Modeling of Recovery and In-situ Distribution of Fracturing Fluid in Shale Gas Reservoirs Due to Fracture Closure, Proppant Distribution and Gravity Segregation

Abstract

Many stimulated shale gas wells experience surprisingly low fracturing fluid recoveries. Fracture closure, gravity segregation, fracture tortuosity, proppant distribution, drawdown pressure and shut-in (soaking) duration have been widely postulated to be the contributing factors. Despite propped fracture and un-propped fracture exhibit different closure behavior during shut-in and early flowback periods corresponding to the dramatic change in effective stress, modeling of the realistic geometry and closure behavior of a partially-propped fracture is rarely performed when analyzing flow-back production data. In this study, geomechanical simulation is firstly used to simulate the closure behavior and to quantify the post-closure geometry of a partially-propped fracture. Then, results from the geomechanical simulation are incorporated into flow simulation to examine the impacts on recovery and distribution of fracturing fluid. At last, field data collected from two shale-gas wells in the Horn River Basin is analyzed to determine the potential implications of these uncertain factors on production forecast.

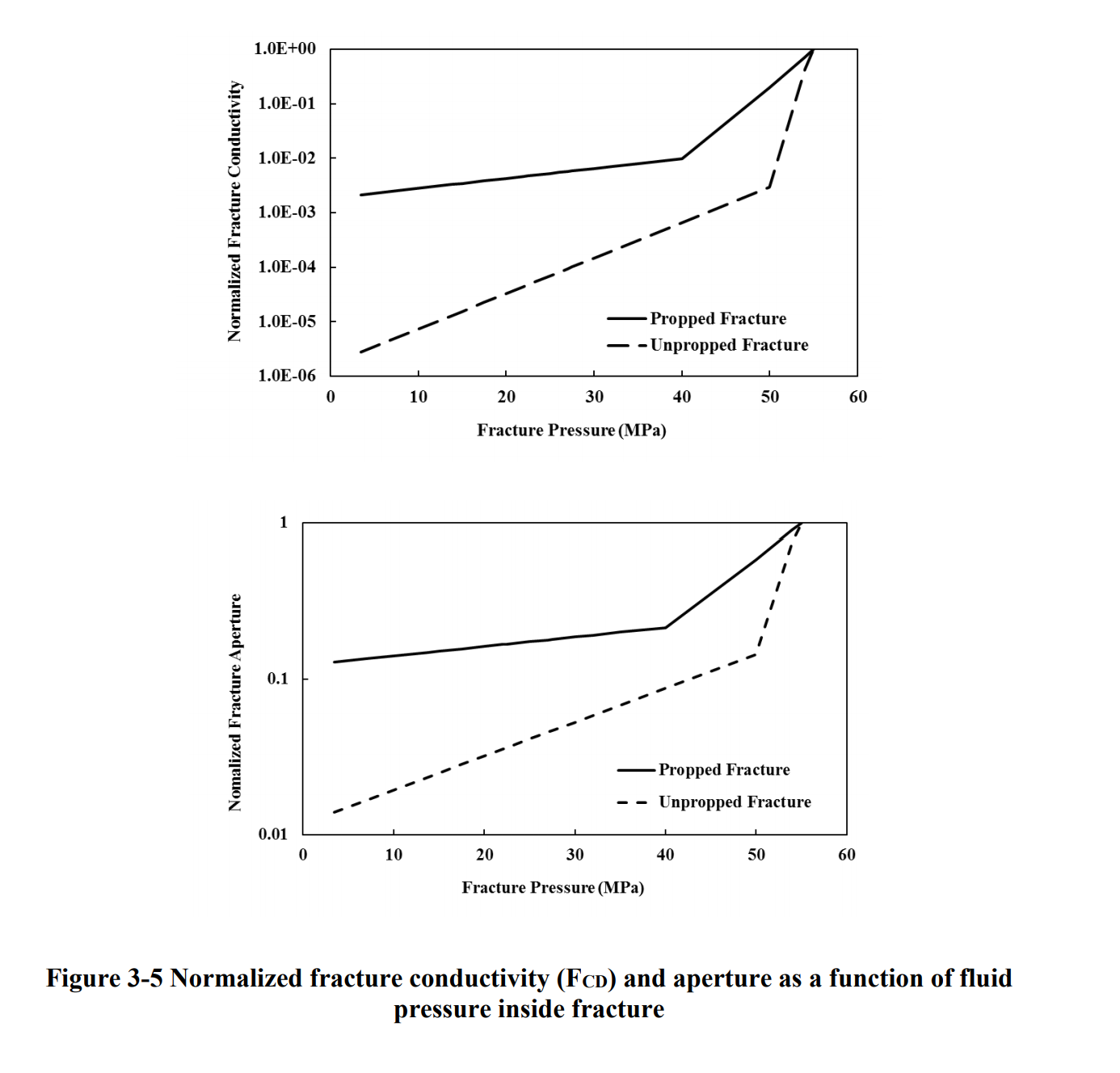

Geomechanical simulation based on explicit finite-difference method is used to simulate the change in effective stress and the corresponding geometry of a partially-propped fracture. Parameters including in-situ stress condition, proppant compaction, propped fracture aperture and secondary fractures are considered to understand their impacts on the post-closure geometry. This partially-propped fracture is then represented explicitly in the computational domain of a series of 3D flow numerical models, whose petrophysical parameters, fluid properties and operational constraints are representative of the Horn River shale gas deposits. The physical process of fracture closure is modeled by adjusting the fracture volume and fracture