Horizontal Well Spacing and Hydraulic Fracturing Design Optimization: A Case Study on Utica-Point Pleasant Shale Play

Abstract

Recent drilling and hydraulic fracturing activities in the Utica-Point Pleasant shale play have recorded true vertical depth of over 13,500 feet. Drilling wells at this depth is very costly and challenging. With the current commodity pricing, drilling in such conditions becomes unaffordable.

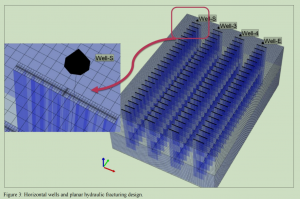

One immediate solution to the current low energy prices is optimizing well spacing to enhance hydrocarbon recovery and, thus, the commercial feasibility of the project. Horizontal well spacing constitutes a fundamental parameter for the success of a shale-drilling venture. Determining the optimum horizontal well spacing in shale reservoirs represents a challenging task because of the complexity of controlling factors. These factors can be categorized into three groups: geological, engineering, and economic.

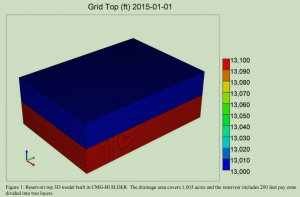

Geological modeling and reservoir simulation are the standard tools utilized in the industry to integrate these controlling factors. In this study, we employed these tools to perform sensitivity analysis of reservoir characteristics and future production optimization for a deep drilling case study in the Utica-Point Pleasant formations. We sought to find the optimum horizontal well spacing scenario as well as hydraulic fracturing design, in order to attain the highest net present value for 50 years of gas production. Our reservoir model represented a portion of Utica-Point Pleasant formations at the depth of 13,000 feet and the dry gas window. A commercial reservoir simulator was coupled with an optimization algorithm to reach the best solution with a minimum simulation cost. Although the outcome of our study is subjective to the chosen asset, the workflow provides a good example of horizontal well spacing and hydraulic fracturing design optimization.