Formation damage simulation of a multi-fractured horizontal well in a tight gas/shale oil formation

钻井过程中的地层损害是由于井筒和地层之间的高压差钻井液侵入造成的。这种机理发生在致密地层中多裂缝水平井的压裂液侵入中。一些多裂缝井的产量和累积产量远低于预期。这些受伤害的油井可能会比预期更低,例如由于新冠肺炎疫情等意外事件而关闭油井,累积产量会进一步减少。

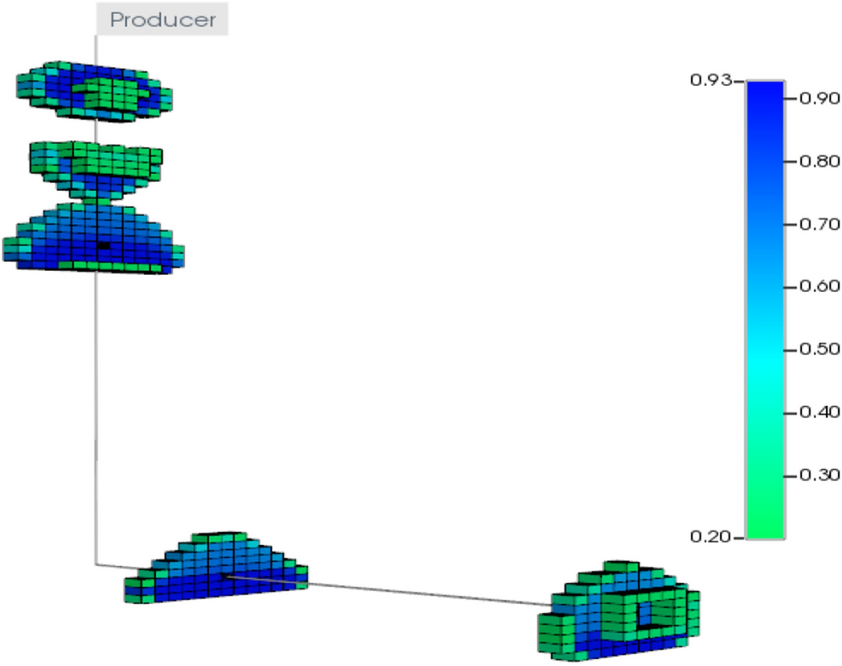

本文重点分析了裂缝地层损害的根本原因,并提出了提高产量的可能解决方案。使用Computer Modeling Group (CMG)软件进行了模拟研究,模拟压裂液侵入和关井造成的地层损害。

模拟结果表明,不同条件下的井的漏失和关井,造成累积油气产量的减少20%至41%。主要原因是致密地层临界含水饱和度高、压降低、地层闭合应力下支撑剂裂缝残余渗透率低。采用敏感性分析提出了两种减轻地层损害的可行解决方案:优化生产过程中的压降和水力压裂过程中的支撑剂充填渗透率。优化压降可以有效修复漏失伤害,但不能减轻关井伤害。应通过使用适当的支撑剂渗透率,提前预防关井造成的地层伤害。这些关键发现提高了产能,改善了致密气和页岩油地层的经济性。

New Mexico Tech 新墨西哥矿业及科技学院

Abstract

Formation damage in drilling comes from drilling fluid invasion due to high differential pressure between a wellbore and the formation. This mechanism happens with fracture fluid invasion of multi-fractured horizontal wells in tight formations. Some multi-fractured wells show production rates and cumulative productions far lower than expected. Those damaged wells may sustain further impact such as well shutting due to unexpected events such as the COVID-19 outbreak and then experience a further reduction in cumulative production. This paper focuses on the root causes of formation damage of fractured wells and provides possible solutions to improve production. A simulation study was conducted using Computer Modelling Group software to simulate formation damage due to fracture fluid invasion and well shut-in. Simulation results revealed that the decrease in cumulative hydrocarbon production due to leak-off and shut-in of the simulated well could range from 20 to 41%, depending on different conditions. The results showed that the main causes are high critical water saturation of tight formations, low drawdown, and low residual proppant permeability under formation closure stress. The sensitivity analysis suggests two feasible solutions to mitigate formation damage: optimizing drawdown during production and optimized proppant pack permeability of the hydraulic fracturing process. Optimizing pressure drawdown is effective in fixing leak-off damage, but it does not mitigate shut-in damage. Formation damage due to shut-in should be prevented in advance by using an appropriate proppant permeability. These key findings enhance productivity and improve the economics of tight gas and shale oil formations.

The removal of water saturation depends on the following factors:

- The available drawdown in the production phase: High drawdown will shorten the clean-up period and thus mitigate production impairment.

