Well Placement Optimization through the Triple-Completion Gas and Downhole Water Sink-Assisted Gravity Drainage (TC-GDWS-AGD) EOR Process

气体和井下水汇辅助重力驱油(GDWS-AGD)是一种在含有大底水的储层中提高油藏采收率(EOR)的新工艺。传统的GDWS-AGD工艺需要 建两口井用用于产油和排水,还需要额外的多个垂直注气井,成本高昂。然而,通过消除注气井并使用三井式多功能油井(TC-GDWS-AGD),可以大幅降低成本。

本文设计和优化了TC-GDWS-AGD增油工艺在一个虚构的油田(Punq-S3)中,模拟一个真实的北海油田。设计旨在使用最少数量的三井式完井,在井的垂直段完成注气,上部段产油(从油/水界面以上),下部段排水(低于油/水界面)。通过液压封隔器这三个完井装置,并通过电潜泵排空油水接触层以下的水。使用粒子群优化(PSO)技术进行井位优化,只考虑1或2个TC-GDWS-AGD油井,以最大化12年的油采收量和最小化产水量。通过考虑数百个可能的井位,找到了最佳井位,并对单井和双井场景进行了评估。

结果显示,单井场景的采油率为58%,含水量为0.28;双井场景的采油率为63.5%,含水量为0.45。有趣的是,双井基础方案中不使用TC-GDWS-AGD工艺将导致最低55.5%的采油量和最高70%的含水量。研究表明,通过减少井的数量,增加采收率,并减少产水量,TC-GDWS-AGD工艺可能更具生产力。

Abstract:

Gas and downhole water sink-assisted gravity drainage (GDWS-AGD) is a new process of enhanced oil recovery (EOR) in oil reservoirs underlain by large bottom aquifers. The process is capital intensive as it requires the construction of dual-completed wells for oil production and water drainage and additional multiple vertical gas-injection wells. The costs could be substantially reduced by eliminating the gas-injection wells and using triple-completed multi-functional wells. These wells are dubbed triple-completion-GDWS-AGD (TC-GDWS-AGD).

In this work, we design and optimize the TC-GDWS-AGD oil recovery process in a fictitious oil reservoir (Punq-S3) that emulates a real North Sea oil field. The design aims at maximum oil recovery using a minimum number of triple-completed wells with a gas-injection completion in the vertical section of the well, and two horizontal well sections—the upper section for producing oil (from above the oil/water contact) and the lower section for draining water below the oil/water contact. The three well completions are isolated with hydraulic packers and water is drained from below the oil–water contact using the electric submersible pump. Well placement is optimized using the particle swarm optimization (PSO) technique by considering only 1 or 2 TC-GDWS-AGD wells to maximize a 12-year oil recovery with a minimum volume of produced water. The best well placement was found by considering hundreds of possible well locations throughout the reservoir for the single-well and two-well scenarios. The results show 58% oil recovery and 0.28 water cut for the single-well scenario and 63.5% oil recovery and 0.45 water cut for the two-well scenario. Interestingly, the base-case scenario using two wells without the TC-GDWS-AGD process would give the smallest oil recovery of 55.5% and the largest 70% water cut. The study indicates that the TC-GDWS-AGD process could be more productive by reducing the number of wells and increasing recovery with less water production.

Keywords: gas injection; downhole water sink; assisted gravity drainage; particle swarm optimization; well placement optimization; enhanced oil recovery

