Optimizing Storage Parameters for Underground Hydrogen Storage in Aquifers: Cushion Gas Selection, Well Pattern Design, and Purity Control

为缓解氢能供需时空错配,含水层地下储氢(UHS)因分布广、容量大、密封好而备受关注。本文基于单井注采概念模型,用 CMG-GEM 组分模拟器系统比较 CO₂、N₂、CH₄ 三种垫底气对氢采收率的影响,并研究温度、初始压力、孔渗参数、注采速率等 8 个因素对采出氢纯度的作用;进一步开展单井、线驱、五点井网方案的经济-技术联合优化。

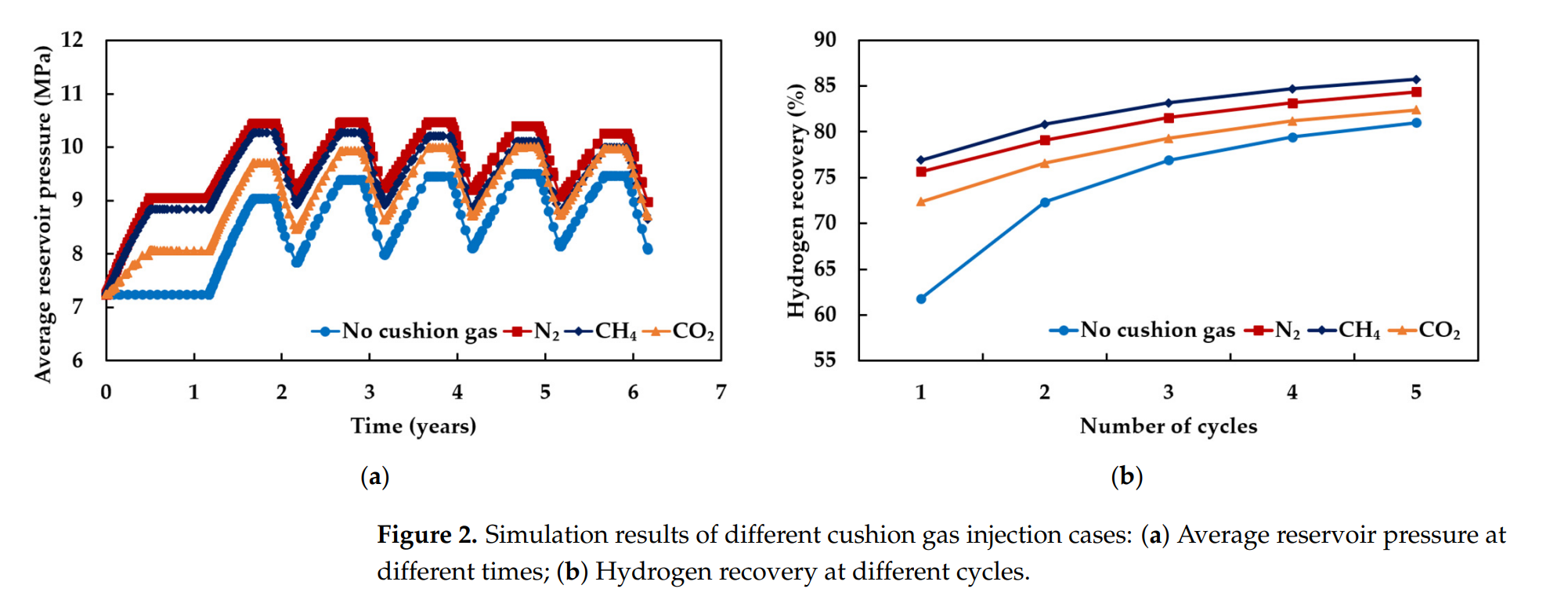

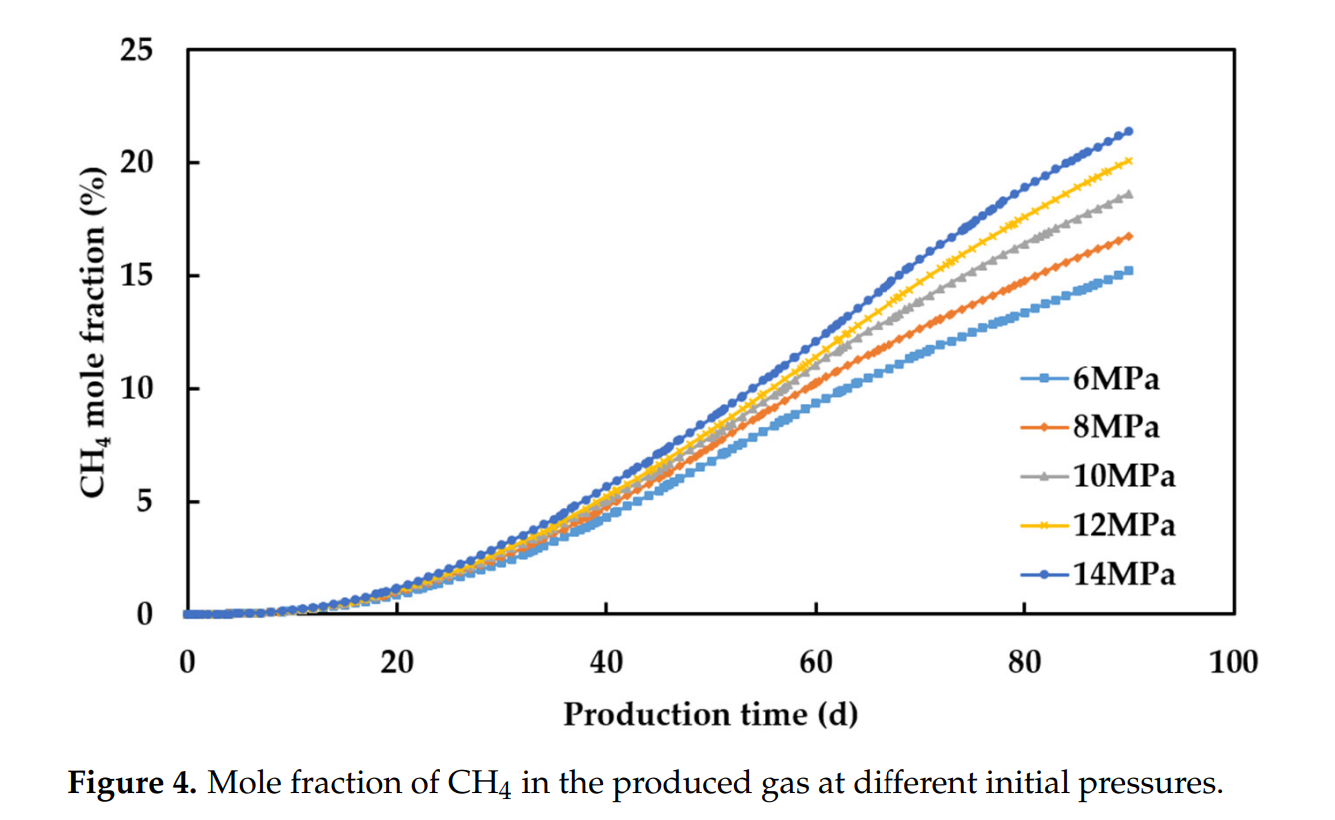

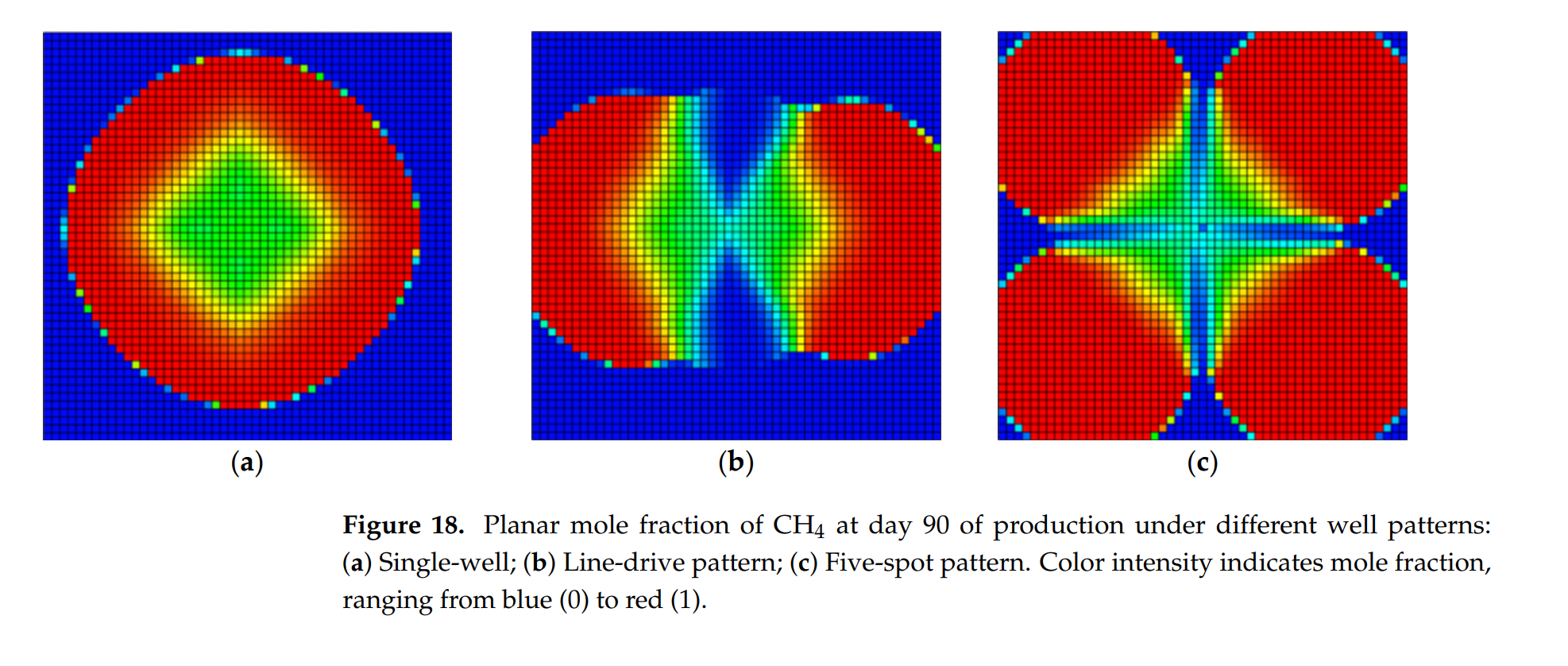

结果表明:①CH₄ 为最优垫底气,5 个注采周期内氢采收率提高 5.81%;②单井模式下采出 CH₄ 摩尔分数常>15 %,五点井网可将其降至 3.05 %,氢纯度达 96.95 %;③反韵律且层间渗透率差异小的储层最利于获得高采收率-高纯度;④产氢速率越大,纯度降幅越大(最高降 5.33 %),注氢速率影响微弱;⑤考虑净化成本与井身材料费用,五点井网的平准化储氢成本最低(0.29 $ kg⁻¹),经济最优。研究为含水层 UHS 的垫底气筛选、井网部署和现场操作提供了可直接落地的量化依据。

CMG 软件应用情况

- 使用模块:CMG-GEM(组分模型,适用于多组分气体扩散、溶解、相态变化)。

- 模型设定:

