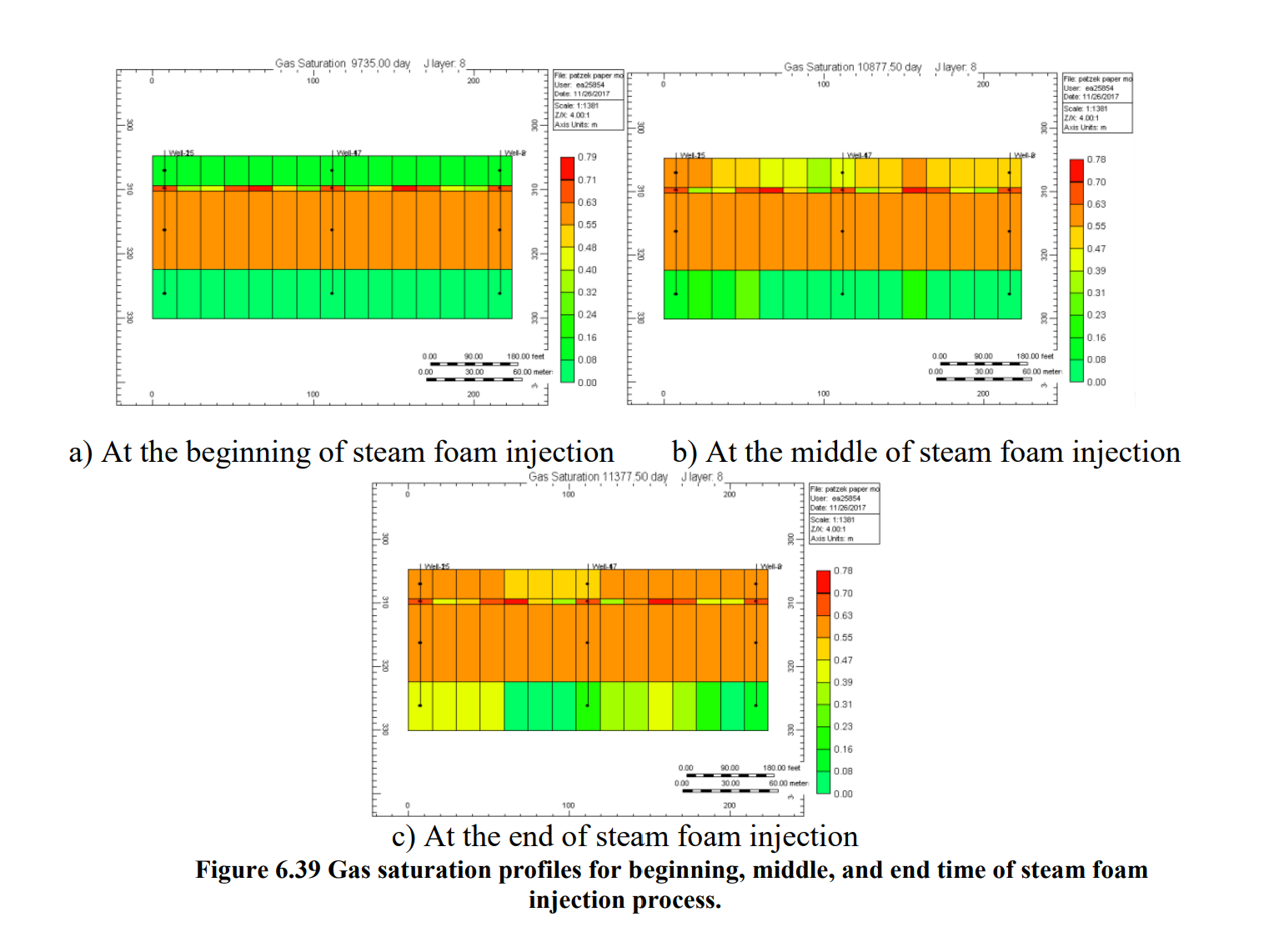

Numerical Simulation and History Matching of Steam-Foam Process to Enhance Heavy Oil Recovery

Thermal enhanced oil recovery techniques have been considered as the best approach to produce heavy oil; however, hybrid methods, which are combinations of different oil recovery methods, reveal more promise in enhancing oil production from heavy and viscose reservoirs. In this research, we investigate improving recovery from heavy oil reservoirs, considering steam foam method to control the mobility of steam and oil in such reservoirs, and delivering proper amount of heat to reservoir in order to reduce oil viscosity.

In this thesis, a compositional K-value based reservoir simulator, CMG-STARS, was used to build simulation models for all case studies. Steam table is used to calculate the phase change during steam injection and to capture latent heat effect on energy balance and mass balance equations. CMG-STARS empirical foam model is used to capture mobility of steam in the presence of surfactant. Simulation models are tuned with experimental core data and field history data. Simulation results illustrated that a considerable increase in oil recovery is obtained when steam foam is used. It is also observed that foam parameters, which was used in modeling, affects oil recovery, reservoir average temperature, average pressure and gas saturation. Optimized foam parameters were determined considering oil recovery, average reservoir temperature, and average reservoir pressure. Finally, simulations revealed that field and simulation results were in good agreement with field data, and that steam foam oil recovery method has the potential to become a promising oil recovery method for heavy oil reservoirs.