EERC Final Topical Report – Findings on Subtask 3.2 – Produced Water Management Through Geologic Homogenization, Conditions, and Reuse

北达科他州工业委员会(NDIC)石油和天然气研究计划(NDIC编号G-051-101)授予能源与环境研究中心(EERC)一份合同,按照北达科塔州众议院1014号法案第19节的指示,对北达科他的油气生产区的油气作业用水(也称为采出水)进行回收研究。本最终报告提供了研究结果的汇编,其中包括与北达科他采出水管理相关的监管、科学、技术和可行性方法和考虑因素。报告提供了该项目先前提交的名为“北达科他州气田水管理和回收方案”(能源与环境研究中心,2020年)的气田水评估报告的概要,并酌情提供了更新。该报告提供了一种新的采出水管理策略的调查结果,该策略被称为地质均质化、调节和再利用(GHCR),旨在将地下地层用作管理采出水再循环和再利用的天然介质。

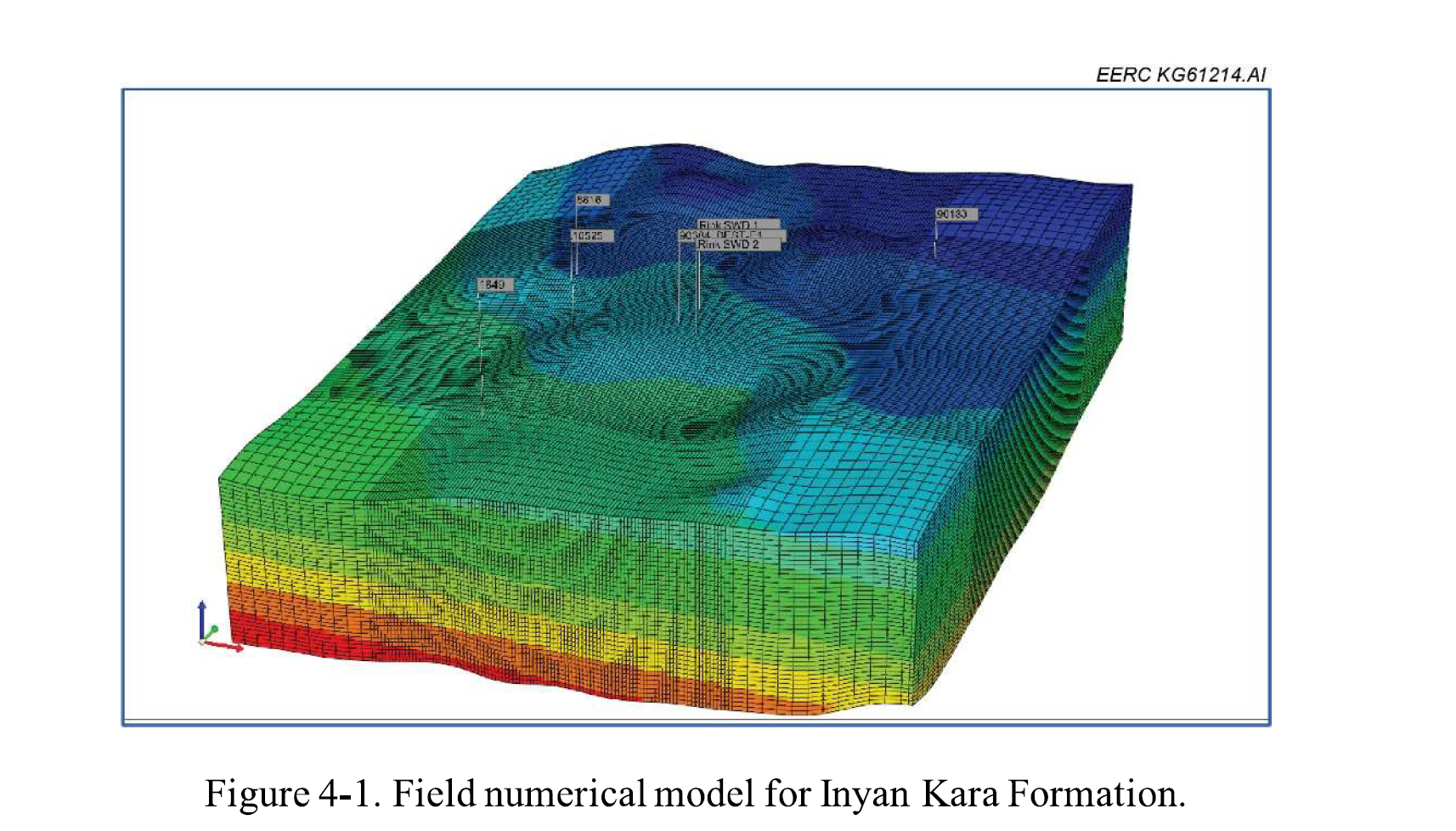

实验室柱测试和现场样品采集表明,Inyan Kara砂岩和天然地层流体能够与Bakken气田水均匀化,达到流体成分趋于稳定的程度。提取稳定流体可以被认为是均质的,能够提供单独批次的液压压裂液。数值模拟结果表明,在GHCR实施方案中从Inyan Kara提取流体能够降低地层压力,这将有助于缓解Inyan Kar的局部增压,并扩大附近现有SWD井的可用容量。经济分析表明,在某些情况下,与传统的水管理方法相比,实施GHCR可能是一种具有竞争力或甚至成本更低的选择。现场特定条件将决定GHCR的经济潜力,但GHCR实施的潜在吸引力将是位于Inyan Kara加压区上方、需要六口或更多Bakken加密井、常规SWD和/或淡水成本高的地点。 。

Abstract

The Energy & Environmental Research Center (EERC) was awarded a contract by the North Dakota Industrial Commission (NDIC) Oil and Gas Research Program (NDIC No. G-051-101) to conduct a study on the recycling of water used in oil and gas operations, also known as produced water, from oil- and gas-producing regions of North Dakota as directed by Section 19 of North Dakota House Bill 1014. This final report provides a compilation of results of the study, which include regulatory, scientific, technological, and feasibility methods and considerations associated with North Dakota produced water management. The report provides a synopsis of this project’s previously submitted produced water assessment report entitled “Produced Water Management and Recycling Options in North Dakota” (Energy & Environmental Research Center, 2020), with updated values provided as appropriate. The report provides the results from the investigation of a novel produced water management strategy, referred to as geologic homogenization, conditioning, and reuse (GHCR), which aims to use a subsurface geologic formation as a natural medium for managing produced water recycling and reuse.