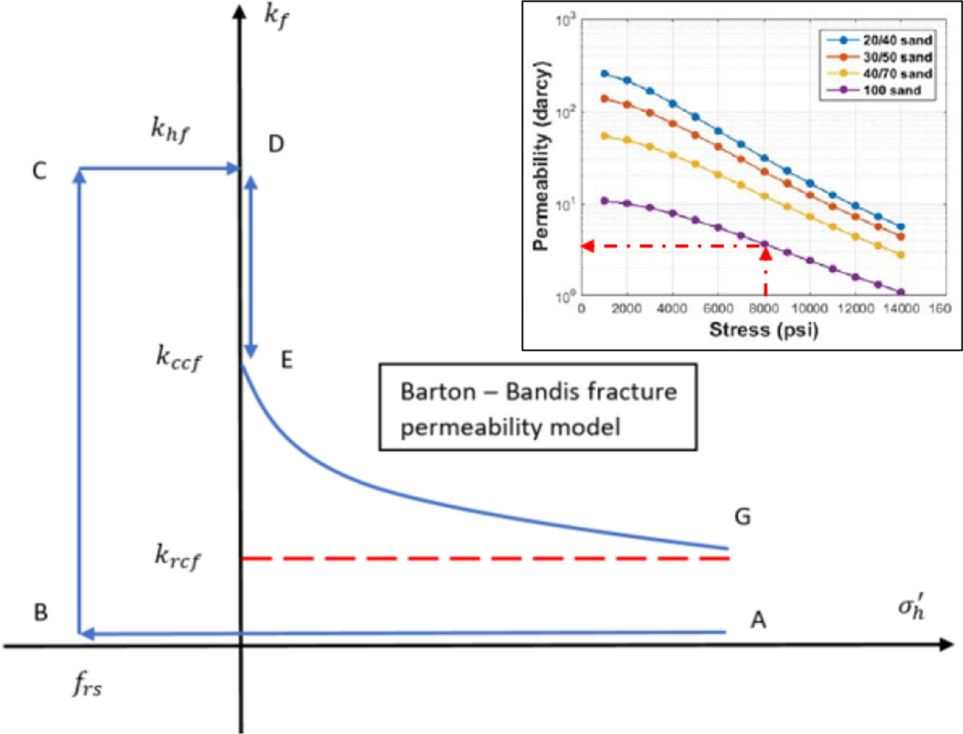

- Residual proppant permeability: critical factor to accelerate the removal of blocking fracture fluid. A high proppant conductivity provides a better clean-up.

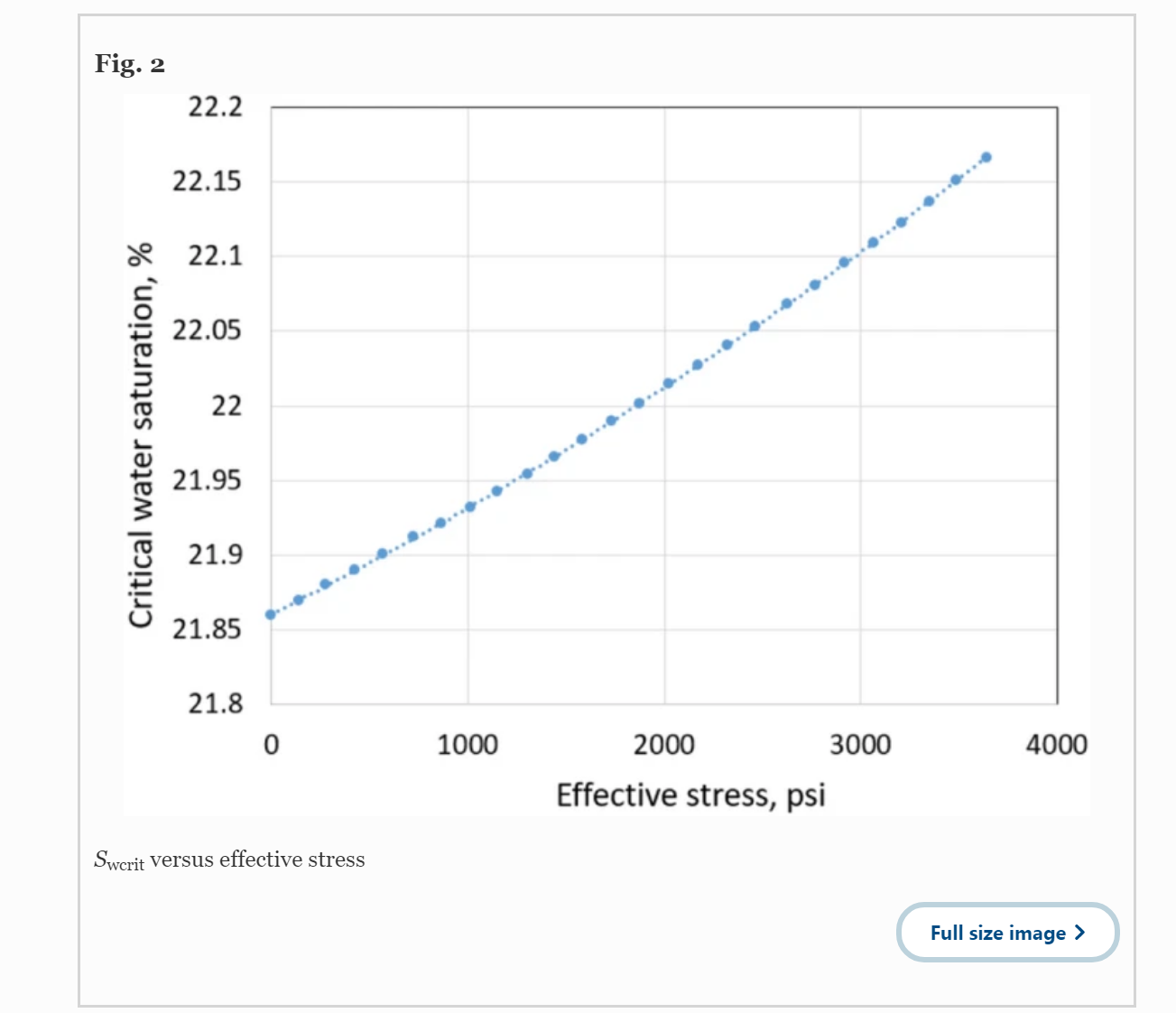

- The difference between Swi and Swcrit: In a tight formation which has a significant difference between Swi and Swcrit, the best practice of minimizing formation damage is to keep altered water saturation below Swcrit as much as possible.

Modified of Barton–Bandis fracture permeability model

Modified of Barton–Bandis fracture permeability model