The impact of thermal fracturing on the nearwellbore region during CO2 injection in depleted gasfields

- 这项研究讨论了热裂缝对耗竭气田中的碳封存项目的影响。在超临界相注入的过程中,二氧化碳以高压和低温的方式注入,而耗竭气田的储层压力较低。压力增加和温度降低导致了热孔隙的弹性响应,从而减少了储层内部的应力。一旦达到开始裂缝的应力阈值,即裂缝应力,热裂缝就会形成。热裂缝主要是由于储层的大规模冷却而产生。这些裂缝影响了井眼附近的NWB区域,使井底压力下降,从而提高了储层的注入能力。

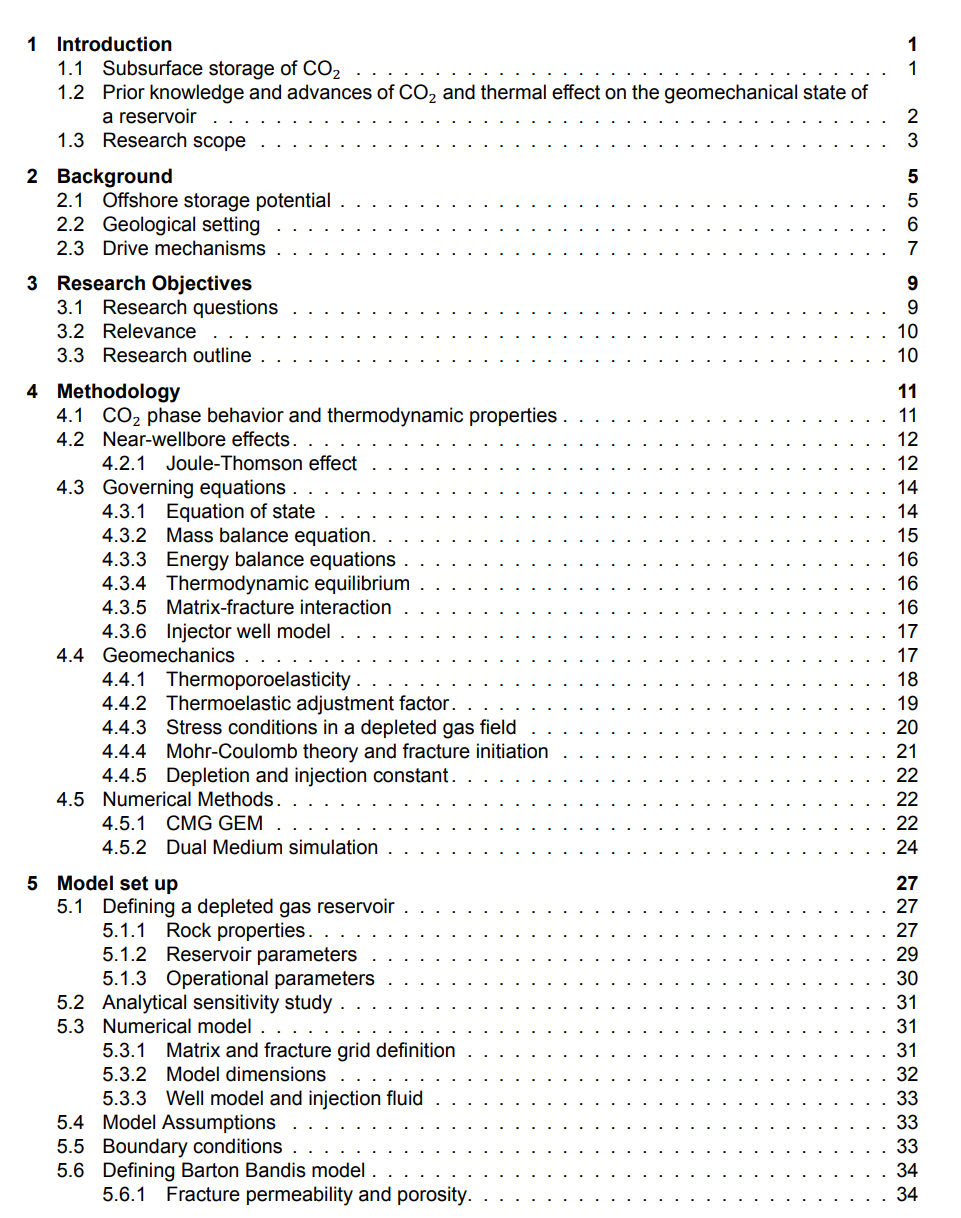

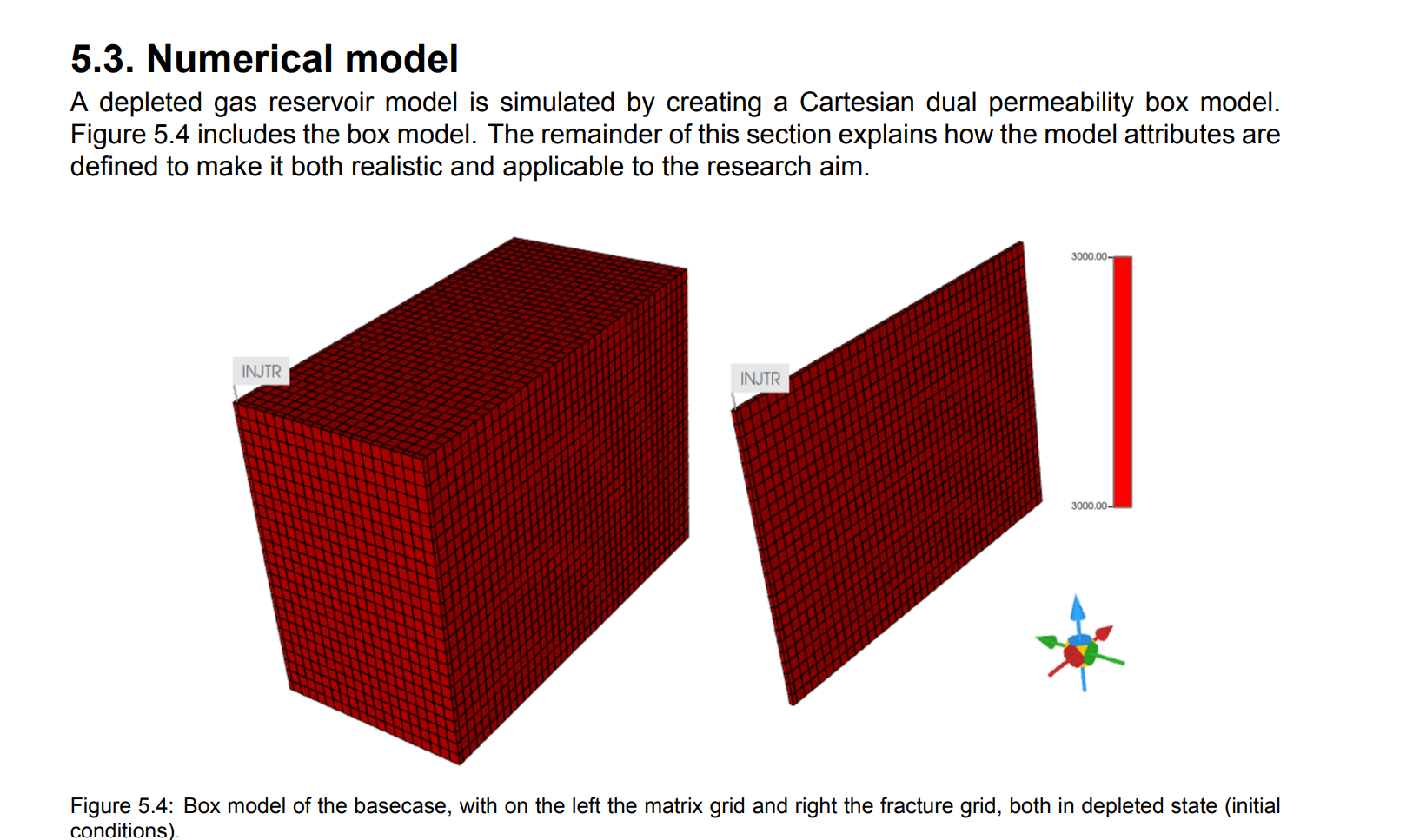

