Numerical simulation investigations of the applicability of THAI in situ combustion process in heavy oil reservoirs underlain by bottom water

稠油油藏存在底水(BW)会给所有开采技术带来问题。因此,有必要研究不同底水层厚度对特定采油方式的影响,以及采用什么样程序来开发这些储层。指端到根端的空气注入(THAI)是一种热高效的过程,通过将一部分石油作为焦炭原位燃烧,在储层中产生能量,且适用于底水油藏且经济性和环境性较好。通过使用商业热采模拟器CMG STARS进行数值模拟研究。结果表明,即使在存在底水的情况下,THAI的燃烧区形状仍保持稳定前倾,并且没有氧气绕过燃烧前沿。然而,底水层厚度对采收率受有负面影响,并且影响的严重程度与底水层厚度成比例。

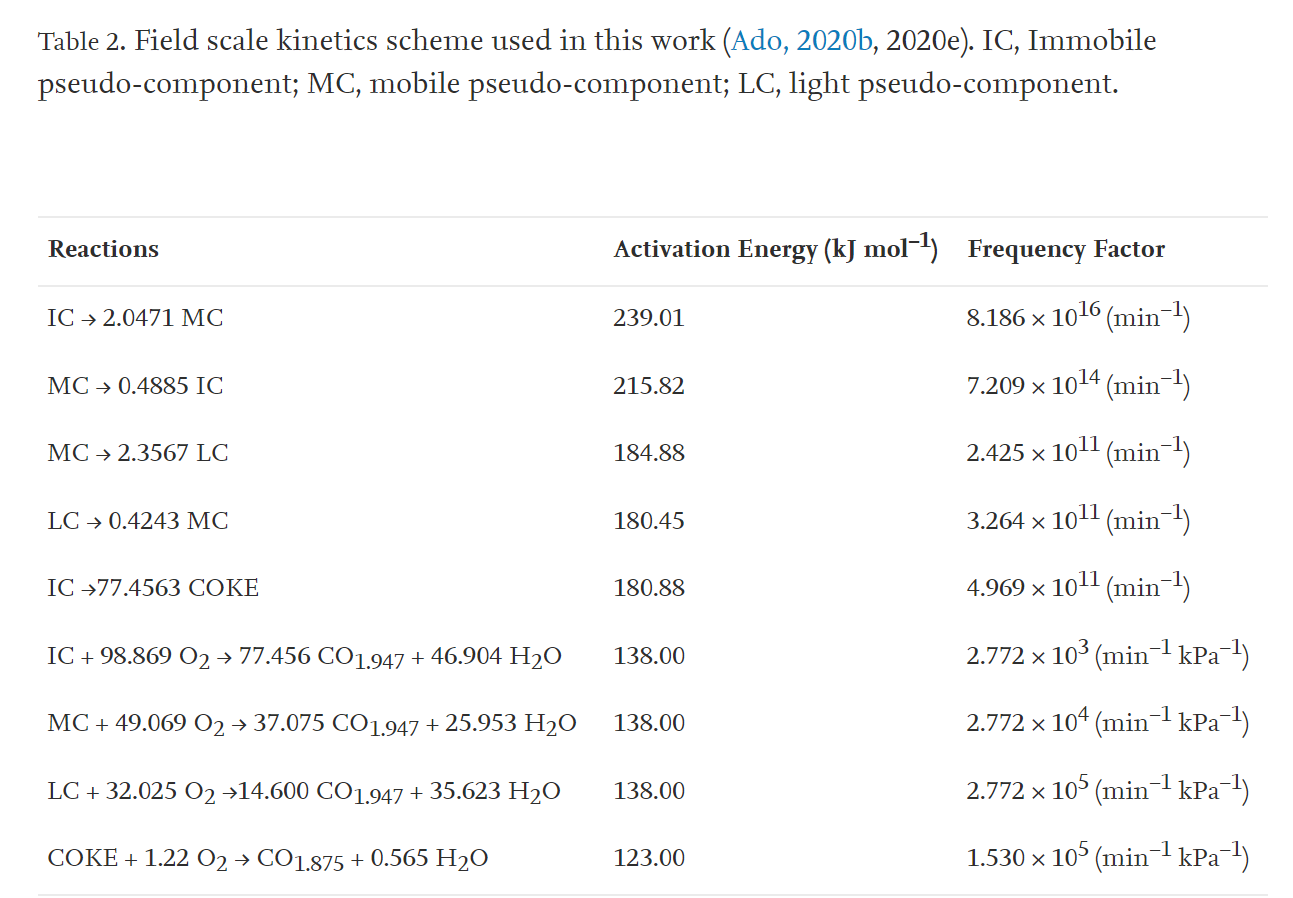

The presence of a bottom water (BW) layer in heavy oil reservoirs can present substantial problems for efficient oil recovery for all recovery techniques. Hence, it is necessary to know how particular production processes are affected by different BW layer thicknesses, and how standard production procedures can be adapted to handle such reservoirs. Toe-to-heel air injection (THAI) is a thermally efficient process, generating in situ energy in the reservoir by burning a fraction of the oil-in-place as coke and has the potential to economically and environmentally friendly work in reservoirs with BW layer. However, to ascertain that, studies are needed first. These are conducted via numerical simulations using commercial reservoir thermal simulator, CMG STARS. This work has shown that the shape of the combustion zone in THAI remains forward-leaning even in the presence of a BW layer, indicating that the process is stable, and that there is no oxygen bypassing of the combustion front. However, the oil recovery rate is highly negatively affected by how large the thickness of the BW zone is, and the severity of such effect is determined to be proportional to the thickness of the BW layer.

This study also shows that there is a period of low oil production rate which corresponds to mobilised oil displacement into the BW zone which in turn causes a surge in water production rate. The practical implication of this is that prolonged period of low oil production rates will expose companies and/or investors to higher risk due to the oil market volatility. In this study, it is also revealed that the height of the mobilised oil that is displaced into the BW zone equates to that of the displaced and replaced water thereby implying that when the BW layer thickness is 50% that of the oil layer (OL), less than 50% of the mobilised oil will be recovered when the entire reservoir is swept by the combustion front. Therefore, conclusively, applying the THAI process in its conventional form in reservoirs containing bottom water is not recommended, and as a result, a new strategy is needed to enhance process economics by improving the oil production and hence recovery rates.

Keywords:

In situ combustion (ISC), Enhanced oil recovery (EOR), Tar sand/heavy oil/bitumen, Reservoir simulation, Toe-to-heel air injection (THAI)

