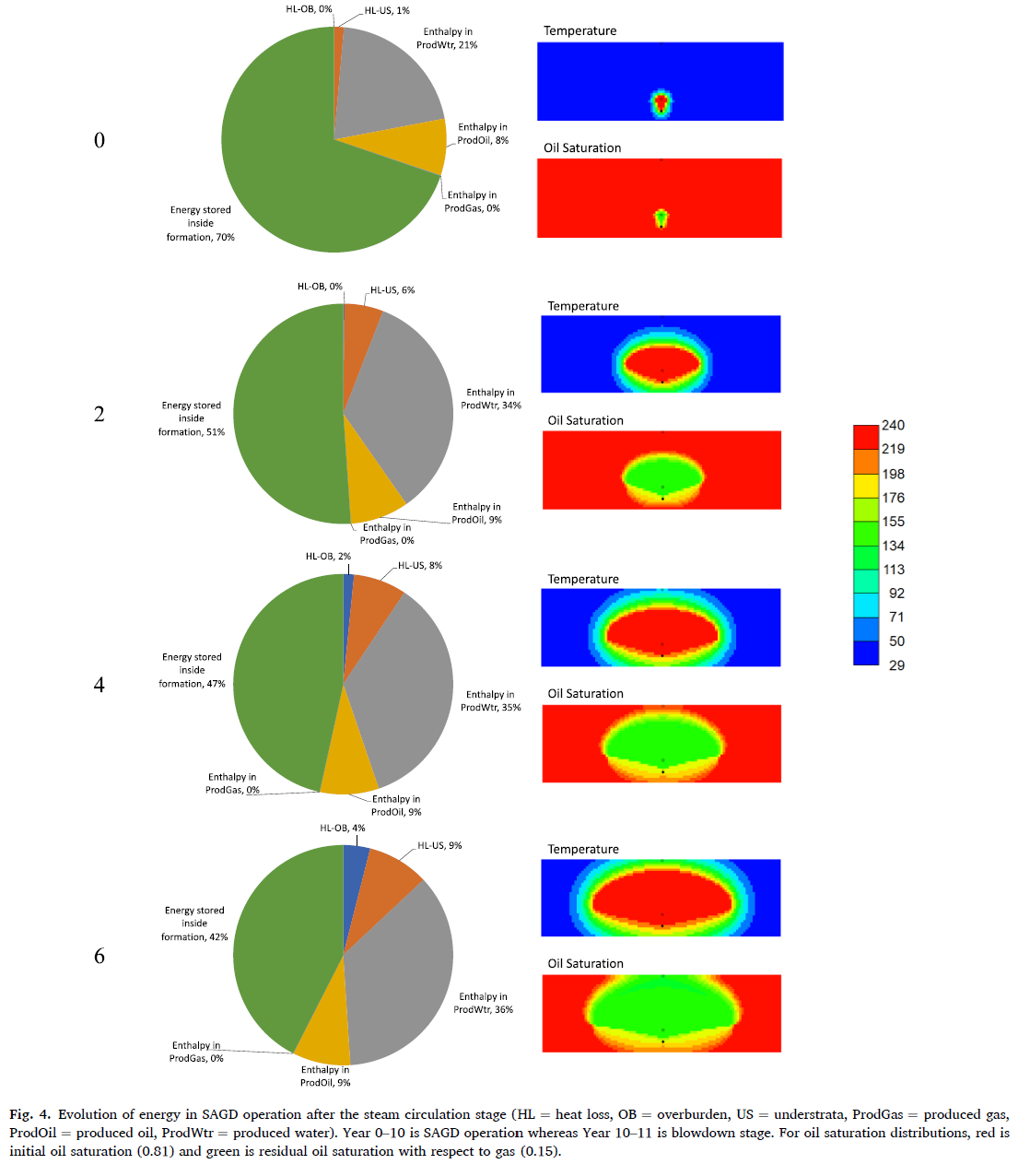

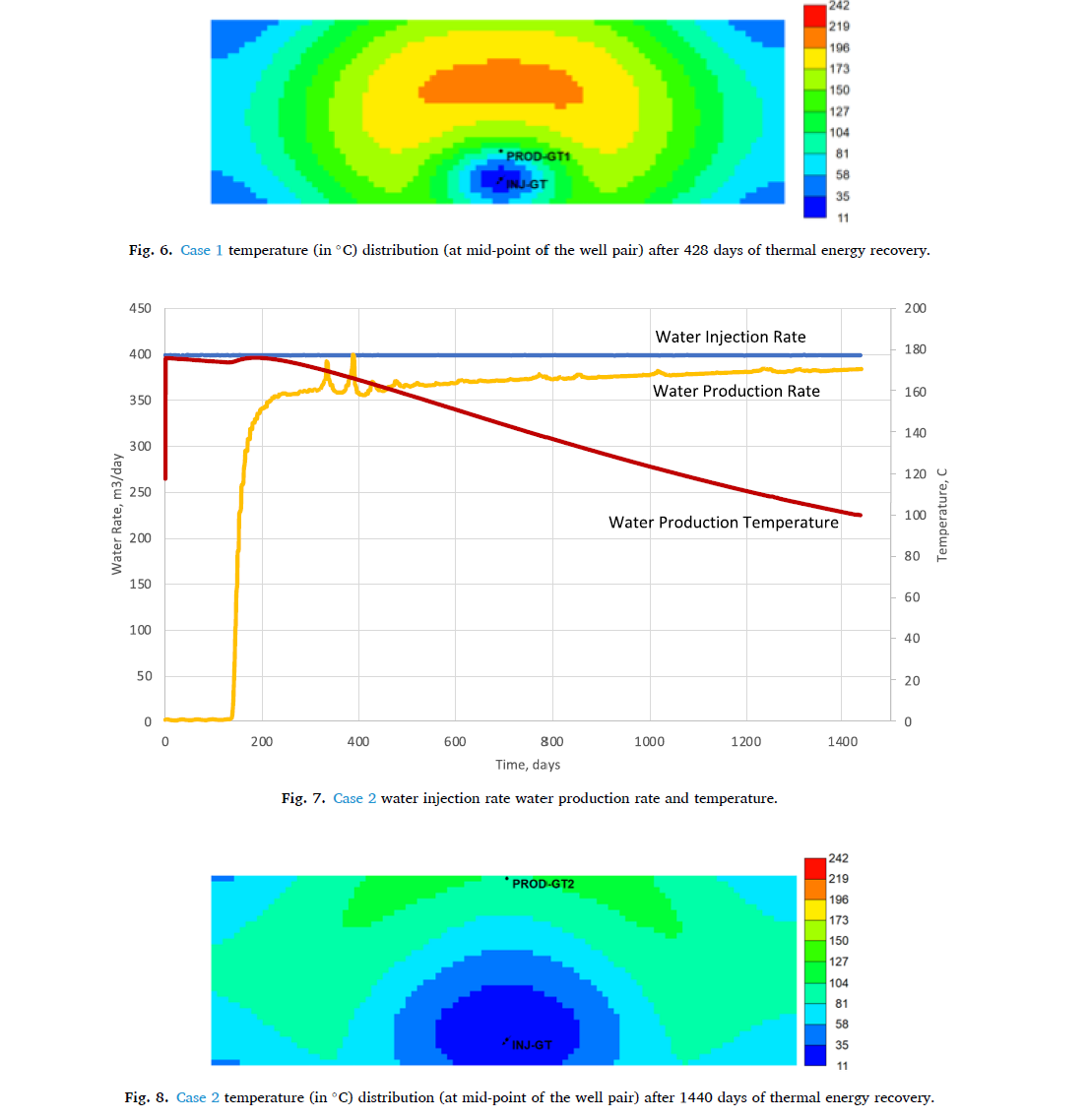

蒸汽辅助重力泄油(SAGD)过程中,将大量蒸汽注入油藏,以将重油采出至地面。注入油藏的热能形成了一个人造地热系统,在SAGD操作完成后,该系统可用于产生热量。本文首次评估了储层中储存的能量,并探索了热能回采的的方法。结果表明,经过10年的SAGD,蒸汽中约35%的总注入能量保留在储层岩石中。SAGD操作结束时,约32%的总注入能量保留在储层岩石中。三个方案的热能回采结果表明,最佳方案是在SAGD井对上方的储层顶部增加一口新的水平井。在这种情况下,>100°C的热水被高速回采了1400多天,在SAGD Blowdown阶段后,储层岩石中所含热能的回收率约为34%。这种回收的能量提供了使SAGD工艺在其整个能源生产寿命内更具热效率的方法。

On geothermal energy recovery from post-SAGD reservoirs

Highlights

- Steam-Assisted Gravity Drainage (SAGD) stores huge amounts of heat in the reservoir during its operation.

