Effective application of solvent Addition for improving the performance of SAGD process

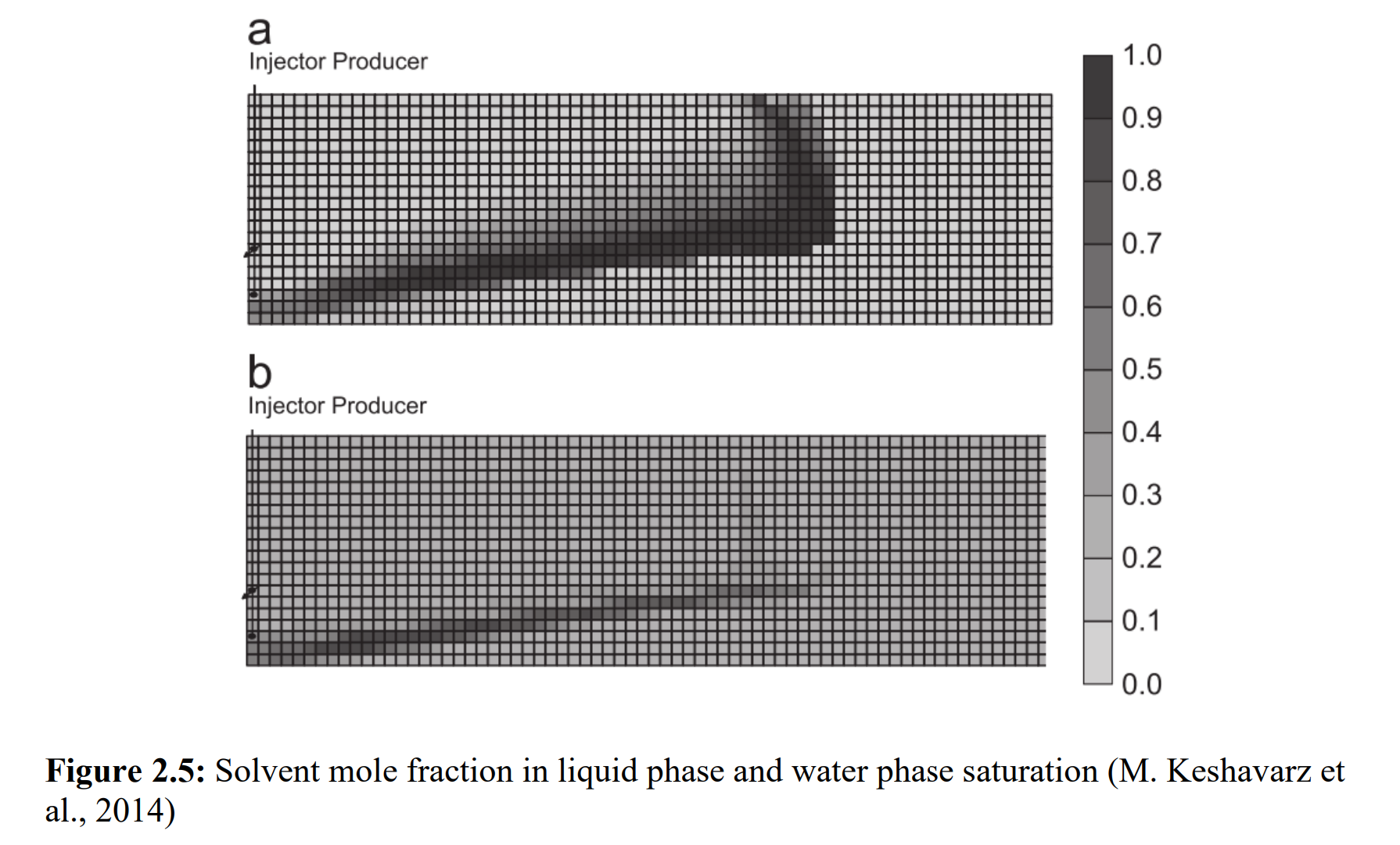

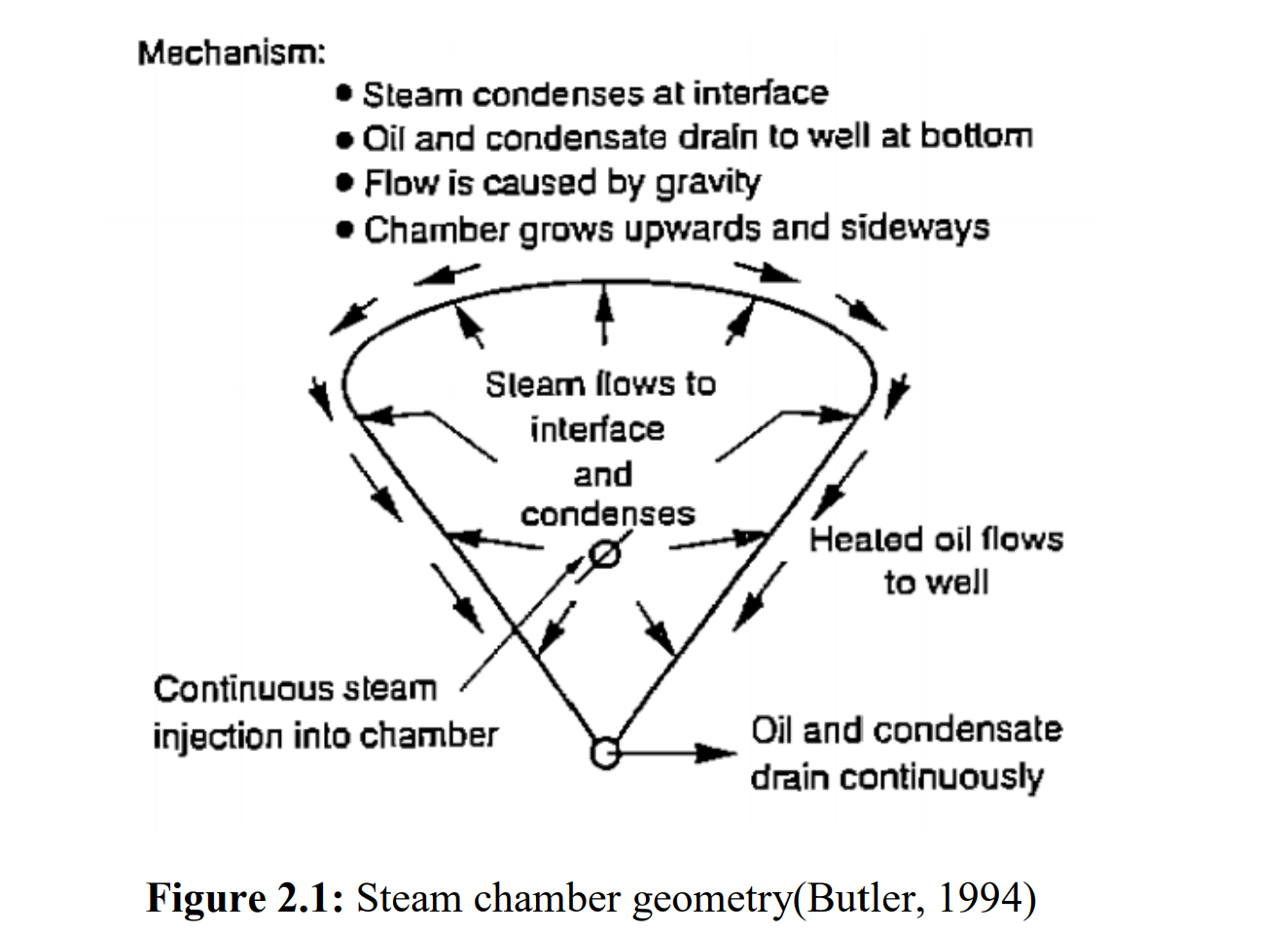

