Workflow for Integrating Geomechanics, Hydraulic Fracturing, and Reservoir Simulation to Determine Marcellus Shale Horizontal Well Production Potential

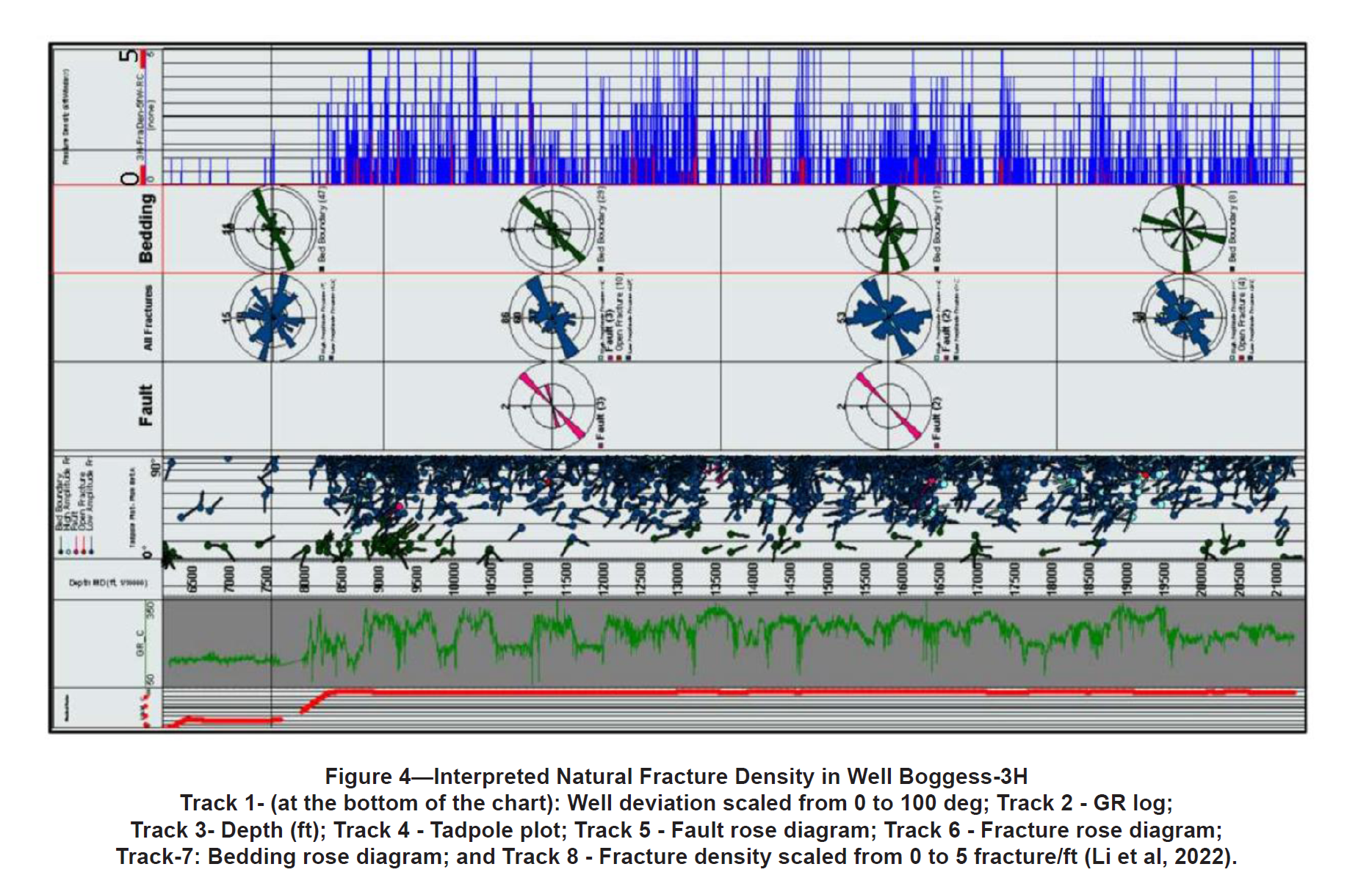

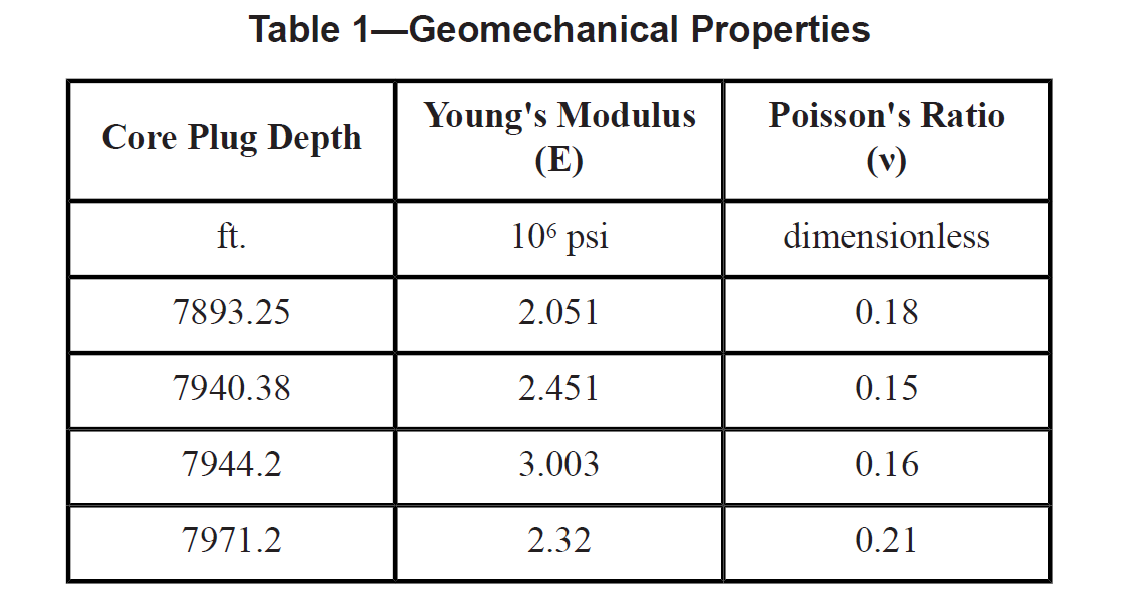

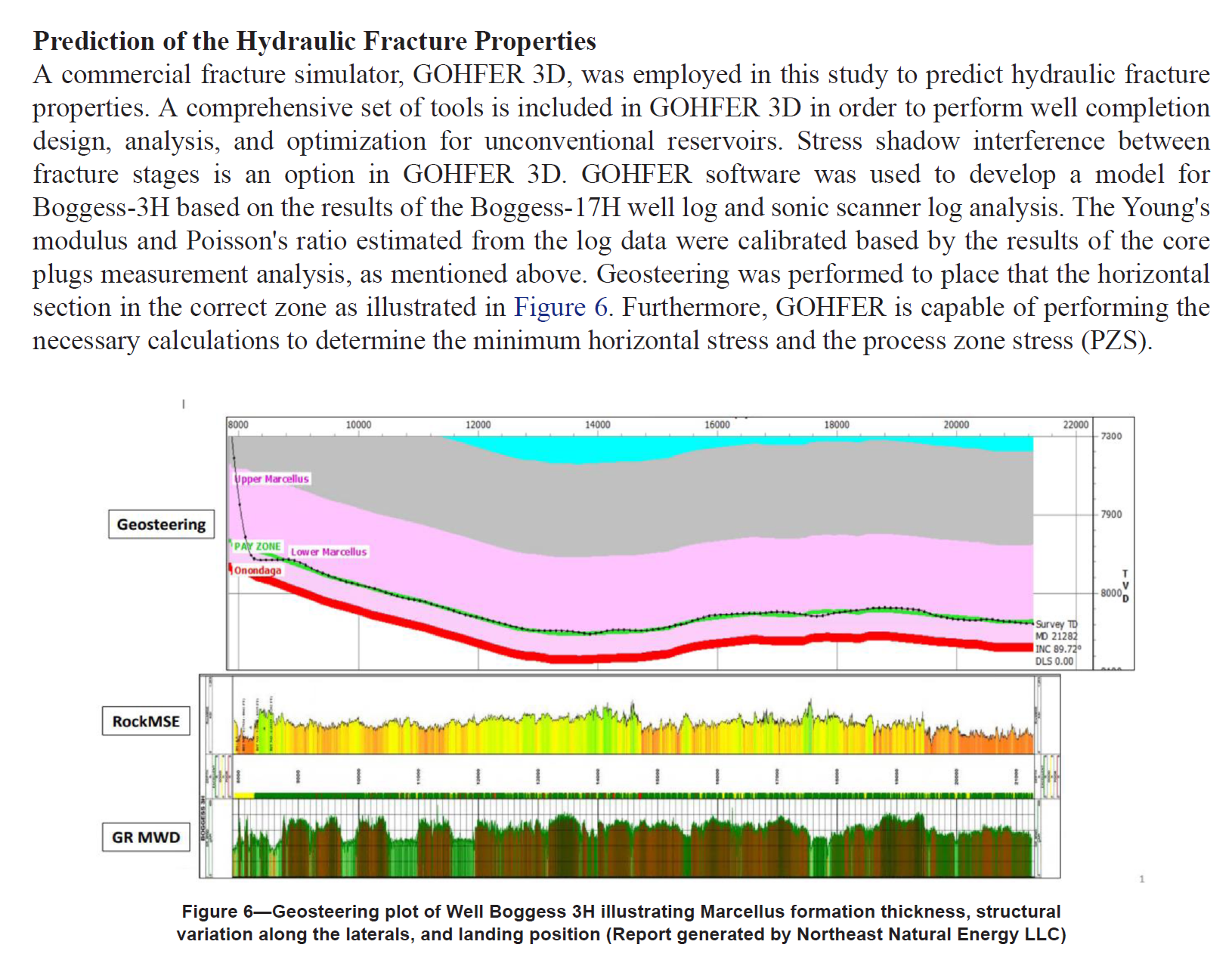

A workflow for data analysis and model development for accurate prediction of the gas production from a Marcellus shale horizontal well with multiple hydraulic fracture stages was developed and implemented. The available data from a Marcellus shale horizontal well were collected, analyzed, and utilized to develop a reservoir simulation model. The properties of the hydraulic fractures were determined from the fracture treatment data and the mechanical properties by employing a commercial fracturing software which accounting for the impact of the stress shadowing. The available core plugs measurements, well logs, and the image logs were analyzed to determine the shale petrophysical and geomechanical properties including natural fracture (fissure) distribution. The available laboratory measurements and published data were analyzed to determine the gas adsorption characteristics and the shale compressibility. The