Integrated geochemical simulation and optimization of smart water injection for enhanced oil recovery and sand production control in unconsolidated sandstone reservoirs

智能水注入(Smart Water Injection, SWI)作为一种环境友好、成本较低的提高采收率(EOR)技术,近年来在砂岩和碳酸盐岩储层中受到广泛关注。其核心机理之一是通过改变岩石润湿性(从油湿向水湿转变)来提高原油采出率。

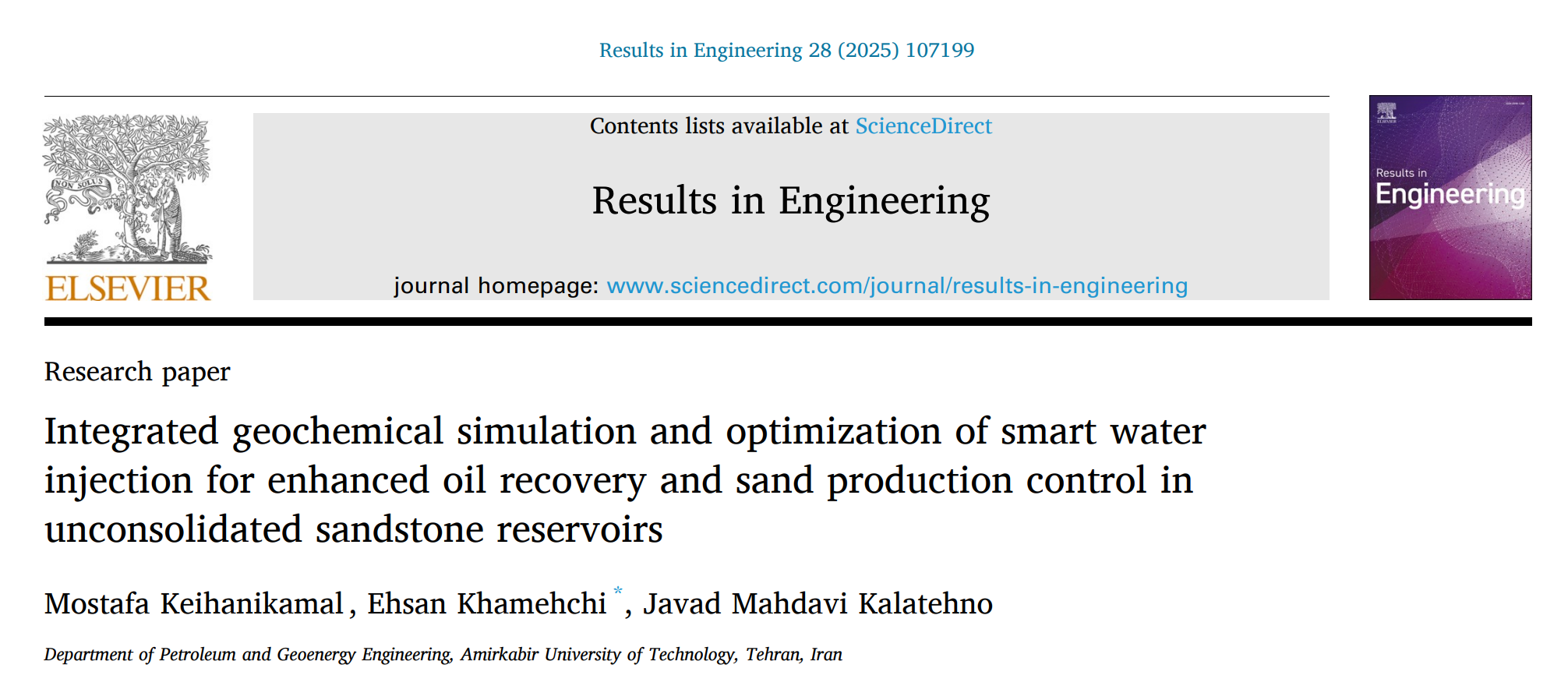

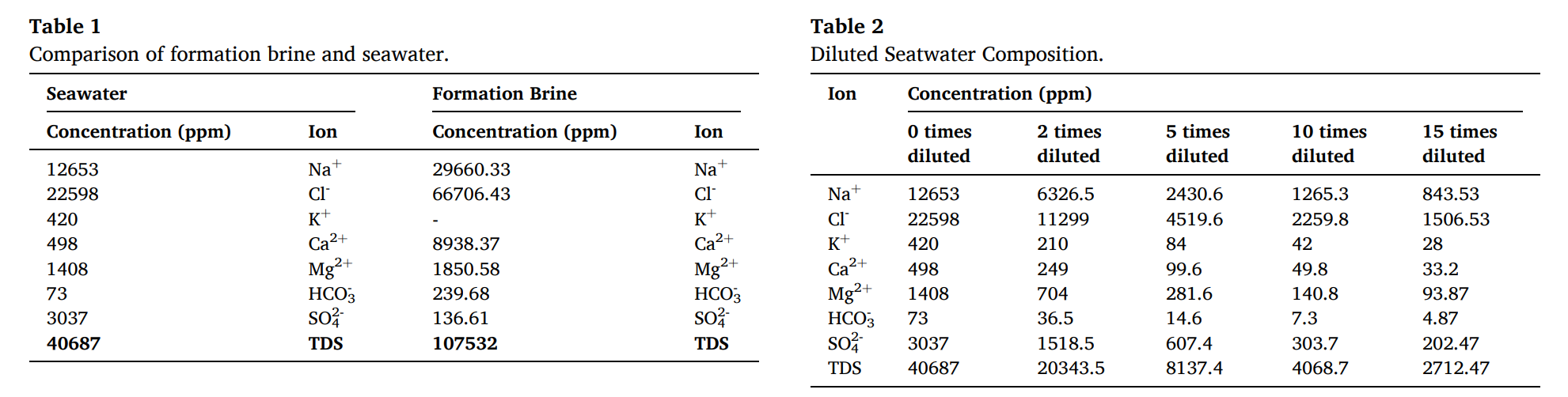

然而,注入水与地层水及岩石矿物之间的不相容可能引发矿物沉淀、微粒运移甚至出砂等问题,尤其在疏松砂岩储层中更为严重。本研究提出了一种集成地球化学与流动模拟的综合方法,系统评估智能水成分对润湿性改变、矿物溶解与出砂的耦合影响。通过PHREEQC与CMG-GEM软件联合模拟,识别出既能提高采收率又能抑制出砂的最优注入水配方,为现场智能水驱应用提供了理论依据和技术支持。

