Screening of Major Chemical Reactions in In-Situ Combustion Process for Bitumen Production from Oil Sands Reservoirs

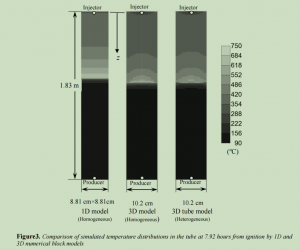

本研究调查了用于油砂储层原位燃烧(ISC)过程的数值模拟中的主要化学反应,以生产沥青。油砂储层的沥青生产已经成功地通过热方法如蒸汽辅助重力泄油(SAGD)进行,但包括水处理在内的运营成本一直是一个重大问题。ISC被期望提供高回收率、低成本和节水。然而,沥青的燃烧化学反应及其动力学参数尚未完全确定。通过CMG STARS软件对燃烧管实验进行了一些数值模拟,以构建化学反应。但是,为了通过减少化学反应数量来减少CPU处理时间,进行场地规模的储层模拟,筛选主要化学反应是必要的。本研究确认了Yang和Gates(2009)提出的模型比其他模型更能模拟燃烧管测试的实验结果。基于数值模拟,从包含八个反应的模型中筛选出了三个主要反应,即低温氧化和高温氧化(LTO和HTO)。使用这三个反应,成功地对典型的油砂储层进行了THAI(趾跟空气注入)过程的场地规模3D数值模拟。此外,还对THAI方法和SAGD方法的数值模拟结果进行了比较。

CMG软件的应用情况

在本研究中,CMG STARS软件被用于对燃烧管实验结果进行历史匹配模拟,以筛选化学反应。研究比较了三种化学反应模型:Kapadia等人(2011)、Yang和Gates(2009)以及Belgrave等人(1993)提出的模型,以构建ISC的数值模拟模型。通过CMG STARS软件的模拟,研究者能够筛选出影响沥青生产行为的主要化学反应,并对THAI过程进行了场地规模的数值模拟。

Abstract

In this study, screening of major chemical reactions used for numerical simulations on in-situ combustion (ISC) process has been investigated to produce bitumen from oil sands reservoir. Bitumen productions from oil sands reservoirs have been successfully carried out using thermal method, such as Steam Assisted Gravity Drainage (SAGD), but operation cost including water treatment has been a big issue to continue the bitumen production. ISC has been expected to provide high recovery, low cost and saving water. However, combustion chemical reactions and their kinetic parameters for bitumen have not been completely fixed. Some numerical simulations on the combustion tube experiments with Athabasca bitumen were conducted to construct the chemical reactions. But, screening to pick up major chemical reactions is necessary to carry out a field size reservoir simulation by reducing of CPU processing time with less number of the chemical reactions. In this study, it was confirmed that the model presented Yang and Gates (2009) could simulate the experimental results of combustion tube test better than other models. Three major reactions, defined as low temperature oxidation and high temperature oxidation (LTO and HTO), were screened based on numerical simulations by extracting a reaction one by one from the model consists eight reactions. The field scale 3D numerical simulation on THAI (Toe-to-Heel Air Injection) process, an expected ISC technology to produce bitumen, has been carried out successfully for a typical oil sands reservoir by using the three reactions. Furthermore, the comparisons of numerical simulation results have been conducted between THAI and SAGD methods.

Keywords

In-Situ Combustion, Numerical Simulation, Screening, Chemical Reactions, Bitumen, Oil Sands

作者单位

作者Yuta Yoshioka、Kyuro Sasaki、Koichi Takatsu和Yuichi Sugai均来自日本九州大学工程学研究生院以及九州大学地球资源工程系。