An Improved Vapour Solvent Injection Technique for Enhanced Heavy Oil Recovery

加拿大拥有丰富的重油和沥青资源,其中大部分位于西部加拿大沉积盆地。基于热力的开采技术,如蒸汽驱、蒸汽吞吐和蒸汽辅助重力泄油,已被广泛应用于降低重油粘度,但这些热采方法在油层薄且含水饱和度高的情况下成本高昂且不经济。非热采方法,如冷采和溶剂注入,是替代方案。溶剂注入技术,如汽化溶剂萃取和周期性溶剂注入,通过注入汽化的溶剂来降低重油粘度并实现原位开采,从而提高重油采收率。本文提出了一种新的溶剂注入技术—— CPCSI(周期性生产伴连续溶剂注入),并通过实验和数值模拟对其性能进行了评估。

CMG软件应用情况:

结论:

-

VAPEX 过程的局限性

在 VAPEX 过程中,溶剂腔上升阶段无法通过圆柱形物理模型进行评估,即使有足够的泄油高度,这一阶段的采收率也非常低。因此,在 VAPEX 过程中,溶剂腔扩展阶段是采收率增加的主要时期。 -

CPCSI 技术的优势

开发了一种新的溶剂注入技术——周期性生产伴连续溶剂注入(CPCSI)。实验结果表明,应用 CPCSI 过程可显著提高采收率。CPCSI 过程分为三个阶段:-

第一阶段:建立注入井与生产井之间的连通性。

-

第二阶段:采收率开始增加。

-

第三阶段:采收率开始下降。

在第一阶段,注入井与生产井之间施加较高的压差以建立溶剂通道。在生产期间,生产井采用 50 分钟关闭/10 分钟开启的井周期,并施加较小的压差以避免过高的气油比。

-

-

压差对采收率的影响

注入井与生产井之间的压差在周期性生产期间对采收率没有显著影响,但较高的压差会导致生产期间的气油比增加,从而降低该过程的经济性。 -

模型放置方向的影响

垂直放置的模型由于重力作用,采收率更高。在溶剂注入/浸泡期间,稀释后的油在重力作用下排到底部的生产井处,并在生产井开启期间容易被冲出。 -

模型长度的影响

中等长度的模型在垂直放置和水平放置的生产方案中均产生了最高的平均采收率,同时溶剂油比也最低。在这些圆柱形模型中可以找到最佳的压差和井关/开方案。 -

CPCSI 过程的机理

CPCSI 过程的优势在于,生产期间的连续溶剂注入可以维持油藏压力,避免稀释后的油因溶解溶剂释放和突然的能量损失而导致粘度重新增加。在注入井与生产井之间施加较小的压差时,稀释后的油中会释放出少量的溶解溶剂,形成泡沫油流和溶液气驱。结合生产井开启期间的气冲,油将被冲出。 -

溶剂捕集概念的验证

本研究发展并验证了溶剂捕集概念。生产井关闭期间允许溶剂持续扩散,稀释后的油在重力作用下持续排到底部的生产井处。稀释后的油将在生产井周围积聚,而溶剂将被困在积聚的稀释油区上方的溶剂腔中。因此,在生产井开启的初期可以生产出大量的稀释油。 -