CMG软件应用情况

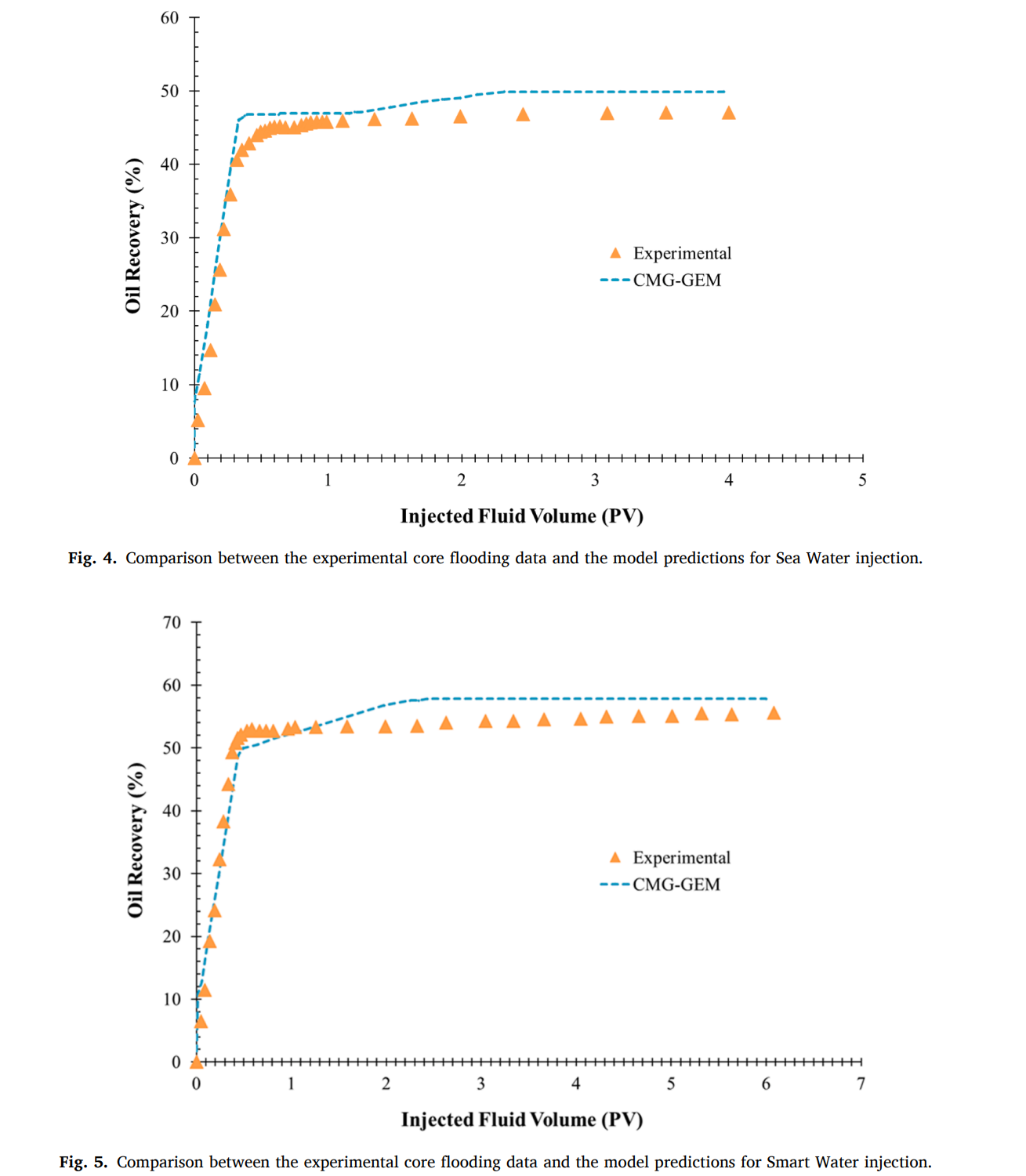

本研究采用 CMG-GEM(2022版) 模拟器进行核心驱替过程的模拟与历史拟合,主要应用包括:

- 建立一维岩心模型,模拟智能水驱过程中的多相流动;

- 耦合地球化学反应(矿物溶解/沉淀、离子交换等);

- 模拟润湿性变化对相对渗透率曲线的影响;

- 模拟不同注入水配方下的采收率变化与出砂趋势;

