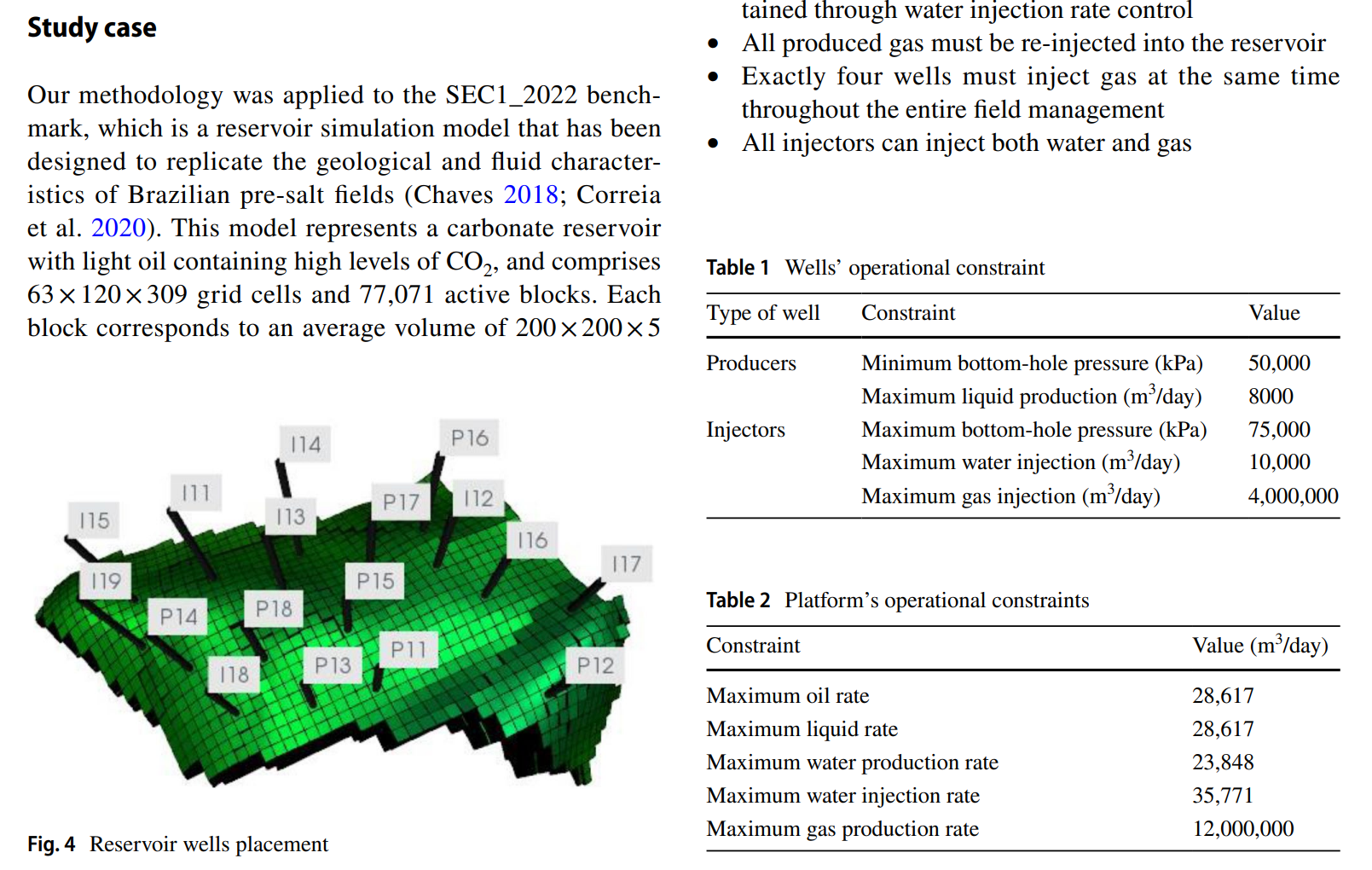

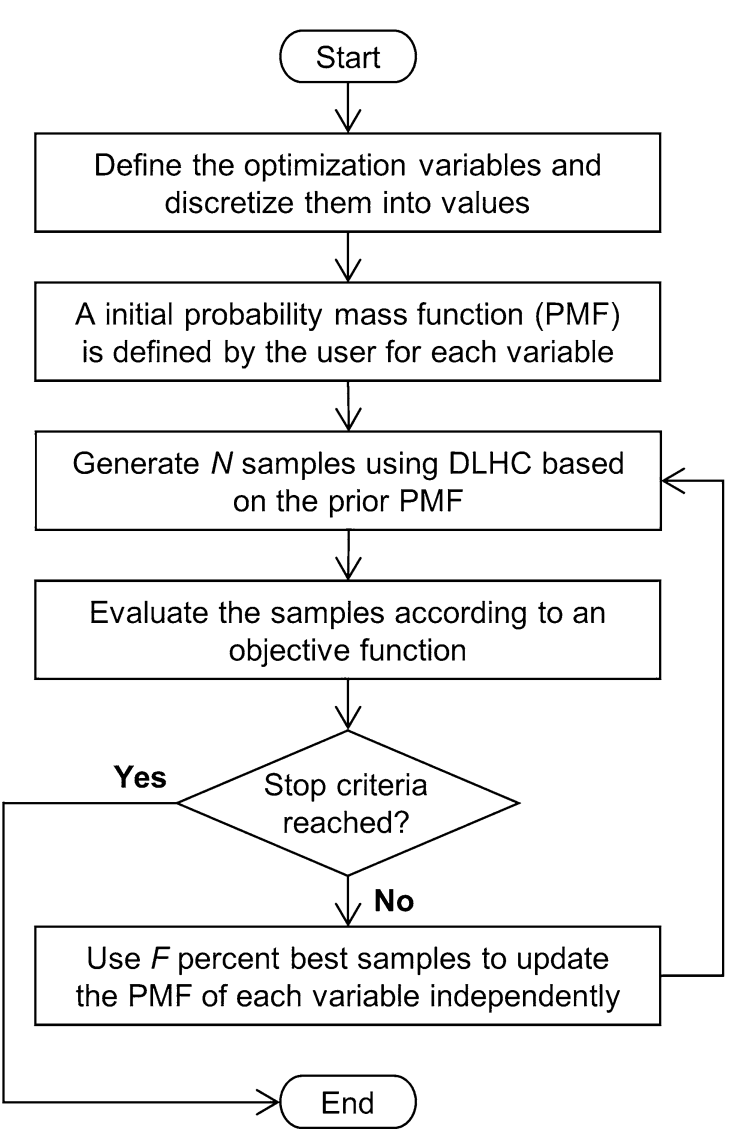

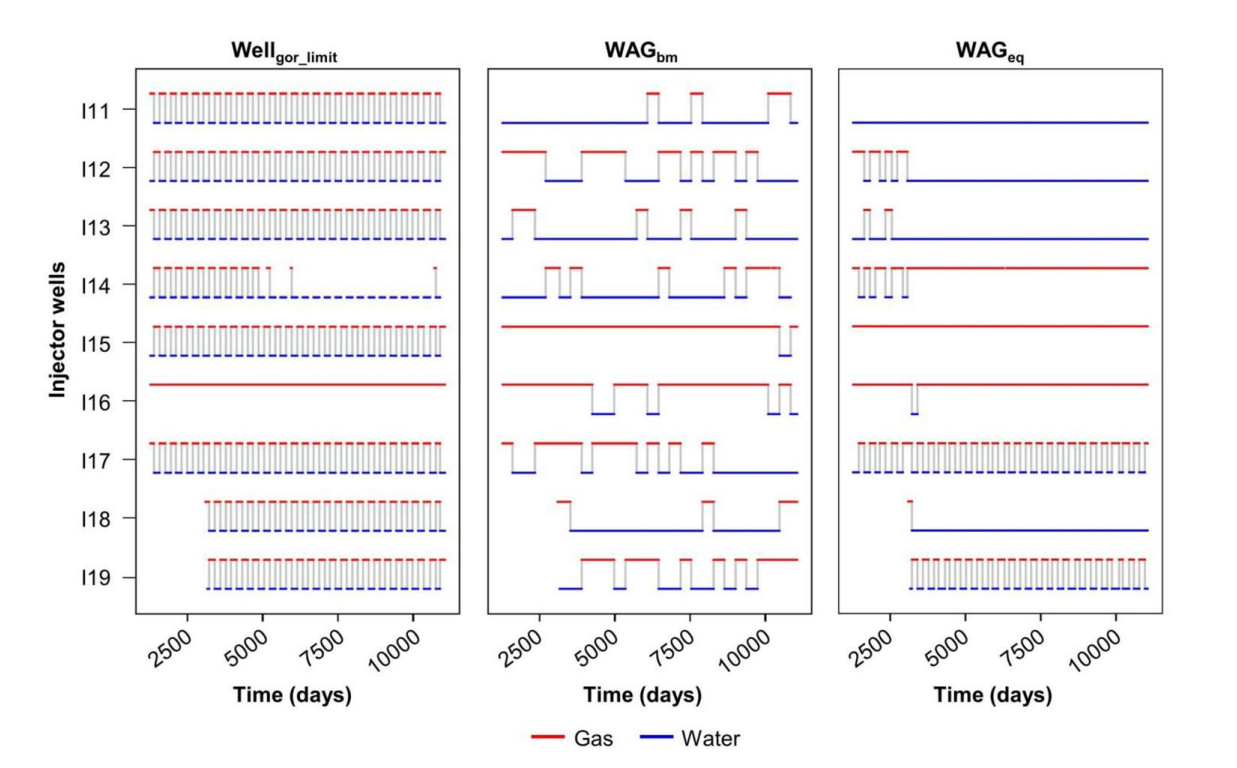

Enhancing oil recovery in reservoirs with light oil and high gas content relies on optimizing the miscible water alternating gas (WAG) injection profile.However, this can be costly and time-consuming due to computationally demanding compositional simulation models and numerous other well control variables. This study introduces WAGeq, a novel approach that expedites the convergence of the optimization algorithm for miscible water alternating gas (WAG) injection in carbonate reservoirs. The WAGeq leverages production data to create flexible solutions that maximize the net present value (NPV) of the field, while providing practical implementation of individual WAG profiles for each injector. The WAGeq utilizes an injection priority index to rank the wells and determine which should inject water or gas at each time interval. The index is built using a parametric equation