Supercritical CO2 Foam Enhanced Oil Recovery: From Mechanistic Model Fit to Lab Experiments to Field-Scale Evaluation

ABSTRACT

This study investigates how a mechanistic foam modeling approach based on bubble population balance is applied to a series of laboratory experimental data of a supercritical CO2 foam in reservoir conditions to extract model parameters (topic 1). The model with model parameters determined from the fit is then used to estimate how far fine-textured strong foam can propagate into the reservoir, before turning into coarse textured weak foam and before being segregated by gravity (topic 2). With the help of mechanistic model, a possible range of gas mobility for supercritical CO2 foam is calculated and the resulting gas-phase mobility reduction factor (MRF) are applied to the field-scale EOR reservoir simulations (topic 3).

A mechanistic foam model that honors three different foam states and two steady state strong-foam flow regimes is used to fit coreflood experimental data from Yin (2007). The results show why supercritical CO2 foams are fundamentally different compared toother gaseous foams. The role of mobilization pressure gradient is shown to be the key to this difference – the pressure gradient required for supercritical CO2 foam is much lower, and thus the attainment of strong foam in the reservoir is easier.

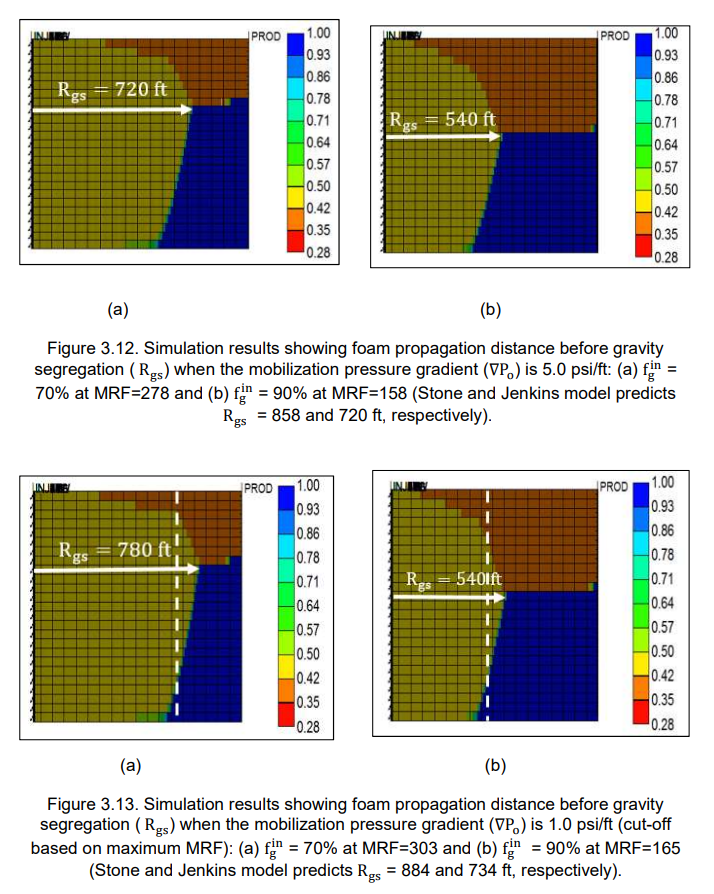

This study shows how far strong foams injected into the injection well can propagate at different injection foam qualities and velocities, which is one of the most important questions in actual field applications. Two main mechanisms that limit field foam propagation, such as “conversion from strong foam to weak foam” and “gravity segregation”, are examined. The results show that foam propagation distance increases with increasing injection pressure or rate and increases with decreasing foam quality xiv down to a certain threshold foam quality below which the distance is not sensitive to foam quality any longer.

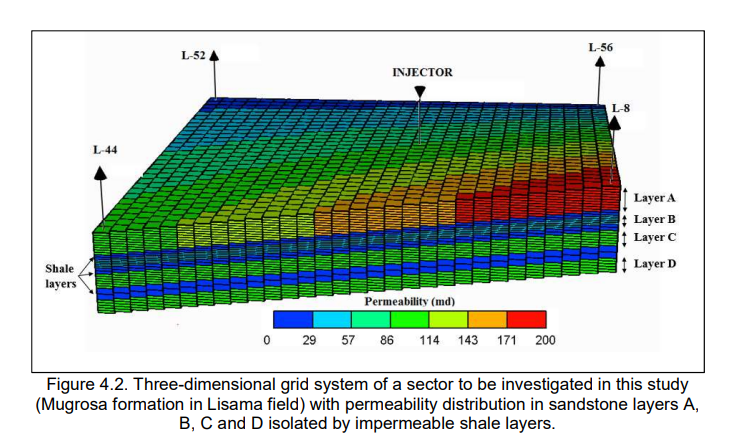

CMG STARS simulations for a sector with an inverted 5-spot pattern are performed to evaluate how oil recovery changes at different injection foam qualities and velocities. The pre-determined values of gas mobility required for the simulation are guided by the mechanistic model. The use of sweep-efficiency contour plots is shown to be a convenient graphical method to determine the optimum injection foam quality that changes at different injection rates.