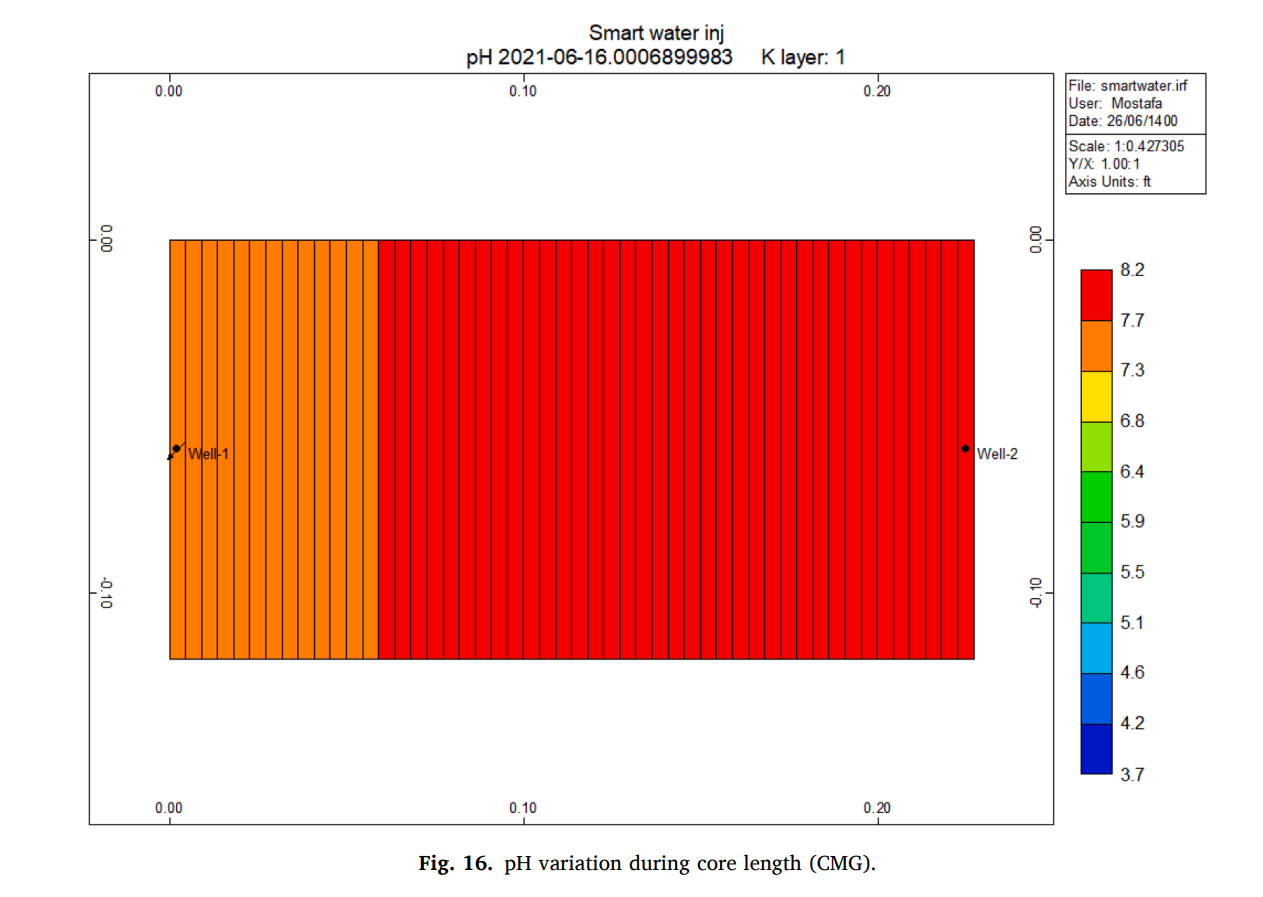

- 与实验数据对比验证模型可靠性,模拟结果与实验采收率、离子浓度变化、pH演化等高度一致。

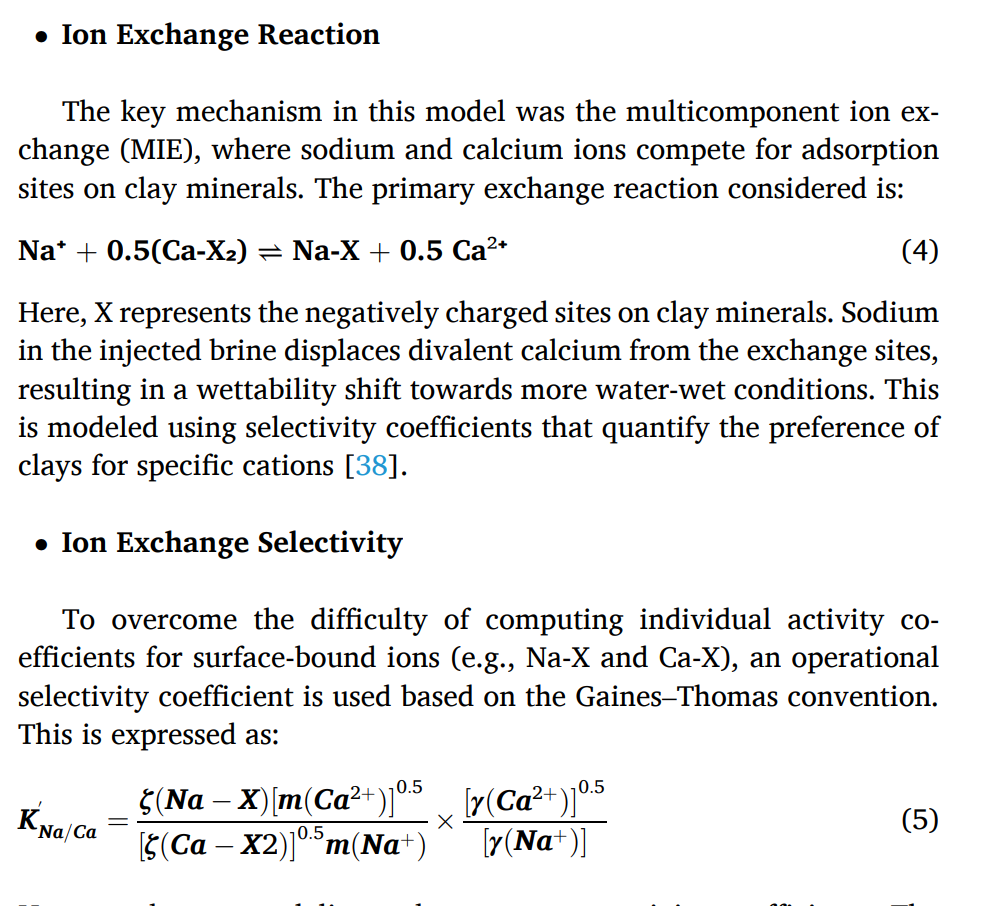

GEM模拟器在本研究中被用于模拟多离子交换(MIE)机制、钠离子与钙镁离子的竞争吸附、pH变化及其对润湿性的影响,充分体现了其在智能水驱建模中的强大能力。

结论

- 智能水注入相比常规海水驱可提高约9%的最终采收率,并延迟水突破时间,提升驱替效率;

- 润湿性改变是提高采收率的主导机理,岩心从油湿向水湿转变后采收率从55.6%提升至89.5%;