that considers factors such as producer and injector relationship, water cut (WCUT), gas–oil ratio (GOR), and wells cumulative gas production, to induce desirable effects on production and WAG profile. To evaluate WAGeq’s effectiveness, two other approaches were compared: a benchmark solution named WAGbm, in which the injected fluid is optimized for each well over time, and a traditional baseline strategy with fixed 6-month WAG cycles. The procedures were applied to a synthetic simulation case (SEC1_2022) with characteristics of a Brazilian pre-salt carbonate field with karstic formations and high CO2 content. The WAGeq outperformed the baseline procedure, improving the NPV by 6.7% or 511 USD million. Moreover, WAGeq required fewer simulations (less than 350) than WAGbm (up to 2000), while delivering a slightly higher NPV. The terms of the equation were also found to be essential for producing a WAG profile with regular patterns on each injector, resulting in a more practical solution. In conclusion, WAGeq significantly reduces computational requirements while creating consistent patterns across injectors, which are crucial factors to consider when planning a practical WAG strategy.

在轻质油和高含气油藏中提高采收率依赖于优化混相水交替气(WAG)注入剖面。然而,由于计算要求高的成分模拟模型和许多其他井控变量,这可能是昂贵和耗时的。本研究介绍了WAGeq,这是一种加快了碳酸盐岩储层混相水交替气(WAG)注入优化算法收敛的新方法。WAGeq利用生产数据创建灵活的解决方案,最大限度地提高油田的净现值(NPV),同时为每个注入井提供单独WAG剖面的实际实施。WAGeq利用注入优先级指数对油井进行排序,并确定每个时间间隔应注入水或天然气的油井。该指数是使用一个参数方程建立的,该方程考虑了生产井和注入井关系、含水率(WCUT)、气油比(GOR)和油井累计天然气产量等因素,以对产量和WAG剖面产生理想的影响。为了评估WAGeq的有效性,比较了另外两种方法:一种是名为WAGbm的基准解决方案,其中随着时间的推移,每口井的注入流体都会得到优化,另一种是固定6个月WAG周期的传统基线策略。该程序应用于一个具有巴西盐上碳酸盐岩油田特征的合成模拟案例(SEC1_2022),该碳酸盐岩油田具有岩溶地层和高CO2含量。WAGeq优于基线程序,将净现值提高了6.7%,即5.11亿美元。此外,与WAGbm(高达2000)相比,WAGeq需要更少的模拟(少于350),同时提供略高的NPV。该方程的项也被发现对于在每个注入井上产生具有规则图案的WAG轮廓至关重要,从而产生更实用的解决方案。总之,WAGeq显著降低了计算需求,同时在注入井之间创建了一致的模式,这是规划实际WAG策略时需要考虑的关键因素。

Accelerated optimization of CO2-miscible water-alternating-gas injection in carbonate reservoirs using production data-based parameterization

Abstract