A review of design factors in steam and gas push for eco-friendly oil sands production and its field application in Canada

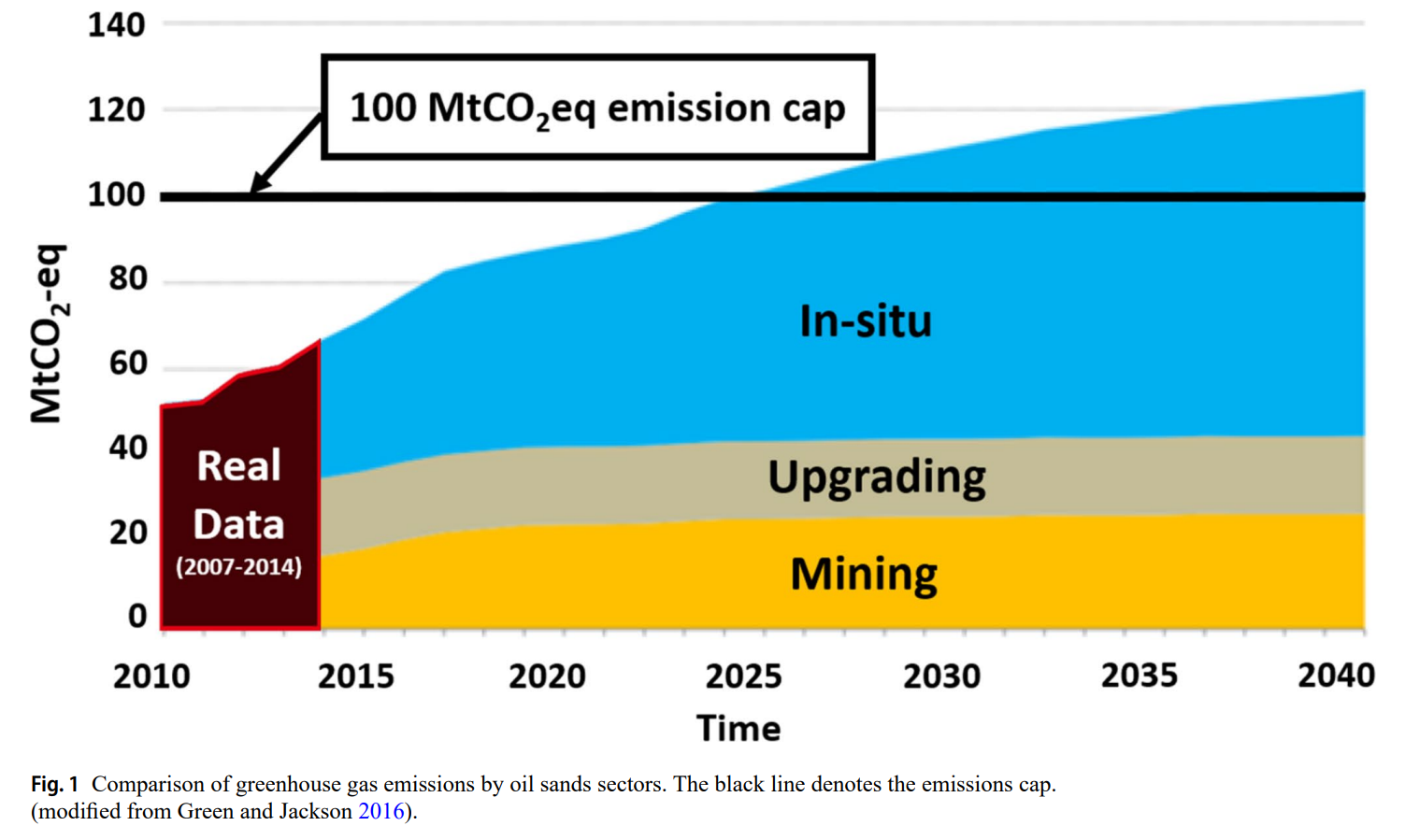

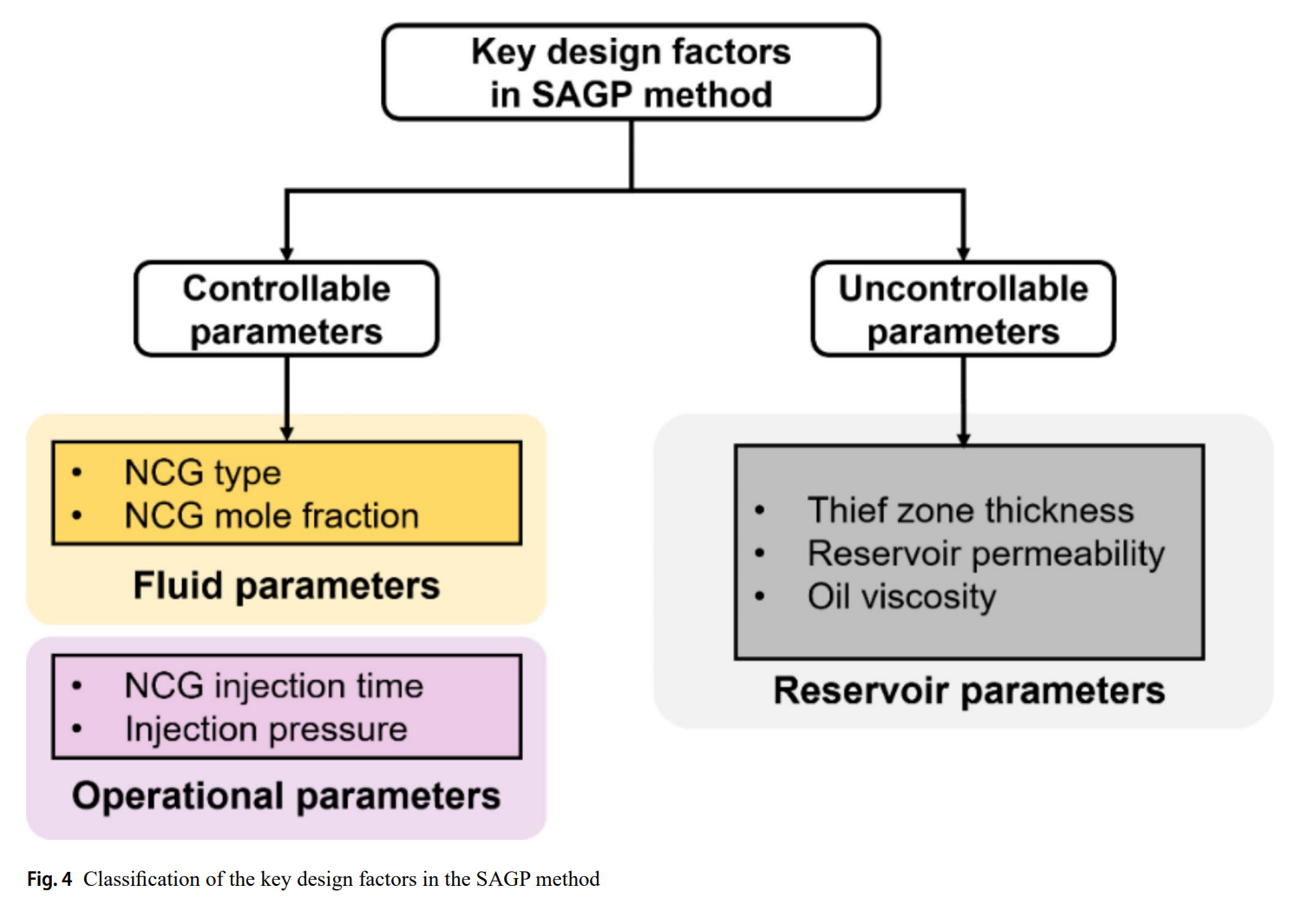

蒸汽与气体辅助重力泄油(SAGP)技术通过与蒸汽共注入非冷凝气体(NCG),减少温室气体排放,防止热量损失到盗气层,并维持蒸汽腔的压力和温度。然而,NCG可能会阻碍蒸汽腔的扩展,导致产油量低于蒸汽辅助重力泄油(SAGD)。此外,根据给定的油藏条件确定NCG的类型、浓度和注入时间是一个挑战。氮气和甲烷因其在油中的低溶解度而常用于NCG,但超过3 mol%的浓度通常会降低SAGP的效率。为了防止NCG干扰蒸汽腔,建议注入压力为油藏压力的0.95-1.1倍,NCG注入时间为总生产周期的0-0.6倍。

数值模拟表明,与从一开始就注入NCG相比,在总8年生产周期的0.125、0.25和0.375倍时注入NCG,累计产油量分别增加了18.6%、163.7%和218.6%。油藏参数的敏感性范围包括:贼气层厚度(0-0.5倍油藏厚度)、砂岩的垂直与水平渗透率比(0.3-0.65)以及基于加拿大主要油砂区的原油黏度(12°C时,阿萨巴斯卡为200万cp,和平河为20万cp,冷湖为6万cp)。贼气层越厚,热量损失越大,垂直渗透率越高,蒸汽室上升越快,需要更早注入NCG。此外,低油黏度区域更适合SAGP。Suncor Firebag项目的应用表明,NCG将累计蒸汽-油比从3.14降低到2.76,证明了SAGP的有效性。

CMG软件应用情况

本文使用了CMG(Computer Modelling Group)的STARS软件进行数值模拟研究。STARS是一个商业化的数值模拟器,广泛应用于能源行业的油藏模拟。研究中通过STARS软件模拟了SAGD、SAGP和eMSAGP(增强型改良蒸汽与气体推送)三种方法在油砂开采中的表现。模拟结果表明,与传统的SAGP相比,eMSAGP在延迟注入NCG的情况下,能够显著提高产油量并降低蒸汽-油比。具体而言,当NCG在总生产周期的1年、2年和3年后开始注入时,与从一开始就注入NCG的SAGP相比,累计产油量分别增加了18.6%、163.7%和218.6%。这些结果为优化SAGP技术提供了重要的参考依据。

