Bitumen Recovery Performance of SAGD and Butane- and HexaneAided SAGD in the Presence of Shale Barriers

ABSTRACT:

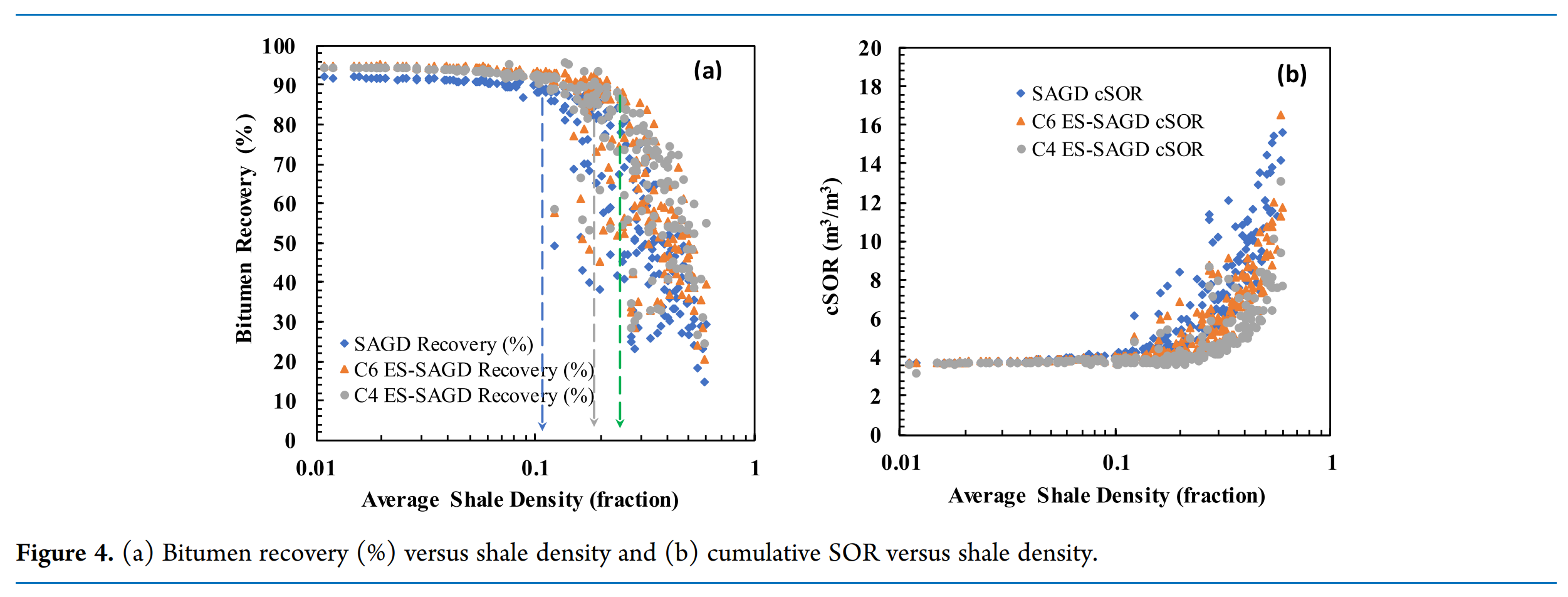

Oil and gas formations are commonly found to be heterogeneous, and one of the most common occurrences of reservoir heterogeneity is the presence of shale barriers. Shale barriers typically have very low permeability and high initial water saturation. Due to low permeability, these barriers obstruct the oil drainage path, specifically in thermal recovery methods such as steam-assisted gravity drainage (SAGD). In addition to flow assistance, they also lead to heat losses due to absorption by the high initial water saturation. Expanding solvent steam-assisted gravity drainage (ES-SAGD) is a hybrid technique comprising solvent co-injection along with steam. Solvent being in the vapor phase can potentially overcome the restricted path due to the presence of shale barriers.

