Assessment of Carbonated Brine Injection as Low-risk Strategy for Geologic Carbon Storage

- 这项早期研究的主要目标是评估在威利斯顿盆地北达科他州部分使用盐水溶解法对SWD井进行盐水和二氧化碳混合储存的技术经济可行性和相关风险。

- 研究包括三个模拟项目:(1) 不同条件下的二氧化碳相态,(2) 井筒相容性,以及 (3) 储层中长期储存情况。

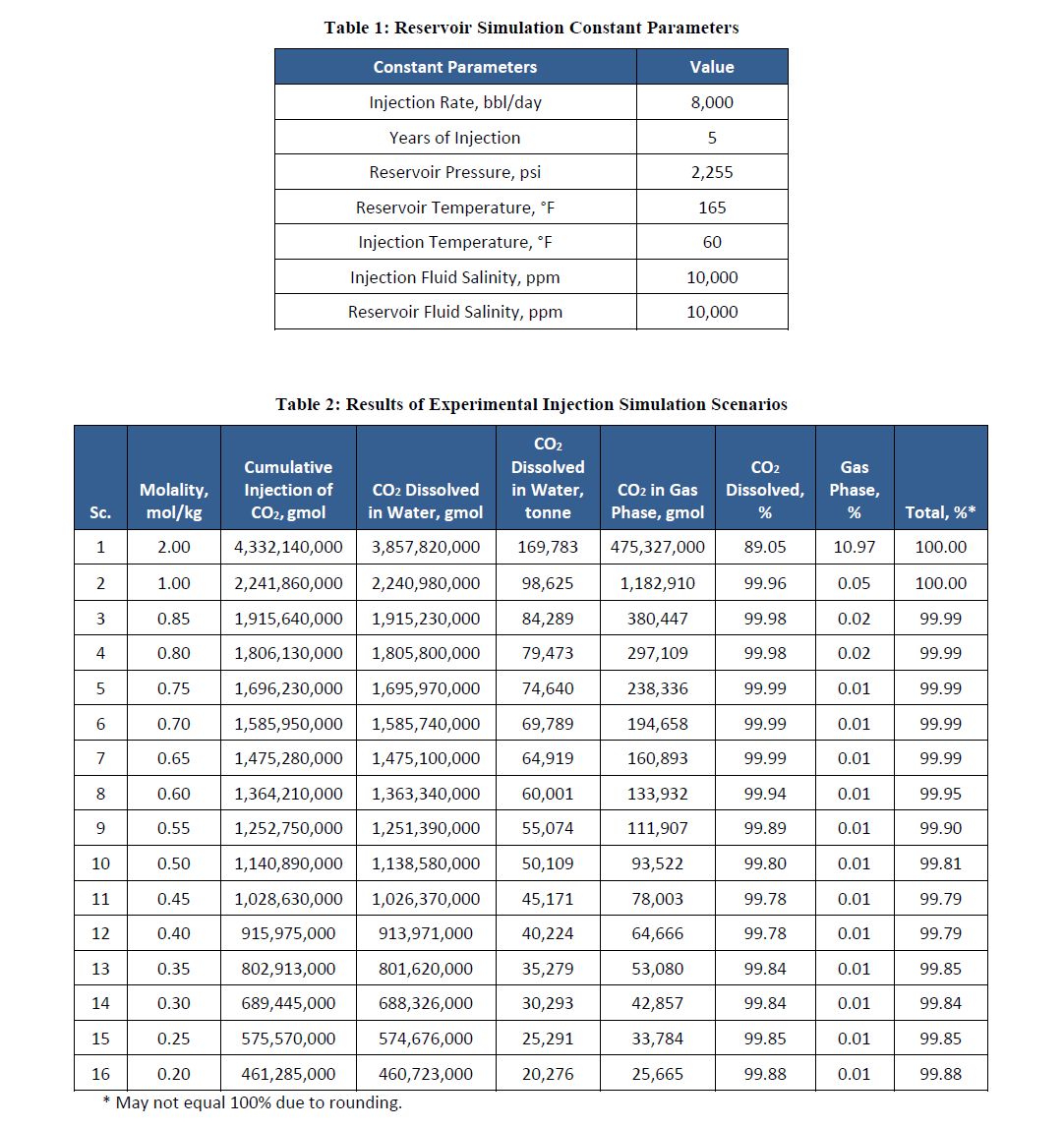

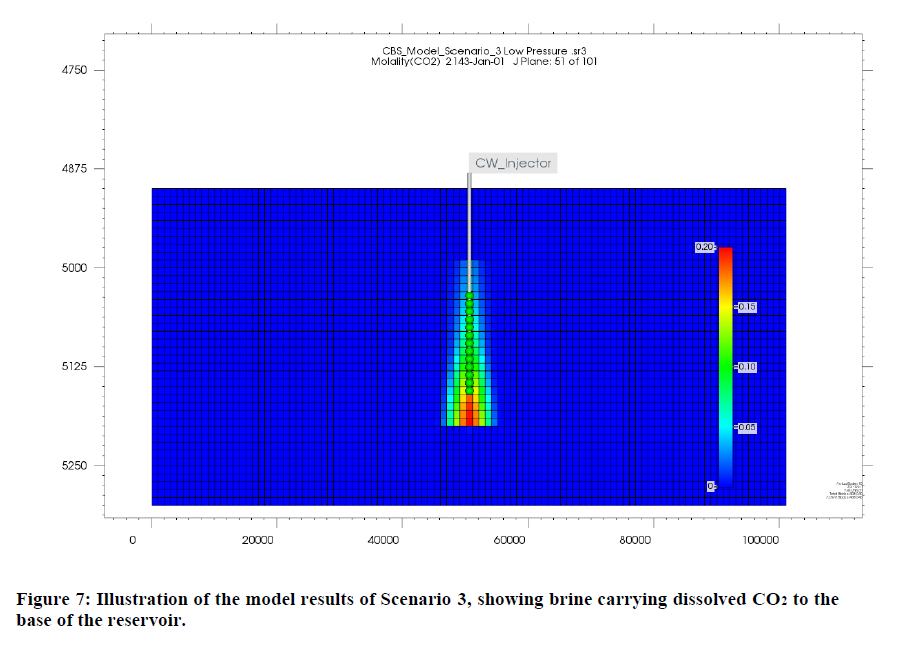

- 首先建立了一个简单的储层模型和注入模拟数据,代表了位于北达科他州沃特福德城附近的BEST(盐水提取和储存测试)场地。模拟了在砂岩油藏中注入CO2导致的压力演变,以及整个项目期间水溶性CO2的情况。模拟考虑了注入水的盐度变化、储层盐水盐度以及溶解在注入水中的CO2量。

