ANALYSIS OF MIXING DURING HYDROGEN STORAGE IN GAS RESERVOIRS

本文旨在提高气藏储氢存技术的成熟水平,特别是在未来荷兰能源系统中,氢将成为主要能源载体的情景下,这将变得尤为必要。论文解决了在气田进行氢储存操作时涉及的与原有气体混合过程相关的问题,并对它们在储层模拟器中的实现进行了分析。

CMG GEM储层模拟器被用于将机械弥散和有效分子扩散纳入模拟中,同时以完全隐式方式解决对流分散传质方程、重力分离和其他宏观混合现象。机械弥散的定量化通过其主要参数——弥散度来实现,而这个参数在文献中存在相当大的不确定性。弥散度反映了多孔介质中微观异质性引起的孔隙尺度流体速度差异。

鉴于缺乏适当的氢弥散度实验,本文从砂岩(地下水)弥散度实验的文献中收集了一系列弥散度值。通过敏感性分析,对不同混合过程对工作气体和缓冲气体之间混合的影响进行了分析。

为此,在CMG GEM中建立了基于荷兰砂岩天然气田的概念储层模型(径向和均质)。研究表明,在典型储层流速下,分子扩散对混合的影响可以被忽略。此外,模拟结果明显受到数值弥散的影响,这是由于计算误差,其大小取决于网格大小和时间步长。

在量化分散与机械弥散效应后,引入了各种选项来处理数值弥散,以更真实地表示物理过程。本论文的工作展示了在储层模拟器中实际实现氢储存混合过程的挑战,并应被视为进一步研究的基础。

Abstract

This thesis contributes to increasing the technology readiness level of hydrogen storage in gas reservoirs, which will be required when hydrogen has become a major energy carrier in the future Dutch energy system. It addresses the mixing processes with resident gases that occur during hydrogen storage operations in gas fields, and analyzes their implementation in a reservoir simulator.

The CMG GEM reservoir simulator allows incorporation of mechanical dispersion and effective molecular diffusion into its simulations, while solving the advection dispersion transport equation fully implicitly, as well as gravitational segregation and other macro scale mixing phenomena. Mechanical dispersion is quantified by its main parameter dispersivity, for which a large uncertainty exists in the literature. Dispersivity represents pore scale fluid velocity differences caused by microscale heterogeneities in a porous medium.

