Numerical Modelling and Simulation of Fully Coupled Gas Hydrate Reservoirs and Wellbore Fluid Flow

本研究探讨了控制天然气水合物储层和井筒内流体流动的机制,以解决与气体流动保障和生产可持续性相关的挑战。研究的动机在于天然气水合物储层储存了人类最大的天然气储量,其对人类的好处不可忽视,从能源来源到工业产品应用广泛。

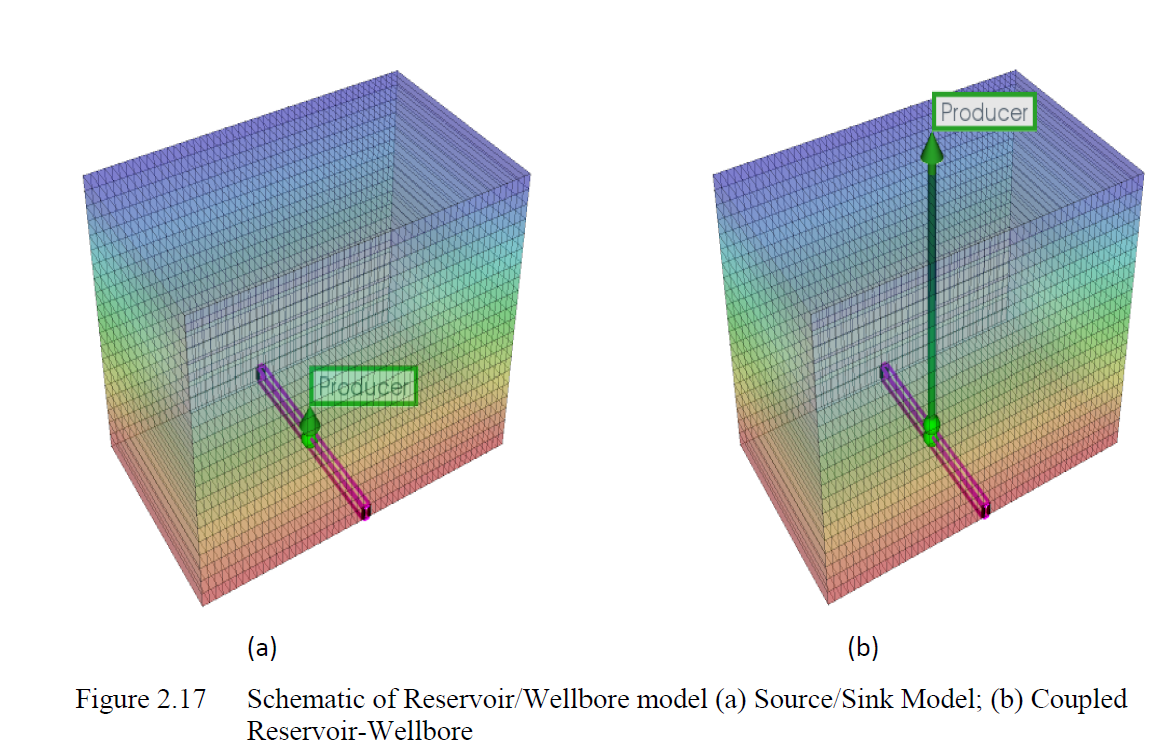

然而,天然气水合物储层的复杂性以及影响非常规资源流动动力学的因素被发现与井筒复杂性相关,从而难以进行可行的天然气水合物系统模拟以实现商业化生产。因此,目前的模拟方法存在局限性。该论文详述了非常规储层和井筒中的瞬变流问题,结合了各种对流和扩散通量现象、非达西流效应、井筒附近对流混合过程、储层-井筒动态,并开发了一种新的动力学水合物储层模拟模型和一个完全隐式完全耦合的储层-井筒流体流模型,用于天然气水合物应用。

因此,该论文包括了两个针对特定天然气水合物储层生产模拟的重要模拟策略。第一个是新的储层模型,集成并同时考虑了影响天然气水合物流体流动的固有挑战特征,包括阈值压力、扩散通量、库仑扩散、惯性和气体滑移效应、热膨胀和焦耳-汤姆逊效应。第二个是天然气水合物生产优化的完全隐式完全耦合的储层-井筒模型。

利用MATLAB中的有限差分数值方案和牛顿-拉弗森迭代方法获得了这些公式的解。模型使用CMG STARS进行验证和验证,与Li等人(2010a)的实验数据和解析模型进行了对比。模拟结果与所测得的关键变量的分析(包括相饱和度分布、压力、温度、产量率和随时间的气体和水的累积产量)显示出良好的一致性。