侧向井网的效果

应用侧向井网时,采收率高于 VAPEX 过程。泡沫油流和溶剂捕集机制将导致稀释油饱和度前沿移动,油藏将通过这一过程重新饱和,从而提高采收率。 -

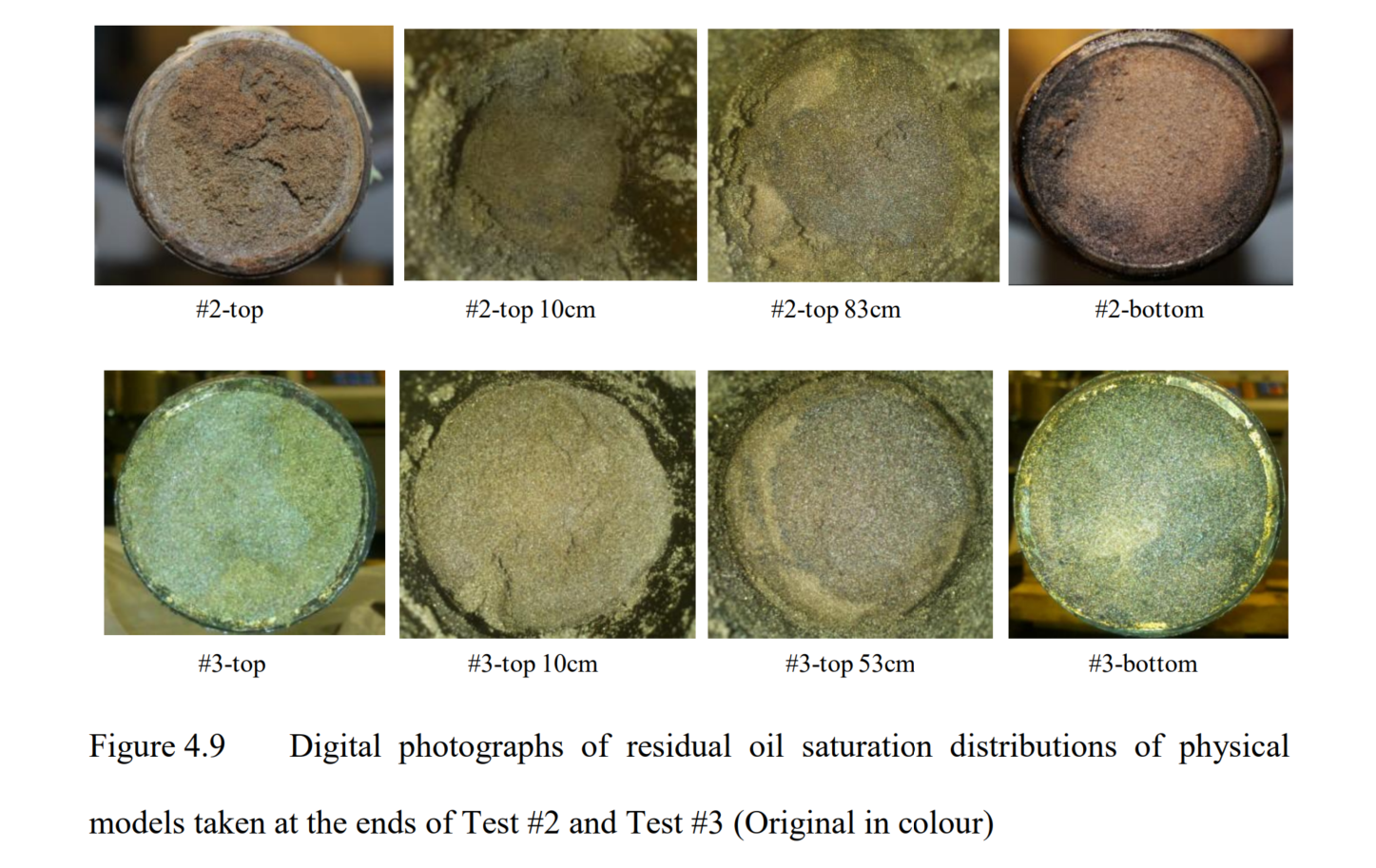

溶剂粘性指进和高渗透率区域的影响

溶剂粘性指进和高渗透率区域将导致重油生产期间溶剂过早突破。然而,粘性指进和高渗透率区域可以扩大溶剂与油的接触面积,使多孔介质中的更多重油在生产井关闭期间被稀释。更多的重油会膨胀,膨胀后的油会显著增加多孔介质中的残余油饱和度。

作者单位:

加拿大里贾纳大学石油系统工程系

Abstract:

