Water-Soluble Solvent as an Additive to Steam for Improved SAGD

SPE-184983-MS

本研究旨在探讨将水溶性溶剂作为蒸汽添加剂以降低蒸汽-油比(SOR)的同时保持类似SAGD的采收率的潜力。通过热力学预测和数值油藏模拟,研究了与蒸汽共注入二甲醚(DME)作为水溶性溶剂对艾伯塔油砂的影响。研究结果表明,与传统SAGD相比,DME-SAGD能够显著降低SOR,并提高采收率。DME在水中的溶解度不仅使腔边缘温度高于C4-SAGD,而且比C4-SAGD的溶剂回采率高出15%。DME在水和油中的溶解特性,以及其在蒸汽腔边缘附近形成的近乎等密度的水相和油相,有助于减少油水两相流的重力分异,从而促进DME与油砂的混合。

CMG软件应用情况:

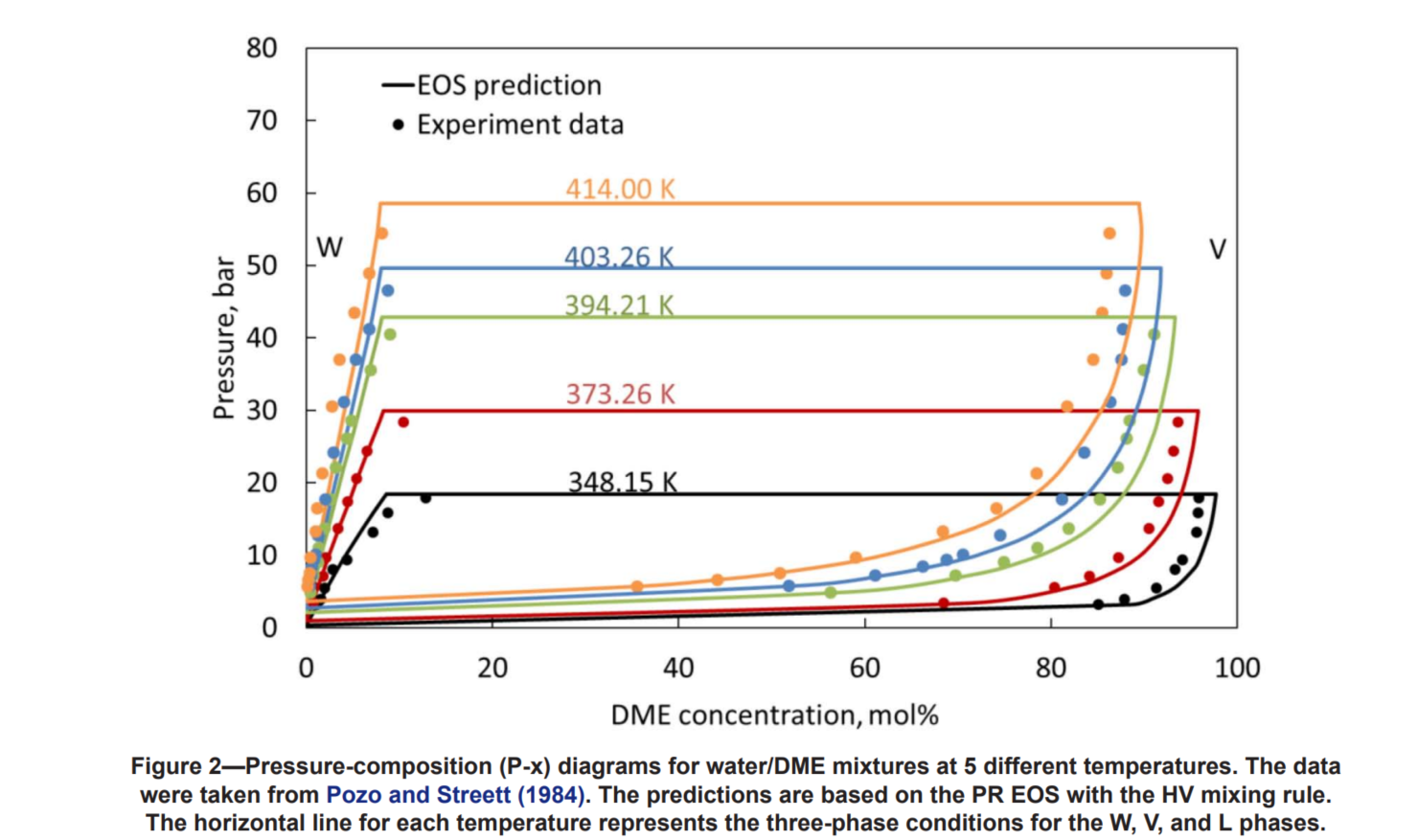

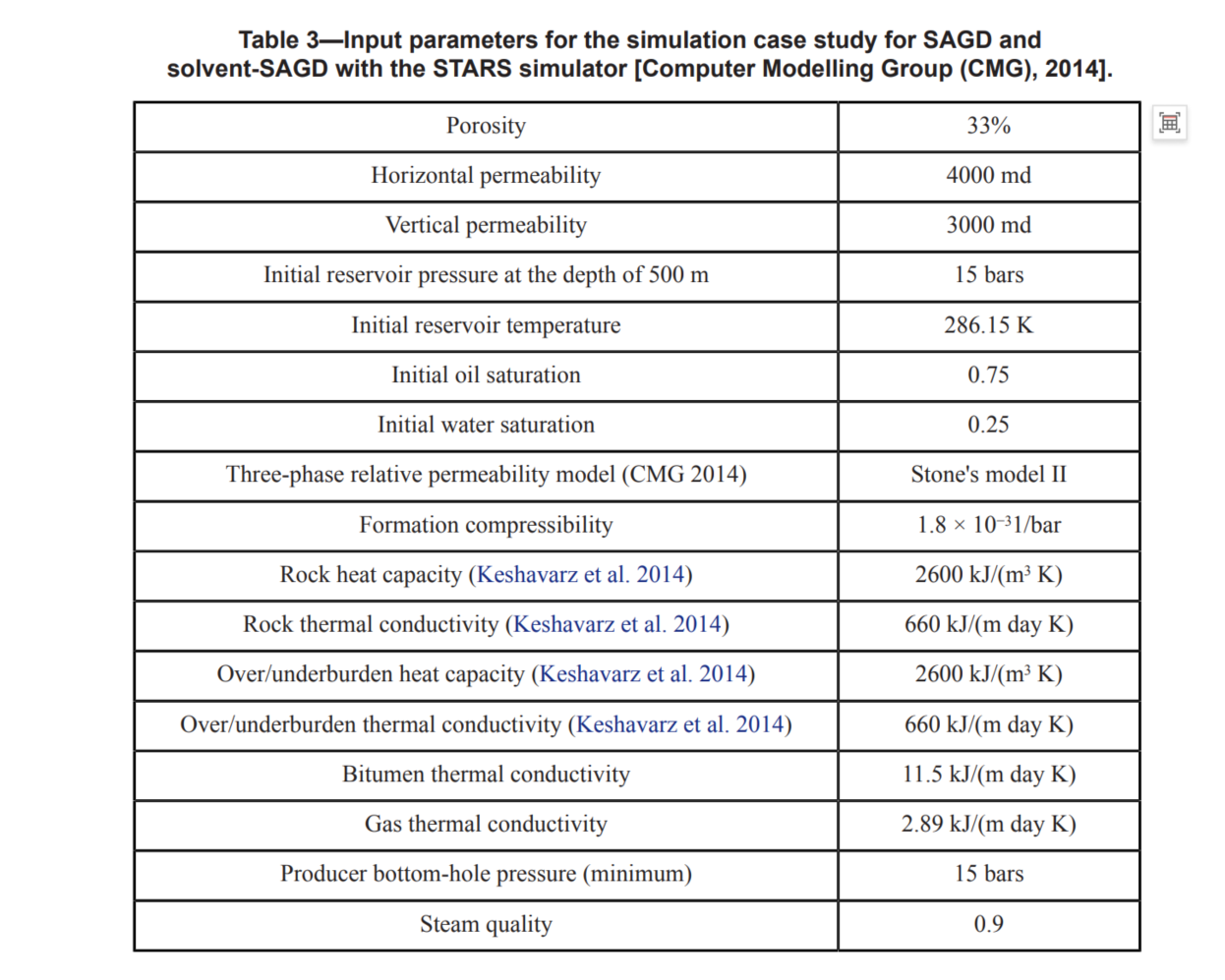

在本研究中,使用了CMG(Computer Modelling Group)公司的STARS模拟器来模拟SAGD、DME-SAGD和C4-SAGD过程。模拟了一个70 m(x)× 37.5 m(y)× 20 m(z)的均质油藏的一半蒸汽腔。油藏被离散化为70 × 1 × 20个网格;也就是说,这是一个垂直二维模型。初始油藏温度为286.15 K,压力为15 bar。生产井位于油藏底部上方3米处,注入井位于生产井上方4米处。注入和生产井分别在35 bar和15 bar下操作。所有模拟运行了10年,首先预热6个月,然后共注入2 mol%的溶剂直到蒸汽腔到达油藏模型的侧边界。之后注入90%干度的100%湿蒸汽直到操作结束。STARS模拟器用于模拟Vapor相密度,液相密度通过混合规则计算。DME的粘度和密度模型也进行了调整以拟合实验数据。

结论:

- DME作为水溶性溶剂,在DME-SAGD过程中,尽管其挥发性高于C4,但由于其在水中的溶解度,使得腔边缘温度高于C4-SAGD。

- DME在油中的溶解度约为C4的一半,但在DME-SAGD模拟中,约47 mol%的DME用于稀释油,这与C4-SAGD中用于油稀释的C4比例相当。

- DME-SAGD中溶剂的蒸汽分数远小于C4-SAGD,且注入的DME可以通过油相和水相回收,因此DME-SAGD的溶剂回采率比C4-SAGD高约15%。

- DME-SAGD相较于传统SAGD能够降低35%的SOR,同时保持类似的采收率,并且最终的油回采率比SAGD高出5%。

作者单位:

