Scaling analysis of hydrogen flow with carbon dioxide cushion gas in subsurface heterogeneous porous media

本论介绍了地下氢气储存在脱碳过程中的重要性和对H2回采效果的影响。作者进行了一项全组份模拟研究,以探究地下H2储存的基本流体力学机理。通过二维垂直模拟和非常细小的网格尺寸,作者观察了H2与CO2作为垫气在不同流动状态下的行为,并分析了粘度不稳定、毛细管绕流、气体捕集和重力分离等问题。作者运用尺度理论总结了计算结果,并验证和应用于地下氢气储存的背景下。作者还提出了三个无量纲组,通过形状因子、毛细/粘度比和重力/粘度比,来关联系统中不同尺度之间的开采效果。研究结果表明,在注入井附近,H2能够渗透到缓冲气体中,而不是被排斥开。因此,回采的H2纯度降低,尤其是在粘度为主的情况下。另一方面,在重力为主的情况下,注入的H2主要积聚在顶部,与CO2形成高度限制的混合区域。此外,尽管毛管力可能会对气体分布造成一定影响,但对H2的开采效果影响较小。这是因为H2的开采并不依赖于气体的掠过效应,而是可以沿着注入时形成的相同路径进行开采。该研究为地下氢气储存的优化和设计提供了理论支持。

摘要

地下氢气储存在脱碳过程中具有日益重要的作用。然而,对涉及多相流动的这一过程缺乏足够的了解,这可能会对H2的回采效果产生重大影响。因此,进行了一项全组份模拟研究,以分析潜在问题并了解地下H2储存的基本流体力学机理。

