Advances in Numerical Reservoir Simulation for In Situ Upgrading of Heavy Oil via Steam-Based Technologies

本文系统综述了近年来用于稠油原位热采改质的数值模拟研究进展,重点聚焦于蒸汽注入技术(如SAGD、CSS、SF)中涉及的热-流-固-化耦合模拟方法。文章分析了不同油藏参数、操作条件以及反应动力学模型对模拟结果的影响,指出准确预测蒸汽腔扩展、气体生成与传热机制是提高采收率模拟精度的关键。

研究强调,考虑水-气溶解度及H₂S生成动力学可使气体预测精度提升约20%。此外,文章还讨论了催化剂、溶剂注入等强化方法的模拟挑战与前景,指出当前模型在催化剂失活、吸附与运移机制方面仍存在显著不足。

CMG软件应用情况:

文章多次提到加拿大CMG(Computer Modeling Group)公司开发的STARS(Steam Thermal Advanced Recovery Simulator)软件在稠油热采模拟中的广泛应用。具体应用包括:

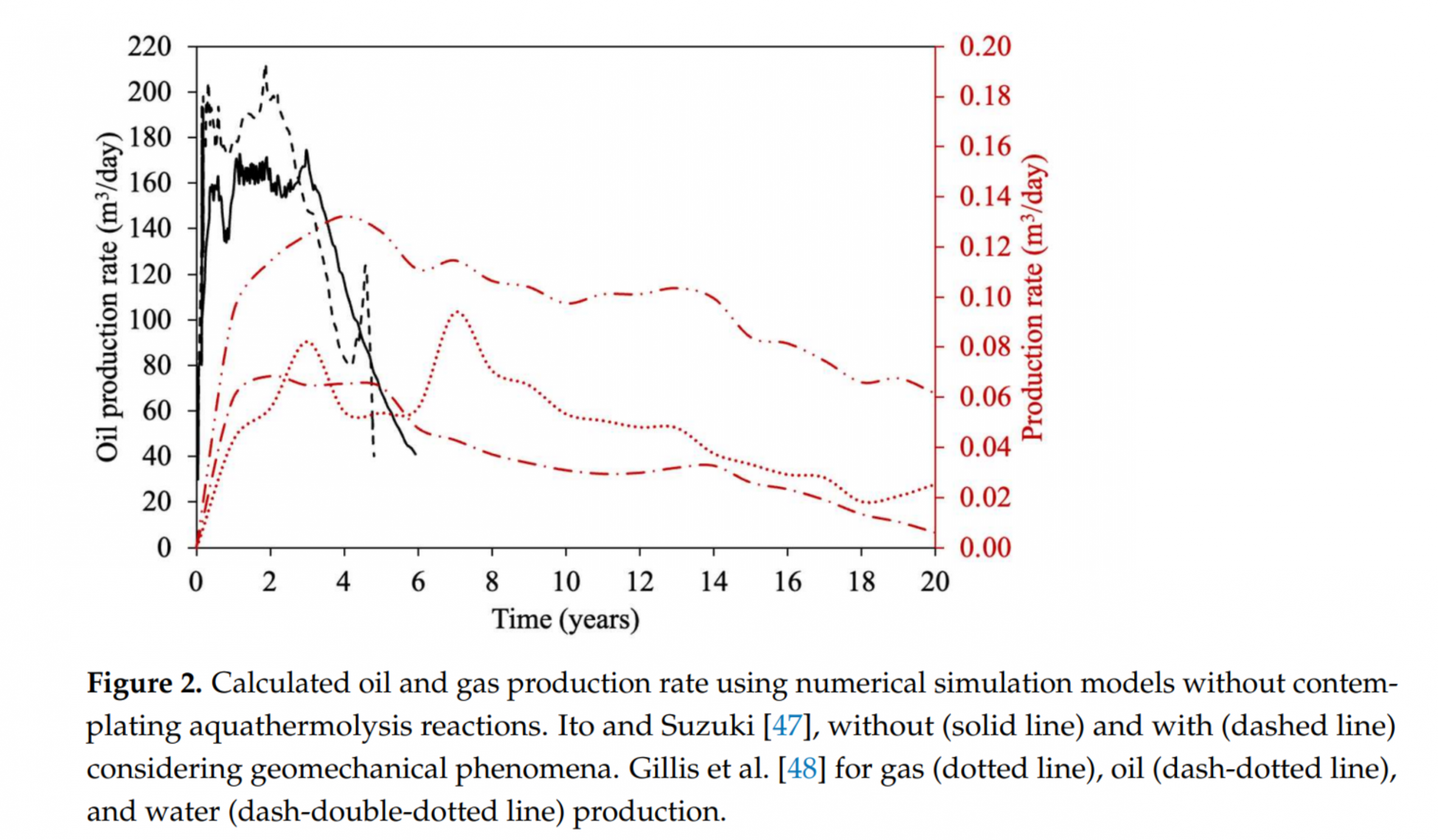

- SAGD模拟:如Ito & Suzuki、Gillis等研究中,使用STARS模拟蒸汽腔扩展、油-气-水三相流动及热传导过程。

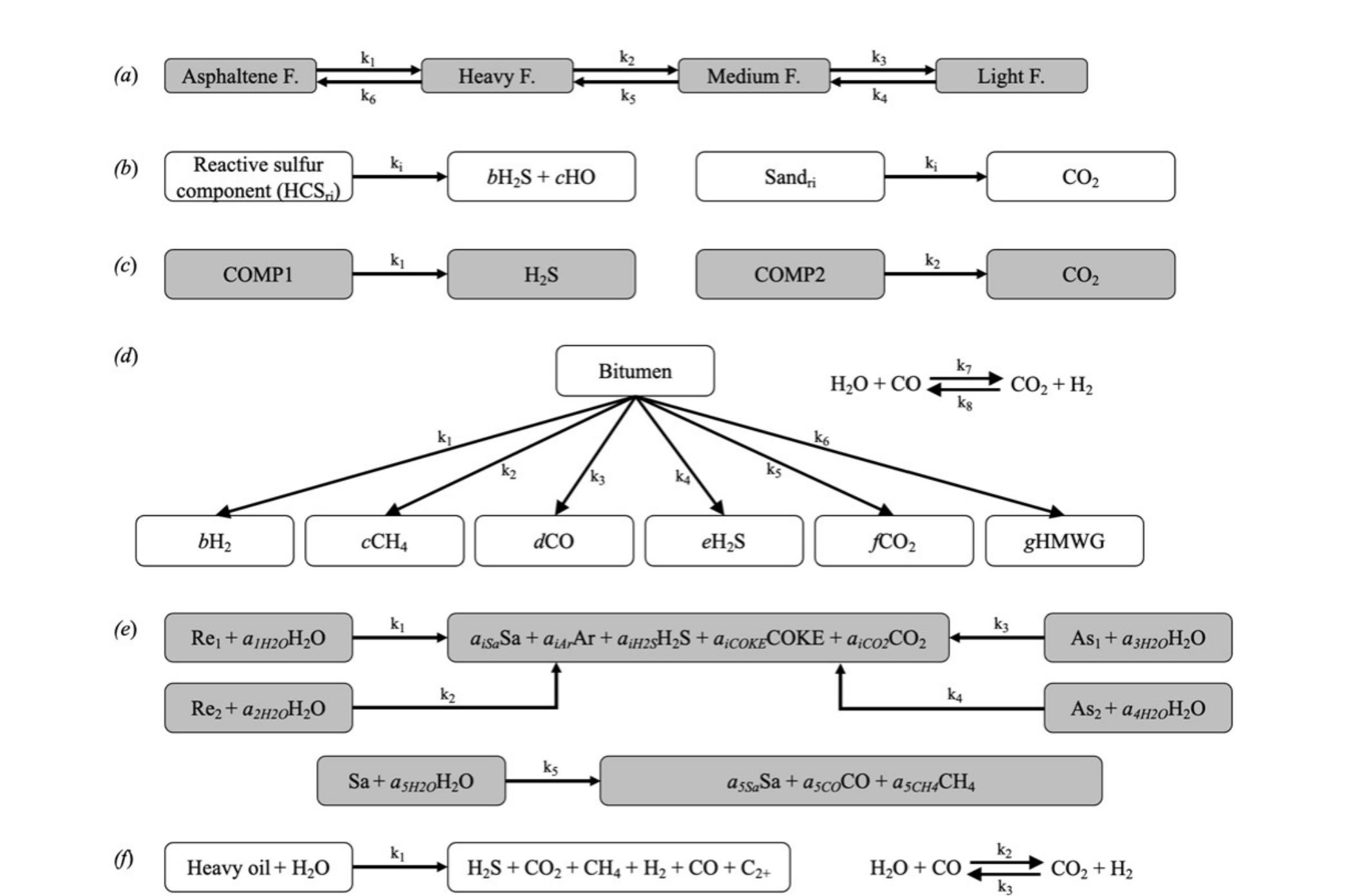

- 反应动力学耦合:如Perez-Perez、Kapadia、Ayache等作者将H₂S、CO₂、CH₄等气体生成反应嵌入STARS,模拟水热裂解(aquathermolysis)过程。

- 催化剂注入模拟:如Nguyen、Bueno等研究中,STARS用于模拟纳米催化剂与氢气共注入下的稠油改质过程,考虑催化剂吸附、失活与运移。

- 溶剂辅助SAGD模拟:如Hassanzadeh、Yang等研究中使用STARS模拟溶剂与电加热协同作用下的油藏响应。

结论:

- 基础模型局限性明显:早期忽略化学反应的模型普遍高估采收率,未考虑气体生成对蒸汽腔扩展的抑制作用。

- 反应动力学模型显著提升预测精度:引入H₂S、CO₂等气体生成反应后,模拟结果更贴近实验与现场数据。

- 催化剂模拟仍面临挑战:尽管实验室中催化剂降黏效果显著,但数值模拟中需进一步考虑催化剂失活、吸附、重力分异等复杂因素。

- 未来发展方向:

- 建立更完整的热-流-固-化耦合模型;

- 引入AI/ML技术优化模拟效率与参数反演;

- 加强对催化剂长期稳定性与现场适应性的模拟研究;