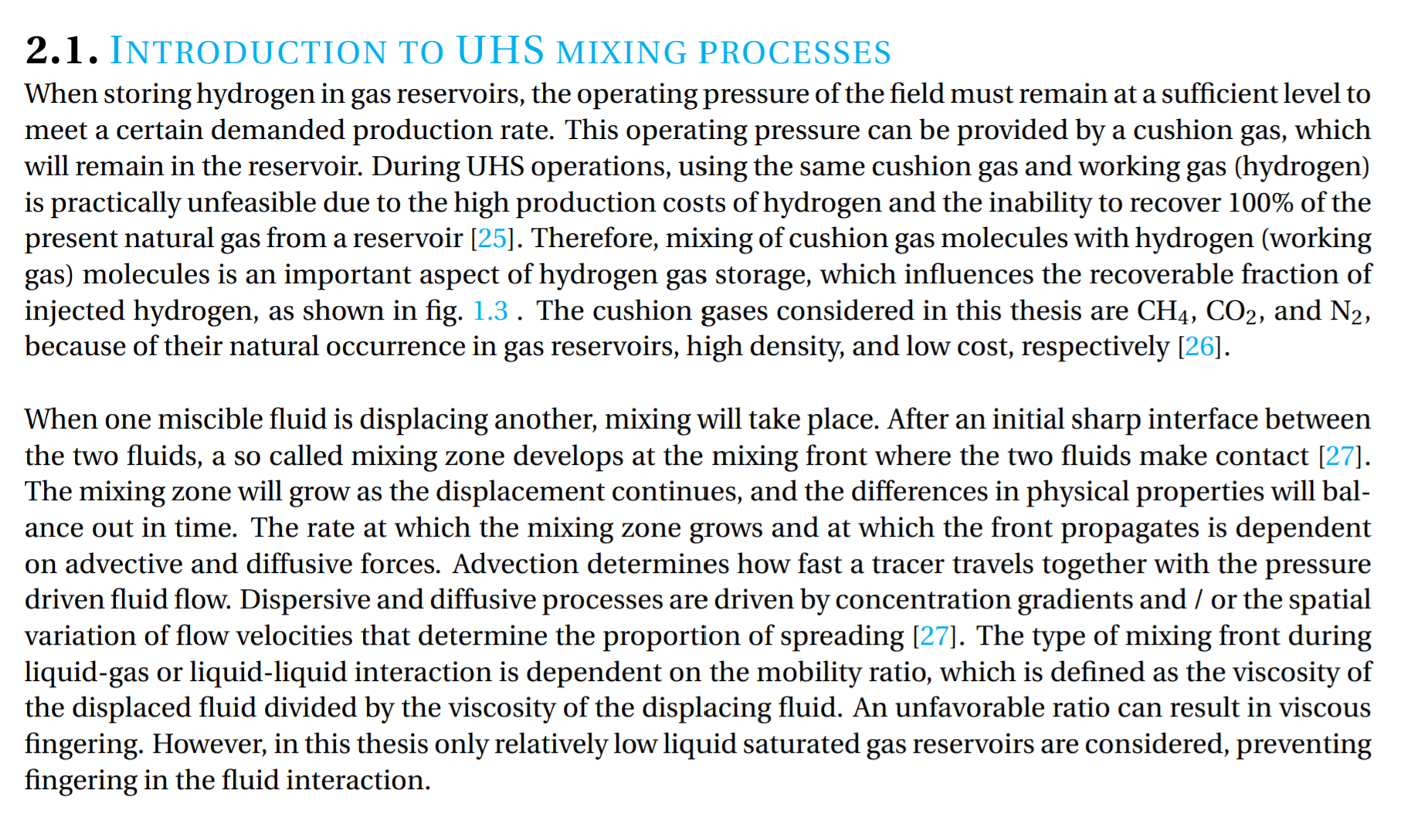

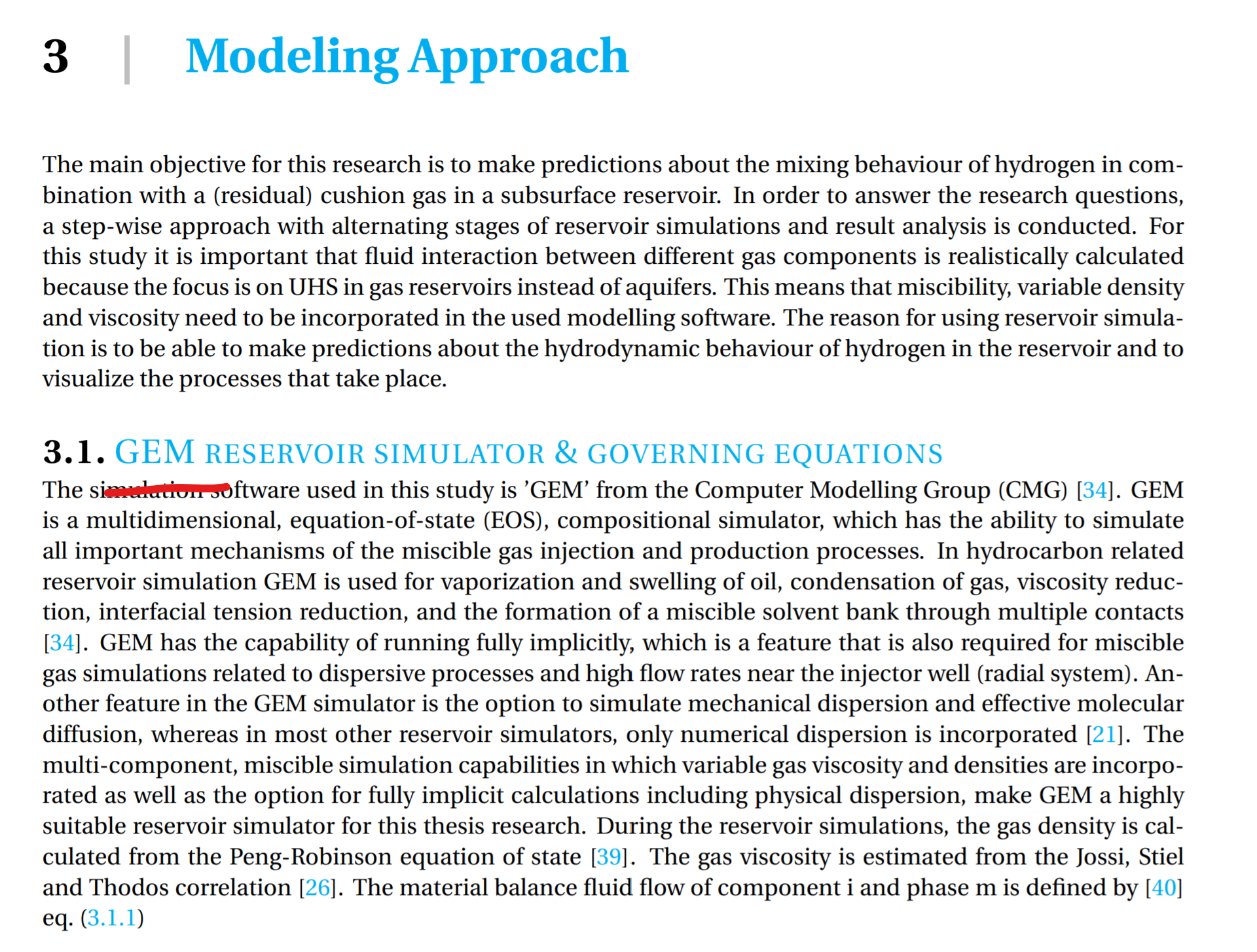

Due to the lack of adequate hydrogen dispersivity experiments, a range of dispersivity values is collected from literature on (groundwater) dispersivity experiments in sandstones. A sensitivity analysis is conducted, in which the influence of the different mixing processes on the mixing between working gas and cushion gas is analyzed. For this, a conceptual reservoir model (radial and homogeneous), with properties based on Dutch sandstone gas fields was built in CMG GEM.

The effect of molecular diffusion on mixing proves to be negligible compared to mechanical dispersion at typical reservoir flow rates. Furthermore, the results of the simulations prove to be significantly influenced by numerical dispersion, which is a calculation error, dependent on grid size and time step. The effect of numerical dispersion compared to mechanical dispersion is quantitatively analyzed, after which various options are introduced to deal with numerical dispersion in a way that the physical processes are most realistically represented.

The work in this thesis demonstrates the challenges of realistically implementing hydrogen storage mixing processes in a reservoir simulator, and should be regarded as a foundation for further research.