NUMERICAL INVESTIGATION OF SOLVENT AND THERMAL HYBRID PROCESSES FOR THIN HEAVY OIL RESERVOIRS

本文是一篇关于薄层储层中稠油溶剂和热混合开发的数值研究硕士论文,作者为朱佐静(Zuojing Zhu),于2012年12月在加拿大里贾纳大学石油系统工程系提交。论文主要探讨了电阻加热与溶剂注入(ERH-S)以及蒸汽与溶剂注入的SAGD和CSS过程,在提高薄层稠油采收率中的潜力。通过CMG的STARS软件进行数值模拟,研究结果表明,这些混合过程能够显著提高原油产量,对于加拿大西部的重油和沥青质资源开发具有重要的实际意义。

CMG软件应用情况

在本研究中,CMG的STARS软件用于模拟和分析两种热和溶剂混合过程:电阻加热与溶剂注入(ERH-S)以及SAGD和CSS的溶剂注入。通过STARS软件,研究者能够模拟不同操作条件下的储层性能,包括电加热、溶剂注入以及它们对产油、温度分布和储层压力的影响。软件能够对这些复杂的混合过程进行详细的数值模拟研究,从而评估它们在提高原油采收率方面的有效性。

Abstract

Western Canada has the second largest oil resources in the world. Over 90% is heavy oil and bitumen. Vapour Extraction (VAPEX), similar to Steam Assisted Gravity Drainage (SAGD) but using solvent to reduce the oil viscosity, has been proposed to produce heavy oil reservoirs in an environmentally sustainable way.

However, while this process might work well for thicker reservoirs, such as those in Alberta, it will likely not meet economic thresholds for thinner reservoirs, such as those in Saskatchewan. The low flow rate in the pure VAPEX process is mainly due to three reasons: low mass transfer rate compared to thermal transfer rate, poor communication efficiency between the injector and the producer because of the reservoir heterogeneity and long distance between the injector and the producer, and poor horizontal well conformity.

In this thesis, two categories of thermal and solvent hybrid processes are investigated to enhance the oil recovery for thin heavy oil reservoirs: electrical resistive heating with solvent injection and steam with solvent co-injection in both SAGD and Cyclic Steam Stimulation (CSS). Both categories are numerically investigated by using CMG’s STARS.

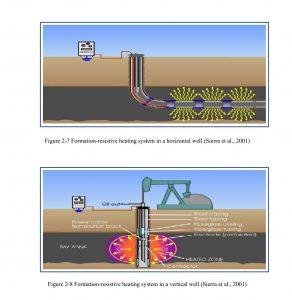

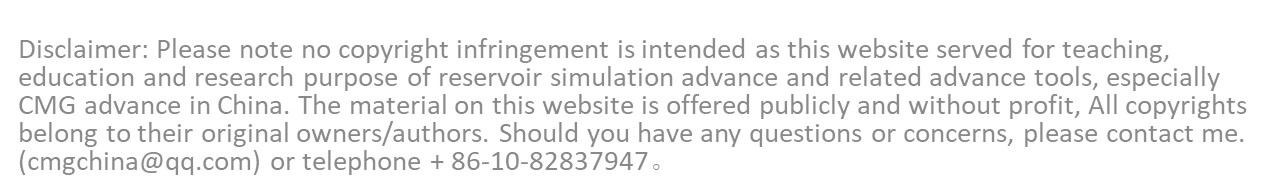

Electrical resistive heating with solvent injection (ERH-S), a novel process, is presented and investigated to enhance the communication efficiency between the injector and the producer. This process can also improve the horizontal well conformity. The electrical heating is the most suitable to be coupled with the solvent process since the electrical heating (1) generates uniform heating results along the horizontal wellbore; (2) increases apparent permeability along the wellbore; (3) is not affected by the reservoir heterogeneity, such as thief zones and shale; (4) reduces water cut; and (5) reduces the formation damage caused by asphaltene precipitation.

Through the numerical simulations and analysis, ERH-S shows three features that contribute to the enhanced oil flow: (1) the heat from the electrode establishes good communication between the injector and the producer by viscosity reduction; (2) the in-situ generated heat through ERH along with the horizontal wellbore is not susceptible to reservoir heterogeneity, and, thus, the horizontal well conformity can be improved; (3) the solvent can reduce the viscosity of the heavy oil in unheated zones where the ERH cannot reach, and it can also assist viscosity reduction of heavy oil in the heated zone. The simulation results show that this hybrid process can improve the oil rate 2 to 5 times over VAPEX.

SAGD and CSS are two successfully applied enhanced heavy oil/bitumen production techniques. When these two techniques are applied in thin heavy oil reservoirs, due to the significant heat loss, the Steam-Oil Ratio (SOR) is too high to make these techniques economical. Simulations for steam with solvent co-injection, SAGD with solvent, and CSS with solvent show that under similar temperature and pressure between solvent dew points and operating conditions, the solvent injection can show better Cumulative Steam-Oil Ratio (CSOR). This study indicates that the hybrid processes using thermal and solvent have great potential to recover Western Canada’s thin heavy oil/bitumen reservoirs. It is recommended that laboratory investigation should be conducted in future.

本研究针对加拿大西部超过90%的重油和沥青资源,探讨了溶剂和热混合过程在提高薄层稠油采出程度方面的潜力。研究主要关注两种混合过程:电阻加热结合溶剂注入以及蒸汽与溶剂共注入的SAGD和周期性蒸汽吞吐(CSS)。这些过程通过CMG的STARS软件进行数值模拟。研究发现,电阻加热与溶剂注入(ERH-S)能显著提高油流,与VAPEX相比,产油量提高了2至5倍。此外,研究还表明,使用热和溶剂混合过程对于加拿大西部薄层重油/沥青储层的开采具有很大的潜力,并建议未来进行实验室研究以验证模拟结果。

作者单位

里贾纳大学石油系统工程系,萨斯喀彻温省,加拿大