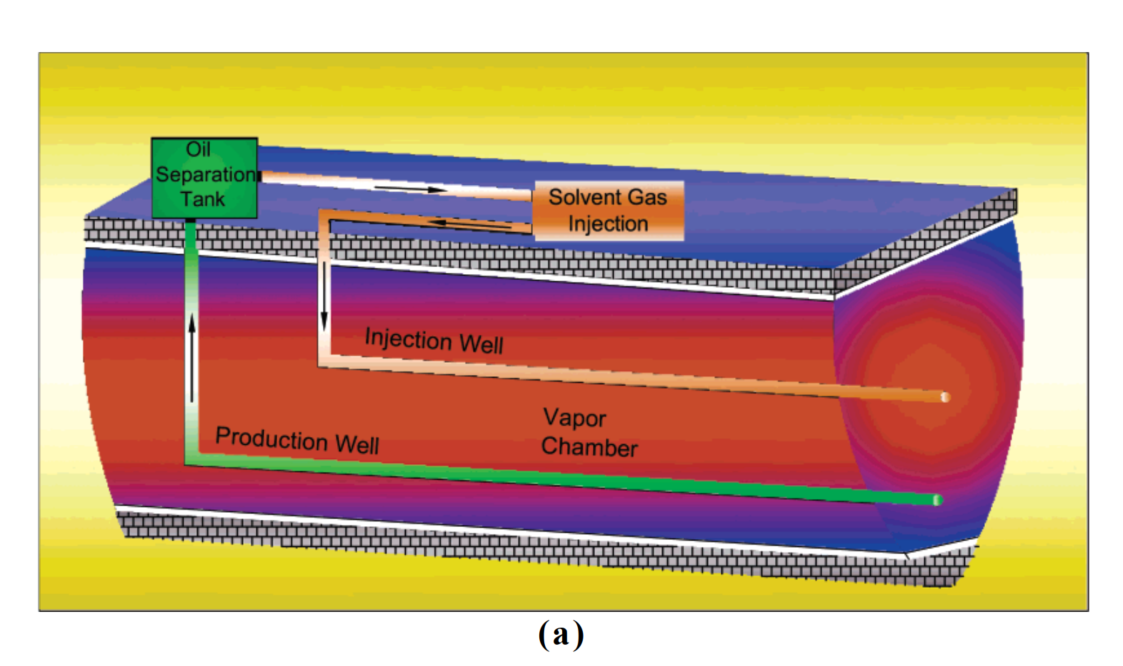

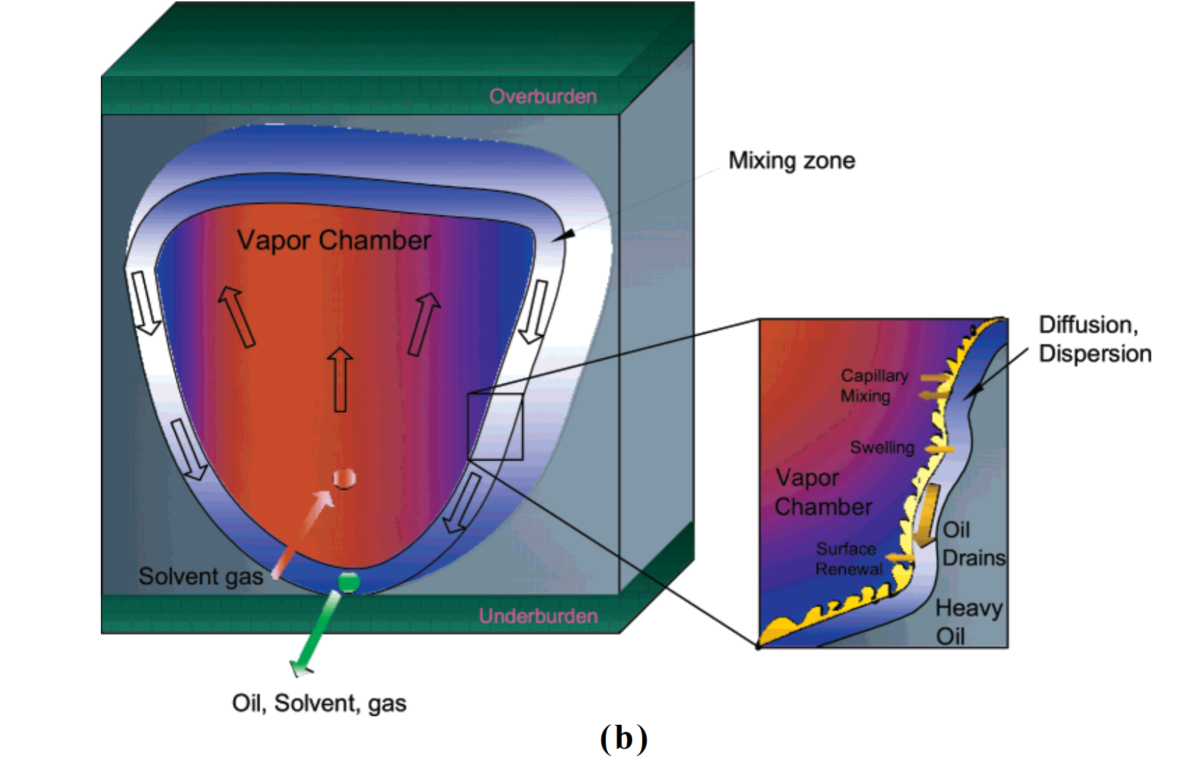

There are tremendous heavy oil and bitumen resources in Canada, and most of them are located in the Western Canadian Sedimentary Basin. Thermal-based recovery techniques, such as steam flooding, cyclic steam stimulation (CSS), and steam-assisted gravity drainage (SAGD), are effective and have been widely applied in the field to reduce heavy oil viscosity. However, thermal-based methods are costly and uneconomic, particularly for reservoirs with a thin net-pay. In Saskatchewan, half of the heavy oil resources are contained in reservoirs with a pay zone thickness of less than 10 metres. Non-thermal methods, such as cold production, and solvent-based methods, are the alternative approaches. Cold production, such as cold heavy oil production (CHOP) and cold heavy oil production with sands (CHOPS), suffers low recovery factor, which is approximate 5–10% of original oil in place (OOIP). Solvent-based heavy oil recovery methods represent a promising technique that has been extensively studied by many researchers. It has the potential to recover heavy oil resources more economically and in a more environmentally friendly fashion in cases in which the thermal-based method is not applicable or after CHOP/CHOPS processes.