conductivity dynamically. Non-Darcy behavior due to high gas velocity in fracture and matrix desorption are considered. The coupling of multi-phase flow, gravity and geomechanics is considered to examine the mechanisms responsible for the low fracturing fluid recovery and the ensuing fluid distribution away from the wellbore.

Geomechanial simulation confirms the formation of a residual opening above of the proppant pack in a partially-propped fracture. The size of this opening is most sensitive to the initial fracture aperture. Stress amplifies at the top of the proppant pack and leads to potential proppant crushing or embedment. Water uptake into the matrix is influenced by forced and spontaneous imbibition due to the large pressure differential across the matrix-fracture interface and matrix capillarity. Additional water is displaced into the matrix as pressure depletes and fracture closes.

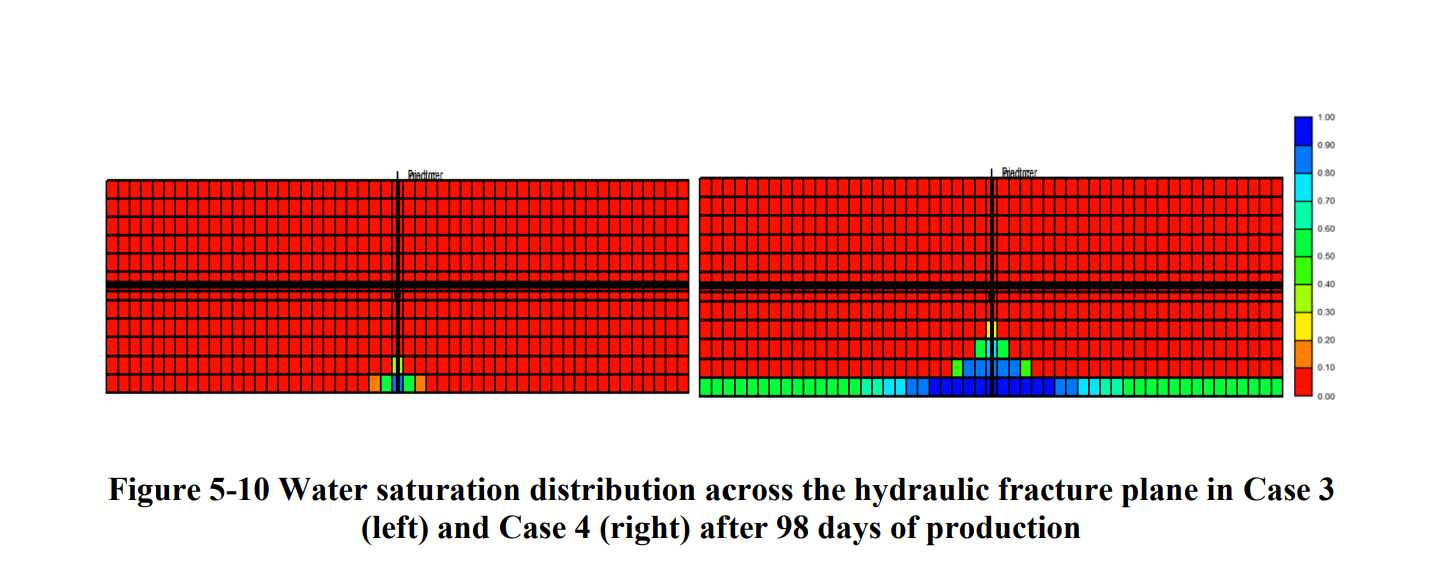

Gravity segregation may lead to water accumulating near the bottom of a vertical planar fracture, but fracture tortuosity could limit the segregation and promote a more uniform fluid distribution. Despite gas production is often hampered by non-uniform proppant distribution, the residual opening offers a highly conductive flow path for gas, which is much more mobile than the waterbased fracturing fluid, further aggravating the phenomenon of gravity segregation. Therefore, more aggressive drawdown is recommended to flow back the fracturing fluid in the case of uneven proppant distribution. Extended shut-in time may enhance the initial gas rate, but lower late-time production is observed. The field case study suggests that considering these various physical mechanisms could improve the accuracy of the numerical model for history matching and the reliability of the ensuing production forecasting. Given that the solution to an inverse problem is generally non-unique, the results illustrate how additional uncertainty in production forecast is introduced when the scenario of non-uniform proppant distribution is ignored.