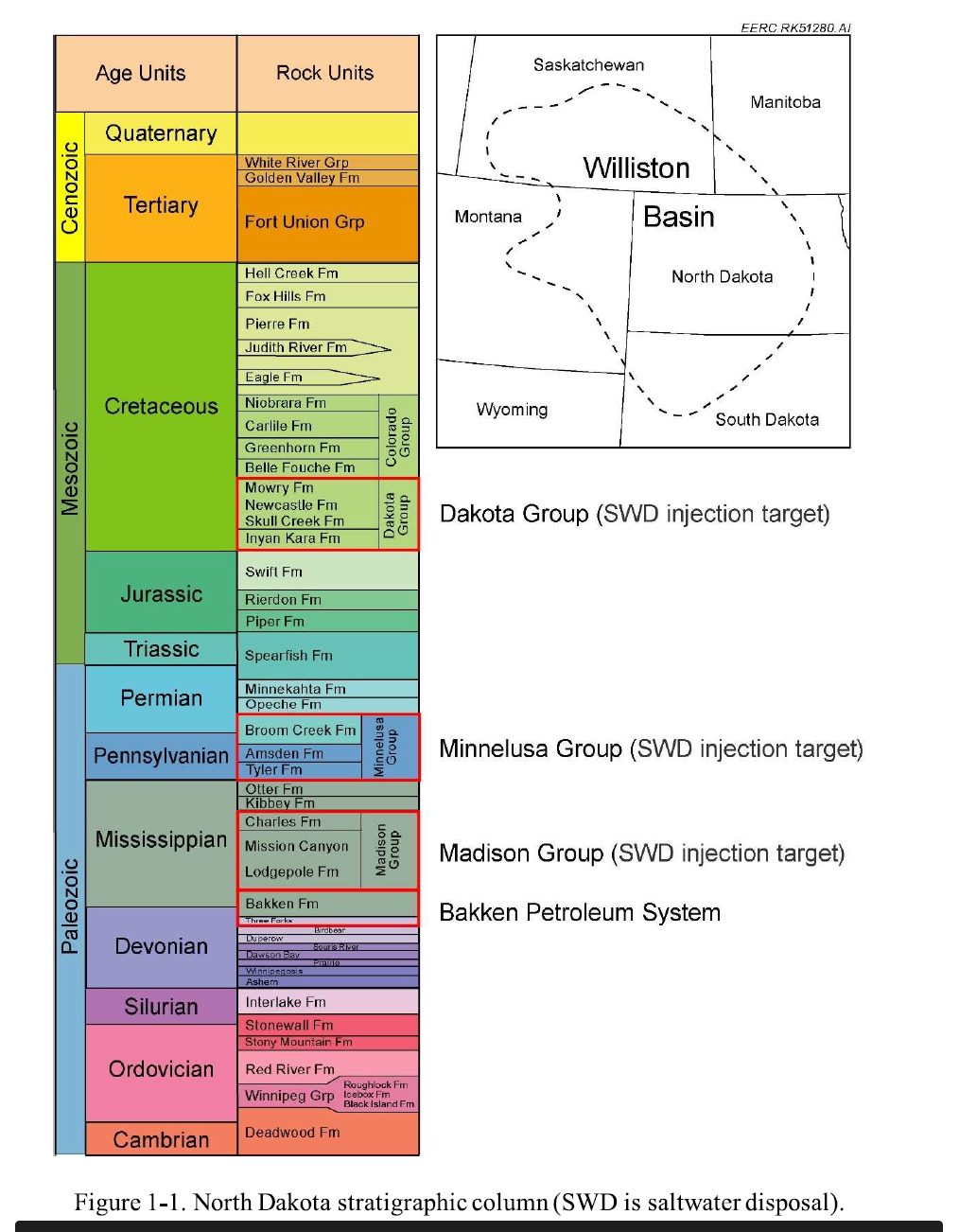

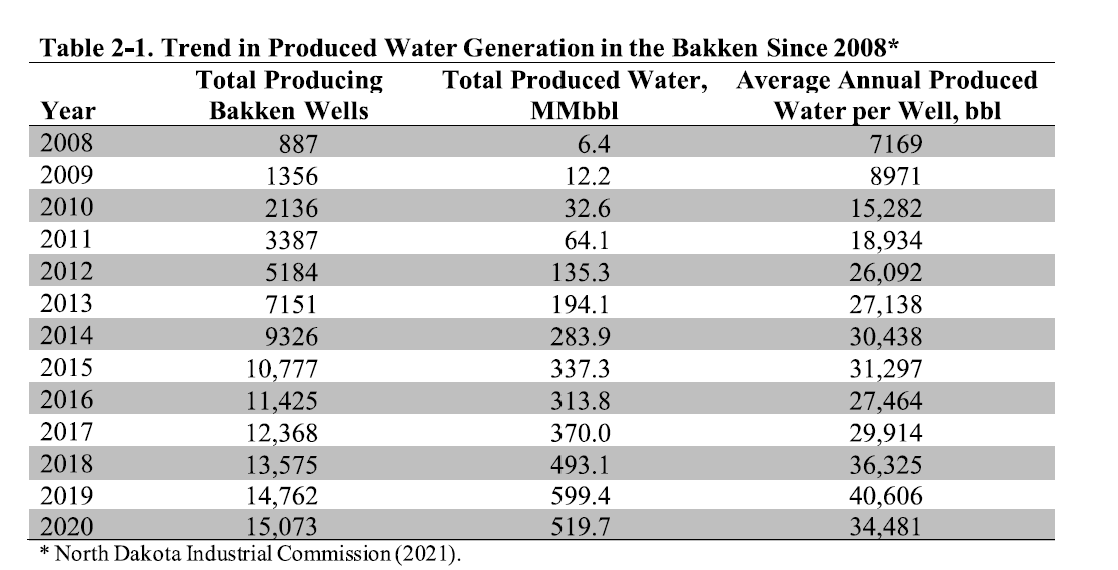

Water management is a significant technical and economic challenge for sustainable oil and gas production, and water volumes are intrinsically linked to oil production volumes. North Dakota oil production rose to over 1.5 million barrels (MMbbl)/day in 2019, and despite a downturn in oil price in early 2020, North Dakota oil production has recovered to 1.1 MMbbl/day as of August 2021. Bakken petroleum system development between 2008 and 2020 has resulted in a nearly fourfold increase in produced water volumes to 642 MMbbl/yr in 2020 after peaking at 740 MMbbl/yr in 2019 and a fivefold increase in saltwater disposal (SWD) volumes to 565 MMbbl/yr in 2020 after a peak of 682 MMbbl/yr in 2019. Produced water and SWD volumes are forecasted to double by 2030.

SWD is the primary method of produced water management used in North Dakota, with approximately 95% of the SWD volume occurring through subsurface injection into sandstones of the Dakota Group (Dakota). Localized pressurization of the Dakota resulting from SWD and projected increases in produced water volumes could impact the economics of North Dakota oil production. As a result, there is an emerging need to pursue alternative produced water management approaches, including recycling and reuse. While produced water recycling is not yet widespread, commercial operators are making strides in overcoming the technical challenges of using high salinity produced water in completion operations (Marathon Oil, 2020). As water management continues to be a key focal point in companies’ environmental, social, and governance (ESG) initiatives, focus on water management, including recycling, will likely continue to increase. Laboratory column testing, field sample collection, geologic modeling and numerical simulation, and techno-economic analysis all indicate that GHCR could feasibly be implemented as a potential water management option.

Laboratory column testing and field sample collection indicate that the Inyan Kara sandstone and native formation fluid are capable of homogenizing with the Bakken produced water to a point where the fluid composition appears to stabilize. Extracting that stabilized fluid could be considered homogeneous and capable of providing individual batches of hydraulic fracturing fluid. Numerical simulation results indicate that extraction of fluids from the Inyan Kara in