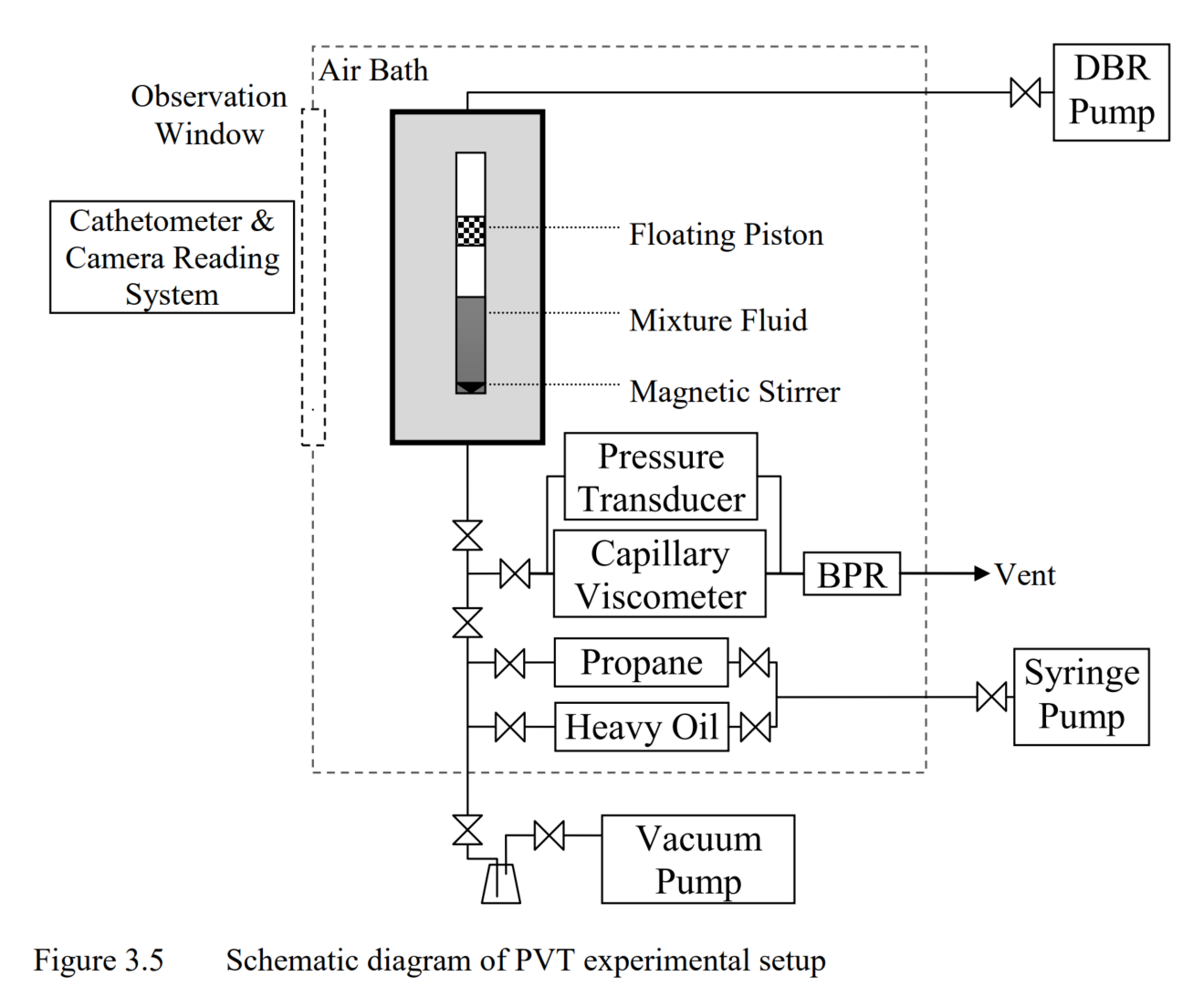

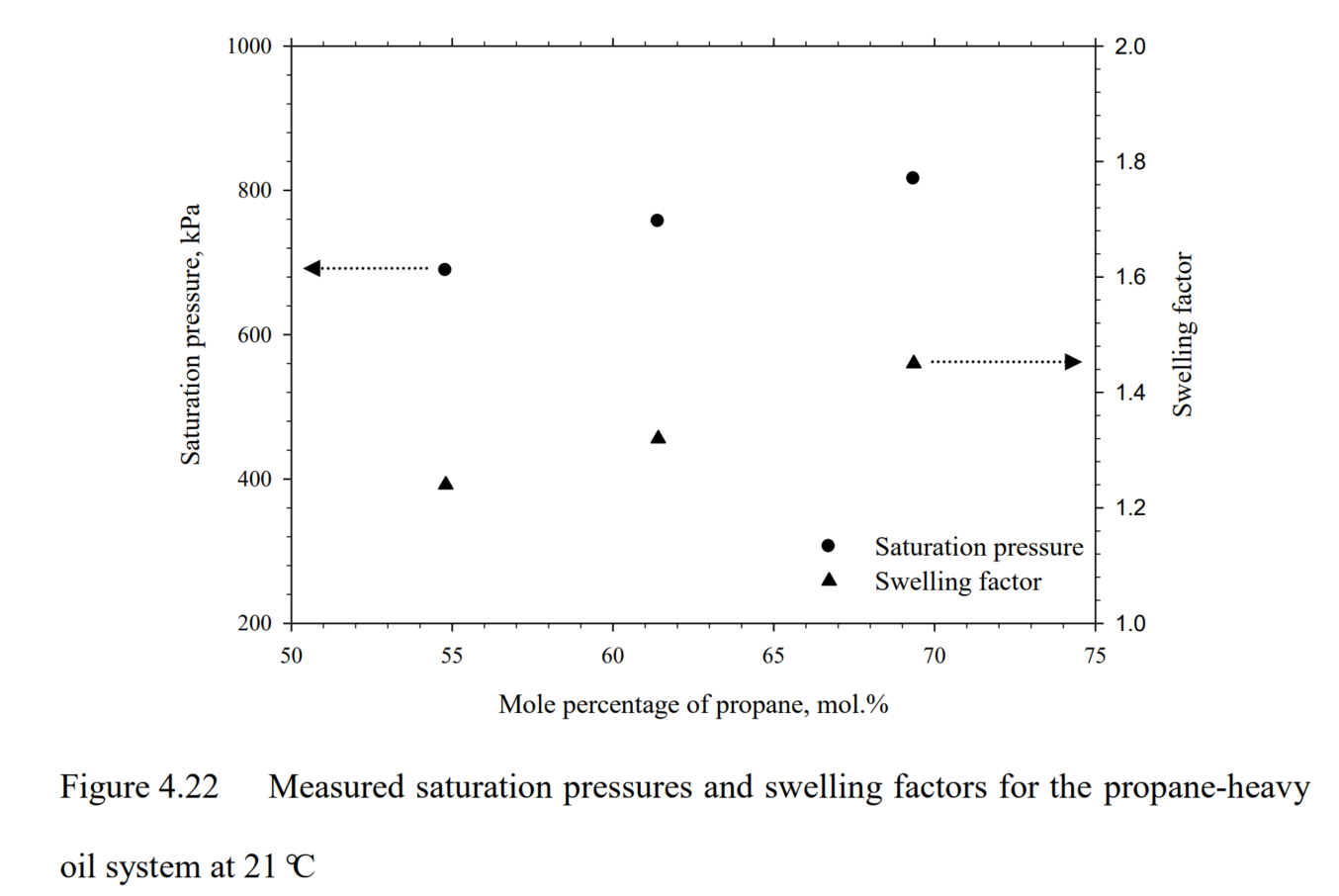

Currently, traditional solvent injection methods include continuous injection processes, such as vapour extraction (VAPEX), and cyclic injection processes, such as cyclic solvent injection (CSI). The low production rates of VAPEX are observed in field tests. CSI does not show exciting results due to the quick pressure depletion and the sudden reservoir energy loss, which causes the oil to regain its viscosity. Thus, a more effective solvent injection technique is urgently required to overcome the disadvantages in traditional solvent injection processes. In this study, a new cyclic solvent production (CSP) technique, cyclic production with continuous solvent injection (CPCSI), was proposed and evaluated through experiments and numerical simulations. Low permeability physical models were packed with Potter glass beads and then saturated with Western Canadian heavy oil samples at connate water saturation. Pure propane was used as gaseous solvent that was injected into the physical models continuously to extract the heavy oil while the producer was operated with a cycle of long shut-in time and short open periods. Solvent breakthrough time, heavy oil production rate, pressure profile, and asphaltene content were measured.

The effects of drainage height, gravity, and production configurations were evaluated. Numerical simulations were performed using CMG STARS to history match the experimental results. It is found that the simulation can match the experimental results but it has the limit to predict the performance for different models. It was found that the heavy oil was diluted and drained down by gravity during the shut-in periods and then produced in the open periods via solution gas drive and gas flush. In comparison with VAPEX and CSI, CPCSI offers a free gas drive to flush the diluted oil out while the reservoir pressure is maintained so that the diluted heavy oil viscosity will not be re-increased. The CPCSI process can be an alternative optimization production scenario for applying solvent-based in-situ EOR techniques in Western Canadian heavy oil reservoirs.