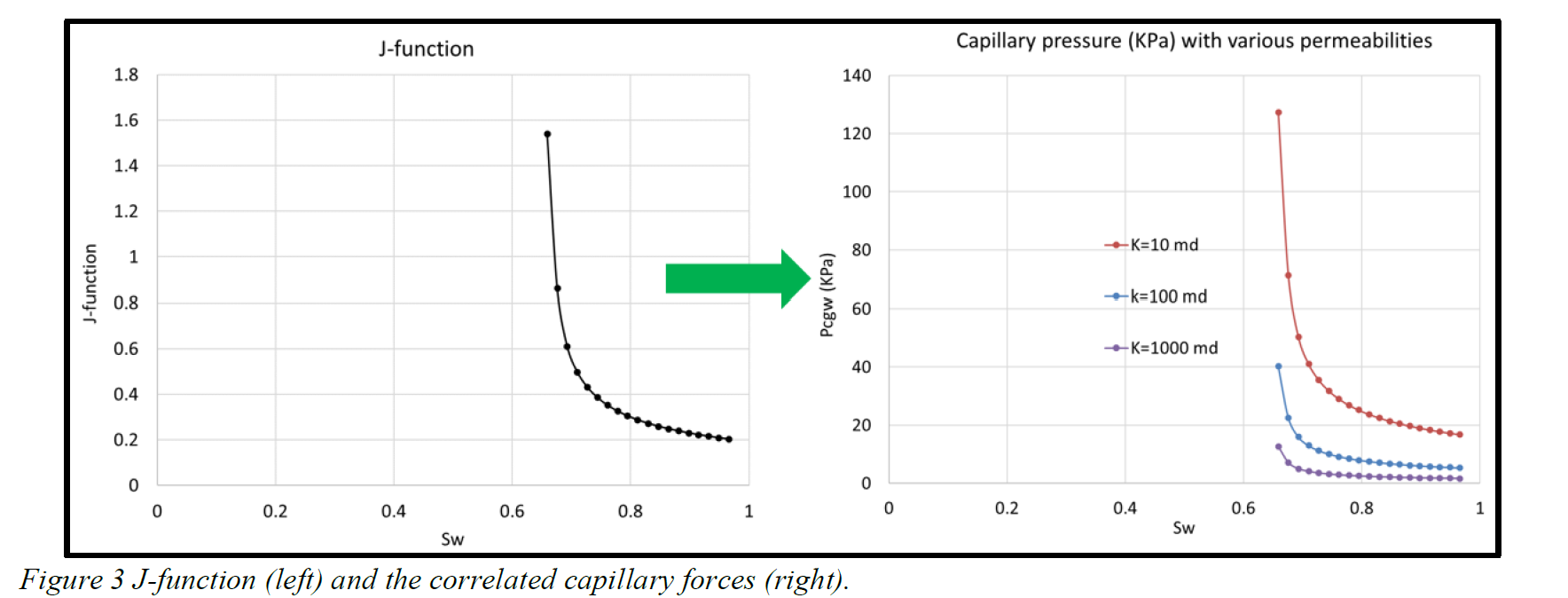

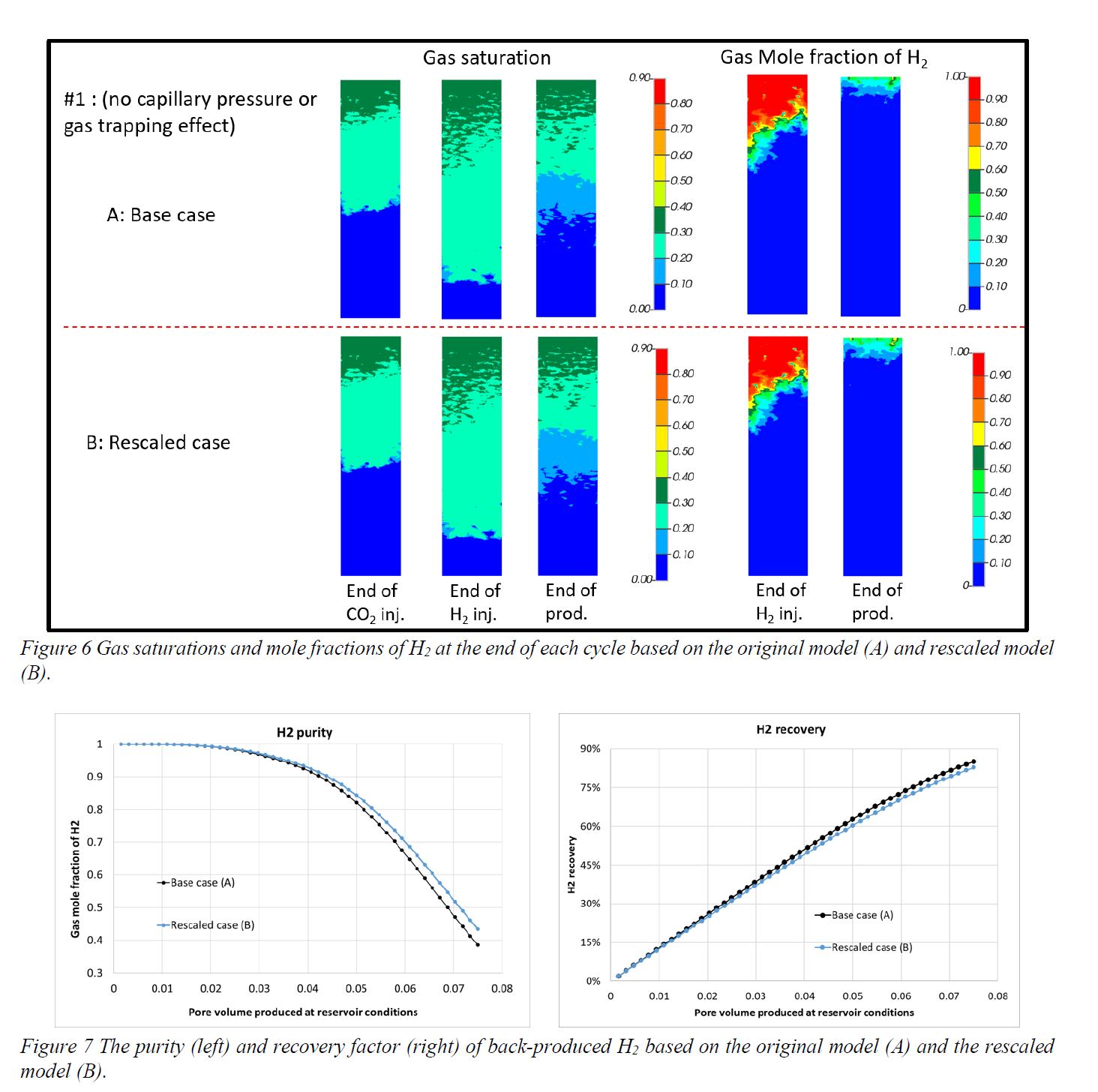

我们进行了一系列二维垂直模拟,使用非常细小的网格尺寸(0.1m),以观察H2与二氧化碳(CO2)作为垫气在各种流动状态下的详细行为。我们分析了粘度不稳定、毛细管绕流、气体捕集和重力分离等问题。为了总结计算结果,应用了尺度理论,并在地下氢气储存的背景下验证和应用了这一理论。