- SAGD steam chambers are typically higher than 150 °C when oil production stops.

- About one-third of the total injected energy is stored in the reservoir rock.

- Heat recovery options include vertical floods of working fluid or cyclic heat removal.

Abstract

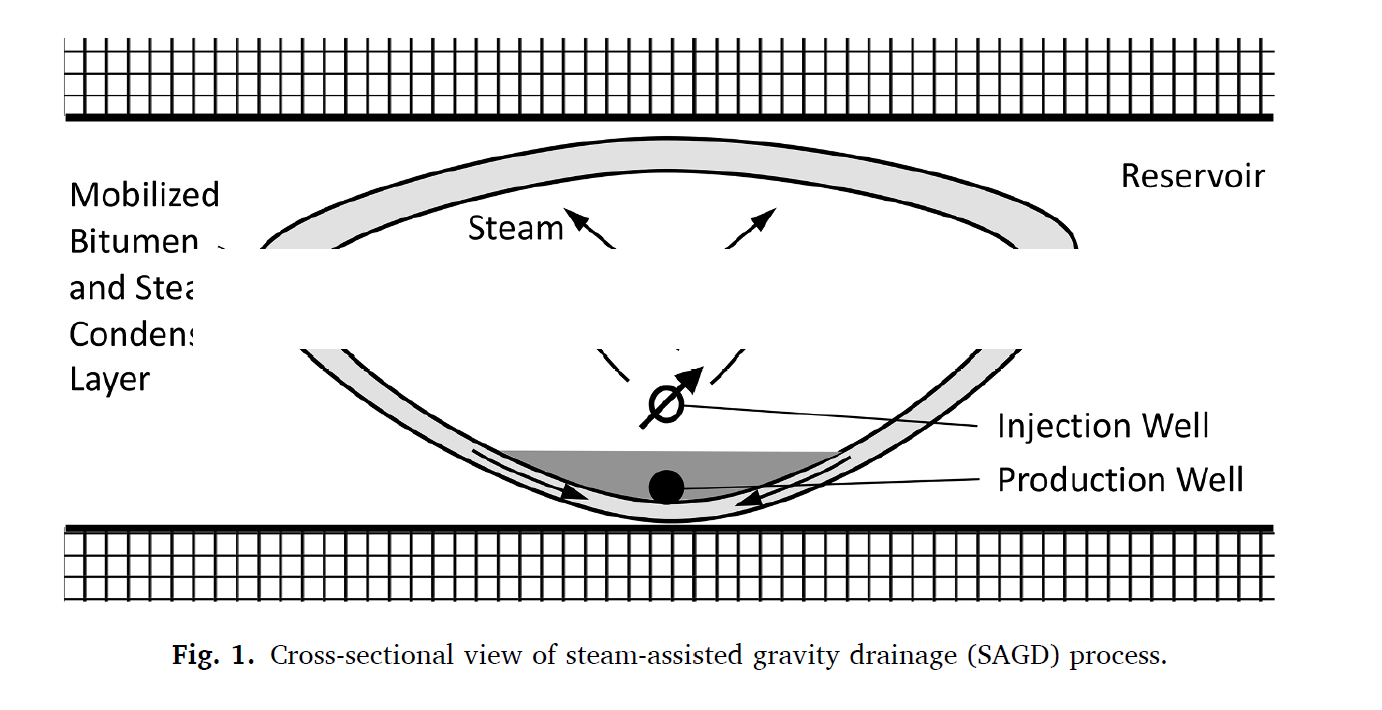

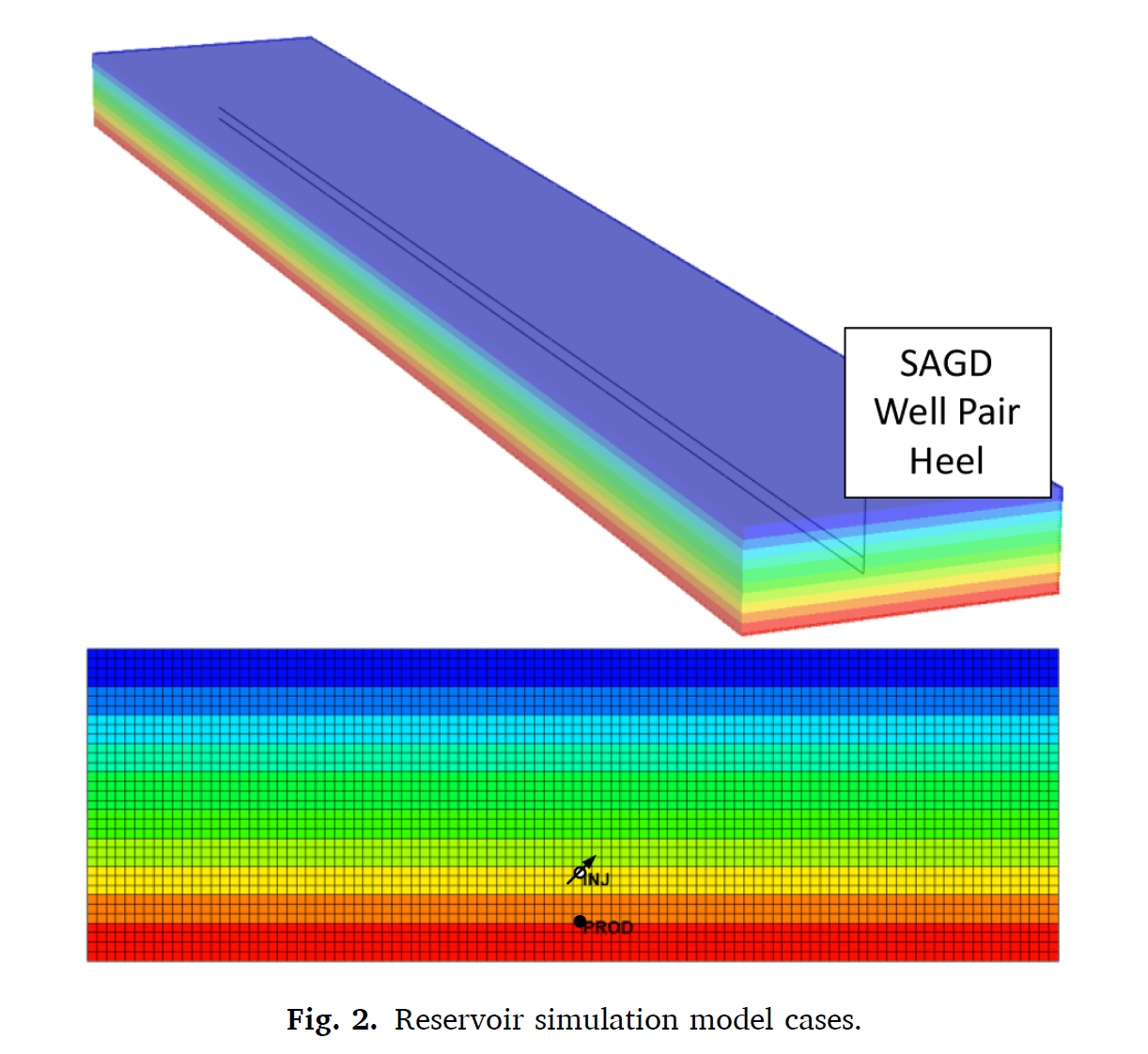

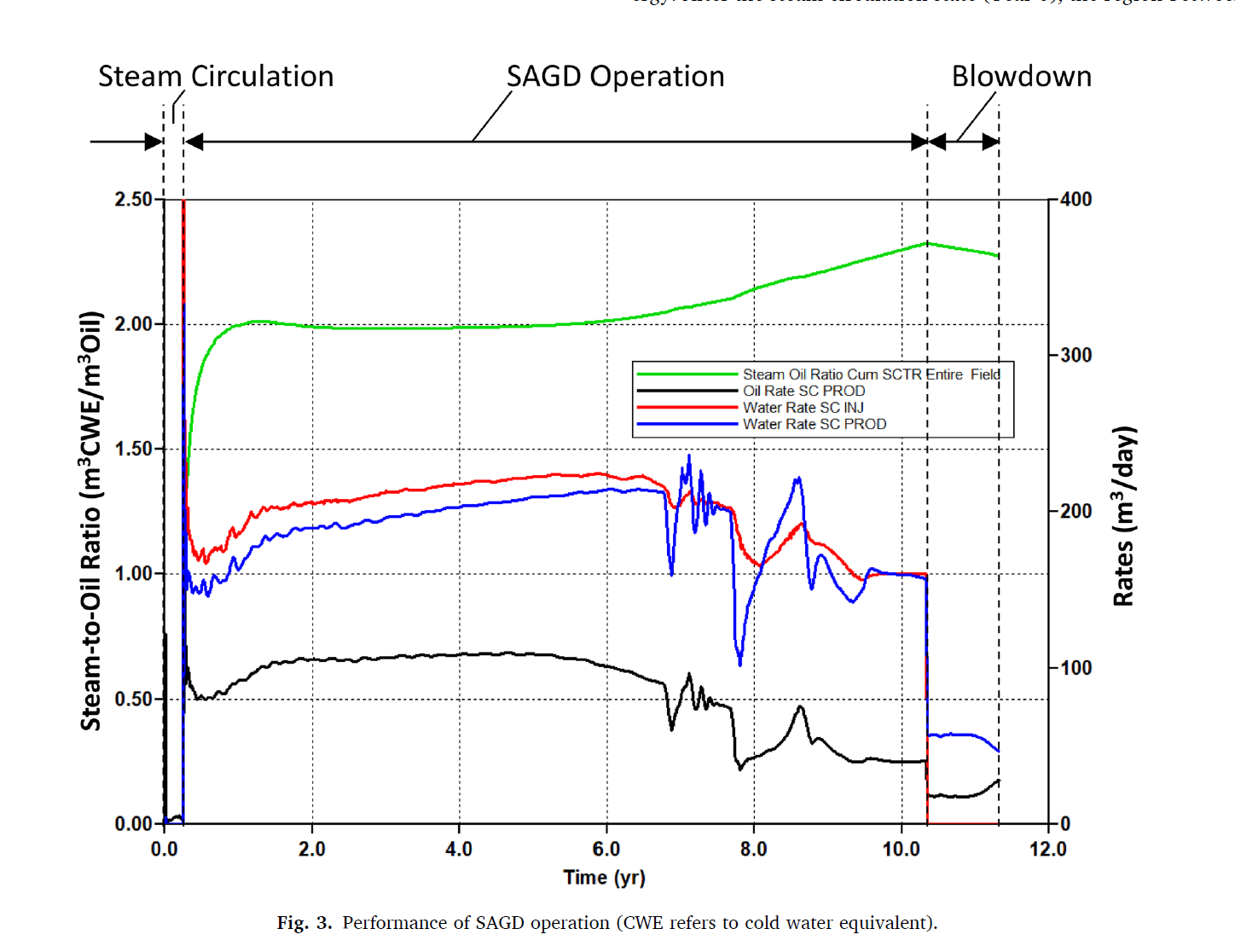

In the steam-assisted gravity drainage (SAGD) process, large amounts of steam are injected into the reservoir to mobilize bitumen for its production to surface. The amount of thermal energy injected into the reservoir creates a man-made geothermal system that could be used to yield heat after the SAGD operation is complete. In the research documented here, for the first time, the amount of energy stored in the reservoir is evaluated and potential processes for recovery of the thermal energy are explored. The results reveal that after 10 years of SAGD, about 35% of the total injected energy in the steam remains in the reservoir rock from which the bitumen was extracted. After a 1 year blowdown stage at the end of the SAGD operation, ∼32% of the total injected energy remains in the reservoir rock. Three cases are used to explore the potential for recovering the thermal energy in the reservoir rock. The results show that the best case is one where a new horizontal well is added at the top of the reservoir above the SAGD well pair. In this case, >100 °C water was recovered at high rate for over 1,400 days realizing about 34% recovery of the thermal energy contained in the reservoir rock after the SAGD blowdown stage. The results demonstrate that there is potential for recovering the thermal energy. This recovered energy offers means to make the SAGD process more thermally efficient over its entire energy production life.