7. Summary and Conclusions

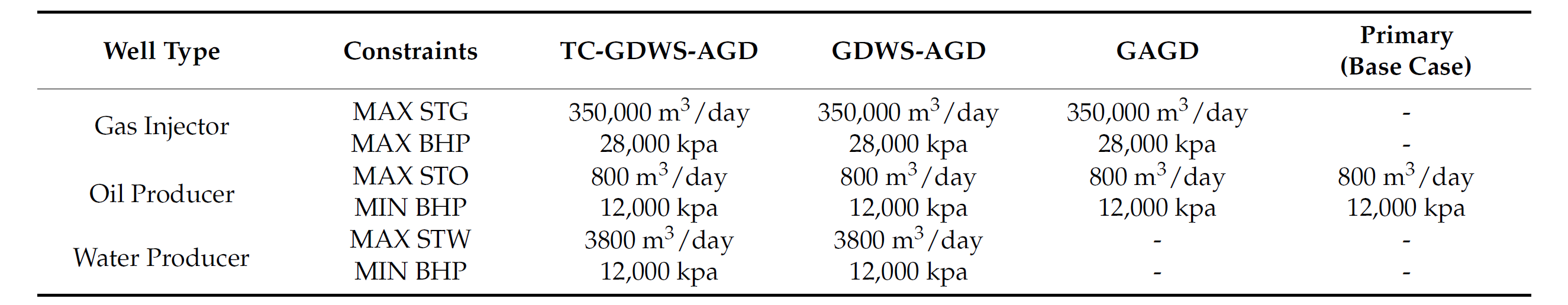

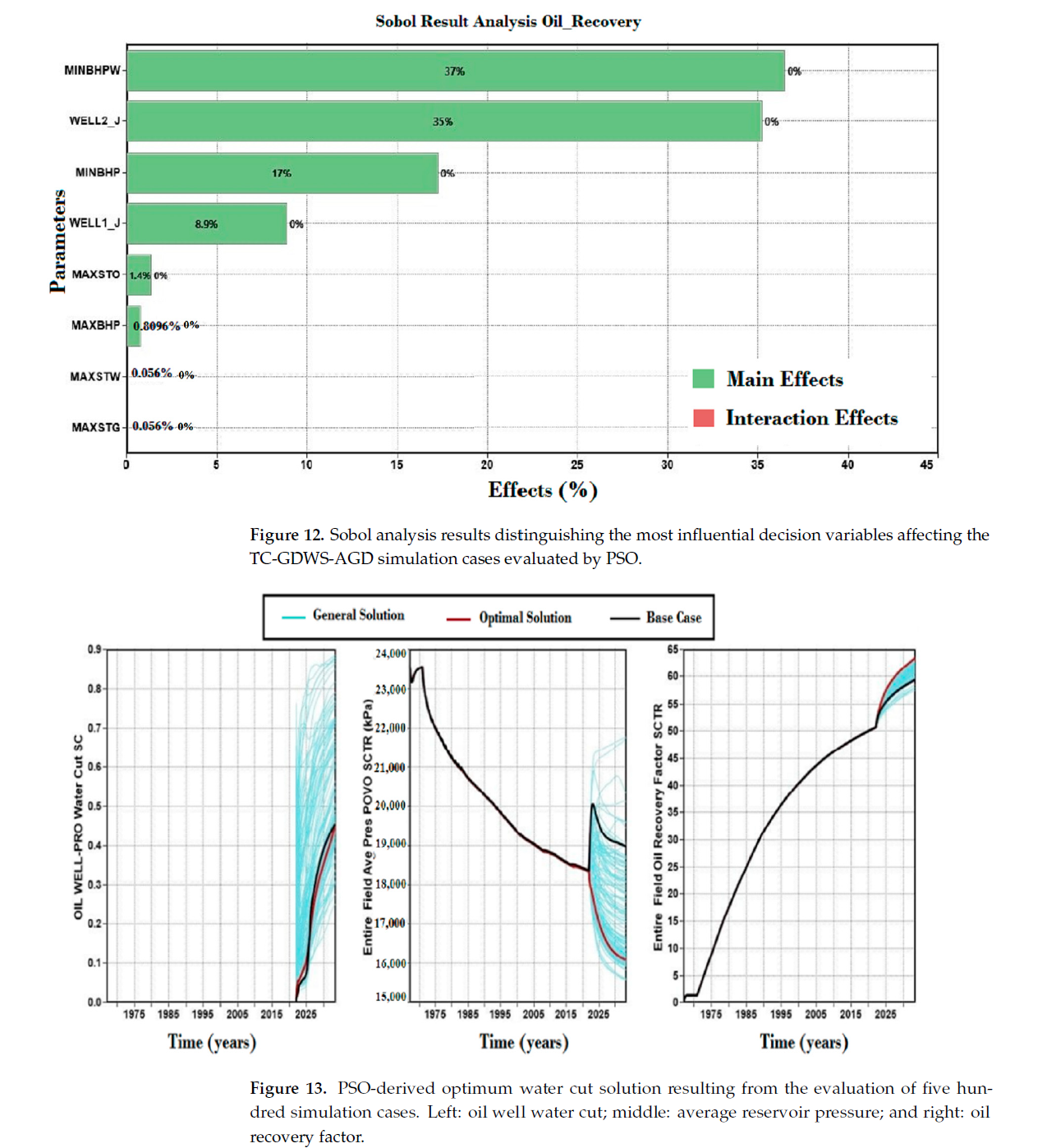

In this study, a black-oil reservoir simulation was conducted on the Punq-S3 heterogeneous reservoir to evaluate and determine the optimal setting of the triple-completion gas and downhole water sink-assisted gravity drainage (TC-GDWS-AGD) process. The evaluation and well placement optimization procedures of the TC-GDWS-AGD process were conducted to achieve maximum oil production with minimum water cut through a 12-year prediction period in a comparison with GDWS-AGD and GAGD processes. The operational decision parameters that were included in the well placement optimization along with the potential well locations included maximum surface oil rate and minimum bottom hole pressure of oil producers; maximum surface water rate and minimum bottomhole pressure of water producers; and maximum surface gas rate and maximum bottom hole pressure in gas injectors. The following points are the main conclusions retrieved from the evaluation and optimization procedures:

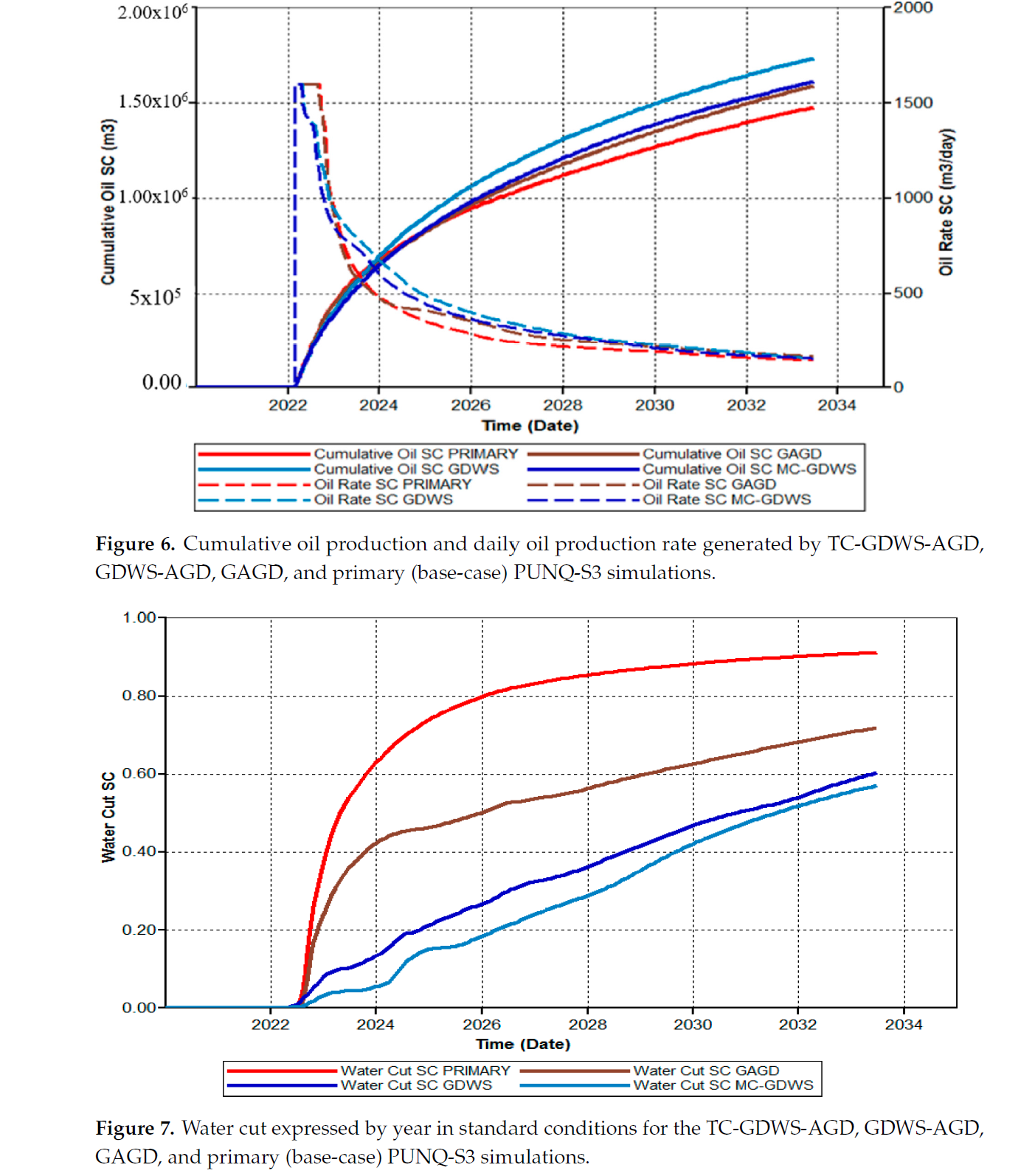

_ The effectiveness of the TC-GDWS-AGD enhanced oil recovery (EOR) technique was confirmed by this simulation study in terms of its ability to increase oil recovery and decrease water cut compared with applying gas-assisted gravity drainage (GAGD) and gas-downhole water sink (GDWS) EOR processes to the Punq-S3 synthetic reservoir.

_ The TC-GDWS-AGD completions are effective in reducing water cut and increasing cumulative oil production. Cumulative oil was increased from 1.47 _ 106 m3 from the primary process to 1.6 _ 106 m3 from the best TC-GDWS-AGD case with an oil recovery factor of 0.58, whereas water cut decreased from 70% in the GAGD process to 57% in the best TC-GDWS-AGD case.

_ As the TC-GDWS-AGD gas-injection rate was enhanced from350,000m3 to 500,000m3, the water cut decreased from 0.57 to 0.50. When the maximum surface-water-production rate (STW) constraint was raised to 20,000 m3/day, the PSO algorithm was able to find locations that achieved high oil recovery with the lowest overall water cut (0.45) for the two-TC-well cases.

_ The PSO algorithm was highly effective at identifying the optimum well completion locations for maximizing oil recovery and minimizing water cut in the studied reservoir. To achieve maximum reservoir coverage, for each simulated scenario, one well completion was placed to the right side of a surface location and one well to the left side.

_ The gas injection rate (STG) had only a minor impact on oil recovery volumes because the permeability of the reservoir layer two was very low. In fact, the transfer of gas from reservoir layer one to reservoir layer three was found to decrease as the gas injection rate increased.