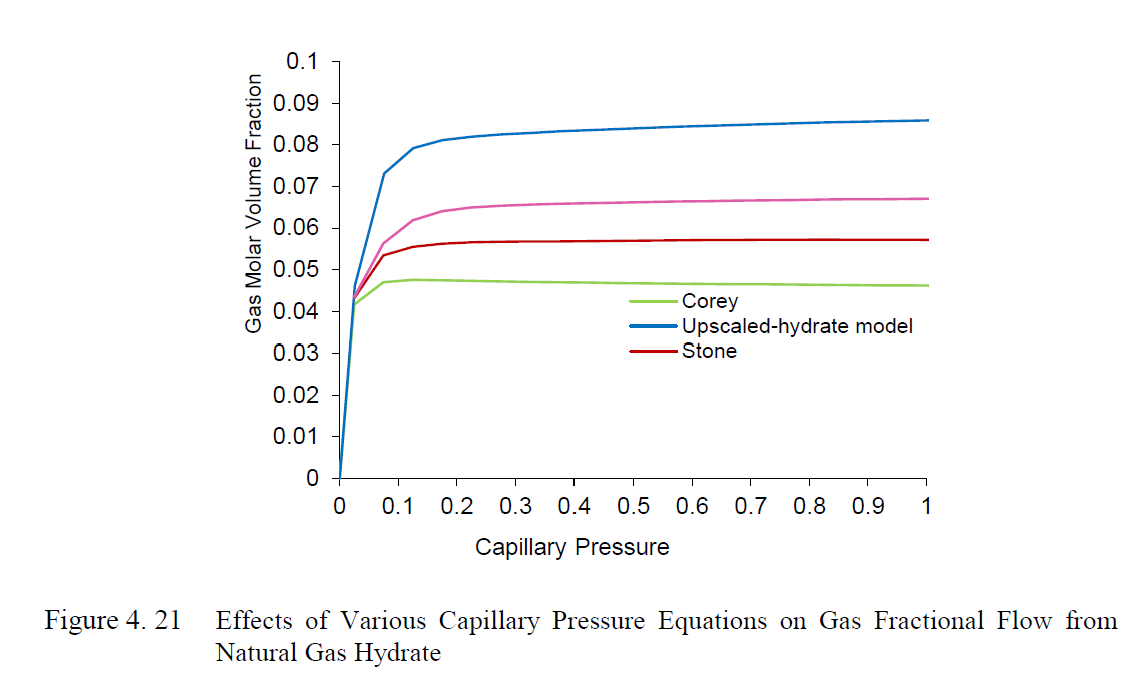

这些模型已被用于对控制流系统行为的重要非常规储层-井筒参数进行敏感性分析;并且利用蒙特卡洛模拟技术评估了它们的比较效果。此外,与井筒附近条件相关的井筒放大的宏观定律被建模,以调查相对渗透率和毛细压力方程以及新的优化技术的各种功能的影响。结果表明,这些因素可能会导致产量高估高达30%的严重累积负面影响。

结论表明,早期阶段的气体生产过程受压力消减和水合物区域内的热对流主导,以及与孔隙空间和井筒附近界面的热传导。温度相关的模型将使长时间的生产成为可能,而后期的气体生产可能由沿井筒的热传导驱动的恢复主导。发现热扩散对所提出的方案的性能有很强的影响,而压力扩散在阈值之外具有中等影响。

开发的完全隐式完全耦合模型在一系列储层参数化方面提供了更有效和更鲁棒的流动保障,包括解离动力学、空间异质性、固有渗透率和气体饱和度;因此,为具有挑战性的天然气水合物储层生产提供了一个有前景的解决方案。在生产了1000天后,解耦模型的累积气体产量开始下降,比完全耦合方法模拟的产量低了2.5倍,同时也有较低的水产量。得出结论,应用完全隐式完全耦合的储层-井筒模型可以保证天然气水合物的可持续生产。