- 明确碳排放与气体归宿,推动绿色低碳开发。

作者单位:

俄罗斯喀山联邦大学(Kazan Federal University)石油工程系

Abstract

The numerical reservoir simulation is a valuable tool to enhance heavy oil recovery by assessing different production strategies (like SAGD and CSS) and operational scenarios. While numerous studies have developed complex models, a systematic review identifying the most critical parameters for achieving accurate production forecasts is lacking. In this work, diverse studies have been reviewed regarding the numerical models of steam injection technologies by examining various parameters (reservoir properties and operating conditions) employed and their impact on the results obtained. Additionally, the effect of using kinetic models in simulations, as well as the modeling of solvent and catalyst injection, is discussed. The outcomes highlight that oil recovery for steam injection methods requires effective steam chamber management and an understanding of geomechanical changes due to the significant role of thermal convection on energy transfer and oil displacement. Increasing steam injection pressures can enhance energy efficiency and reduce emissions, but controlling the gases generated during the reaction poses difficulties. The gas formation within the reservoir in simulations is crucial to prevent overestimating oil production and improving precision. This can be achieved using simple kinetic models, but it is essential to incorporate gas–water solubilities to mimic actual gas emissions and avoid gas buildup. Crucially, our synthesis of the literature demonstrates that incorporating gas–water solubilities and kinetic models for H2S production can improve the prediction accuracy of gas trends by up to 20% compared to oversimplified models. Enhanced recovery methods (adding solvent and catalyst injection) provide advantages compared with conventional steam injection methods. However, suitable interaction models between oil components and solid particles are needed to improve steam displacement, decrease water production, and enhance recovery in certain circumstances. The use of complex reaction schemes in numerical modeling remarkably enhances the prediction of experimental reservoir data.