- 然后,使用基于沉积模拟选择的CO2浓度进行井筒腐蚀模拟,以研究产生的碳化物对井筒的影响。

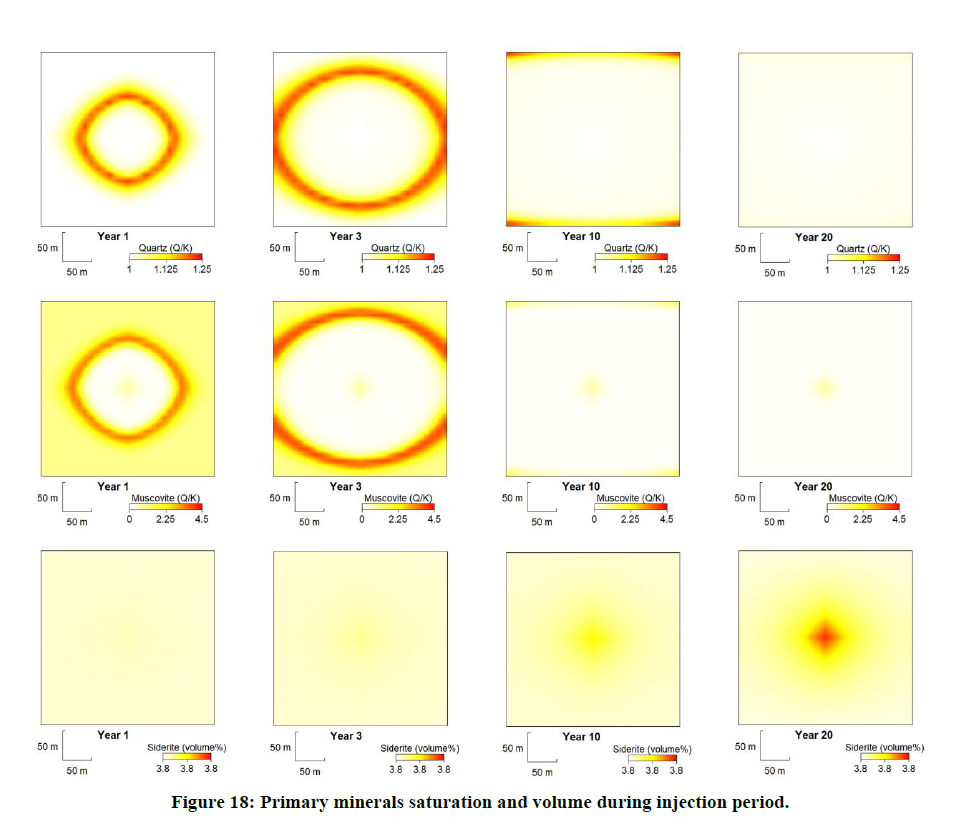

- 最后,使用最佳的CO2浓度进行反应传质模拟研究,探讨岩石和流体之间的相互作用,以及CO2在储层中的演变情况。

- 研究结果显示,溶解在产出水中的CO2可以安全注入,而不会显著增加地下压力或泄漏风险。压力增加与盐度有关,但与CO2质量分数无关。研究表明,在较高盐度注入时,较低的CO2质量分数可溶解更多的CO2。

- 此外,传统碳储存项目中,溶解气体的目标从一开始就已实现,降低了与浮力CO2潜在运移相关的风险,只要确定储层压力和温度下溶解CO2的最大质量分数即可。

Abstract

The main objective of this early-phase research was to evaluate the techno-economic feasibility and risk associated with combined brine and CO2 storage in SWD wells using brine dissolution in the North Dakota portion of the Williston Basin. Three simulation studies were conducted to investigate: (1) CO2 phases at different conditions, (2) wellbore compatibility, and (3) long-term storage fate in reservoir. (1) A simple reservoir model and injection simulations were created using data to represent the BEST (brine extraction and storage test) site, an operational SWD facility located near Watford City, North Dakota. The pressure evolution caused by CO2 comingled in produced water injectate in a layer cake reservoir was then modeled while tracking aqueous CO2 throughout the project. The salinity of the injection water, the salinity of the reservoir brine, and the amount of dissolved CO2 comingled in the injection water were varied. (2) A wellbore corrosion model was performed using the CO2 concentrations selected based on the reservoir modeling to examine the carbonated produced water impact on wellbore. (3) Reactive transport modeling was conducted with the optimal CO2 concentration for this injection site to study the rock-fluid interactions and CO2 fate in the reservoir.

Results suggest that CO2 dissolved in produced water can be injected without appreciably increasing subsurface pressure or leakage risks. Pressure buildup was found to vary with salinity but not with CO2 mass fraction.

Simulation results show that lower CO2 percent mass fraction leads to a higher amount of CO2 that can be dissolved at a higher injection salinity. Furthermore, the long-term goal of dissolution trapping in a traditional carbon storage project is accomplished from the start, mitigating risks associated with potential migration of buoyant CO2, so long as the reservoir pressure and temperature are used to determine the maximum mass fraction of the dissolved CO2.

2.1 RESERVOIR MODEL SETUP

The Computer Modeling Group (CMG) simulation program was utilized in this project to create a reservoir model. Within the CMG launcher, several sub-programs were accessed to derive the desired simulation outcomes. Specifically, the Builder, GEM, and results graph components were employed to execute the simulations and procure the results. For this particular project, the Builder, GEM, and results graph functionalities were sufficient to conduct the simulations and achieve the desired outcomes.

The Builder component of CMG encompasses various aspects of data input, including grid creation, grid property definition, incorporation of production data, fluid properties, rock-fluid interactions, fluid models, and initial conditions. An assessment of CBI was conducted using representative data and properties from typical Williston Basin SWD wells that inject into the Inyan Kara Formation of the Dakota Group. The initial phase involved estimating the quantity of CO2 that could be injected at specific brine volumes and injection pressures. These parameters were established based on existing SWD operations, adhering to Class II injection regulations.

Numerical simulations of CBI into the targeted formation were carried out across 16 scenarios. The objective was to ascertain the maximum amount of CO2 that could be dissolved into the formation fluid, leaving no residual undissolved CO2. A consistent injection rate of 8,000 barrels per day over 5 years was adopted for all scenarios, mirroring the operational practices at SWD sites within the Williston Basin.