Lab to Field Scale Modeling of Low Temperature Air Injection with Hydrocarbon Solvents for Heavy-Oil Recovery in Naturally Fractured Reservoirs

-

气体序列设计影响油回收。

-

在空气循环中,浸泡在丁烷而非丙烷后的O2消耗更高。

-

与纯空气或溶剂相比,浸泡在空气+C3混合物中的岩心更有益;即,产生的气体中O2浓度更低,溶剂使用量更少,油回收速度更快且更高。

CMG软件的应用情况

作者单位

Abstract

Alternatives for enhanced oil recovery processes in heavy oil containing deep naturally fractured reservoirs (NFR) are limited due to excessive heat losses when steam is injected. Air injection at high temperature oxidation conditions (in-situ combustion) has been considered as an alternative to aqueous based thermal applications. However, its implementation has serious limitations including poor areal distribution of injected air and poor combustion efficiency due to the heterogeneous nature of these reservoirs as well as the safety risk of unconsumed injected oxygen (O2) reaching the production wells.

Taking advantage of the low cost and availability of air, one option is to use air at low temperature conditions (low temperature oxidation, LTO) as a pressurizing agent in NFR. Oxygenated compounds are generated at these conditions resulting in oil viscosity increase, reducing fluid mobility. In order to minimize this detrimental effect, a combination of air injection with hydrocarbon solvents can be applied. The objectives of this thesis are to evaluate air injection at LTO conditions in NFR containing heavy oil as a way to improve oil recovery, to clarify the effect of hydrocarbon solvent addition into air on oil recovery and O2 consumption, and to propose optimal conditions (temperature, air/solvent ratio) and implementation strategies for an efficient use of this suggested method.

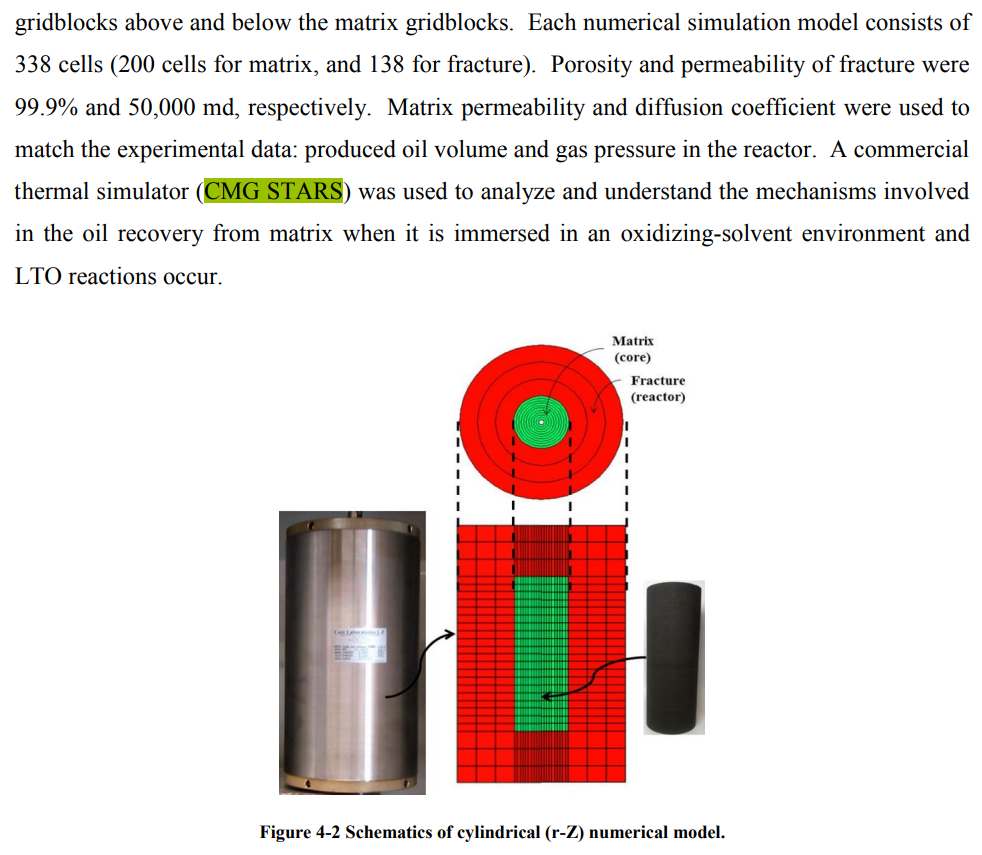

Comprehensive laboratory and numerical simulation studies were conducted to achieve these objectives. Static diffusion experiments—simulating cyclic gas injection (huff-and-puff)—were carried out by soaking heavy oil saturated cores into a reactor filled with gas representing a matrix/fracture system. Oil recovery and O2 consumption were the main parameters assessed and an extensive set of variables including rock type, temperature, fracture volume, solvent type, matrix size, gas injection sequences, and soaking times were studied. From experimental studies, the following conclusions were made: 1. Gas sequence design affects oil recovery, 2. O2 consumption in air cycles is higher after the core is soaked into butane rather than propane, 3. It is beneficial to soak cores in air+C3 mixture rather than pure air or solvent; i.e., lower O2 concentration in produced gas, less solvent usage, higher and faster oil recovery compared to alternate injection of air and C3.

Then, core scale numerical simulation models were created for modeling lab experiments for a sensitivity analysis on Air/C3 ratio and matrix size. The results show that the process is extremely sensitive to matrix size and optimization of air injection (assisted by hydrocarbon solvents) can be achieved based on the minimized hydrocarbon solvent for a given matrix size. Additionally, a sensitivity analysis was performed using an up-scaled numerical model to the field scale containing meter-scale matrix blocks. It was observed that oil production mechanisms acting in a matrix block surrounded by gas filling the fractures are predominantly gas-oil gravity drainage, effective diffusion, and voidage replacement of oil by gas.

Finally, a numerical simulation sector model of a hypothetical NFR was created and several air gas injection sequences were analyzed. It was concluded that injection of air (LTO conditions) and propane represents an alternative for heavy oil recovery from NFRs at the field scale, and an optimum production time/soaking time ratio can be obtained for given gas injection sequences (type of gas and injection/soaking durations), temperature, and block sizes.