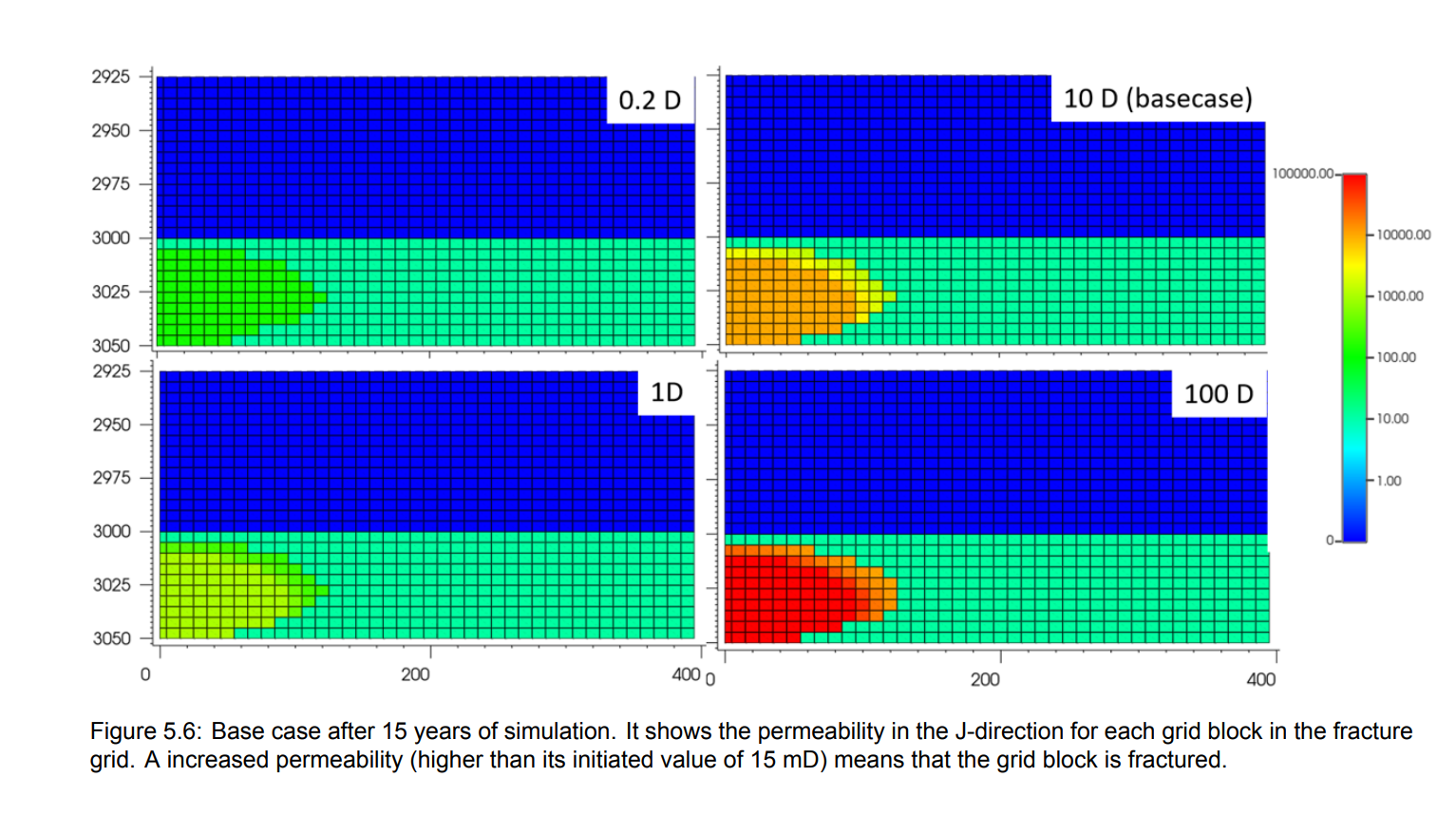

- 该研究使用了CMG GEM进行模拟建模。采用了一个双渗透率的均质盒子模型,该模型以北海的一个普遍耗竭气体储层为基础。为了建模裂缝,使用了Barton Bandis模型。一旦满足裂缝条件,该模型将改变裂缝单元中的渗透性。通过对关键参数进行敏感性分析,研究了裂缝形成时刻、裂缝半长度和储层的注入能力。

- 研究发现,热裂缝遵循最冷部分热前缘的传播路径。一旦满足裂缝条件,热前缘将进一步传播,因为流体通道或储层内的压力升高较慢。地质力学参数的敏感性分析表明,储层内的应力条件发生变化,从而导致注入量的变化,从而改变了裂缝形成时间。对于每个参数,注入能力都会有相似的改善。有效渗透性和注入速率共同决定了储层内压力增加的方式,由于裂缝的形成,注入能力略有增加。增加储层容积会导致储层内压力升高较慢,使得热前缘可以进一步传播,从而延长裂缝长度。最后,对热效应的敏感性分析表明,储层和注入温度之间的较大差异会使裂缝不太依赖于压力的增加而形成,从而导致较早的裂缝和更长的裂缝半长度。虽然压力增加没有改变,但注入能力与基础情况相似。

- 总的来说,该论文揭示了关键参数对热裂缝行为的影响,并展示了预期的参数范围。结合这两个方面,我们可以了解应该关注哪些参数以更好地描述热裂缝的行为,并通过大量数据的收集来经济化运营,排除或包含关键参数。这有助于改进在耗竭气田中进行CO2注入项目的注入策略。

Conclusion

- This research describes how thermal fractures can impact the near-wellbore region during CO2 injection in a depleted gas reservoir that is being used for CCS purposes. Firstly, the flow characteristics of CO2 and the geomechanical reaction under changing pressure and temperature conditions are discussed.