德克萨斯大学奥斯汀分校

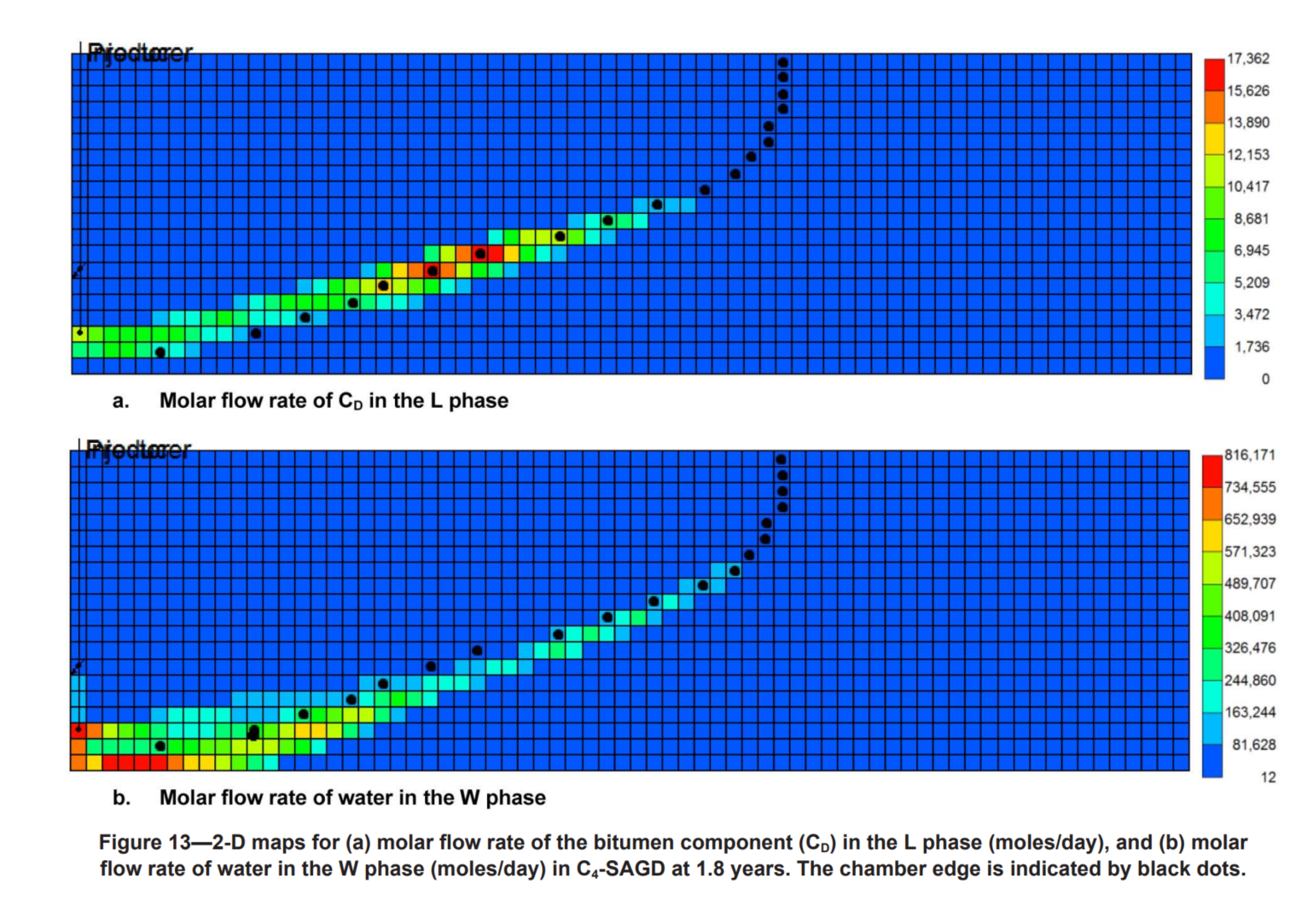

Abstract

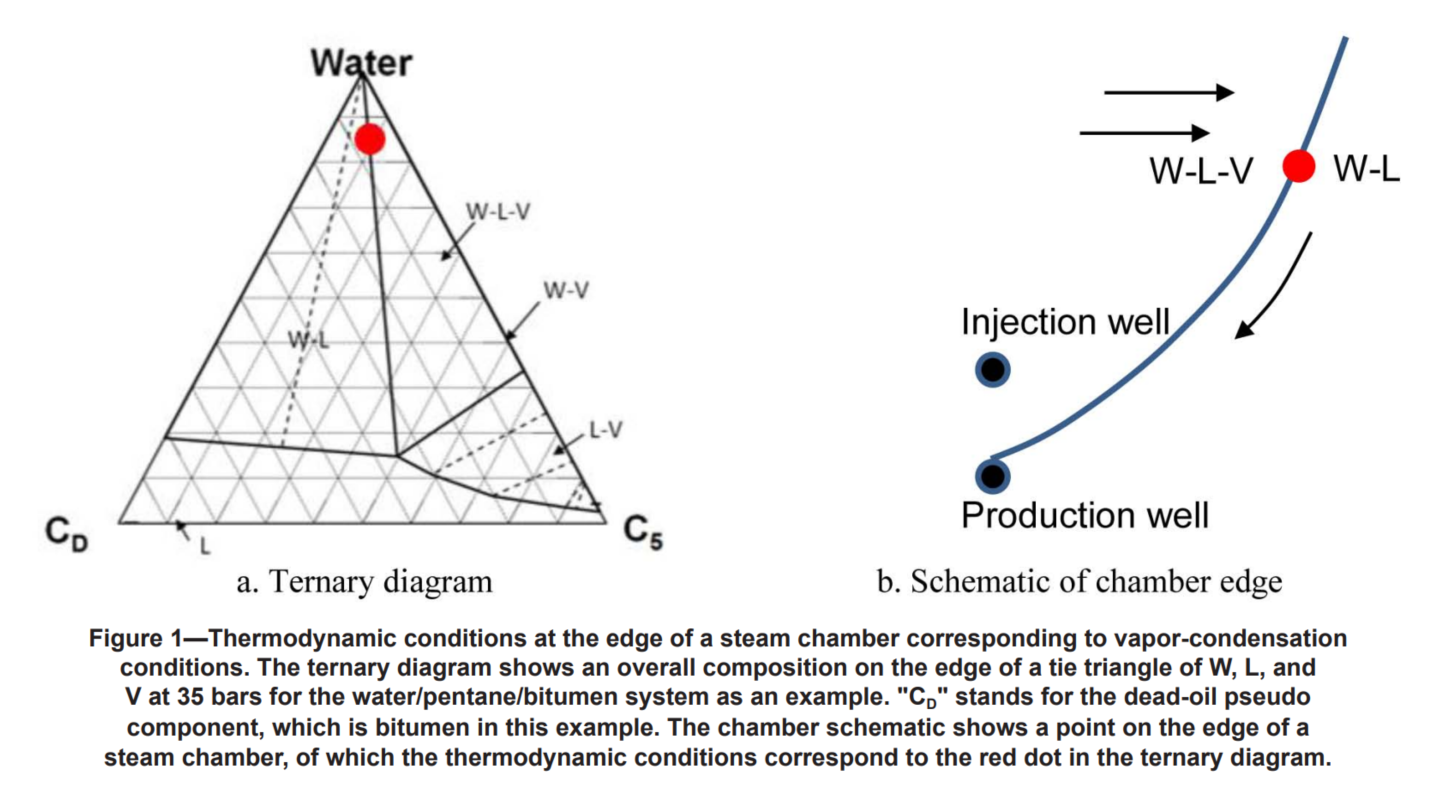

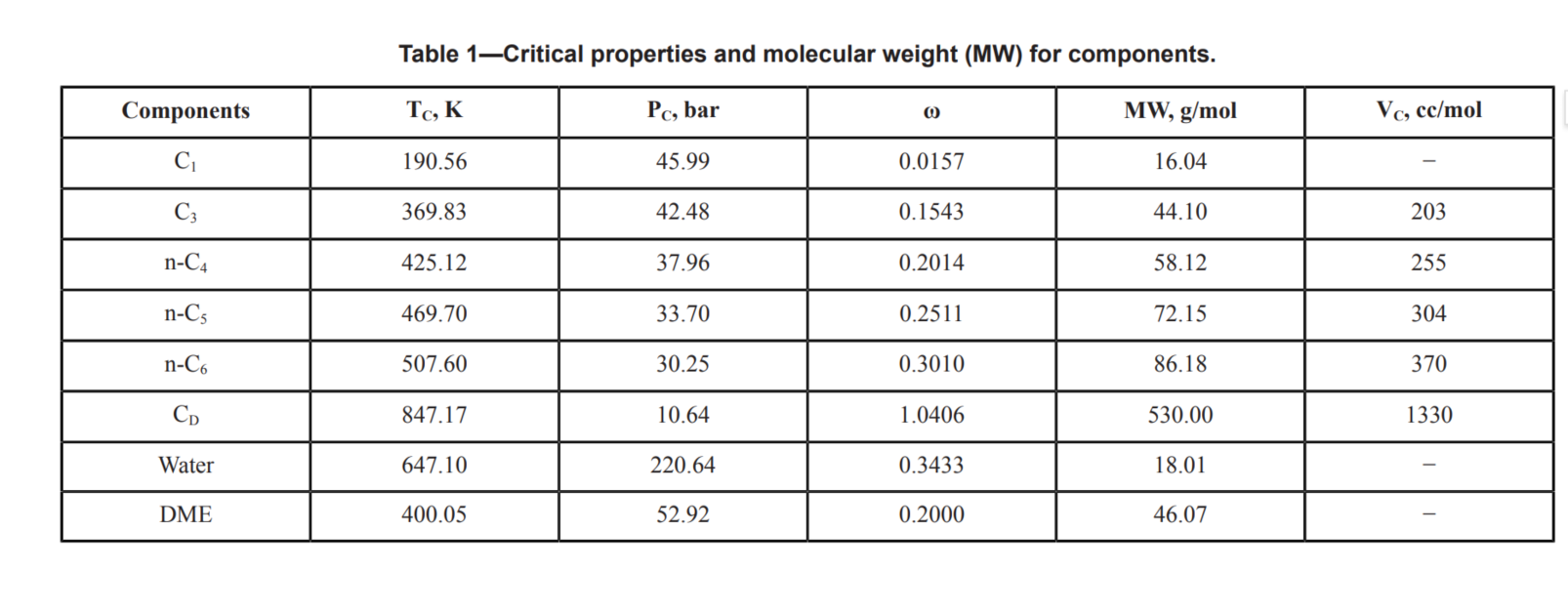

Coinjection of solvent with steam results in lower chamber-edge temperatures than those in steam-assisted gravity drainage (SAGD), which enable to decrease heat losses to the overlying formation rocks. However, use of highly volatile solvents, such as propane, can yield significantly slow bitumen production due to low chamber-edge temperatures. The objective of this research is to investigate the potential of water-soluble solvent as an additive to steam for reducing steam-oil ratio (SOR) while keeping SAGD-like rates of bitumen production. The chamber-edge temperature for a given overall composition and operating pressure is defined as the temperature at which the vapor phase completely condenses with decreasing temperature. Thermodynamic predictions show