Simulation Studies on the Effect of Asphaltene Precipitation on Oil Recovery during CO₂ Injection for Light Oil Reservoir

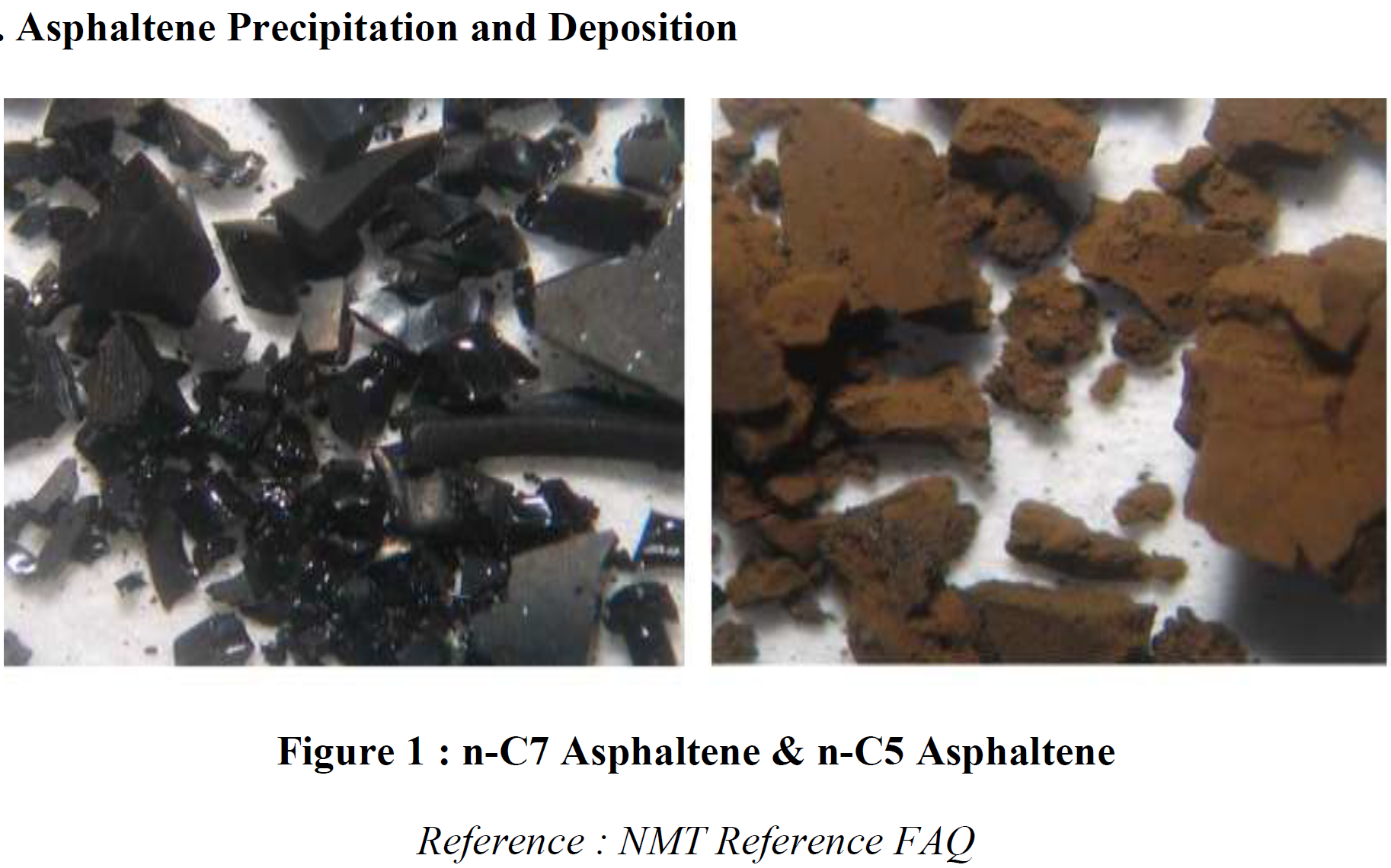

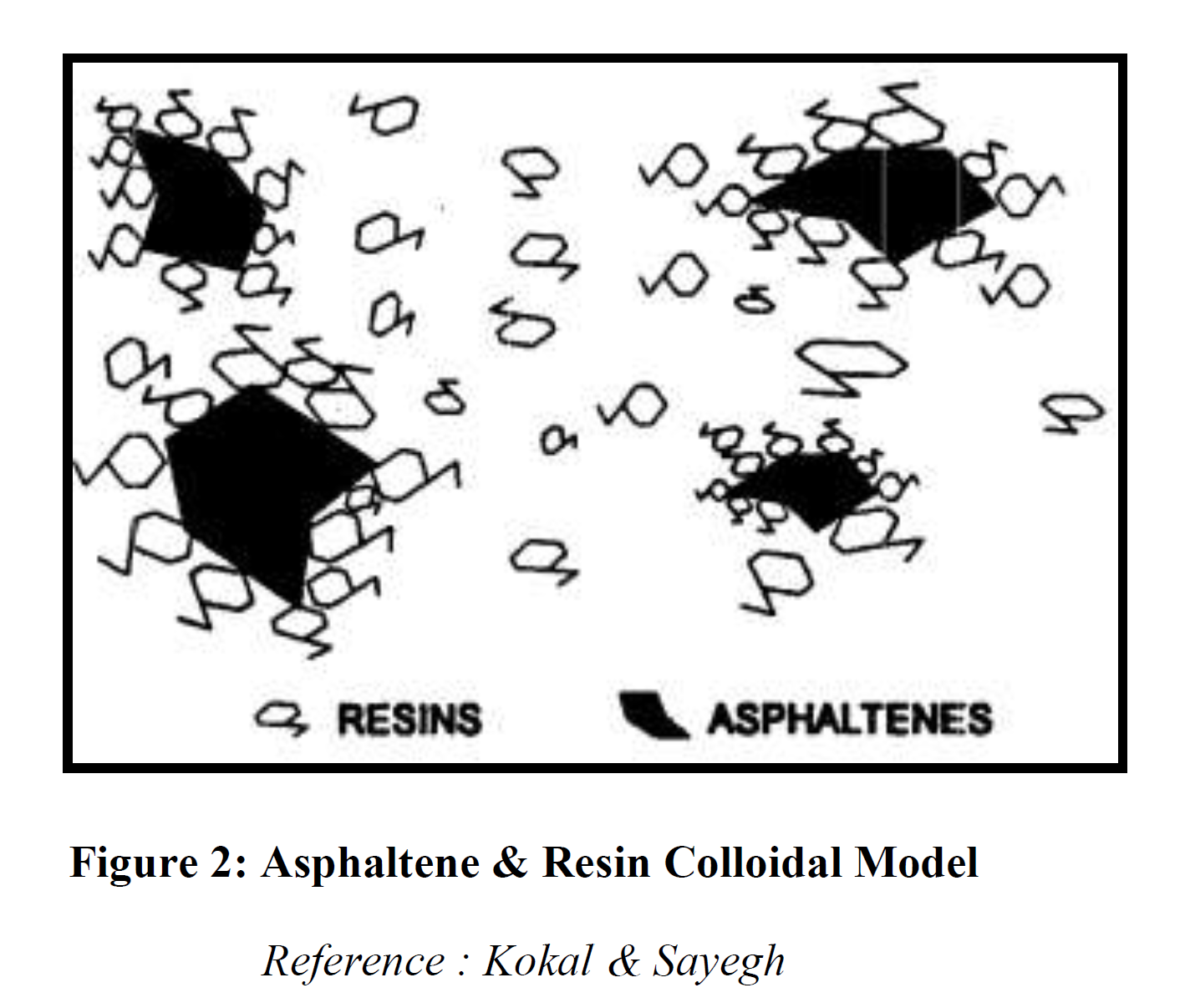

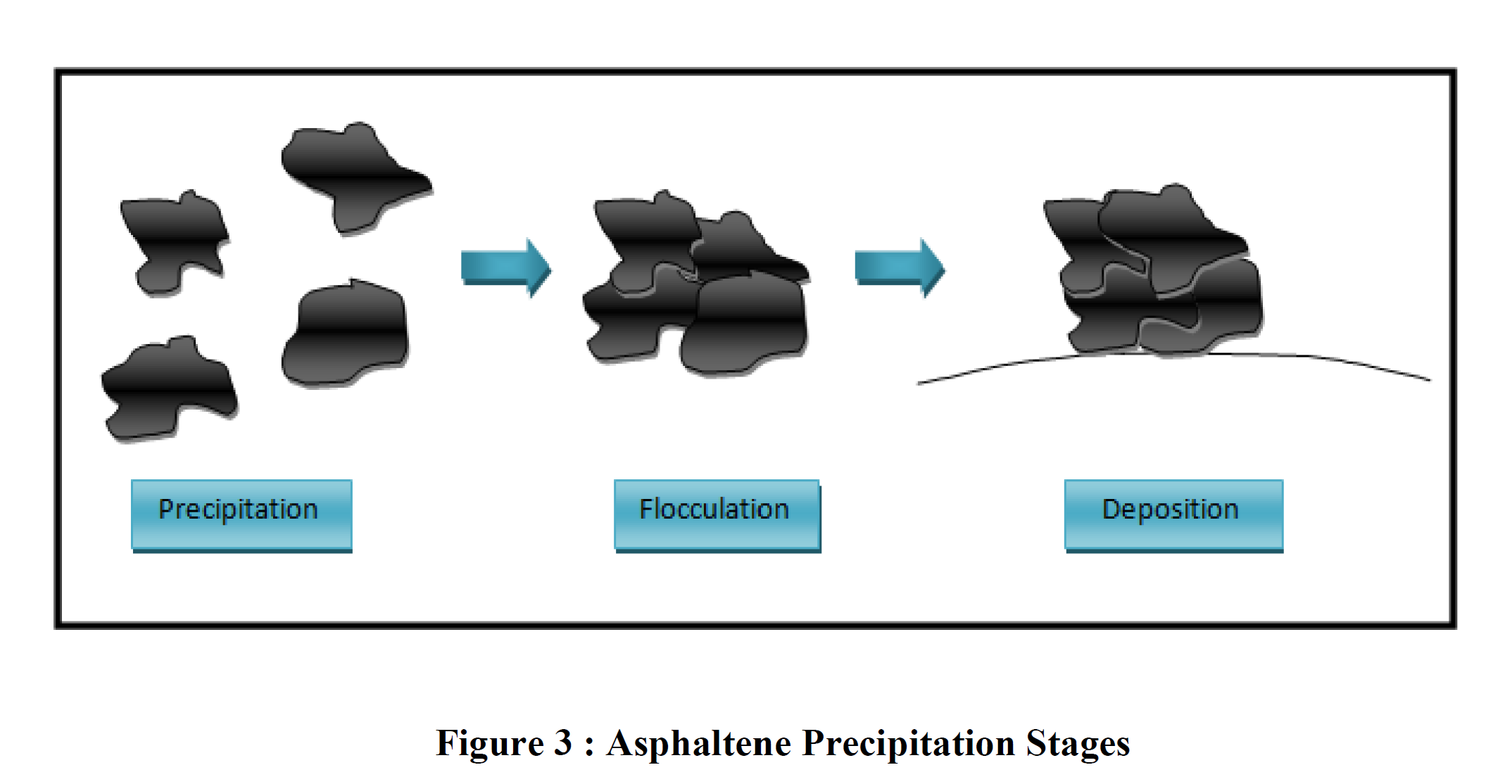

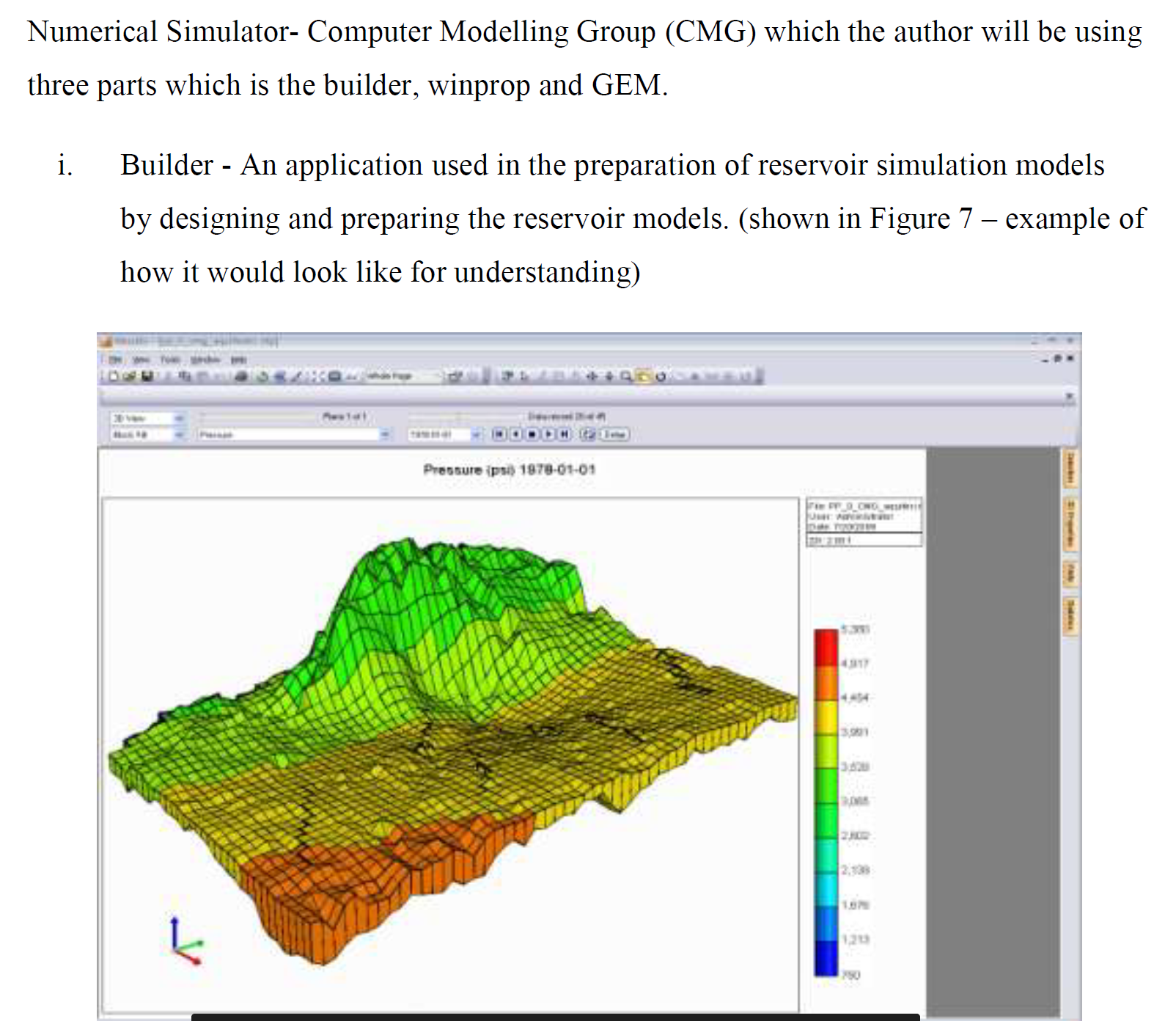

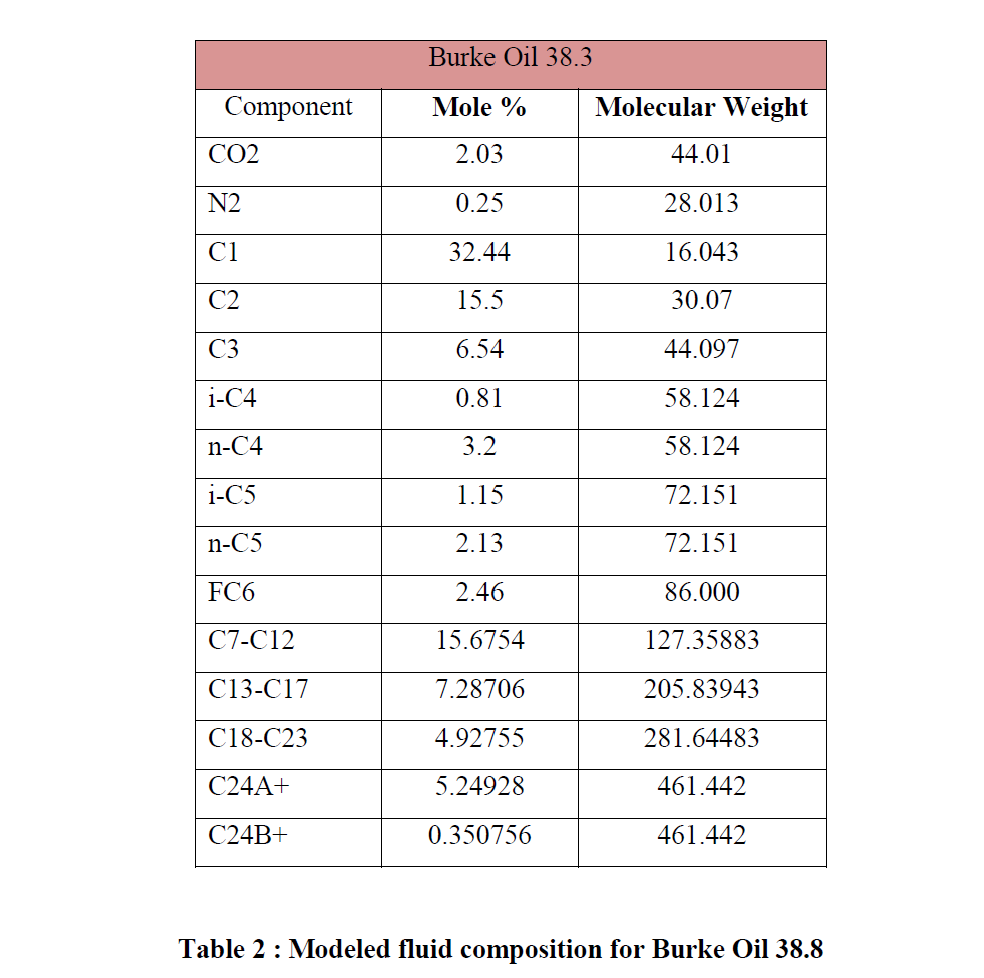

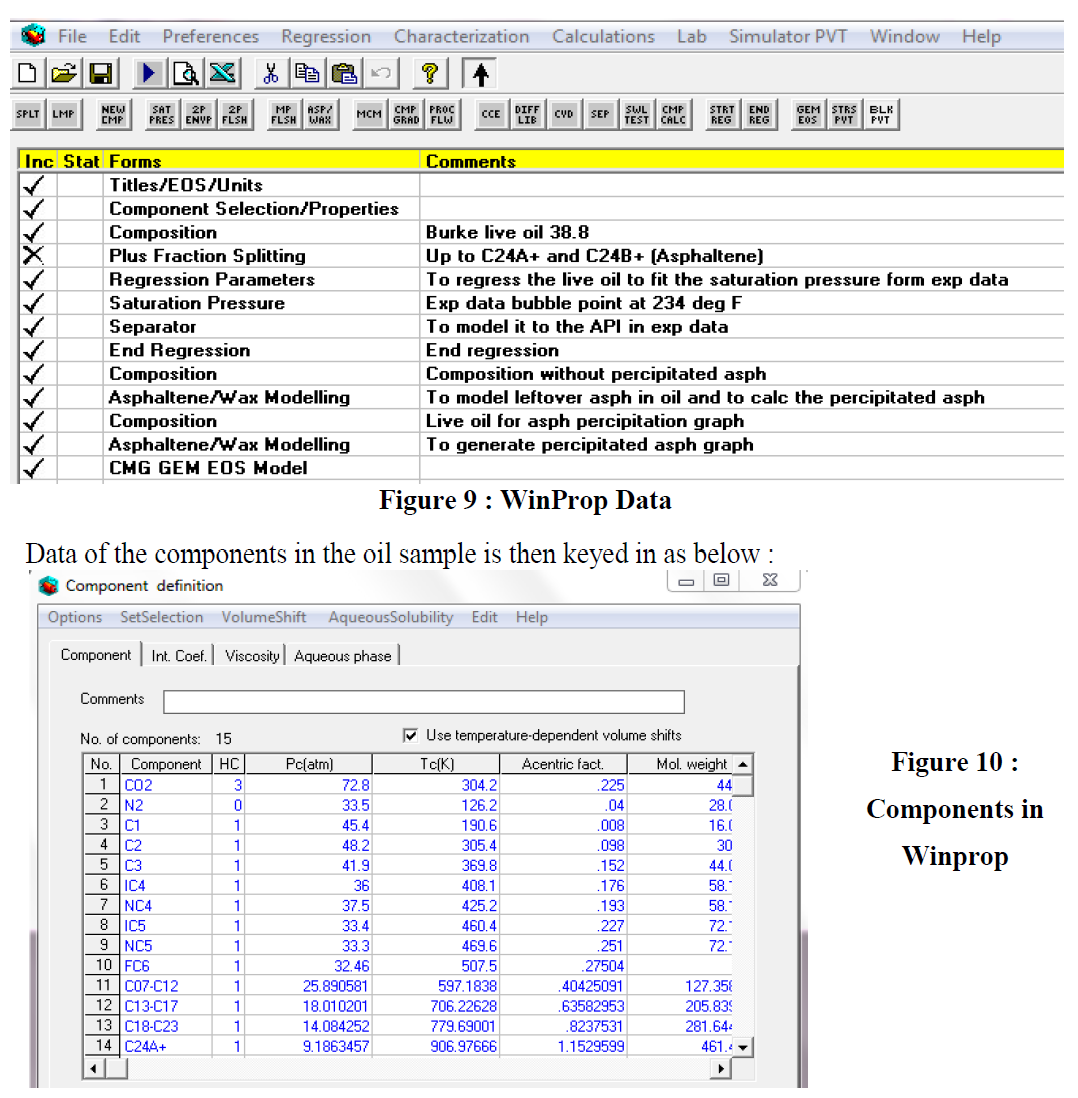

