Numerical study of the mechanisms of nano-assisted foam flooding in porous media as an alternative to gas flooding

本研究利用CMG软件进行了系统的模拟实验,以探讨纳米辅助泡沫驱油在多孔介质中的机理,作为气体驱油的替代方法。研究的主要目标是通过数值模拟,将纳米技术与泡沫驱油相结合,以提高采收率(EOR)技术的效果。

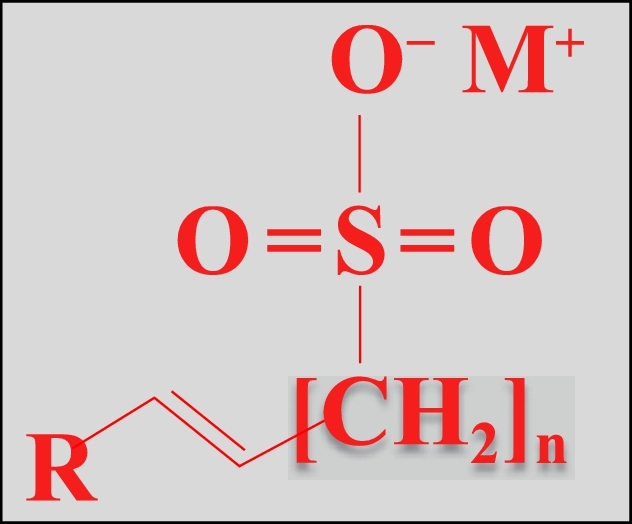

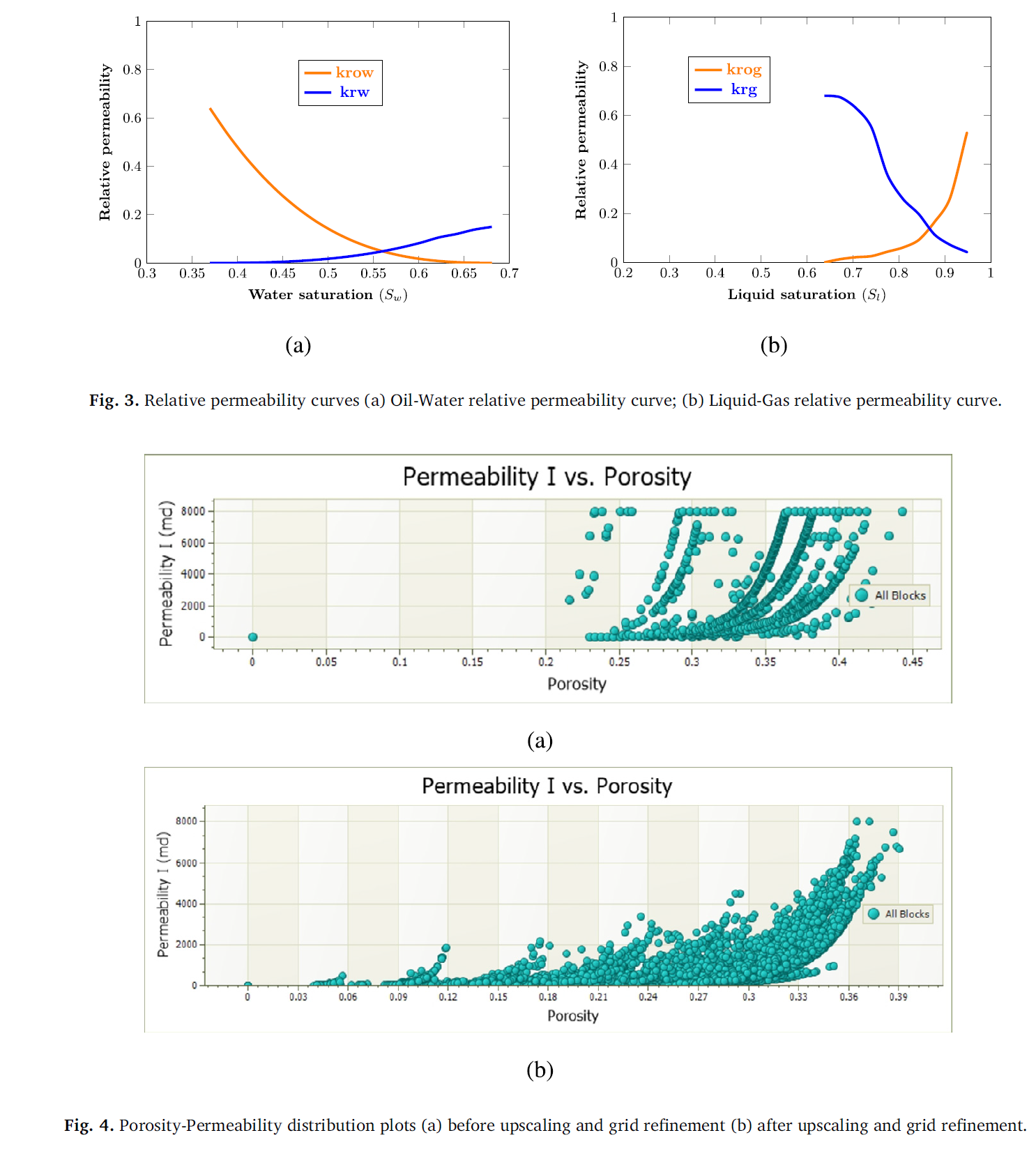

在实验和模拟方法方面,研究使用了阴离子表面活性剂Alpha-Olefin Sulfonate (AOS)作为泡沫剂,并通过添加纳米颗粒来增强泡沫的稳定性。模拟过程中,考虑了油藏的物理特性,如孔隙度、渗透率、油藏压力和温度等,并采用了网格加密和粗化技术来减少计算时间并识别平均地质属性。