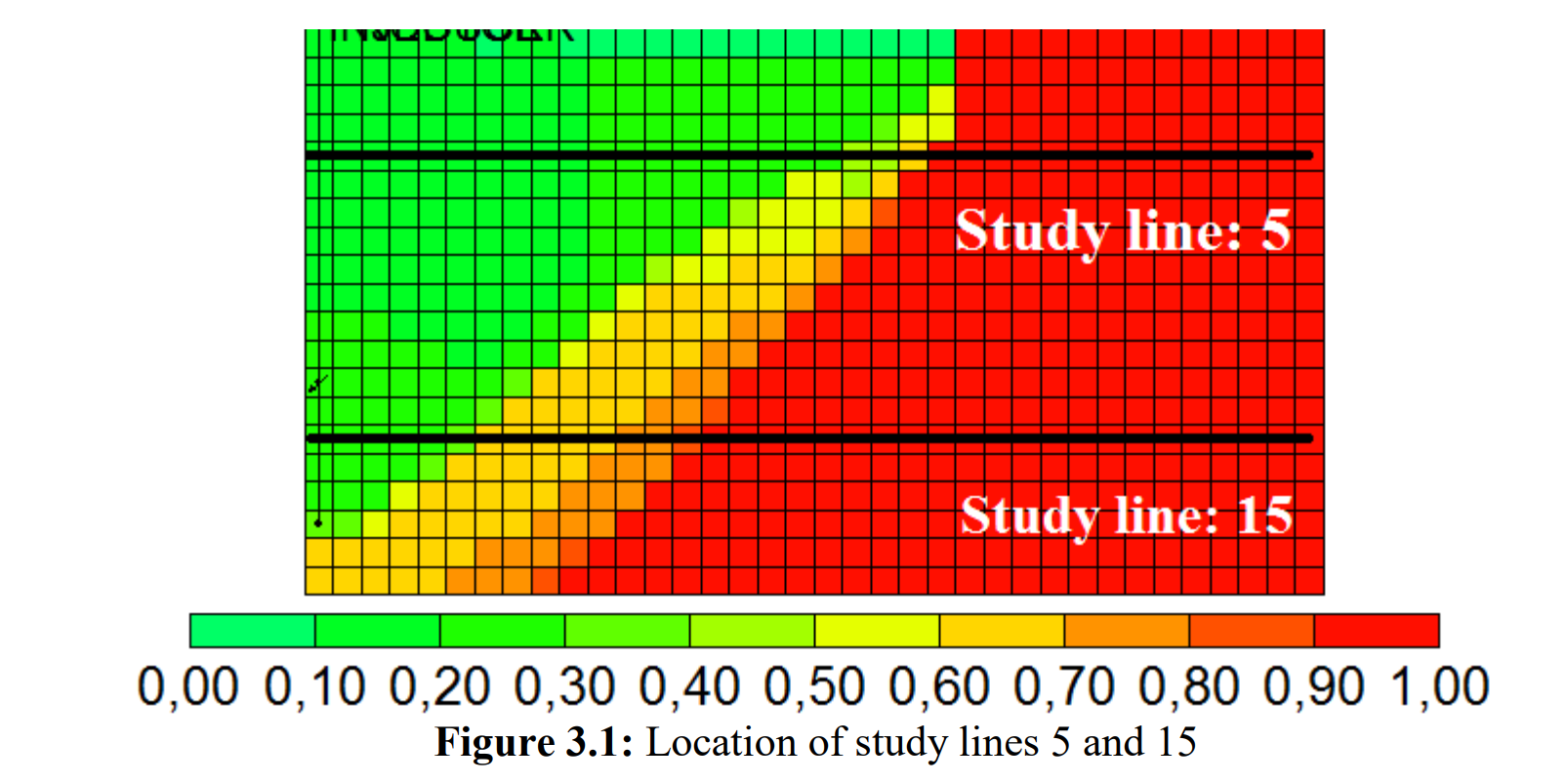

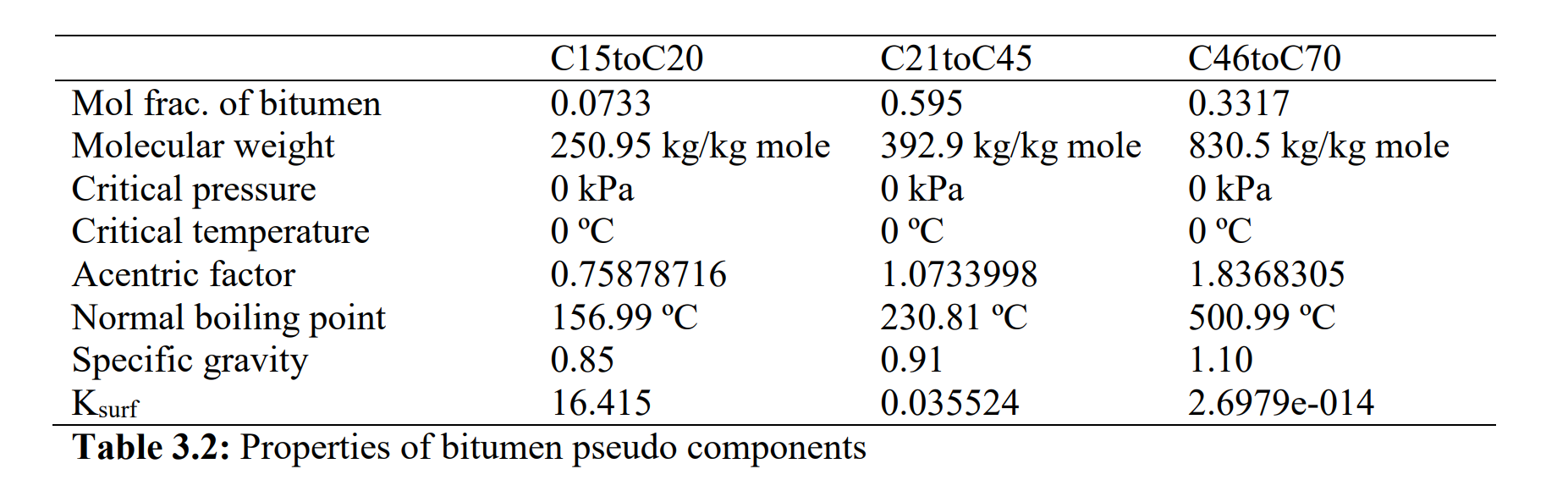

本研究旨在评估在溶剂辅助 SAGD(蒸汽辅助重力泄油)过程中改变二氧化碳溶剂注入时间的效果,并研究蒸汽、溶剂和油的相态特征,使用CMG STARS 进行模拟。研究评估了注入开始时间、溶剂浓度和溶剂选择对能源效率、累计产油量和从储层中回采的溶剂等指标的影响。研究了两条独立水平研究线上的相态为,以解释溶剂效果的差异。比较了四种不同烃类溶剂与蒸汽单独 SAGD 过程的注入效果,并将二氧化碳与烃类溶剂共注的效果与未添加不可冷凝气体的相同溶剂进行了对比。