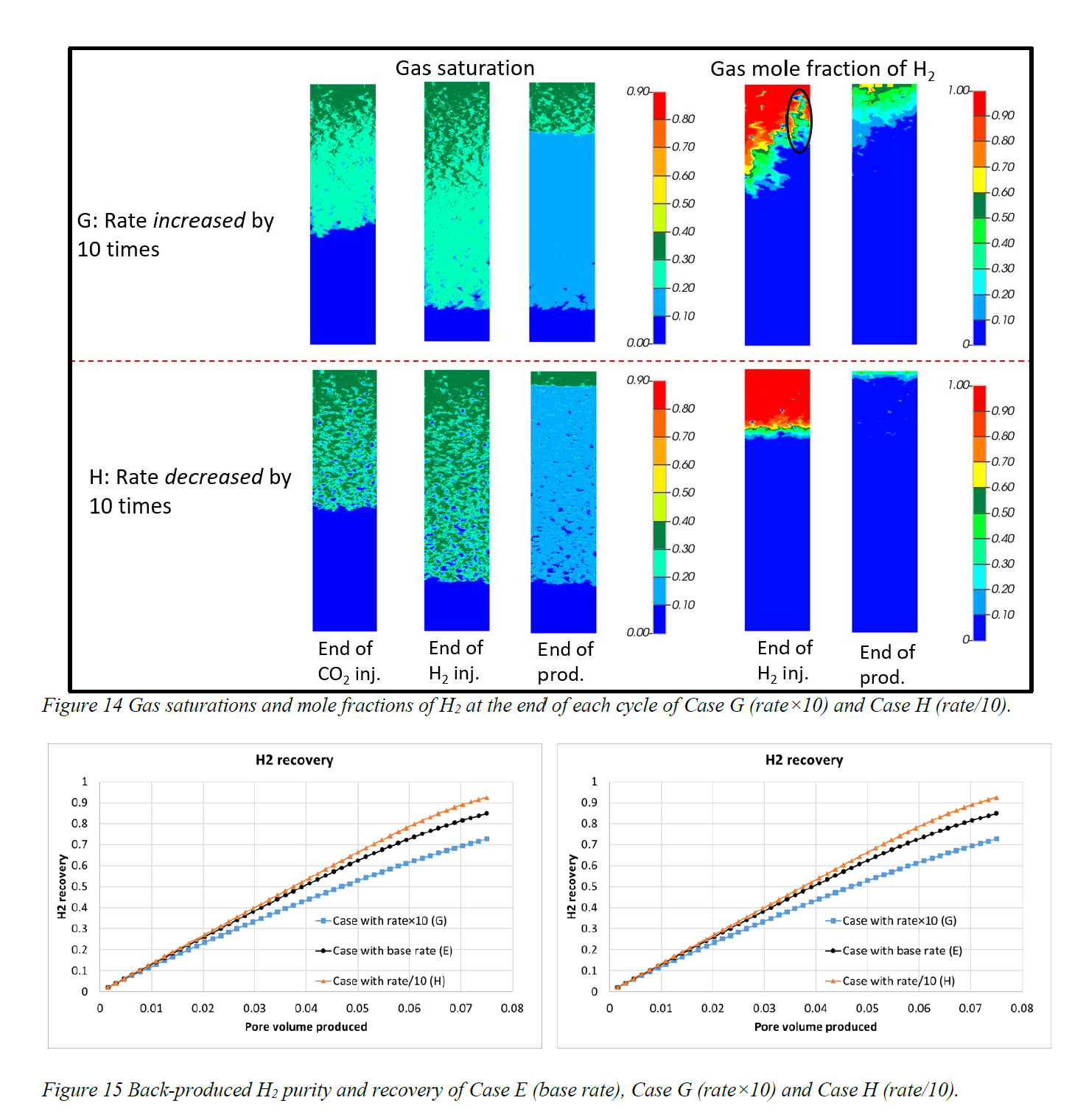

由于本研究侧重于流体力学行为,我们提出了三个无量纲组,包括形状因子、毛细/粘度比和重力/粘度比,以关联固定非均匀系统中不同尺度之间的回收性能。结果表明,在注入井附近,H2能够渗透到缓冲气体中,这意味着CO2不会像活塞一样被排斥开。因此,回收的H2纯度大大降低,特别是在粘度为主的情况下。另一方面,在以重力为主的情况下,注入的H2主要积聚在顶部,与CO2形成高度限制的混合区域。因此,在这种情况下,开采效果大大提高。尽管毛管力可能会显著改变气体分布,导致绕流区域,但对H2的开采效果影响很小。这是因为H2的开采并不依赖于气体的掠过效应,而是可以沿着注入时形成的相同路径进行开采。

