Scale-up of Solvent Injection Processes in Post-CHOPS Applications

Abstract

Cold Heavy Oil Production with Sand (CHOPS) is widely used as a primary non-thermal production technique in thin heavy oil reservoirs in Western Canada and some other regions in South America. It has been reported that more than 85% of the original oil in place remains trapped in-situ, requiring additional follow-up (i.e., post-CHOPS) recovery strategies to be implemented. Solvent-aided processes, such as cyclic solvent injection (CSI), are commonly adopted due to the particular thin pay zone, which renders the application of thermal approaches uneconomical. It is widely accepted that configuration of wormhole networks (i.e., high permeability channels caused by sand production) and foamy oil flow are key characteristics pertinent to these processes, and they play an important role in the overall success. Field-scale flow simulations are often performed to approximate the reservoir response and to optimize operating strategies. However, grid block sizes in field-scale models are generally much larger than the wormhole scale, and numerical analysis is often performed by arbitrary adjustment of dispersivity. This thesis proposes a practical workflow to scale up these mechanisms for field scale simulations in wormhole networks that span over multiple scales.

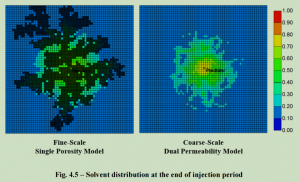

First, a set of detailed high-resolution (fine-scale) simulation models, where both matrix and high-permeability wormholes (modeled as fractal networks) are represented explicitly in the computational domain, is constructed to model how the solvent propagates away from the wormholes and into the bypassed matrix. Next, a dual-permeability approach is adopted to facilitate the scale-up analysis. Solvent transport and additional mixing in wormhole networks can be captured by parameters such as shape factor and effective dispersivity in an equivalent coarse-scale dual-permeability system. Bivariate distributions of effective longitudinal/transverse dispersivities and wormhole intensity are constructed and calibrated by minimizing the difference in recovery response (i.e., profiles of gas/oil production) between the detailed model and an equivalent dual-permeability continuum model.

Finally, field-scale simulations are constructed using average petrophysical properties and initial conditions (fluid saturations, pressure distribution, and wormhole development) commonly encountered at the end of CHOPS. Multiple field injection scenarios (i.e., of different number of cycles and durations of the soaking period) are simulated and analyzed. As expected, extended soaking period is more beneficial in terms of ultimate oil recovery (slower decline in oil rate), but it also reduces the early production rate. These observations can be attributed to the fact that a longer soaking period may prolong the production phase by increasing the effective drainage area contacted by the solvent; however, the amount of solvent in the near well region is also diluted. Interestingly, when an economic limit (i.e., minimum oil producing rate) is imposed, the optimal soaking time is not necessarily the longest one. It depends on the trade-off between extracting additional oil recovery at late times versus producing at a higher rate at early times. The analysis also reveals that during the implementation of multiple consecutive cycles, the two initial cycles contribute the most to the final oil recovery. Therefore, injecting larger volumes of solvent and extending the soaking times are recommended strategies during the first and/or second cycles. In addition, when the amount of solvent available is limited, the results support in the strategy of injecting all the solvent in one single consolidated cycle, with an extended soaking period, rather than performing shorter consecutive cycles.