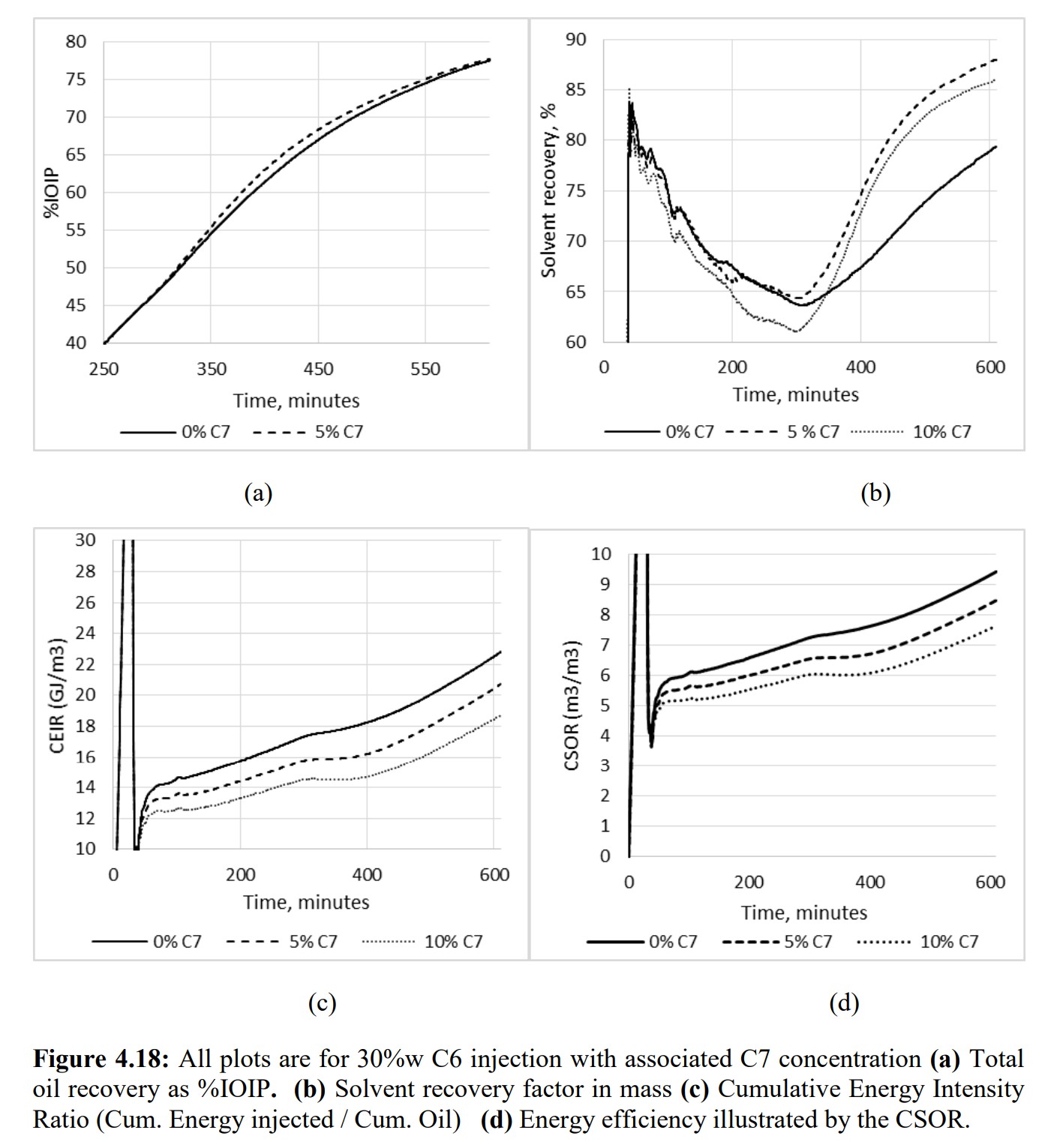

研究发现,己烷在能源效率和采收率方面表现最佳,但其溶剂回采不佳。庚烷在溶剂采方面表现出色,两种溶剂成功共注,其组合效果优于相同浓度下的单一组分,表明两者之间存在正协同作用。二氧化碳与之前研究的己烷和庚烷溶剂共注时,发现二氧化碳共注应在烃类溶剂注入开始后的一段时间再启动,若延迟时间足够长,则对效果有积极影响。

最有趣的结论是,从多个性能指标综合来看,溶剂之间存在正协同作用,以及在开始烃类溶剂注入后的一段时间内不应启动二氧化碳注入。

CMG 软件应用情况

本研究使用计算机模拟软件集团(CMG)的高级过程模拟器 STARS 来模拟不同情况下蒸汽、液体和气体相的流动。模拟了各种溶剂在不同浓度下的使用情况,研究了溶剂类型、浓度和注入方案对溶剂辅助 SAGD 过程的影响。考虑了油和水的流动性、产油量、压力和温度等因素,并将结果与基础方案进行了对比。

结论

- 与当前的溶剂辅助 SAGD 数值研究相比,本研究结果与其合理一致,差异可能由操作条件和储层模型不同所致。

- 己烷是储层中注入最有益的单一组分溶剂,庚烷紧随其后。

- 储层中残留的溶剂量与溶剂浓度呈近似线性关系。

- 成功共注入了一种具有出色溶剂回采效果的溶剂与第二种溶剂,以提高总溶剂回采率。

- 二氧化碳可以与烃类溶剂成功共注入,但注入模式取决于二氧化碳浓度。

- 在开始烃类溶剂注入后的一段时间内不应尝试二氧化碳共注入。

- 对于低浓度的二氧化碳,延迟启动没有益处。

- 在 20% 到 25% 的溶剂重量浓度之间,储层温度、压力、特定温度下的 K 值等参数发生了显著变化。

- 这些变化对累计石油产量有负面影响,对能源效率有正面影响。

作者单位

挪威斯塔万格大学理学与技术学院

Abstract

This research attempts to assess the effects of changing the injection times for CO2 solvent injection in the Solvent Assisted SAGD process and to study the phase behavior of Steam, Solvent and Oil. Simulations were conducted using the Computer Modeling Group simulation software STARS 2014. The research evaluates the effect of injection start time, solvent concentration and solvent selection on performance criteria such as Energy efficiency, Cumulative oil production, and Solvent recovered from the reservoir. The phase behavior over two individual horizontal study lines was investigated to try and explain the difference in solvent performance. The injection performance of the four different hydrocarbon solvents was compared to the Steam-only SAGD process. The effect of co-injecting CO2 with hydrocarbon solvents was compared to the same solvents without the non-condensable gas. Hexane was discovered to be the optimal solvent for energy efficiency and oil recovery at the cost of a suboptimal solvent recovery. The most optimal single-component concentration when considering the performance criteria lies in the range 20-30% by weight and an economic analysis would be needed to further narrow the range. The poor solvent recovery was remedied with Heptane which was shown to have an excellent solvent recovery and the two solvents were successfully co-injected. The proposed combination of solvents achieved better results than any single-component at the same concentration, which leads to the conclusion that there is a positive synergy between the two solvents. CO2 co-injection was tested with the previously investigated Hexane and Heptane solvents. It was found that there is a time period after starting hydrocarbon solvent injection where CO2 co-injection should not be initiated. There was however, a positive effect on the performance if the injection start time is delayed sufficiently. The most interesting conclusion drawn from the research was the positive synergy between solvents when looking at multiple performance criteria in unison and the reported time period after starting hydrocarbon solvent injection where CO2 injection should not be initiated.