Abstract

Subsurface hydrogen (H2) storage in geological formations is of growing interest for decarbonization. However, there is a knowledge gap in understanding the multiphase flow involved in this process, which can have a significant impact on the recovery performance of H2. Therefore, a full-compositional modelling study was conducted to analyze potential issues and to understand the fundamental hydrodynamic mechanisms of H2 storage. We performed a range of 2D vertical simulations at the decametre scale with a very fine cell size (0.1m) to observe the detailed flow behaviour of H2 with carbon dioxide (CO2) as cushion gas in various flow regimes. Issues such as viscous instability, capillary bypassing, gas trapping and gravity segregation are analysed here. To generalise our calculations, we have validated and applied the scaling theory in the context of subsurface H2 storage. Since this study is focused on the hydrodynamic behaviour, three dimensionless groups, including aspect factor, capillary/viscous ratio and gravity/viscous ratio were identified to correlate recovery performance between various scales in a fixed heterogeneous system. It was found that H2 could infiltrate the cushion gas in the proximity of the injectors, meaning that CO2 is not displaced away from the injectors in a piston-like fashion. As a result, the purity of the back produced H2 is much degraded, particularly in a viscous-dominated scenario. On the other hand, the injected H2 mostly accumulates at the top forming a highly restricted mixing zone with CO2 in the gravity-dominated case. The recovery performance is therefore much improved in this case. Although the gas distribution can be significantly altered by capillary forces leading to bypassed zones, the recovery performance of H2 is hardly influenced. This is because the back-produced H2 recovery is not dependent on the sweep efficiency of the gas. H2 can be back produced following the same paths which were formed during injection.

Conclusions

In this work, we have validated scaling theory in the context of H2 flow with CO2 as cushion gas in a heterogeneous subsurface aquifer system, using fine scale full-compositional simulations (Δx=0.1m). Based on scaling theory, we identified various flow regimes and how they affect flow behaviour and the subsequent recovery of H2. The impact of several physical processes, namely viscous fingering, bypassing due to capillary pressure, gas trapping and gravity segregation were investigated in detail. Specifically, we have made the following five principal observations.

1. We identified that three dimensionless groups, including aspect factor, gravity/viscous ratio, gravity/capillary ratio and capillary/viscous ratio, are adequate to correlate recovery performance of H2 with CO2 cushion gas between various scales based on a fixed permeability field. Reservoir response, such as the gas distribution, H2 purity and H2 recovery, can be properly matched between the different model length scales. Although the discrepancy resulting from the pressure difference is very minor, scaling laws should be used with some caution in cases with significant pressure change.

2. In the heterogeneous model studied here, the low-viscosity H2 infiltrates the cushion gas in the proximity of the injectors, meaning that CO2 is not efficiently displaced away from the injectors in a piston-like fashion. In the viscous-dominated case (highest operation rates), the purity of back-produced H2 experiences a dramatic decline during the early stage of production. Less than 10% of the H2 can be produced above the purity required for fuel cells (99.97%). Therefore, heterogeneous formations may not be directly appropriate storage targets for end users of fuel cells. A purification process would be needed, particularly if the operational rates are required to be high.

3. On the other hand, the injected H2 accumulates almost evenly at the top in the gravity-dominated case (lowest operation rates). The mixing zone between H2 and CO2 is much restricted by the gravity force, due to the density difference between H2 and CO2. The gravity-dominated flow regime has the best H2 recovery performance: in the configuration studied approximately 23% and 57% of H2 can be produced with a purity level for fuel cell and combustion, respectively.

4. In our cases, the capillary pressure is not a key influencing factor to the recovery performance of H2 given the sufficient volume of CO2 as cushion gas in any of the flow regimes. The reasons are twofold. In the case with extreme operational rates, impacts of capillary pressure are masked by either the viscous force or the gravity force. Although the gas distribution can be evidently altered by capillary pressure, the gas phase follows the same path during back production as it did while flowing into the system, implying that H2 recovery is not strongly dependent on the gas sweep efficiency.

5. Gas trapping effects do not play an essential role in driving recovery performance in the cases presented here. This is because the volume of cushion gas is sufficient to prevent water breakthrough when back producing. However, we wish to point out that the significance of gas trapping effects should not be ignored. In future work on optimization, we will present more results with various operational strategies, where gas trapping effects may lead to very early water breakthrough and drive down the recovery performance.