SIMULATION OF DEPLETED GAS RESERVOIR FOR UNDERGROUND GAS STORAGE

ABSTRACT

For a natural gas importing country, “take or pay” approach creates problems since the demand for natural gas varies during the year and the excess amount of natural gas should be stored.

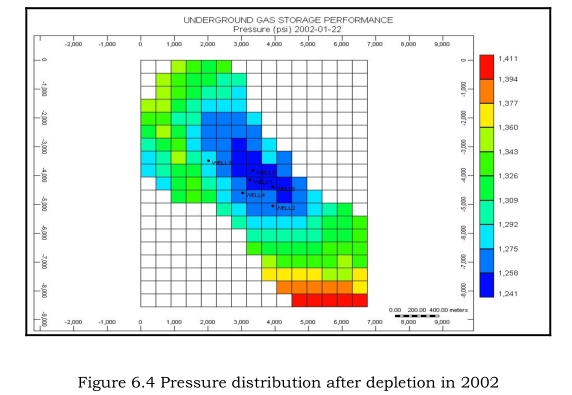

In this study, an underground gas storage project is evaluated in a depleted gas Field M. After gathering all necessary reservoir, fluid, production and pressure data, the data were adapted to computer language, which was used in a commercial simulator software (IMEX) that is the CMG’s (Computer Modelling Group) new generation adoptivesimulator, to reach the history matching.

The history matching which consists of the 4 year of production of the gas reservoir is the first step of this study. The simulation program was able to accomplish a good history match with the given parameters of the reservoir.

Using the history match as a base, five different scenarios were created and forecast the injection and withdrawal performance of the reservoir. These scenarios includes 5 newly drilled horizontal wells which were used in combinations with the existing wells.

With a predetermined injection rate of 13 MMcf/D was set for all the wells and among the 5 scenarios, 5 horizontal – 6 vertical injectors & 5 horizontal - 6 vertical producers is the most successful in handling the gas inventory and the time it takes for a gas injection and production period. After the determination of the well configuration, the optimum injection rate for the entire field was obtained and found to be 130 MMcf/D by running different injection rates for all wells and then for only horizontal wells different injection rates were applied with a constant injection rate of 130 MMcf/d for vertical wells.

Then it has been found that it is better to apply the 5 th scenario which includes 5 horizontal – 6 vertical injectors & 5 horizontal - 6 vertical producers having an injection rate of 130 MMcf/d for horizontal and vertical wells. Since within the 5 th scenario, changing the injection rate to 1.3 Bcf/d and 13 Bcf/d, did not effect and change the average reservoir pressure significantly, it is best to carry out the project with the optimum injection rate which is 130 MMcf/d.

The total gas produced untill 2012 is 394 BCF and the gas injected is 340 BCF where the maximum average reservoir pressure was recovered and set into a new value of 1881 psi by injection and cushion gas pressure as 1371 psi by withdrawal. If 5 th scenario is compared with the others, there is an increase in injection and production performance about 90%.

Keywords: Underground Gas Storage, Depleted Gas Reservoir, History Matching and Simulator.