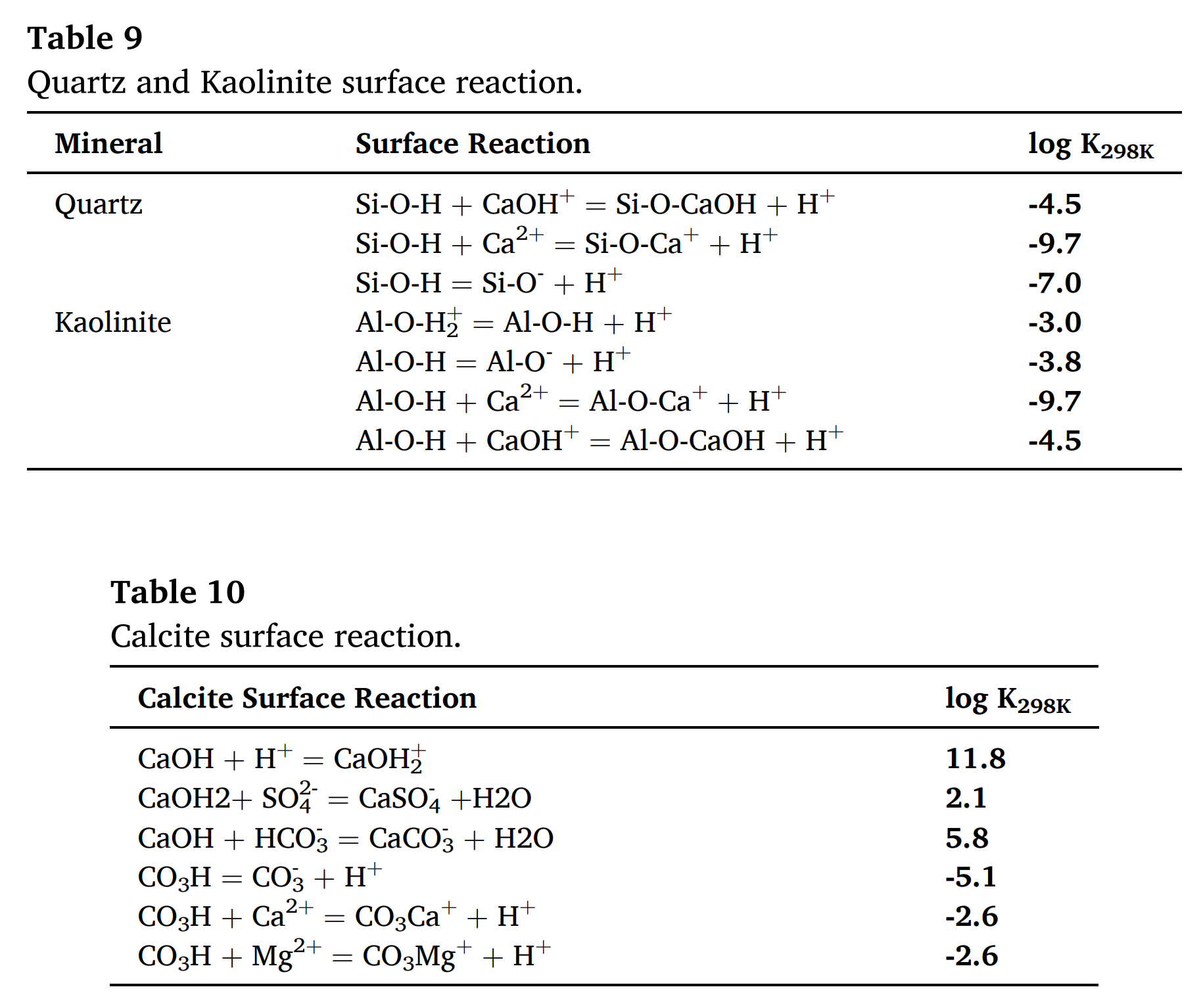

- 离子交换反应(Na⁺与Ca²⁺/Mg²⁺)导致pH升高,削弱油-岩结合,促进油膜脱附;

- 注入水中Ca²⁺浓度是控制矿物沉淀与出砂的关键因素,Mg²⁺与SO₄²⁻浓度可辅助调控;

- 石英溶解与出砂量随注入量增加呈线性增长,模拟预测出砂量与注入水量关系为:

出砂量 = 0.2764 × 注入PV – 0.393; - 采用Taguchi实验设计优化注入水配方,成功识别出低沉淀、低出砂、高采收率的最佳配方;

- 本研究提出的集成模拟方法可有效指导智能水注入方案设计,兼顾提高采收率与储层稳定性。

作者单位

- 伊朗阿米尔卡比尔理工大学

Abstract

Over the past decade, smart water injection has emerged as a promising enhanced oil recovery (EOR) technology for sandstone and carbonate reservoirs, offering an environmentally friendly alternative that avoids the use of costly and toxic chemicals. Numerous studies have identified wettability alteration—from oil-wet to water-wet states—as the primary mechanism underlying increased oil production in sandstone formations. However, incompatibility between smart water compositions and both reservoir fluids and minerals can lead to undesired precipitate formation, adversely affecting reservoir performance. In weakly consolidated sandstone reservoirs, the interaction between injected smart water and reservoir rock disrupts ion equilibrium, promoting the dissolution of essential minerals such as quartz and intergranular cement. This process commonly results in rock matrix weakening and mobilization of sand particles, which not only reduce permeability but also cause significant formation damage by blocking flow pathways. Therefore, optimizing the ionic composition of smart water is crucial to achieve maximum oil recovery while mitigating mineral dissolution and sand production. This study introduces an integrated methodology for the assessment and optimization of smart water injection in unconsolidated sandstones, highlighting the importance of balancing wettability alteration with geochemical stability. Our findings demonstrate that simultaneous modeling of fluid flow and mineral reactions accurately predicts sand production trends and their implications for reservoir performance. The proposed workflow effectively identifies brine compositions that enhance oil recovery and minimize formation damage, offering valuable guidelines for the field-scale application of smart water EOR in unconsolidated sandstone reservoirs.