Geomechanical modeling of potential leakage pathways through caprocks at natural gas storage sites

Fugitive gas emissions are unintended releases of gas from energy processes. Natural gas emissions are composed mainly of methane and can contaminate groundwater or contribute to greenhouse gases after migrating from production wells or underground storage. As natural gas is relied on as a low-carbon energy option, more storage sites will be needed, increasing opportunities for gas leakage. This study investigated methane leakage from storage reservoirs due to injection induced caprock fractures by varying injection rate, gas temperature, and reservoir permeability and possible policy improvements to ensure safe gas storage.

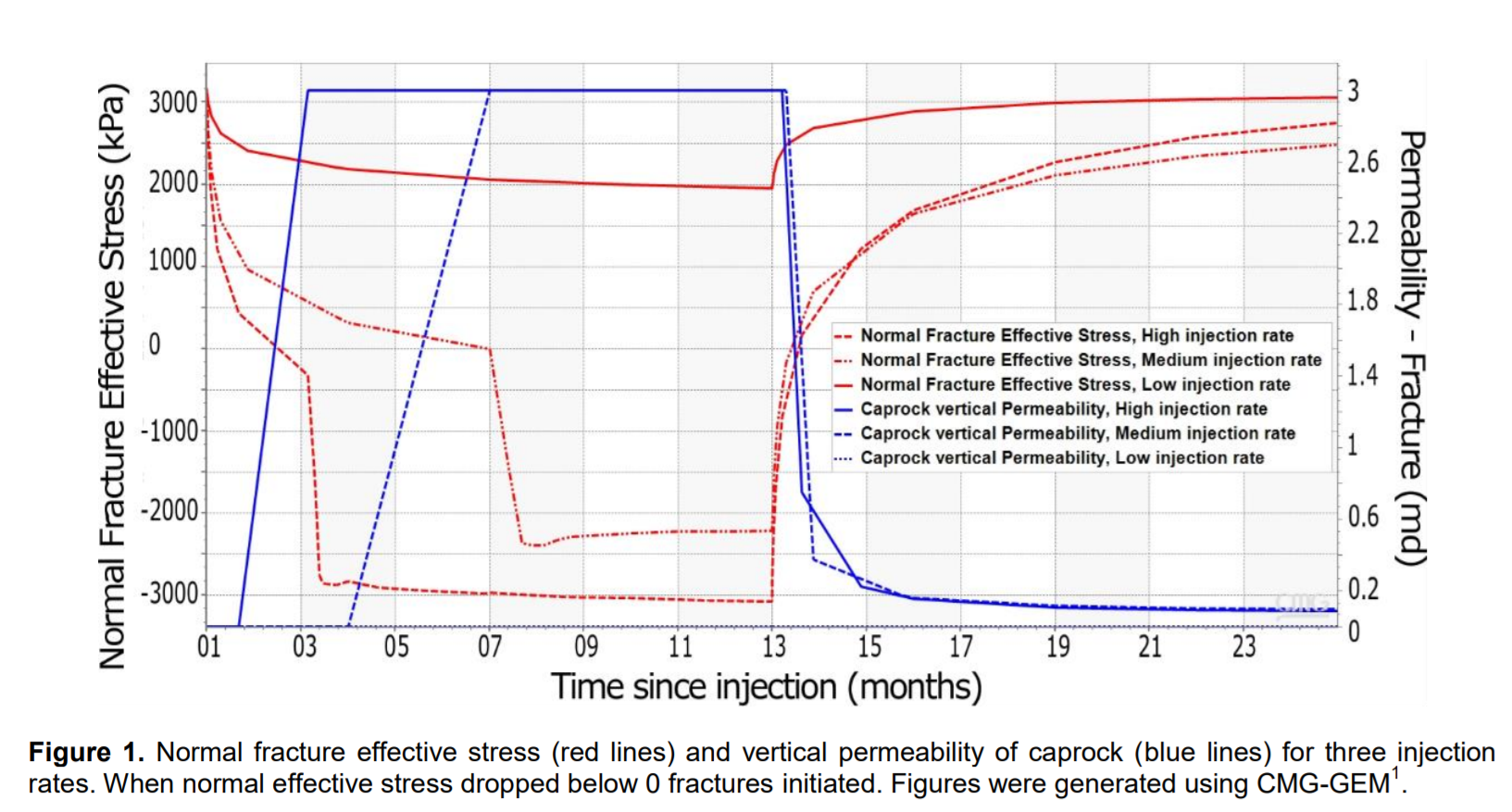

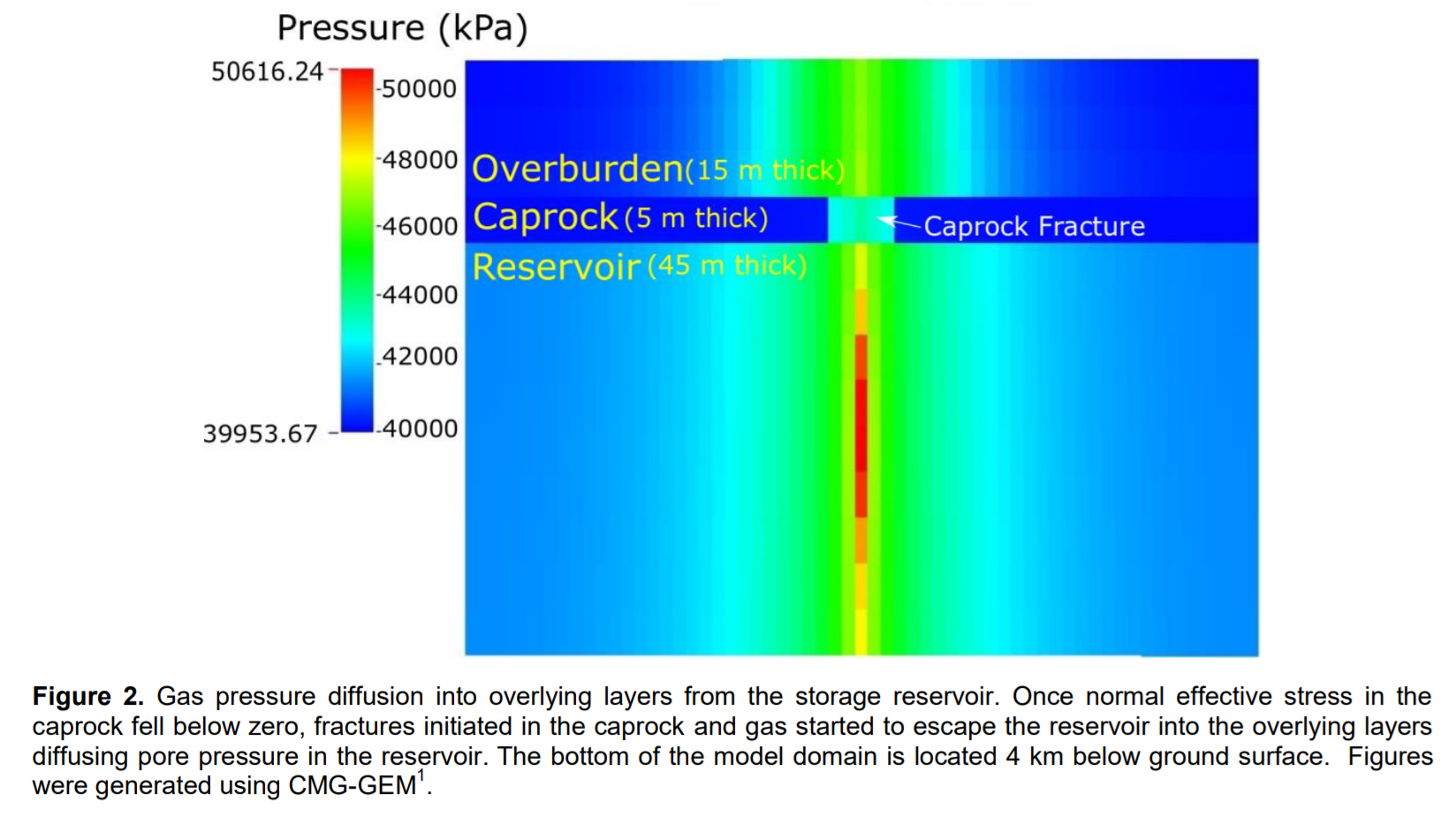

Sensitivity analyses were performed on a 3D thermo-hydro-mechanical model of a storage reservoir, caprock, and overburden layer using normal effective stress and vertical displacement as metrics for fracture development. Analyses used coupled fluid-flow and geomechanics simulator CMG (Computer Modeling Group) GEM-2019. Higher injection rates-initiated fractures earlier than lower rates (Figure 1). Cooler gas temperatures reduced volumetric strain, which delayed caprock failure. Lower reservoir permeability slowed pressure diffusion which decreased effective stress around the well and initiated fractures earlier than higher permeability reservoirs. After fracture initiation, gas pressure diffused into caprock, and overburden (Figure 2) and gas saturation increased in layers overlying the reservoir.

The results showed the importance of injection rate and reservoir characterization for optimizing injection parameters and reducing gas permeable fractures. For instance, reservoir permeability controlled the onset of fracture initiation, and cooler gas delayed fracturing in fault-free reservoirs such as the one modeled but may reactivate any pre-existing faults.