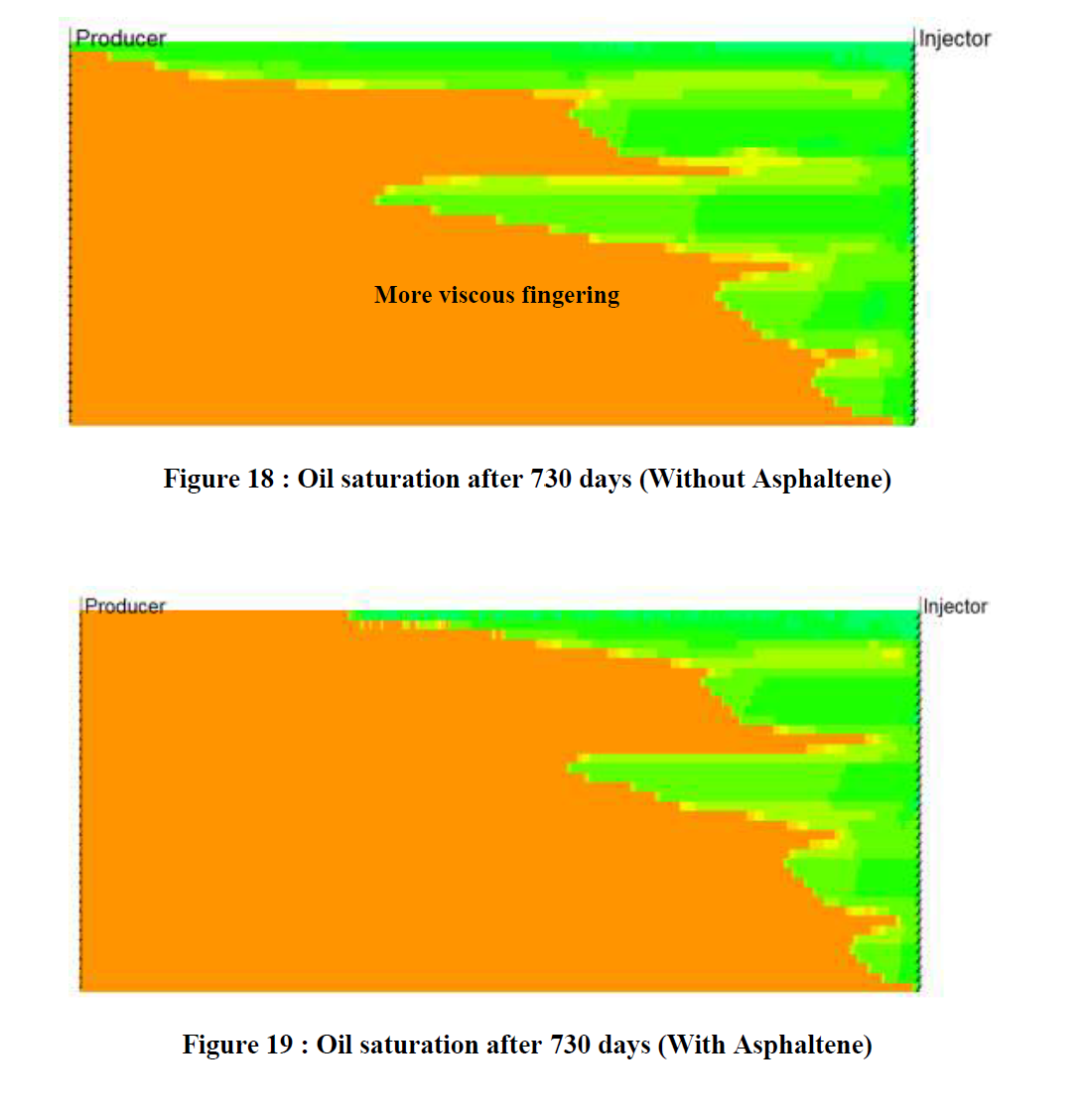

Enhanced Oil Recovery (EOR) is method widely use in many company for production. Gas injection is one of the oldest and most popular methods used in EOR. EOR is used to increase oil recovery. Gas is injected inside the reservoir and is stored in the geological formation. CO2 injection is one type of gas injection and is preferred to use