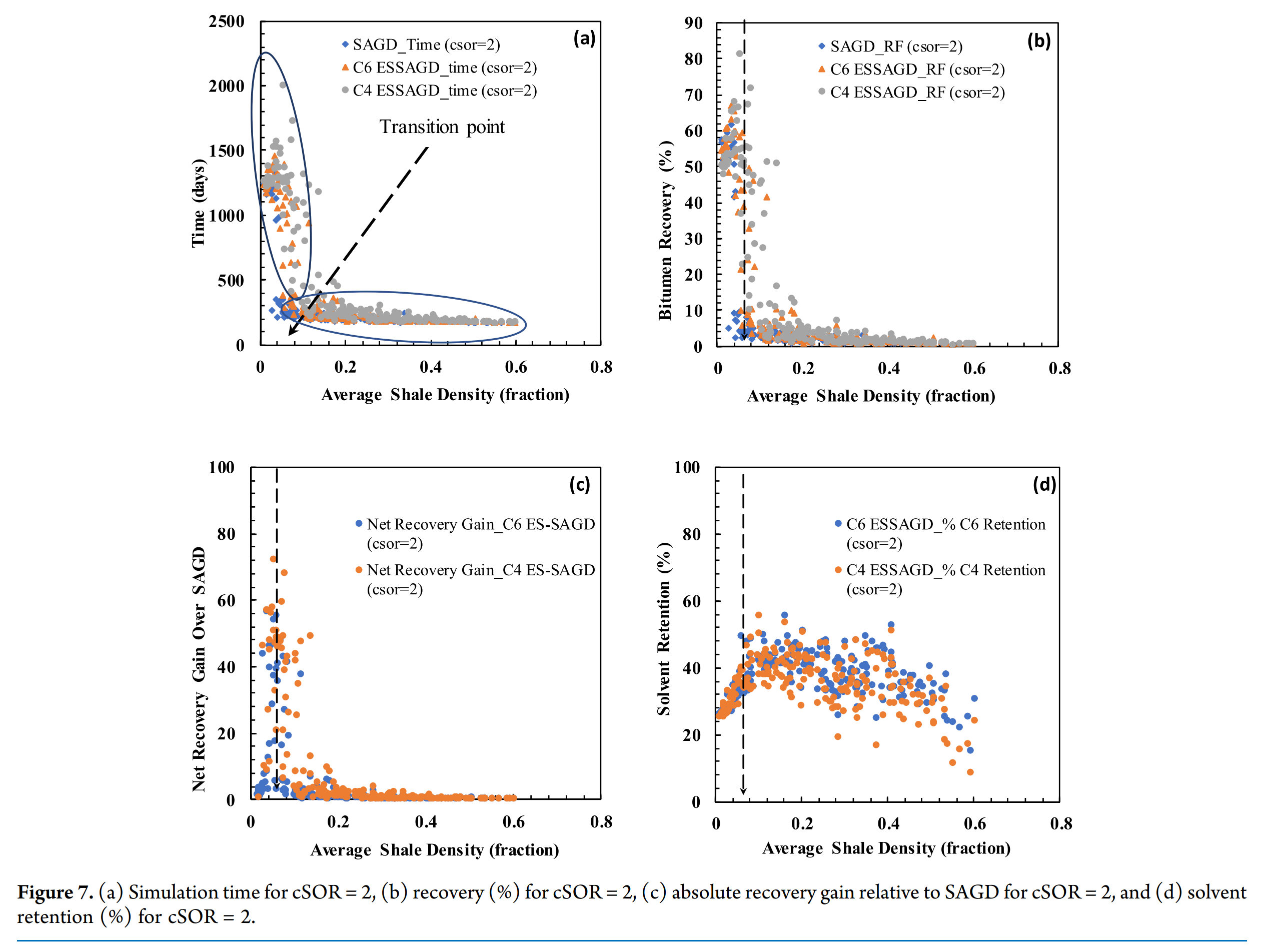

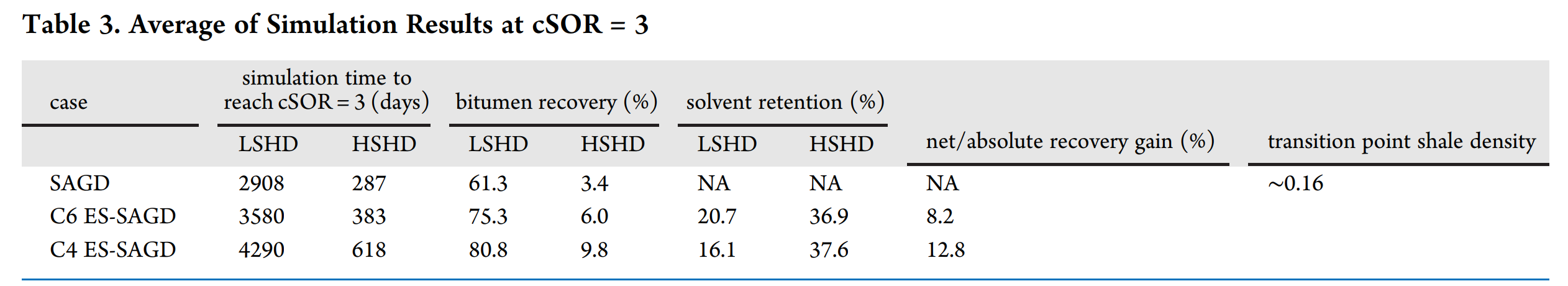

This paper presents a numerical simulation study on comparison between SAGD and ES-SAGD in the presence of shale barriers. SAGD and ES-SAGD with hexane and butane are numerically simulated for 240 lognormally generated shale realizations. First, both recovery processes are analyzed over the whole simulation period. Additionally, they have also been evaluated at multiple cumulative steam oil ratio cut-offs at 2, 2.5, 3, and 3.5. Transition points are defined and explained to cluster the shale density/fractions based on similar behaviors. It was shown that the oil that cannot be mobilized and produced by SAGD because shale barriers can be reached by the vaporized solvent through tortuous paths and recovered. Also, thermal losses are reduced because of lower steam chamber temperature. This led to efficient results for ES-SAGD over SAGD in heterogeneous formations.