ABSTRACT

This research work explored mechanisms that control fluid flow in the natural gas hydrate reservoir and the wellbore to resolve the challenges related to the gas flow assurance and production sustainability. The study was motivated by the fact that natural gas hydrate reservoirs hold the largest deposit of natural gas whose benefit to human being, ranging from energy source to industrial products, cannot be over-emphasised. However, complex nature of the gas hydrate reservoir and factors that influence the flow dynamics in the unconventional resource have been found to correlate with the wellbore complexities to defy viable simulations of the gas hydrate system toward commercial production. Thus, current modelling approaches are limited. This thesis expatiated the transient flow problems in both the unconventional reservoir and the wellbore, incorporated the various convective and diffusive flux phenomena, non-Darcy flow effects, near-wellbore convective mixing processes, reservoir-wellbore dynamics, and developed a new kinetic hydrate reservoir simulation model and a fully implicit fully coupled reservoir-wellbore fluid flow model for natural gas hydrate application. Thus, the thesis consists of two important simulation strategies for the specific gas hydrate reservoir production simulation. First is the new reservoir model that aggregated and simultaneously incorporated the inherent defying features to the gas hydrate fluid flow including threshold pressure, diffusivity flux, Knudsen diffusion, inertia and gas slippage effects and thermal expansion and Joule-Thomson effects. The second is the fully implicit fully coupled reservoir-wellbore model for gas hydrate production optimisation. The solutions of the formulations were obtained using finite different numerical scheme and Newton-Raphson iteration method implemented in MATLAB. The models were verified and validated using CMG STARS benchmarked with the experimental data of Li et al. (2010a) and analytical model of Selim and Sloan (1989). Simulation results showed excellent agreement with the analyses of the key variables measured, including distributions of phases saturations, pressure, temperature, production rates and cumulative productions of gas and water over time. The models have been used to perform sensitivity analysis of the important unconventional reservoir-wellbore parameters that control the flow system behaviour; and their comparative effects were evaluated using the Monte Carlo simulation technique. Furthermore, near-wellbore conditions related to the macroscopic laws of near wellbore upscaling was modelled to investigate effects of the various functions of the relative permeability and capillary pressure equations and the new optimisation technique. Results indicated that these factors can have severe cumulative negative impact of over estimation of production rate by up to 30%. It was deduced that the gas production process at early stage is controlled by pressure depletion and sensible heat of dissociation dominated by heat advection in the hydrate zone and along the interface of the pore spaces and near wellbore. The temperature dependent model would enable long time production and the later stage gas production could had been dominated by thermal conduction-driven recovery through of the wellbore. It was identified that the thermal diffusion has a strong effect on the performance of the proposed scheme while the pressure diffusion has moderate impact beyond the threshold. The developed fully implicit fully coupled model offered a more efficient and robust flow assurance over a range of the reservoir parameterisation, including dissociation kinetics, spatial heterogeneities, intrinsic permeability and gas saturation; thus, offers a promising solution to the challenging gas hydrate reservoir production. After 1000 days of production, the cumulative gas production of decoupled model began to decrease up to 2.5 times lower than that simulated by the fully coupled approach which also has lower water production. It is concluded that application of the fully implicit fully coupled reservoir-wellbore could guarantee sustainable gas hydrate production.

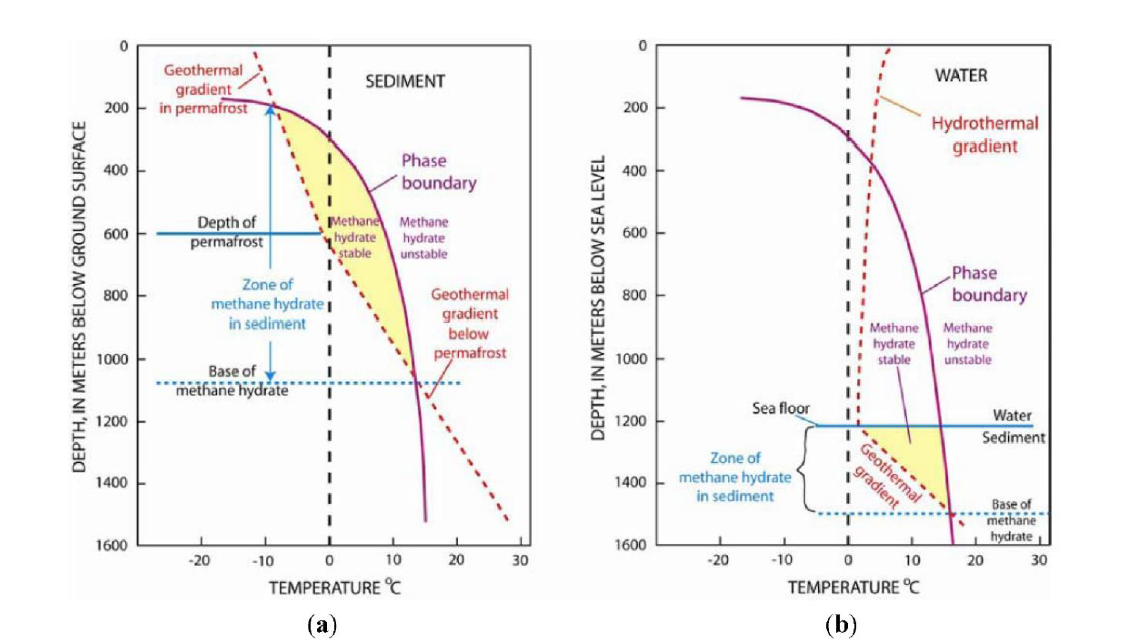

Figure 2:1 Phase diagram for methane hydrate formation under the (a) permafrost and (b) ocean bed (Sloan et al, 2010)