impact of the shale compressibility was then incorporated in the model by developing multipliers for different s components of the compressibility, i.e., fissure permeability, matrix permeability, and hydraulic fracture conductivity as function of net stress.

The model provided accurate prediction of the gas production which was confirmed by comparison against the production data. The inclusion of the compressibility multipliers (matrix, fissure, and hydraulic fracture), stress shadow-impacted hydraulic properties, and adsorbed gas were critical for achieving accurate gas production predictions. The low stress barriers between Marcellus shale and the upper zone caused the hydraulic fractures to grow in upward direction from Marcellus Shale and reduced efficiency of the hydraulic fractures. The compressibility and stress shadowing were found to negatively impact the gas production, particularly during the early stages of the production (1-5 years). The workflow developed in this study can be used to accurately predict the gas production and determine the optimal hydraulic fracture spacing for horizontal shale wells with multiple hydraulic fracture stages.

开发并实施了一个数据分析和模型开发的工作流程,用于准确预测具有多个水力压裂阶段的Marcellus页岩水平井的天然气产量。收集、分析了Marcellus页岩水平井的可用数据,并利用这些数据建立了储层模拟模型。水力裂缝的性质是通过使用商业压裂软件根据裂缝处理数据和力学性质确定的,该软件考虑了应力阴影的影响。分析了可用的岩心塞测量、测井和图像测井,以确定页岩的岩石物理和地质力学性质,包括天然裂缝(裂缝)分布。对现有的实验室测量结果和公布的数据进行了分析,以确定气体吸附特性和页岩压缩性。然后,通过开发可压缩性的不同s分量的乘数,即作为净应力函数的裂缝渗透率、基质渗透率和水力裂缝电导率,将页岩压缩性的影响纳入模型中。该模型提供了对天然气产量的准确预测,并通过与产量数据的比较得到了证实。包含压缩系数乘数(基质、裂缝和水力裂缝)、应力阴影影响的水力特性和吸附气体对于实现准确的天然气产量预测至关重要。Marcellus页岩与上部区域之间的低应力屏障导致水力裂缝从Marcellus泥岩向上生长,降低了水力裂缝的效率。压缩性和应力阴影对天然气生产产生了负面影响,尤其是在生产的早期阶段(1-5年)。本研究开发的工作流程可用于准确预测具有多个水力压裂阶段的水平页岩井的天然气产量和确定最佳水力压裂间距。

Conclusions

The following conclusions were reached during this study:

The impacts of the stress shadow and compaction must be considered for accurate prediction of thegas production from horizontal Marcellus shale with multiple hydraulic fracture stages.

Stress Shadow has a negative impact on gas production, particularly during the early stages of theproduction (1-5 years).

Compaction has more impact on gas production as compared to the impact of the stress shadow s dueto Marcellus shale’s low Young’s modulus and high density of natural fractures along the horizontallength.

Ignoring the impacts of the stress shadow and compaction leads to over-estimation of the gas recovery.