Abstract

Steam and gas push (SAGP) reduces greenhouse gas emissions by co-injecting non-condensable gas (NCG) with steam, preventing heat loss to thief zones and maintaining steam chamber pressure and temperature. However, NCG can hinder steam chamber growth, reducing oil production than steam-assisted gravity drainage (SAGD). Additionally, determining the type, concentration, and injection timing of NCG based on the given reservoir conditions can be challenging. Nitrogen and methane are commonly used NCGs due to their low solubility in oil, but concentrations above 3 mol% typically decreases SAGP efficiency. To prevent NCG interference with steam chamber, an injection pressure of 0.95–1.1 times reservoir pressure and an NCG injection between 0 and 0.6 times total production period are recommended. Numerical simulations showed that injecting NCG after 0.125, 0.25, and 0.375 times total 8-year production period increased cumulative oil production by 18.6%, 163.7%, and 218.6% respectively, compared to injection from the start. Sensitivity ranges for reservoir parameters include thief zone thickness of aquifer (0–0.5 times reservoir thickness), ratio of vertical to horizontal permeability for sandstone (0.3–0.65), and oil viscosity based on major oil sands regions in Canada (2,000,000 cp. for Athabasca, 200,000 cp. for Peace River, and 60,000 cp. for Cold Lake at 12 °C). Thicker thief zones increase heat loss and higher vertical permeability accelerates steam chamber rise, requiring earlier NCG injection. Additionally, lower oil viscosity regions are more suitable for SAGP. Field application of Suncor Firebag project that NCG reduced cumulative steam-oil ratio from 3.14 to 2.76, demonstrating SAGP’s effectiveness.

作者单位

韩国公州国立大学地理环境科学系