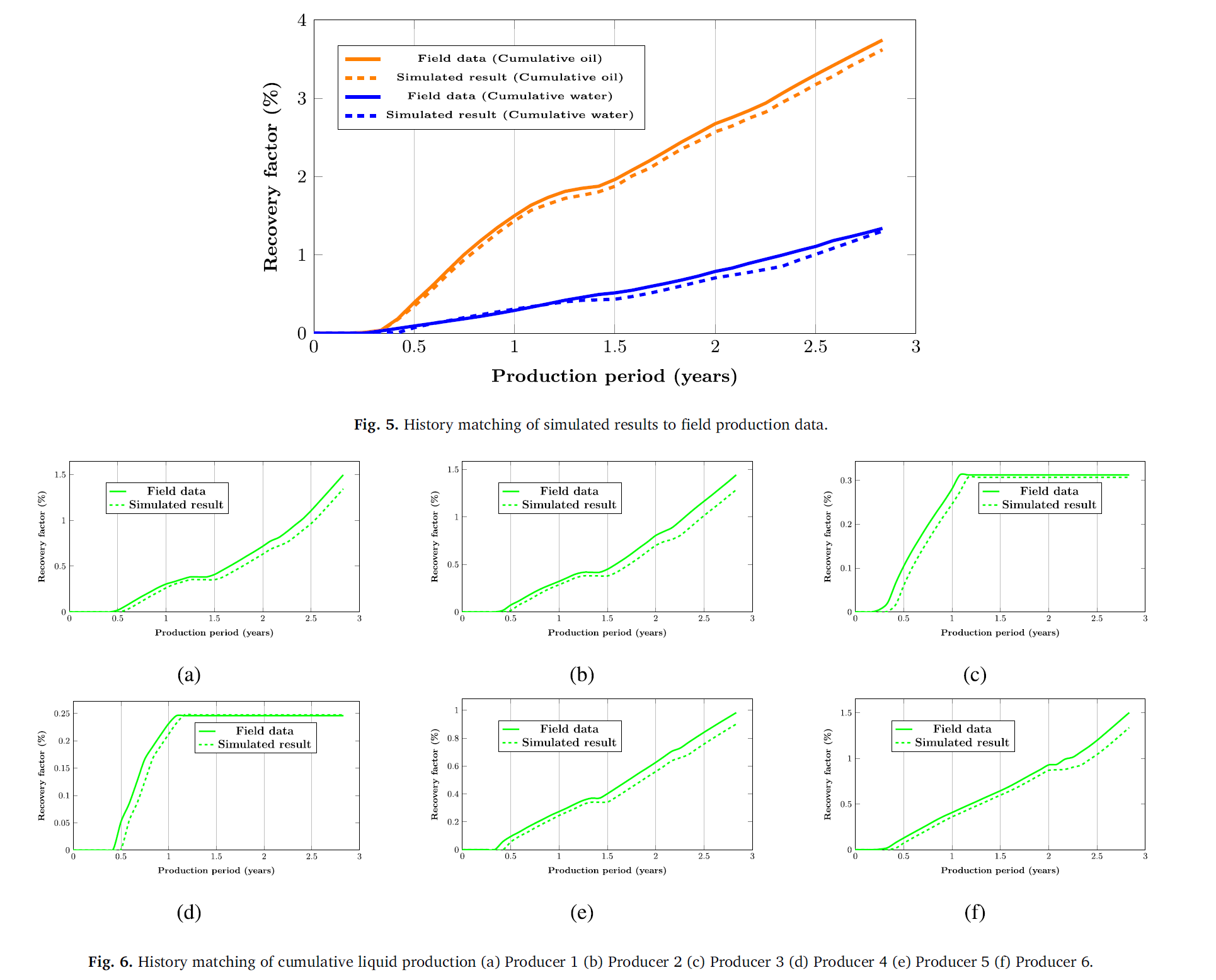

通过CMG软件的应用,研究者人员够模拟不同的注入策略,包括注水、注气、水-气交替(WAG)注入以及在有无纳米颗粒存在下的泡沫注入。模拟结果表明,纳米泡沫注入至少比WAG和气体注入分别提高了38%和95%的采收率。这一发现表明,泡沫注入相比WAG和气体注入在提高油藏采收率方面具有显著的优势。

此外,研究还探讨了纳米颗粒浓度对油藏采收率的影响。通过敏感性分析,研究人员发现纳米颗粒的加入显著降低了油水界面张力,从而提高了泡沫的稳定性和驱油效率。研究结果还表明,纳米泡沫在提高采收率和经济效益方面具有潜在的优势。

总之,本研究通过CMG软件的应用,成功模拟了纳米辅助泡沫驱油过程,并展示了其在提高油藏采收率方面的潜力。这些模拟优化技术为未来在该领域的工艺开发提供了重要的参考。通过结合纳米技术和泡沫驱油的优势,纳米泡沫驱油可能成为提高油藏采收率的一种有效的EOR方法。

Abstract

Oil reservoirs are nearing maturation, necessitating novel enhanced oil recovery (EOR) techniques to meet escalating global energy demands. This demand has spurred interest in reservoir production analysis and forecasting tools to enhance economic and technical efficiency. Accurate validation of these tools, known as simulators, using laboratory or field data is pivotal for precise reservoir productivity estimation. This study delves into the application of nanoparticles in foam flooding for mobility control to improve sweep efficiency. Foam generation can occur in-situ by simultaneous injection of surfactants and gas or through pre-generated foam injection into the reservoir. In this work, a series of systematic simulations were run to investigate how much injected fluids can reduce gas breakthrough while also increasing oil recovery. Subsequently, we analyzed the most effective optimization strategies, considering their economic limits. Our primary objective is to numerically model nanofoam flooding as an innovative EOR approach, synergizing foam flooding mechanisms with nanotechnology benefits. In this work, modeling of nanoparticles in foam liquid was represented by the interfacial properties provided to the injection fluid. Additionally, we simulated Water-Alternating-Gas (WAG) injection schemes across various cycles, comparing their outcomes. Our results showed that nanofoam injection achieved a higher recovery factor of at least 38% and 95% more than WAG and gas injections, respectively. The superior efficiency and productivity of foam injection compared to WAG and gas injection suggest an optimal EOR approach within the scope of our model. These simulated optimization techniques contribute to the future development of processes in this field.

Keywords: Foam, Nanoparticles, Gas, Surfactant, Hydrodynamic modeling