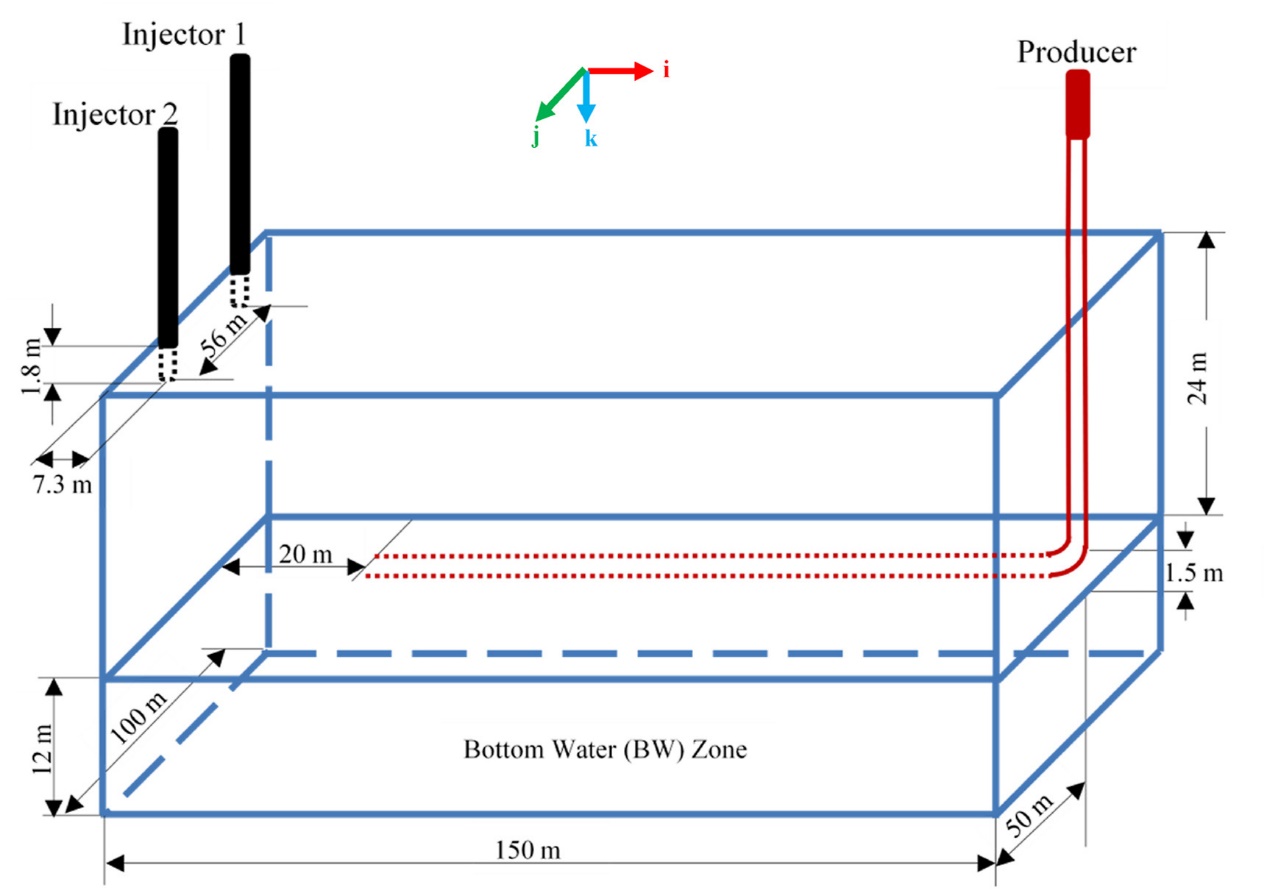

Fig. 1. Schematic diagram of dimensions and wells layout for model of reservoir with BWL. This is for model BW2 which has BWL thickness to OL thickness ratio of 1:2.

Fig. 2. Effect of BWL thickness on THAI oil production rate.