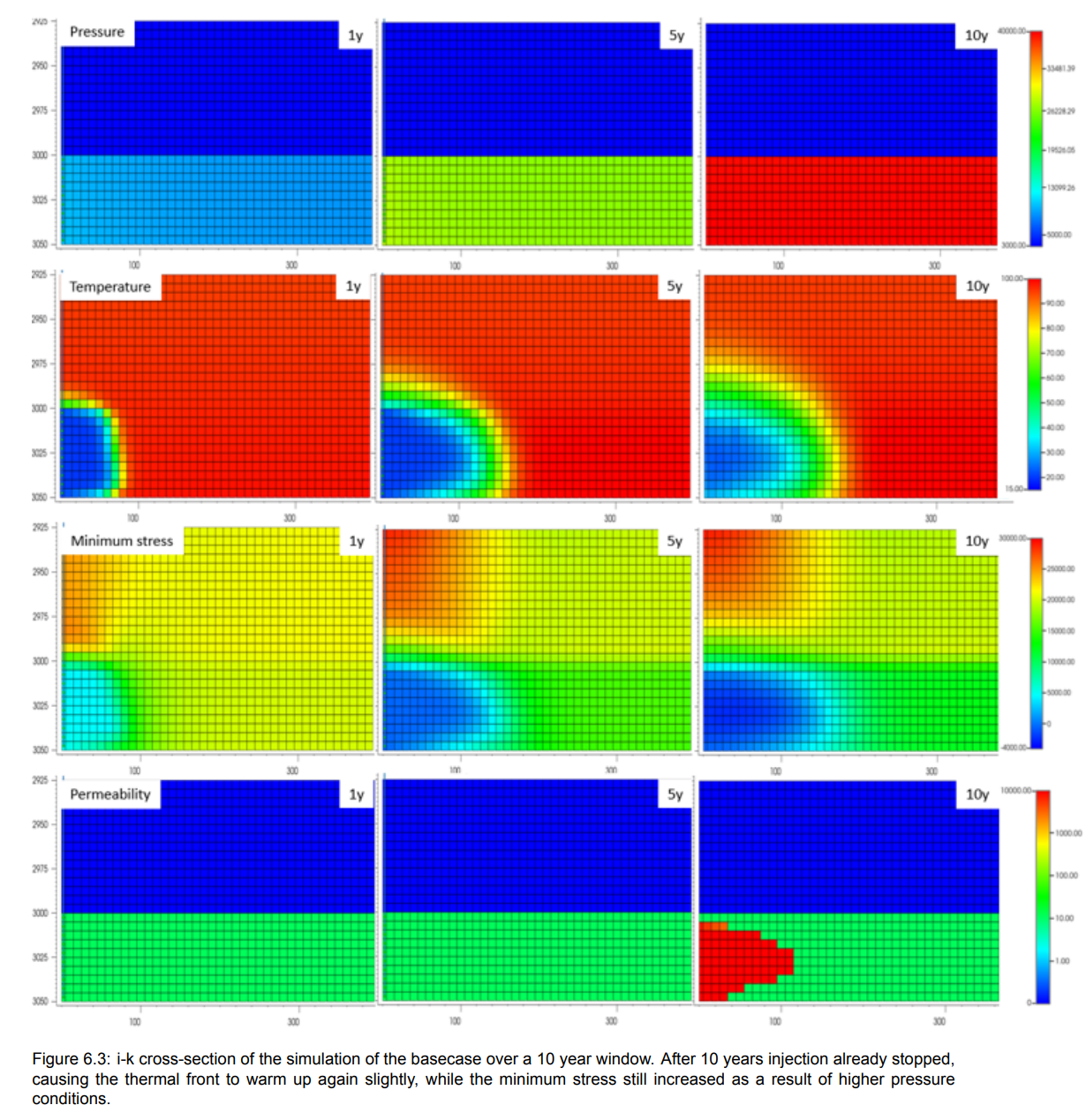

- Secondly, a method for accurately simulating a homogeneous box model with a dual permeability grid system is defined, to simulate propagation of the CO2 in a depleted gasfield. Hereby it is also explained how the temperature and the pressure develops during injection.

- Thirdly, a basecase model is defined together with a low- and highcase scenario for each influential parameter. Each sensitivity’s fracture time, fracture halflength and BHP at fracture time is determined, together with the effect on the injectivity of the reservoir. It is found that the geomechanical properties do not affect how the near-wellbore region of the reservoir reacts to fracturing, resulting in constant injectivity increases for each parameter. It does, however, impact the fracture time. Sooner fracturing leads to further propagation of the thermal front, whose extent means longer fracture halflengths. The reservoir parameters do not change how the reservoir reacts to stress, but changes the way the reservoir handles pressure build-up. The thickness and the permeability define the effective permeability, where a lower effective permeability means faster and higher pressure values around the well, resulting in a more local thermal plume, but sooner fracture initiation. As these parameters effectively change the way the reservoir reacts to pressure build-up, these parameters influence the injectivity increase due to fracturing. The volume has a similar effect as the effective permeability, but with a slower pressure build-up for larger volumes around the well due to a lower average pressure, instead of the higher BHP values due to the flow properties. The operational parameters are similar to the reservoir parameters. The rate influences the pressure build-up around the well and thus the injectivity increase due to fracturing, while the injection temperature determines the pressure dependence during thermal fracture initiation, with lower injection temperatures resulting in fracturing at lower pressure conditions. It is important, however, to realise that the last two parameters are the only two that can be changed during operation.

- Furthermore, it is found that the injection constant due to stress hysteresis not necessarily changes the results much in terms of injectivity increase, but, similarly to the geomechanical parameters, cause earlier fracture time and a prolonged fracture propagation due to the fluid paths the fracture creates.

- Then, the numerical solution is validated by the analytical solution, which is based on the thermoporoelastic effect. It is found that with an adjustment factor of 0.77 to the thermoelastic effect the analytical solution of the pressure at which fracture initiation occurs is more or less the same as the numerical solution. This means that the analytical solution can be used to make an indication on the fracture time once the pressure development is known in a reservoir under the preferred injection strategy.

- Lastly, the outcome as showcased above can be used to better understand on which parameters the focus must be on during data collection to better describe the effect of thermal fractures. In this consideration, the accepted consequences must be known; if the thermal fractures are preferably avoided, if the injectivity increase must be minimized or that the fracture halflength must be contained to a certain region. Economic considerations should also be made, e.g. if it is as costly to gather information on the Biot’s coefficient as it is for the stress conditions, it is much more appealing to have a closer understanding of the stress conditions. This way, the injection strategy can be maximally improved with the minimal economic costs in terms of the effect thermal fractures have on the operation.