that the chamber-edge temperature so defined will increase substantially if the solvent can partition into the aqueous phase at chamber-edge conditions. This is confirmedin numerical reservoir simulation for coinjection of steam with dimethyl ether (DME), as a water-soluble solvent, for Athabasca bitumen. In simulation case studies, coinjection of steam with DME (DME-SAGD) is compared with SAGD and coinjection of steam with C4 (C4-SAGD), in terms of SOR, bitumen production, local displacement efficiency, and solvent recovery. The steam-injection pressure is 35 bars for all cases, and 2 mol% of solvent is coinjected in solvent-SAGD simulations until the steam chamber reaches the side boundary of a 2-D homogeneous reservoir model. DME is more volatile and less soluble in bitumen than C4 at their corresponding chamber-edge conditions. However, results show that DME-SAGD results in 35% lower SOR than SAGD while being able to increase bitumen-production rates of SAGD. Analysis of simulation results indicates that the solubility of DME in water not only makes the chamber-edge temperature higher than that of C4-SAGD, but also yields15% higher solvent-recovery factor than C4-SAGD. The main reason for the latter observation is that a much smaller fraction of the injected solvent is present in the vapor phase in DME-SAGD than in C4-SAGD. Also, DME dissolves in both water and bitumen, which results in the aqueous and oleic phases of nearly-equal density within the gravity-drainage zone near the edge of a steam chamber. This is the neutral regime of oil-water two-phase flow along the chamber edge between the two extreme cases: SAGD and C4-SAGD. Unlike in C4-SAGD, the reduced gravity segregation in DME-SAGD is expected to facilitate the mixing of condensed solvent with bitumen near the edge of a steam chamber.