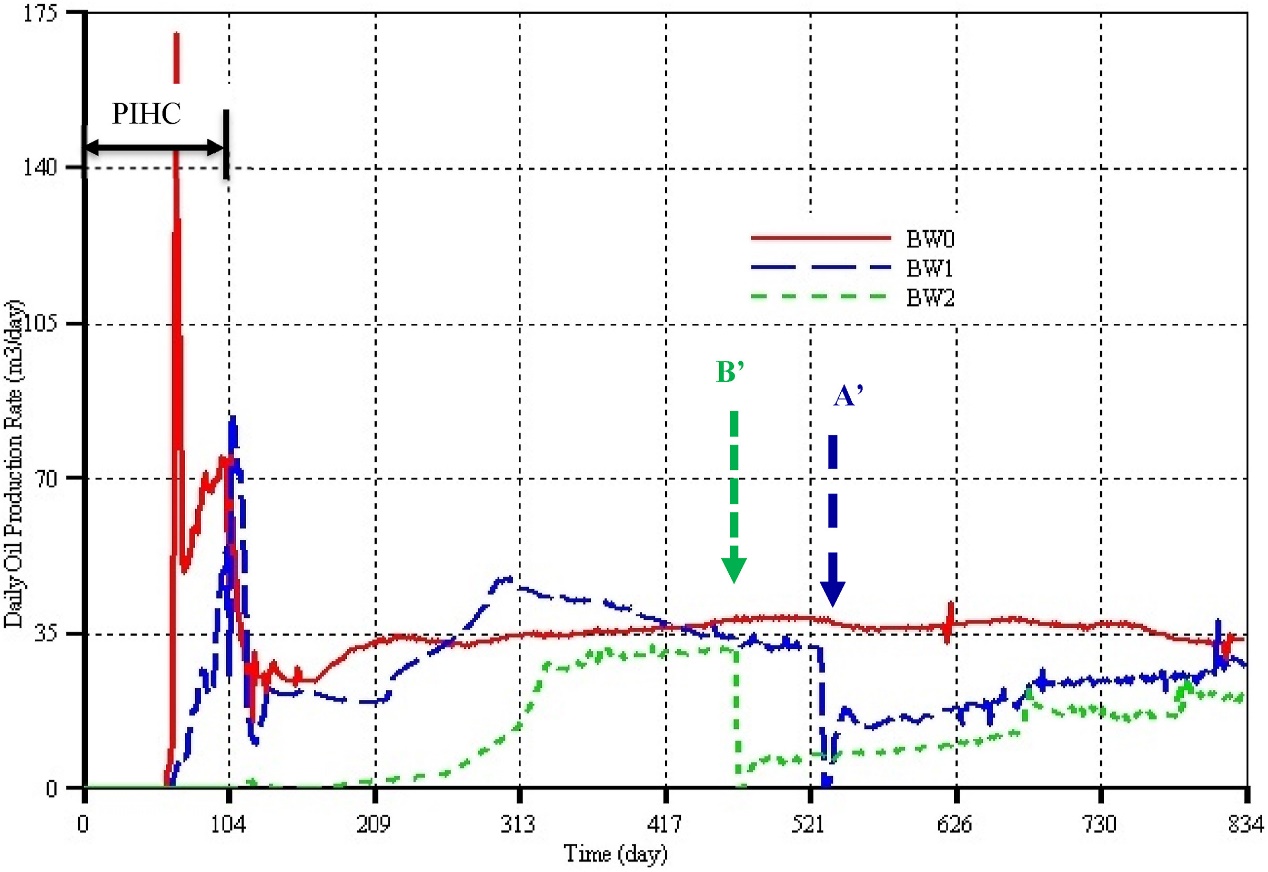

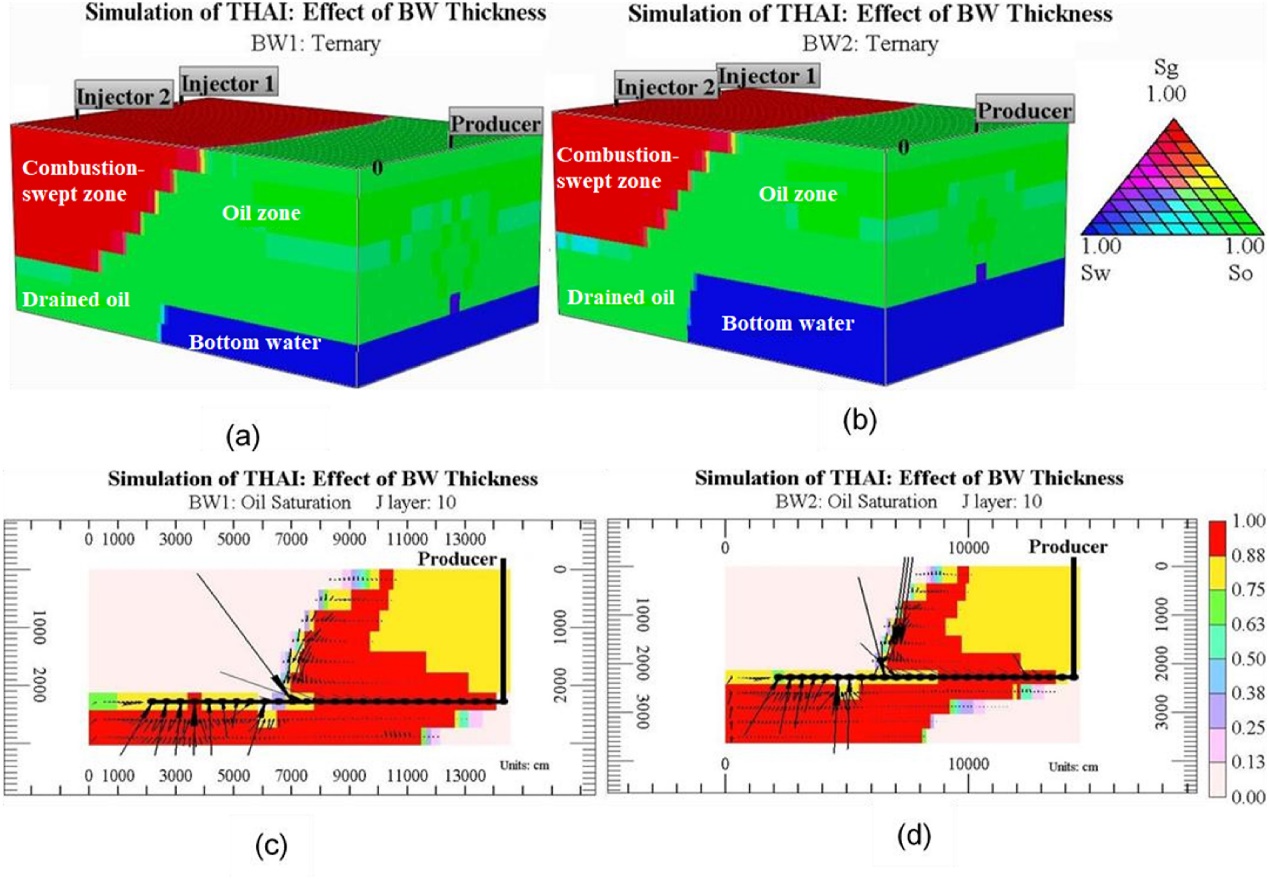

Fig. 6. Ternary diagrams for BW1 (a) and BW2 (b), and oil saturation profiles along the vertical mid-plane of models BW1 (c) and BW2 (d), all after two years of operation. The singled-headed arrows represent the magnitude and direction of the oil flow.

一条评论