a GHCR implementation scenario is capable of reducing formation pressure, which would help ease localized pressurization of the Inyan Kara and extend the available capacity for nearby existing SWD wells. Economic analysis indicates that there are scenarios where GHCR implementation can be a competitive or even lower-cost option than a conventional water management approach. Site-specific conditions will dictate the economic potential of GHCR, but potentially attractive sites for GHCR implementation will be those that are located above a pressurized zone of the Inyan Kara, need six or more Bakken infill wells, and face high costs for conventional SWD and/or freshwater. Based on the regulatory review, drilling into the Inyan Kara for SWD and to harness as a source water for industrial use have precedent in North Dakota, and a workable regulatory solution for GHCR seems likely. However, restrictions in the state regarding surface storage and transport of produced fluids may limit some activities, which will affect how GHCR could ultimately be implemented.

In summary, this study reveals pursuing GHCR can be a viable approach to water management in North Dakota. The GHCR concept addresses some of the challenges that hinder the more traditional approaches to recycling in the industry. Furthermore, an assessment of the current landscape of water management within the state reveals the ongoing trend of increasing volumes of produced water and SWD. Projections reveal that the volumes of produced water that need to be managed are expected to double over the next decade (Energy & Environmental Research Center, 2020). With the continued development of the Bakken and continuing driving factors related to ESG initiatives, implementing a practice such as GHCR is a feasible approach to adding recycling of produced water to industry within the state.

This subtask was cofunded through the EERC–U.S. Department of Energy Joint Program on Research and Development for Fossil Energy-Related Resources Cooperative Agreement No. DE-FE0024233. Nonfederal funding was provided by the North Dakota Industrial Commission Oil and Gas Research Program. References Energy & Environmental Research Center, 2020, Produced water management and recycling options in North Dakota: Final Report for North Dakota Legislative Management Energy Development and Transmission Committee and North Dakota Industrial Commission. Marathon Oil, 2020, Sustainability report: