with ensuing effective horizontal stress reduction up to 9.1 MPa. However, a caprock integrity issue is unlikely because of the horizontal stress contrast within layers and low hydraulic communication with the injection zone. This work indicates that the injectant temperature should be considered in the design of high-rate CO2 injector.

Keywords: Carbon geological storage, Cranfield, fracturing, well testing, CO2 injection