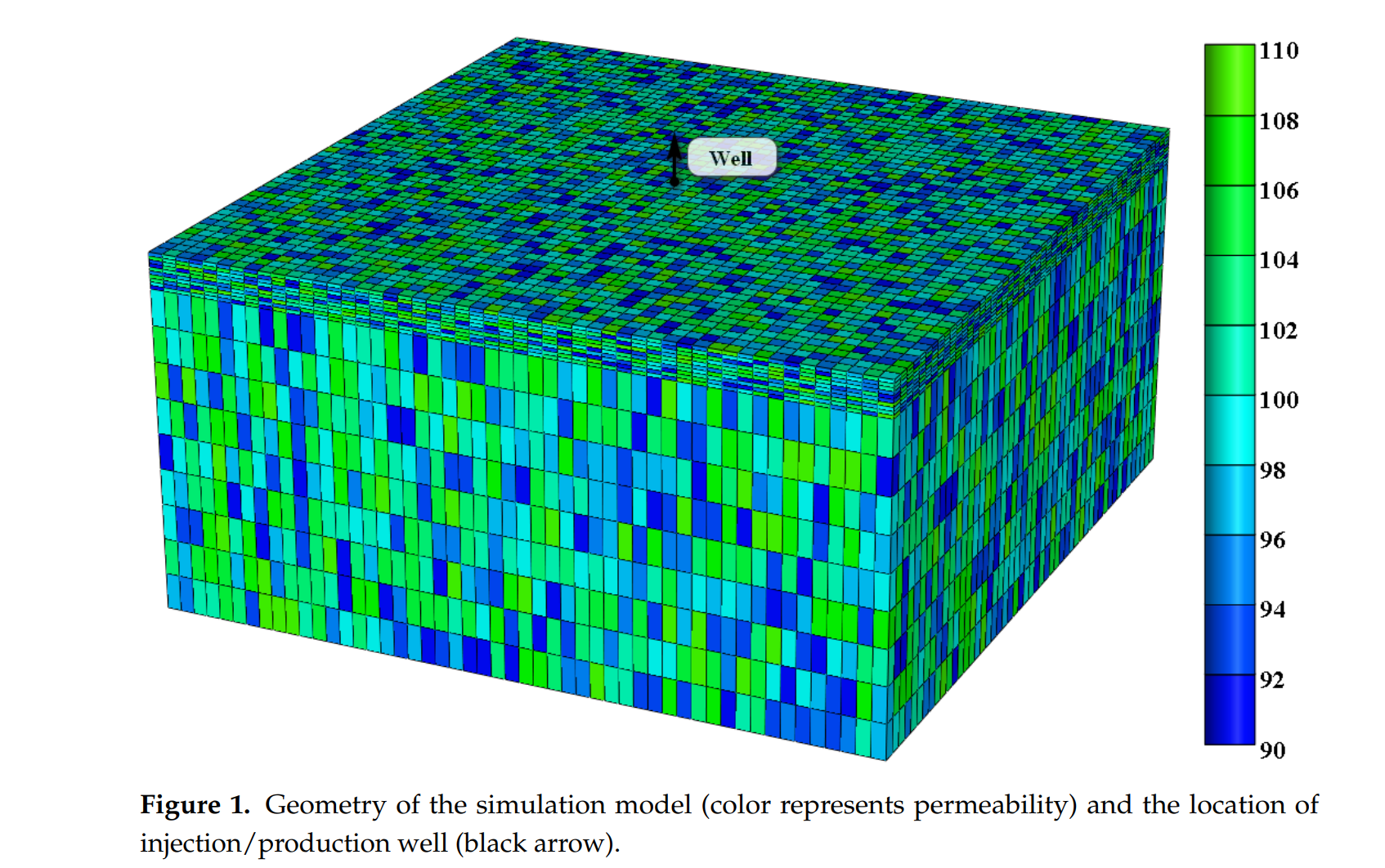

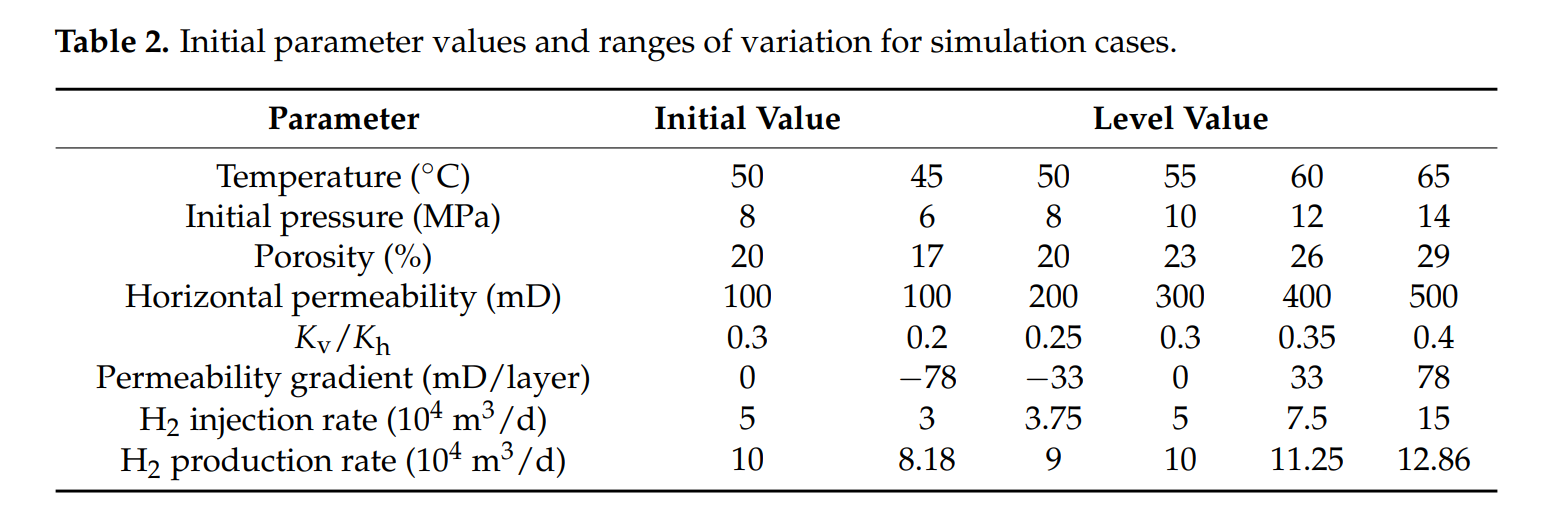

– 三维 Cartesian 网格 51×51×19(顶部 0.5 m 细网格),顶深 800 m,温度 50 ℃,初始压力 8 MPa;

– 基质渗透率 100 mD(Kv/Kh=0.3),孔隙度 20 %,水体初始饱和度 1;

– 采用 Brooks-Corey 毛管力、Corey 相对渗透率,Peng-Robinson EOS + Henry 定律计算气体溶解度;

– 粘度模型:Yoon-Thodos → Herning-Zipperer → Jossi-Stiel-Thodos 三步法。 - 模拟流程:垫底气先注 6 个月→静停 8 个月→进入 5 年期“注-停-采”循环(每周期 6-3-3 个月)。

- 研究功能:

– 对比三种垫底气、八因素灵敏度、三种井网共 60+ 方案;

– 输出氢采收率、采出组分、压力-饱和度场,用于纯度-经济耦合分析;

– 结合净化成本公式与井口成本模型,计算平准化储氢成本(LCHS)。

主要结论

- 垫底气优选:CH₄ 压缩因子高、分子量低,可显著提升氢采收率,综合性能优于 N₂ 与 CO₂。

- 井网优化:五点井网通过“角注中采”形成侧向压力屏障,抑制 CH₄ 突破,氢纯度由 83 % 提升至 97 %,为经济最优方案。

- 储层选择:反韵律且渗透率差异小的含水层可同时获得高采收率与高纯度;正韵律层易致垫底气早期突破。

- 操作参数:产氢速率是纯度最敏感操作变量,应控制在 10×10⁴ m³ d⁻¹ 以下;注氢速率影响可忽略。

- 经济评价:五点井网因纯度最高,净化成本由 2.14 kg⁻¹,总平准化成本最低(0.29 $ kg⁻¹)。

作者单位

中国石油大学(华东)石油工程学院

Abstract

Underground hydrogen storage in aquifers is a promising solution to address the imbalance between energy supply and demand, yet its practical implementation requires optimized strategies to ensure high efficiency and economic viability. To improve the storage and production efficiency of hydrogen, it is essential to select the appropriate cushion gas and to study the influence of reservoir and process parameters. Based on the conceptual model of aquifer with single-well injection and production, three potential cushion gas (carbon dioxide, nitrogen and methane) were studied, and the changes in hydrogen recovery for each cushion gas were compared. The effects of temperature, initial pressure, porosity, horizontal permeability, vertical to horizontal permeability ratio, permeability gradient, hydrogen injection rate and hydrogen production rate on the purity of recovered hydrogen were investigated. Additionally, the impact of different well pattern on the purity of recovered hydrogen was studied. The results indicate that methane is the most effective cushion gas for improving hydrogen recovery in UHS. Different well patterns have significant impacts on the purity of recovered hydrogen. The mole fractions of methane in the produced gas for the single-well, line-drive pattern and five-spot pattern were 16.8%, 5%, and 3.05%, respectively. Considering the economic constraints, the five-spot well pattern is most suitable for hydrogen storage in aquifers. Reverse rhythm reservoirs with smaller permeability differences should be chosen to achieve relatively high hydrogen recovery and purity of recovered hydrogen. An increase in hydrogen production rate leads to a significant decrease in the purity of the recovered hydrogen. In contrast, hydrogen injection rate has only a minor effect. These findings provide actionable guidance for the selection of cushion gas, site selection, and operational design of aquifer-based hydrogen storage systems, contributing to the large-scale seasonal storage of hydrogen and the balance of energy supply and demand.