in light oil reservoir as the gas and oil can be mix forming a miscible phase reducing the interfacial tension of crude oil and flowing together to the surface. Unfortunately, in wells that has asphaltene, precipitation tends to exist even though the percentage of asphaltene is small. Once precipitation occurs, the asphaltene will clump together forming a flock of asphaltene and deposit in the reservoir when it is too heavy to be carried out by the flow causing formation damage such as porosity and permeability reduction and wettability alteration. Asphaltene precipitation will also cause the wellbore, tubing and facilities equipment’s to break down due to the accumulation in it. All these will lead to decrease in production. The author will continue doing research work reading more to understand the effect of asphaltene. Then, the author will use CMG software to simulate light oil reservoir under CO2 injection to anticipate the outcome before it actually happens as when precipitation occurs, the cost to clean it mechanically and chemically is time consuming, expensive and unsafe. The author will use the Builder, WinProp and GEM to do the simulation work. The findings that the author found was consistent which the experimental work done by many experts in the industry and the author had proven that asphaltene precipitation causes formation damaged which in turn reduces the permeability and porosity of the formation.

提高采收率(EOR)是许多公司广泛使用的采油方法。注气是EOR中最古老、最流行的方法之一。天然气被注入储层内部并储存在地质构造中。CO2注入是一种类型的气体注入,并且优选用于轻质油藏,因为气体和油可以混合形成混溶相,从而降低原油的界面张力并一起流到地面。但是,在含有沥青质的井中,即使沥青质的百分比很小,也往往存在沉淀。一旦发生沉淀,沥青质就会聚集在一起,形成沥青质团,并在太重而无法通过流动而沉积在储层中,从而导致地层伤害,如孔隙度和渗透率降低以及润湿性改变。沥青质沉淀还会导致井筒、油管和设施设备因其积聚而发生故障,从而导致产量下降。作者将继续进行研究工作,以更多地了解沥青质的作用。本文使用CMG软件模拟CO2注入下的轻质油藏,以在实际发生之前预测结果,因为当沉淀发生时,机械和化学清洁的成本是耗时、昂贵和不安全的。作者将使用Builder、WinProp和GEM进行模拟工作。作者发现的发现与许多业内专家和作者所做的实验工作一致,证明沥青质沉淀会导致地层损坏,进而降低地层的渗透率和孔隙度。